Three-dimension porous tissue engineering carrier material and preparation and application

A three-dimensional porous and tissue engineering technology, applied in prosthetics, medical science, etc., can solve problems such as no similar or similar patents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

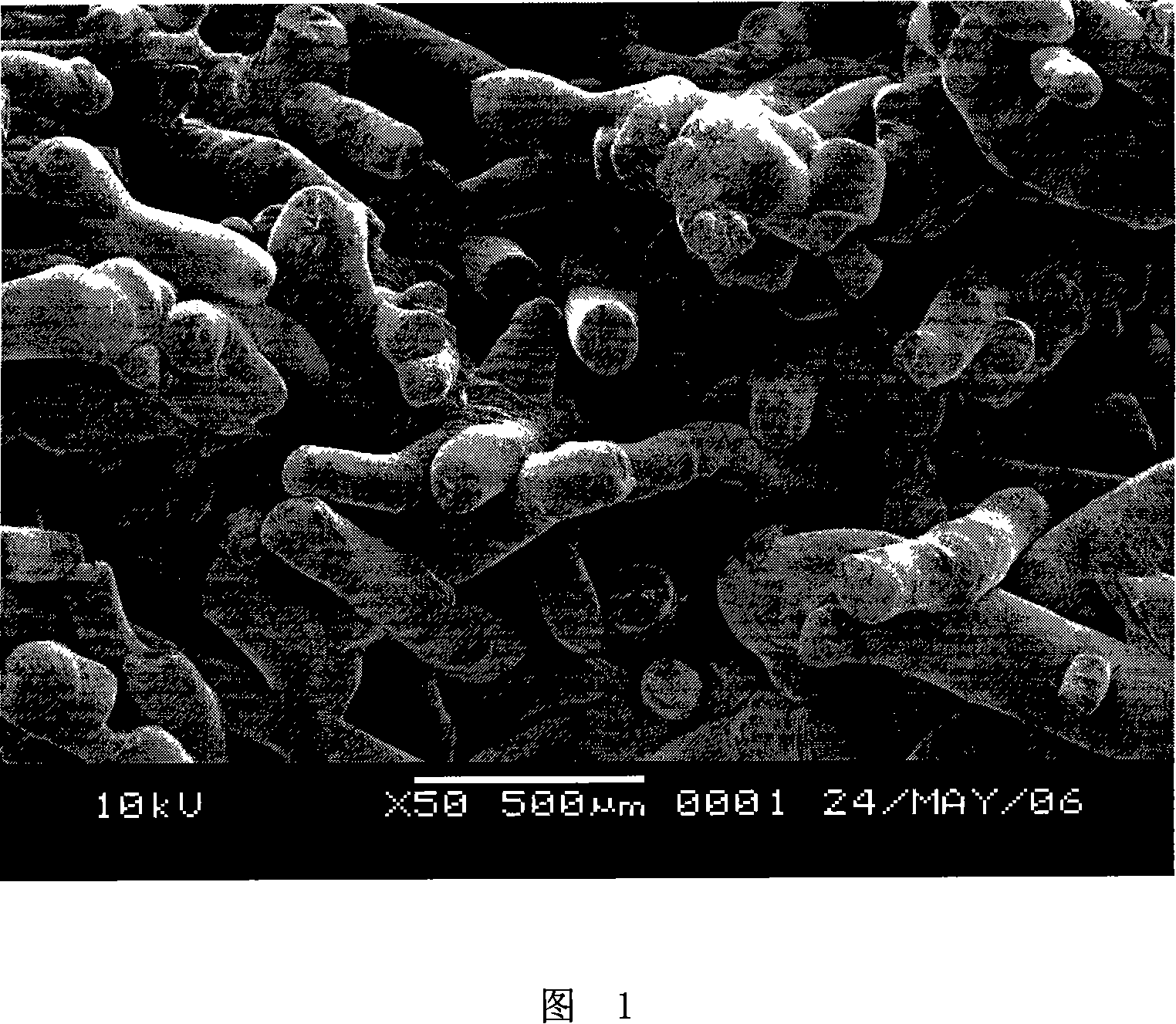

[0019] The high polymer PCL with a molecular weight of 100,000 and a melting point of 60°C, and the high polymer PHBV with a molecular weight of 460,000 and a melting point of 174°C were melt-spun at 175°C to obtain fibers with an average diameter of 500 μm, which were cut into After the equal length is 10.0mm, fill it into a mold with a specific shape. The filling quality is calculated based on the porosity of 85%. After demoulding, the tissue engineering carrier material with specific shape and good performance can be obtained. The material has a pore diameter of 50-200 μm measured by a scanning electron microscope, a porosity of 82% measured by a liquid displacement method, and a degree of pore penetration of more than 90%. The in vitro degradation cycle is appropriate and the mechanical properties are excellent. The material can be used as a bone tissue engineering carrier material for repairing and reconstructing bone damage.

Embodiment 2

[0021] Polymer PCL with a molecular weight of 80,000 and a melting point of 58-60°C, and a polymer PHBV with a molecular weight of 460,000 and a melting point of 174°C were melt-spun at 175°C to obtain fibers with an average diameter of 500 μm, and cut After the equal length is 10.0mm, fill it into a mold with a specific shape. The filling quality is calculated based on the porosity of 85%. Set the temperature of the vacuum oven at 75°C. After the mold is sealed, place it in the vacuum oven to keep the temperature for 1 hour, take it out, and cool it at room temperature After demoulding, the tissue engineering carrier material with specific shape and good performance can be obtained. The material has a pore diameter of 50-200 μm measured by a scanning electron microscope, a porosity of 84% measured by a liquid displacement method, and a degree of pore penetration of more than 90%. The in vitro degradation cycle is appropriate and the mechanical properties are excellent. The ma...

Embodiment 3

[0023] Polymer PCL with a molecular weight of 50,000 and a melting point of 58-60°C, and a polymer PHBV with a molecular weight of 460,000 and a melting point of 174°C were melt-spun at 175°C to obtain fibers with an average diameter of 500 μm, and cut After the equal length is 6.0mm, fill it into a mold with a specific shape. The filling quality is calculated based on the porosity of 85%. Set the temperature of the vacuum oven at 75.0°C. After the mold is sealed, place it in the vacuum oven to keep the temperature for 1 hour, take it out, and cool it at room temperature After demoulding, the tissue engineering carrier material with specific shape and good performance can be obtained. The pore diameter of the material measured by a scanning electron microscope is 300-500 μm, the porosity measured by a liquid displacement method is 75%, the in vitro degradation period is appropriate, and the mechanical properties are excellent. The material can be used as a bone tissue engineer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com