Microlens array based large-power ceiling lamp

A technology of LED ceiling lamp and microlens array, which is applied to the parts of lighting device, cooling/heating device of lighting device, lighting and heating equipment, etc. Efficiency, low utilization rate of LED light-emitting light energy, etc., to achieve the effect of being conducive to assembly line production, efficient and reliable performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

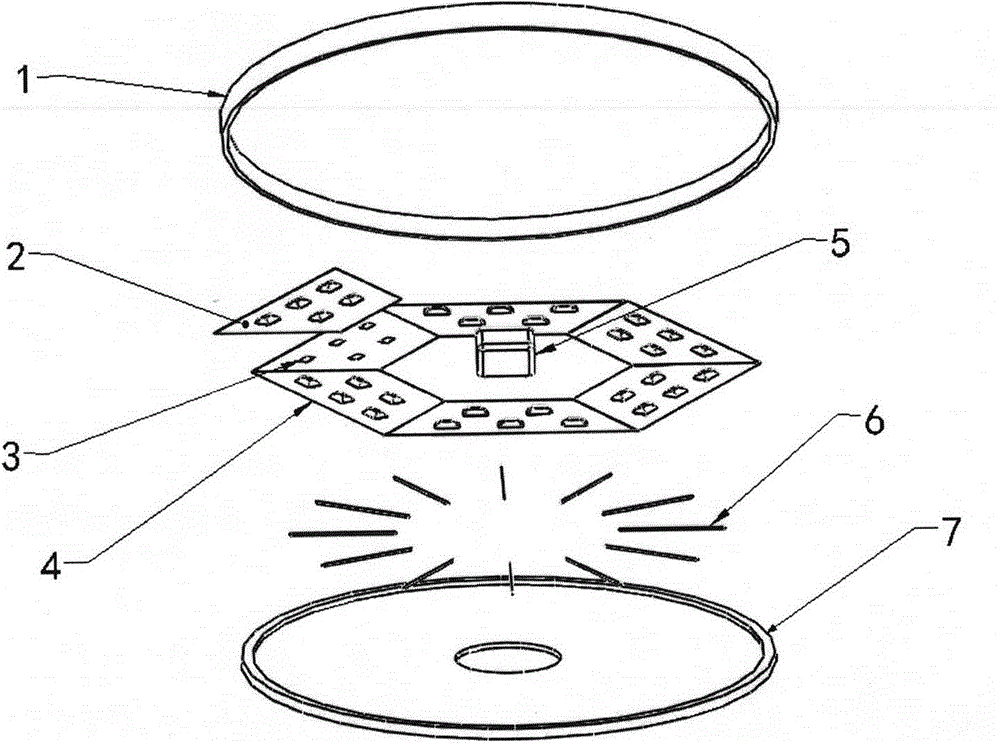

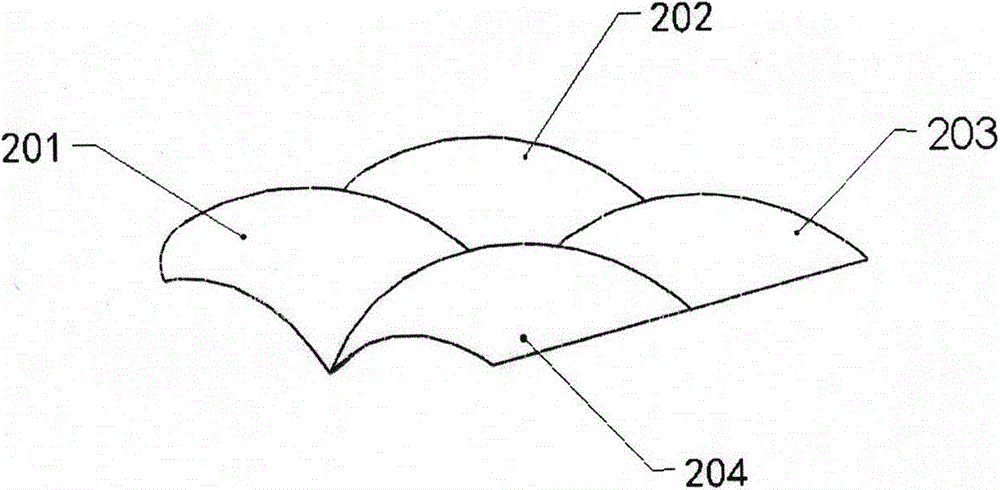

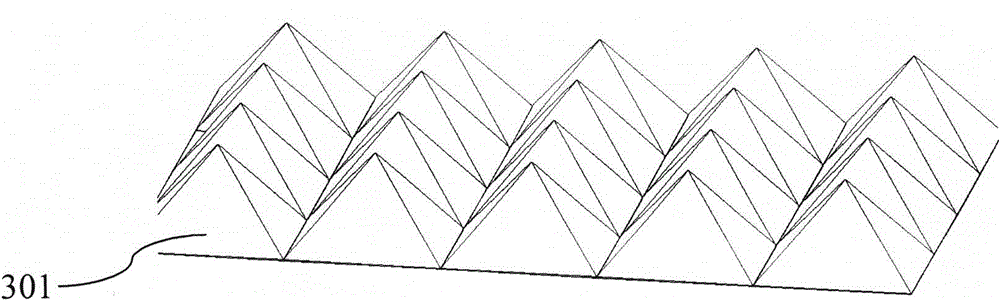

[0024] figure 1 Among them, a high-power LED ceiling lamp based on a microlens array includes a lamp housing, a light source module, a driving power supply 5, and a heat dissipation system; the lamp housing includes a chassis 7 and a lampshade 1; the light source module includes a microlens array 2. LED array light source 3 and substrate 4; the microlens array is composed of four-petal microlenses with the same number as the LED lamp beads; the heat dissipation system includes thermal conductive glue and ceramic heat sink 6; the lampshade 1 is located at The top of the lamp is tightly combined with the chassis through the fixing parts. The LED array light source 3 and the driving power supply 5 are both located on the substrate 4. The fixing parts are combined with the substrate 4. The driving power supply 5 is located at the center of the ring formed by the substrate 4. In the center; the LED array light source 3 is covered with a microlens array 2, and each four-petal microl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com