Composite bottom aluminum pot and production process thereof

An aluminum pan and process technology, applied in the field of kitchen utensils, can solve problems such as affecting the appearance, affecting the service life of products, blackening of walls and articles, and achieving the effects of excellent product performance, solving large cooking fumes, and reasonable production technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

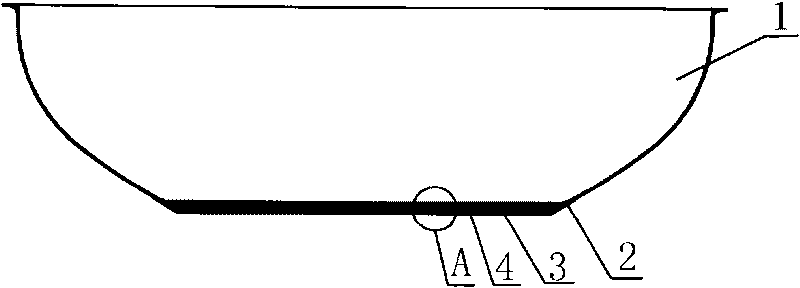

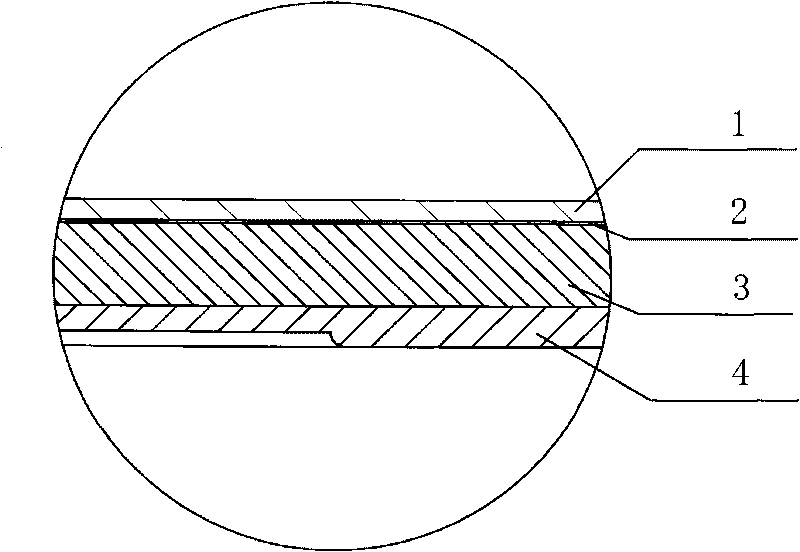

[0028] Example 1, see Figure 1-2 :

[0029] A kind of production technology of compound bottom aluminum pan, its production steps are:

[0030] 1. Surface roughening:

[0031] (1) Adjust the size of the tooling on the turntable of the four-station automatic dry sandblasting machine, and place the bottom of the pot body 1 after stretching, trimming, and cleaning on the tooling;

[0032] (2) Adjust the sandblasting air pressure to 6~8kgf / cm 2 (0.6~0.8MPa), sandblasting distance 100~150mm, spray gun angle 70~80°, roughen with 36 mesh corundum sand, control sandblasting time, make the surface roughness reach 10~20μm.

[0033] 2. Thermal spraying:

[0034] (1) Using arc spraying equipment, put two aluminum alloy or nickel-aluminum alloy wires with a diameter of 1.6-2.0mm into the spray gun, and adjust the spraying pressure to 0.4-0.6MPa;

[0035] (2) Control the spraying working voltage at 30-40V, the wire feeding voltage at 15-20V, adjust the spray gun to be about 200mm away...

Embodiment 2

[0043] Example 2, see Figure 1-2 :

[0044] The present embodiment is basically the same as Embodiment 1, except that the aluminum sheet 3 and the metal composite bottom sheet 4 are placed successively on the pan bottom 1 after the bonding layer 2 is applied, and then the preheating before the compounding is carried out together, and finally with A 500-2500T press presses the aluminum pot, the aluminum sheet 3 and the metal double bottom sheet 4 together to produce a double bottom aluminum pot with a firm double bottom.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com