Electrical insulating phase-change heat conducting material and preparation method thereof

A phase-change heat-conducting and electrical insulation technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problem that it is difficult to meet the insulation requirements of electronic components and radiators, phase-change heat-conducting materials cannot be used as electrical insulating materials, and electronic components cannot be used. Device short circuit and other problems, to achieve the effect of improving safety and reliability, good insulation, and reducing contact thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

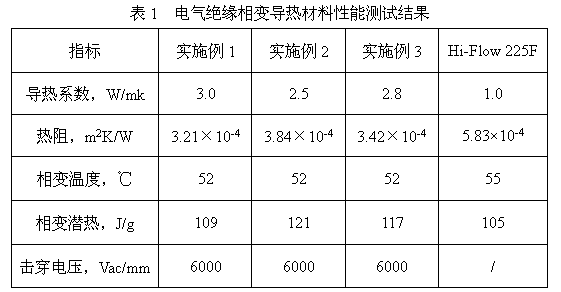

Examples

Embodiment 1

[0029] Weighed 42g of alumina with an average particle size of 70μm, 14g of alumina with an average particle size of 30μm, and 7g of aluminum nitride with an average particle size of 0.5μm, which were baked at 200°C to remove moisture, and mixed to obtain thermally conductive powder raw materials.

[0030] 1 g of silane coupling agent was weighed, added to the heat-conducting powder raw material, put into a high-speed mixer, and stirred at a rate of 300 rpm for 60 minutes at normal temperature and pressure to obtain a modified heat-conducting powder.

[0031] Weigh 5g of vinyl-terminated silicone oil with a viscosity of 20000cst, mix it with 10g of vinyl-terminated silicone oil with a viscosity of 3000cst, add 10g of component A in the two-component addition type liquid silicone rubber, mix well, put it in a vacuum mixer, Add the above-mentioned modified heat-conducting powder, 10.9g of paraffin-acrylic phase change microcapsules with an average particle size of 40μm, and 0.1g ...

Embodiment 2

[0035] Weighed 35g of alumina with an average particle size of 75μm, 15g of silicon carbide with an average particle size of 35μm, and 5g of silicon carbide with an average particle size of 0.7μm, which were baked at 200°C to remove moisture, and mixed to obtain thermally conductive powder raw materials.

[0036] Weigh 1.5 g of silane coupling agent, add it to the heat-conducting powder raw material, put it into a high-speed mixer, and stir at 350 rpm for 80 minutes at normal temperature and pressure to obtain a modified heat-conducting powder.

[0037] Weigh 3g of vinyl-terminated silicone oil with a viscosity of 25000cst, mix it with 7.5g of vinyl-terminated silicone oil with a viscosity of 3500cst, add 10g of component A in the two-component addition type liquid silicone rubber, mix well, and put it into a vacuum mixer , add the above-mentioned modified heat-conducting powder, 22.9g of paraffin-acrylic phase change microcapsules with an average particle size of 45μm, and 0.1...

Embodiment 3

[0041]Weighed 42g of silicon carbide with an average particle size of 80μm, 12g of alumina with an average particle size of 40μm, and 6g of aluminum nitride with an average particle size of 1μm, which were baked at 200°C to remove moisture, and mixed to obtain thermally conductive powder raw materials.

[0042] Weigh 2 g of silane coupling agent, add it to the above-mentioned heat-conducting powder raw material, put it into a high-speed mixer, and stir at 400 rpm for 100 min at normal temperature and pressure to obtain a modified heat-conducting powder.

[0043] Weigh 3g of vinyl-terminated silicone oil with a viscosity of 30000cst, mix it with 9g of vinyl-terminated silicone oil with a viscosity of 4000cst, add 10g of component A in the two-component addition type liquid silicone rubber, mix evenly, put it in a vacuum mixer, Add the above-mentioned modified heat-conducting powder, 15.9g of paraffin-acrylic phase change microcapsules with an average particle size of 50μm, and 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com