Chip cooling device

A cooling device and chip technology, applied in electrical components, electrical solid devices, circuits, etc., can solve problems affecting chip integration and packaging, occupation, large space, etc., and achieve small contact thermal resistance, uniform temperature distribution, and high critical heat flow. Effects of Density Values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

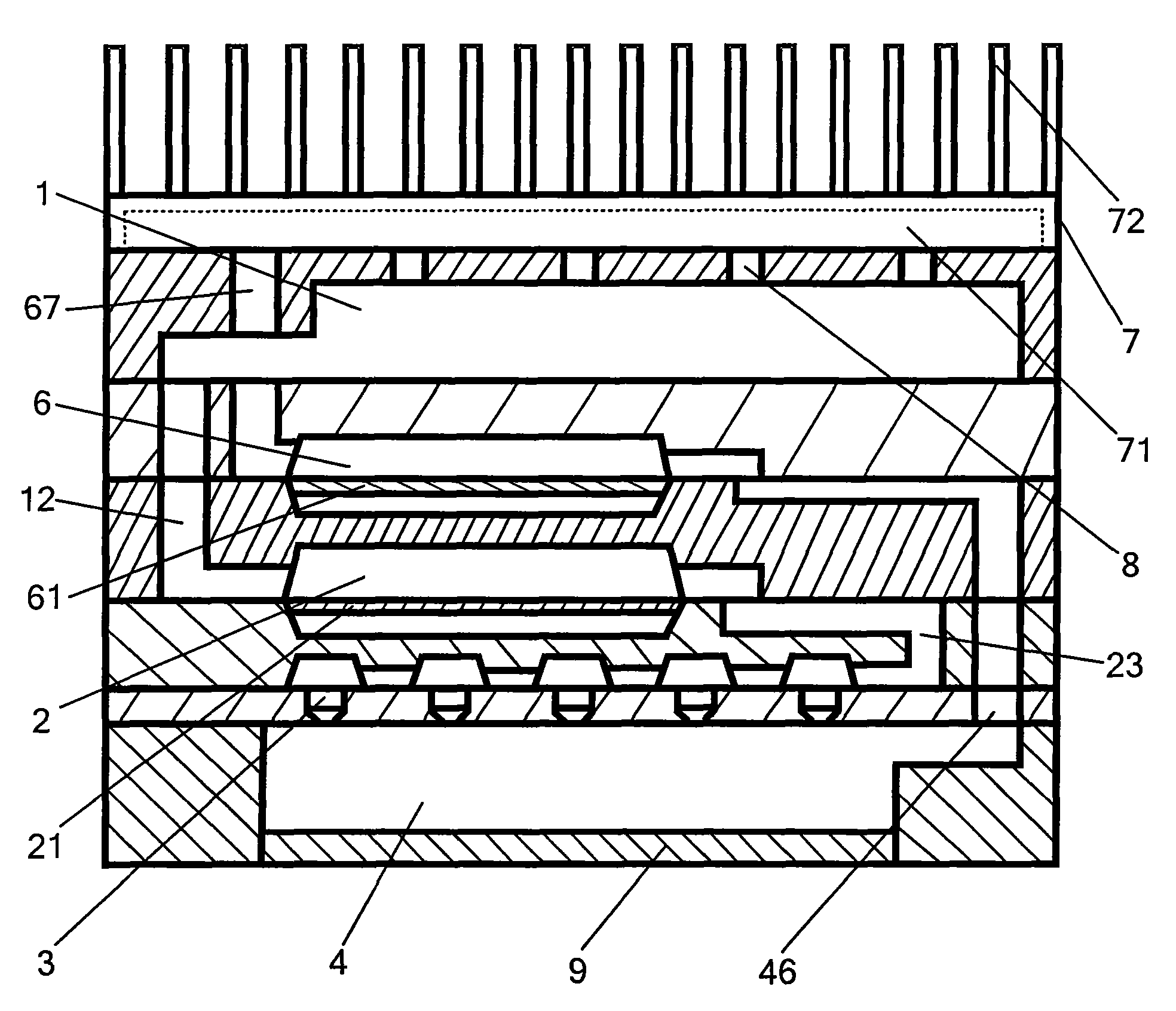

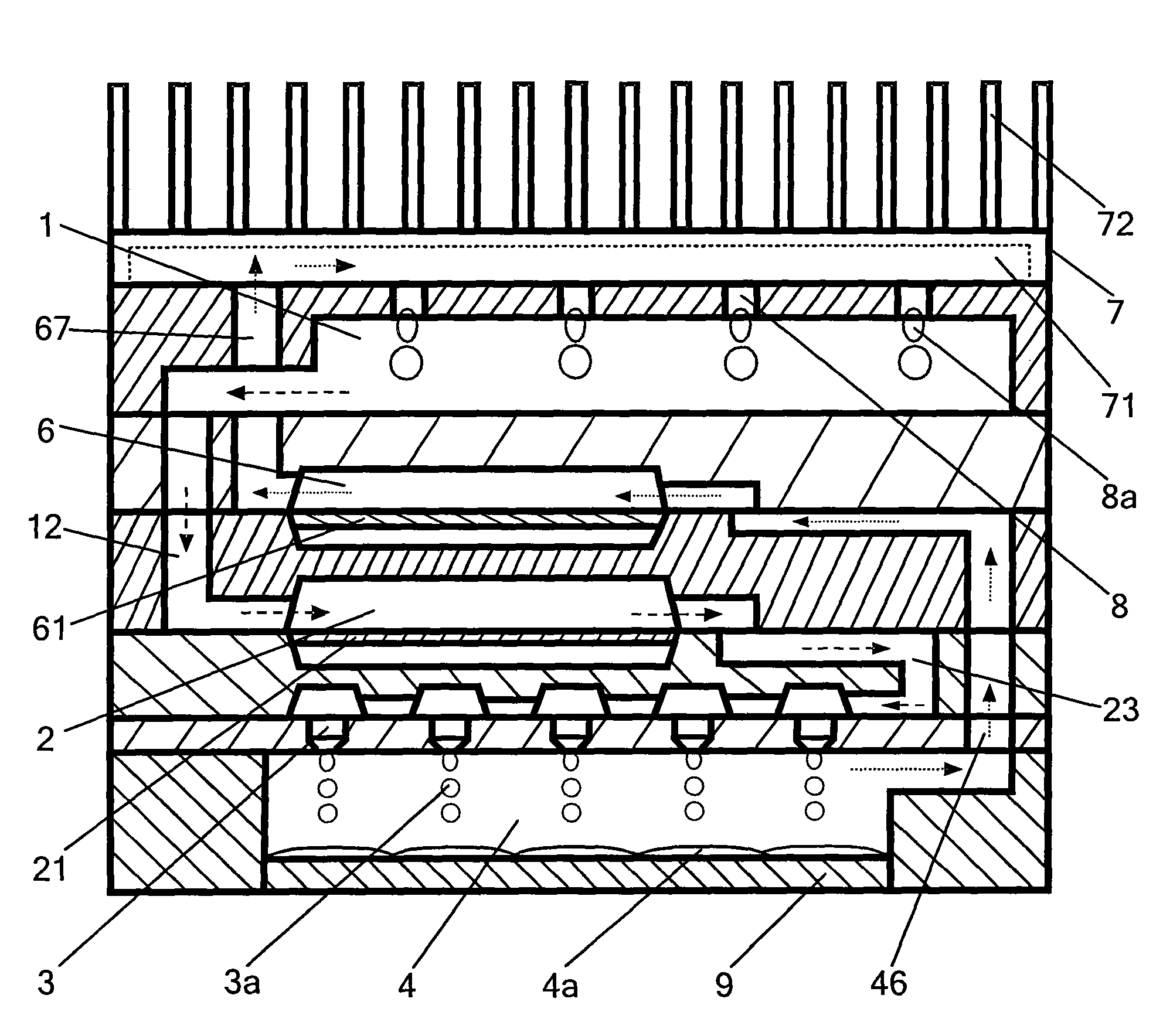

[0019] The chip cooling device of the present invention will be described below with reference to the accompanying drawings.

[0020] See figure 1 , figure 2 ,in figure 2 The arrow symbol in -→ represents the flow direction of liquid coolant, and the arrow symbol Indicates the direction of flow of gaseous coolant. The chip cooling device of the present invention mainly includes a cooling liquid pool 1, a first micro-channel 12, a first micro-pump 2, a second micro-channel 23, a micro-nozzle 3, a cooling chamber 4, a third micro-channel 46, a second micro-channel Pump 6 , fourth microchannel 67 , condenser 7 , and micropore 8 . The cooling liquid pool 1 stores cooling liquid (not shown in the figure). Coolant is required to have good thermophysical properties, electrical properties, corrosion inhibition, safety and stability for chips. Thermophysical properties include suitable boiling point temperature, higher latent heat of vaporization and specific heat, higher dens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com