Graphene spontaneous heating floor, manufacturing method and low-voltage spontaneous heating floor system

A graphene and self-heating technology, applied in the field of building decoration materials, can solve problems such as energy waste, inability to effectively meet the use needs, and traditional home building materials that cannot meet consumer decoration needs, etc., to achieve rapid heating, prolong the service life, and reduce energy consumption. The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

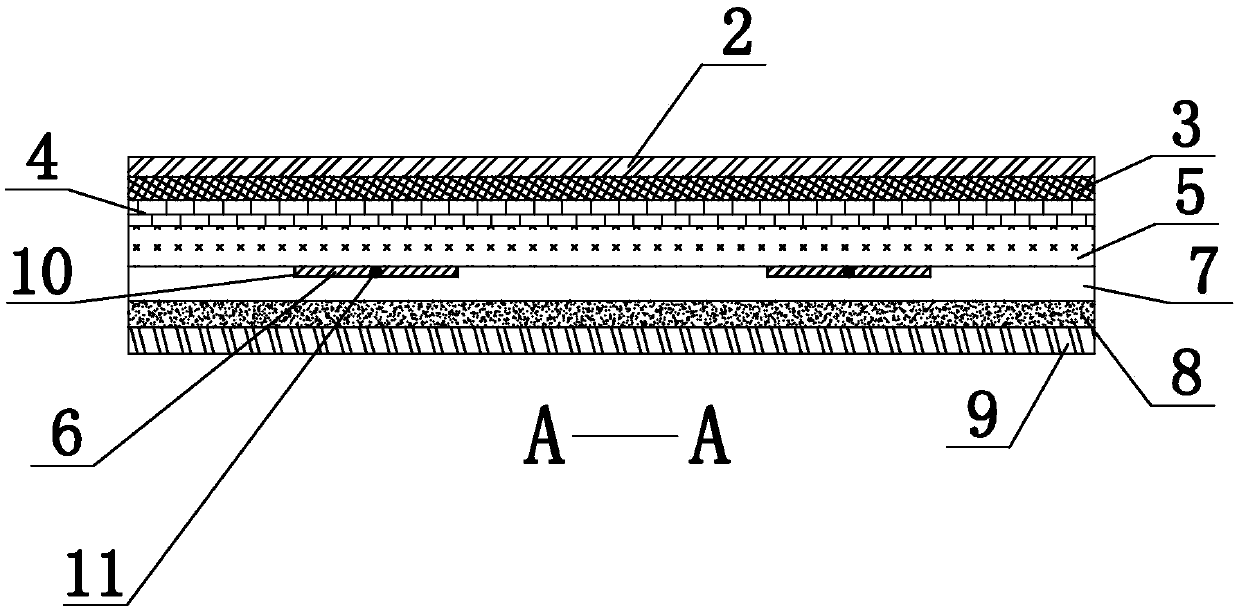

[0046] figure 1 It is a top view of a graphene self-heating floor; figure 2 for figure 1 longitudinal section view. Such as figure 1 , figure 2 As shown, a graphene self-heating floor includes a floor body 1, and the floor body 1 sequentially includes a closely fitted wear-resistant layer 2, a surface decoration layer 3, an upper insulating flame-retardant, temperature-resistant and waterproof layer 4, an upper The substrate plate layer 5, the lower substrate plate layer 7, the lower insulation, flame-retardant, temperature-resistant and waterproof layer 8 and the heat preservation layer 9.

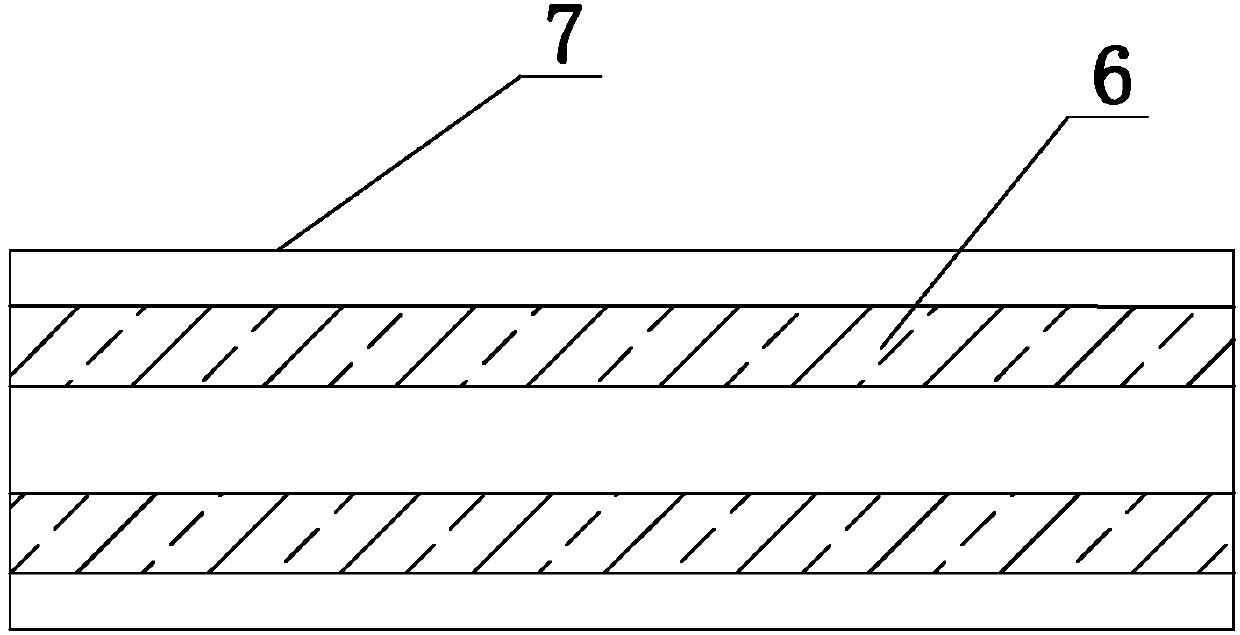

[0047] The upper surface of the lower substrate ply 7 is provided with at least one groove 10 whose groove depth is smaller than the thickness of the lower substrate ply 7, and the two ends of the groove 10 pass through the lower substrate ply 7, such as image 3 shown. A graphene heating element 6 is laid in the groove 10, and a conductive circuit 11 closely attached to the graph...

Embodiment 2

[0073] Embodiment 2 provides a more preferred graphene self-heating floor structure on the basis of embodiment 1. Specifically, this embodiment 2 further defines:

[0074] Wear-resistant layer 2 is made of surface paper impregnated with melamine resin added with aluminum oxide, which is a key part of determining the life of laminate flooring. The wear-resistant layer endows the surface of laminate flooring with important physical and chemical properties such as wear resistance, scratch resistance, cigarette burning resistance, pollution resistance, corrosion resistance, and moisture resistance.

[0075] The surface decoration layer 3 is any one of melamine decorative paper, PVC board, fireproof board, and decorative wood veneer. After the surface of the board layer is processed by three methods of machining, veneer decoration or painting, the three-dimensional effect of the board surface is increased. , special performance and aesthetics.

[0076] Both the upper insulating fl...

Embodiment 3

[0081] Embodiment 3 On the basis of Embodiment 1, a more preferred graphene self-heating floor structure is provided. Specifically, this Embodiment 3 further defines that the number of grooves 10 is 2n, wherein n is a natural number , and the sum of the widths of the 2n grooves 10 is smaller than the longitudinal width of the lower base plate layer 7 . The graphene heating element 6 releases a large amount of heat energy after being energized and excited. In order to ensure that the floor absorbs heat evenly, it is further preferred that the grooves 10 are symmetrically distributed along the central axis of the lower substrate layer 7 in the transverse direction. Also in order to ensure that the magnetic field is evenly released, and to control the magnetic force of the magnetic field to suit the needs of the human body, it is further preferred that the center of the blind hole 13 coincides with the central axis in the transverse direction of the upper substrate plate 5, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com