Full-scale hydrazine propellant leakage detection system and method

A leak detection and propellant technology, applied in the field of full-range hydrazine propellant leak detection systems, can solve problems such as leakage, test failure safety accidents, etc., and achieve the effects of avoiding consumption, improving service life, wide-ranging and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

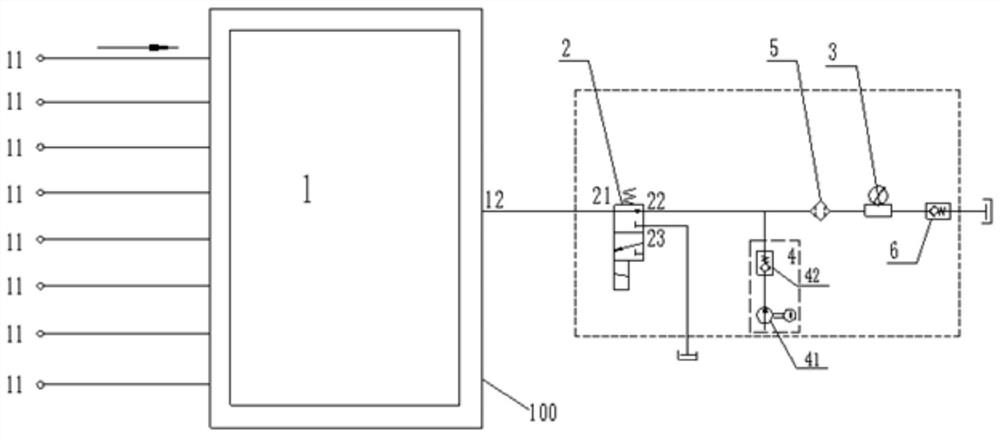

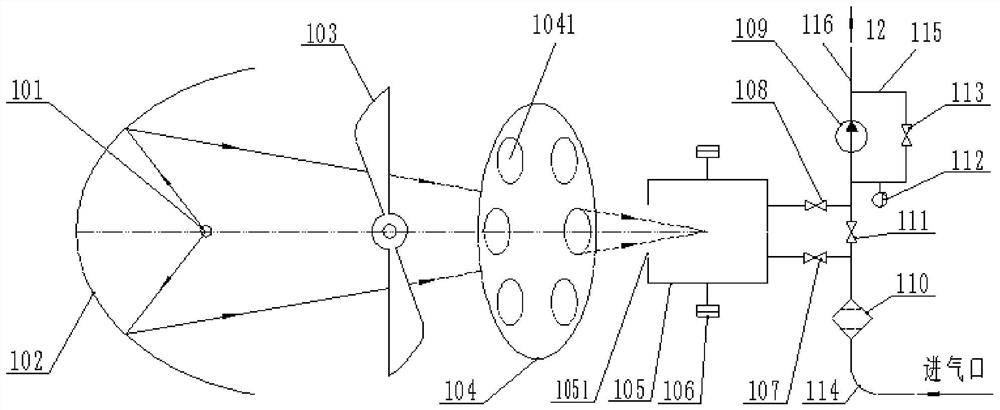

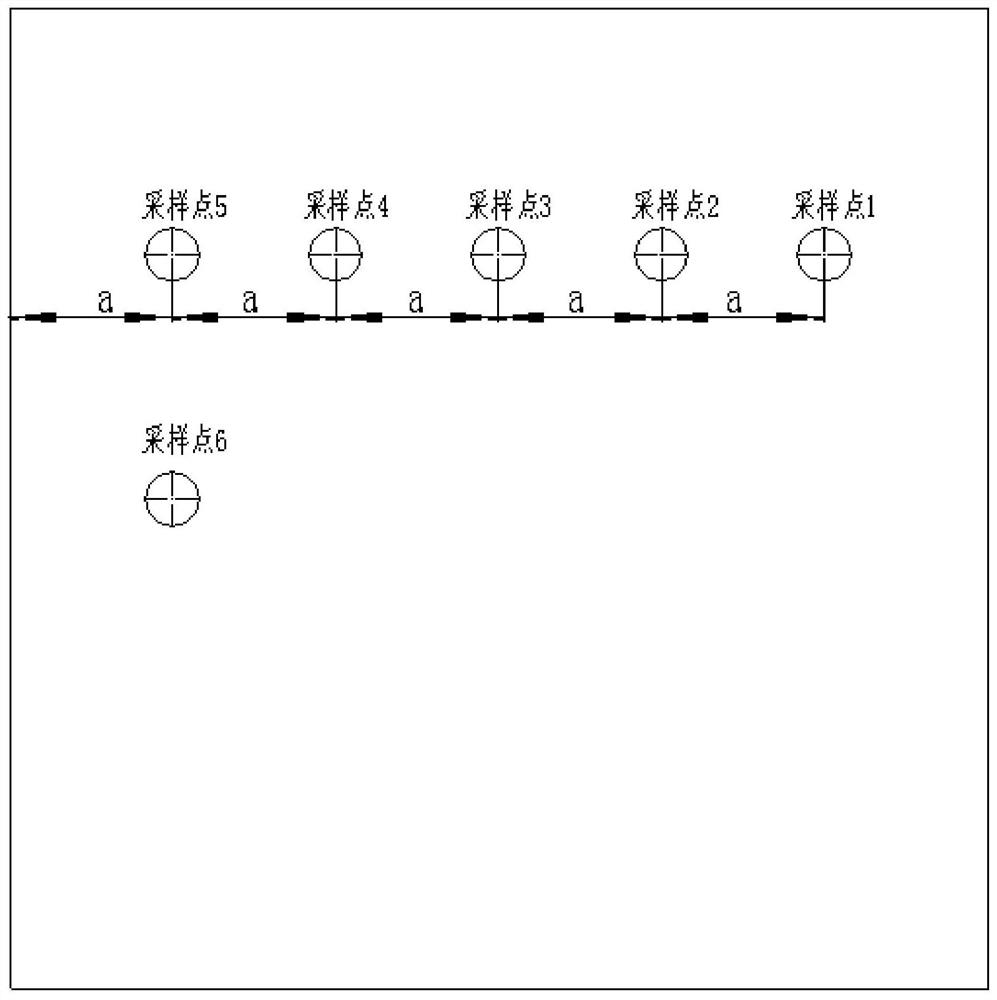

[0053] Such as figure 1As shown, a full-range hydrazine propellant leakage detection system of the present invention includes an acousto-optic infrared detector 1, a three-way solenoid valve 2, an electrochemical detector 3, a gas purging assembly 4 and a control mechanism; the acousto-optic infrared detection Device 1 is provided with sampling point 11, and the quantity of sampling point 11 can be multiple, and three-way solenoid valve 2 is a two-position three-way solenoid valve in the present embodiment, and the inlet port I21 of three-way solenoid valve 2 is connected with the acousto-optic infrared detector The exhaust port 12 of 1 is connected, the first outlet port 22 of the three-way solenoid valve 2 is connected to the inlet port of the electrochemical detector 3, and the second outlet port 23 of the three-way ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com