Method for manufacturing graphite foil capable of heat conduction and electricity conduction

A technology of conductive graphite and manufacturing method, which is applied in the field of film material preparation, can solve problems such as uneven heat conduction, fragile and broken flexible graphite sheets, and affect the production environment, and achieve uniform heat conduction effect, avoid poor heat dissipation, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

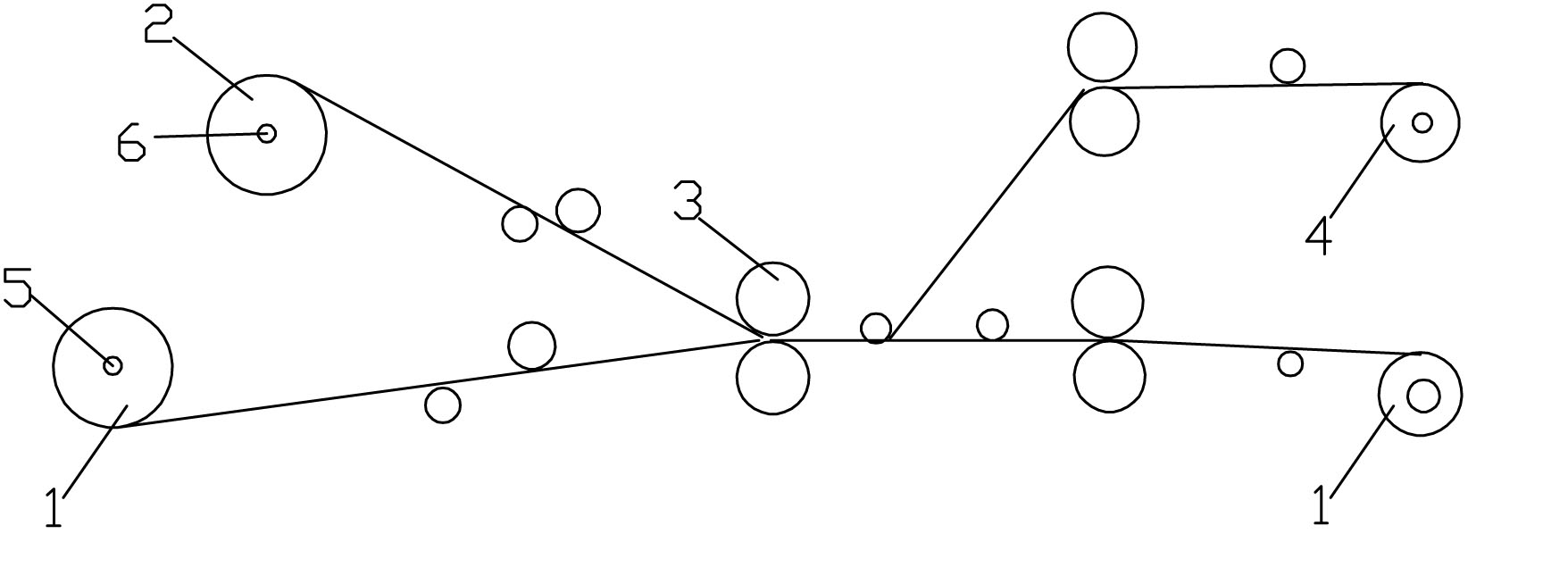

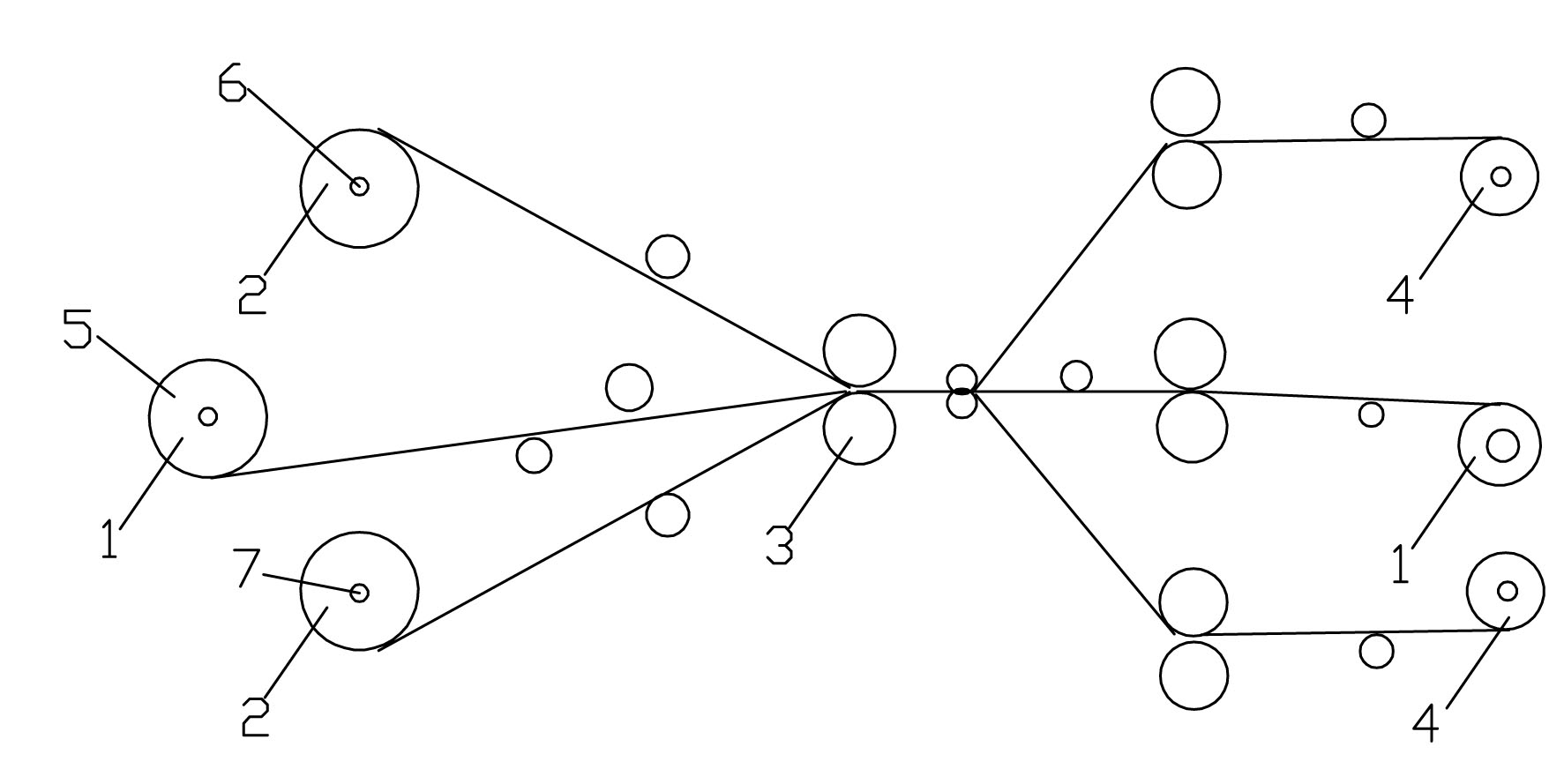

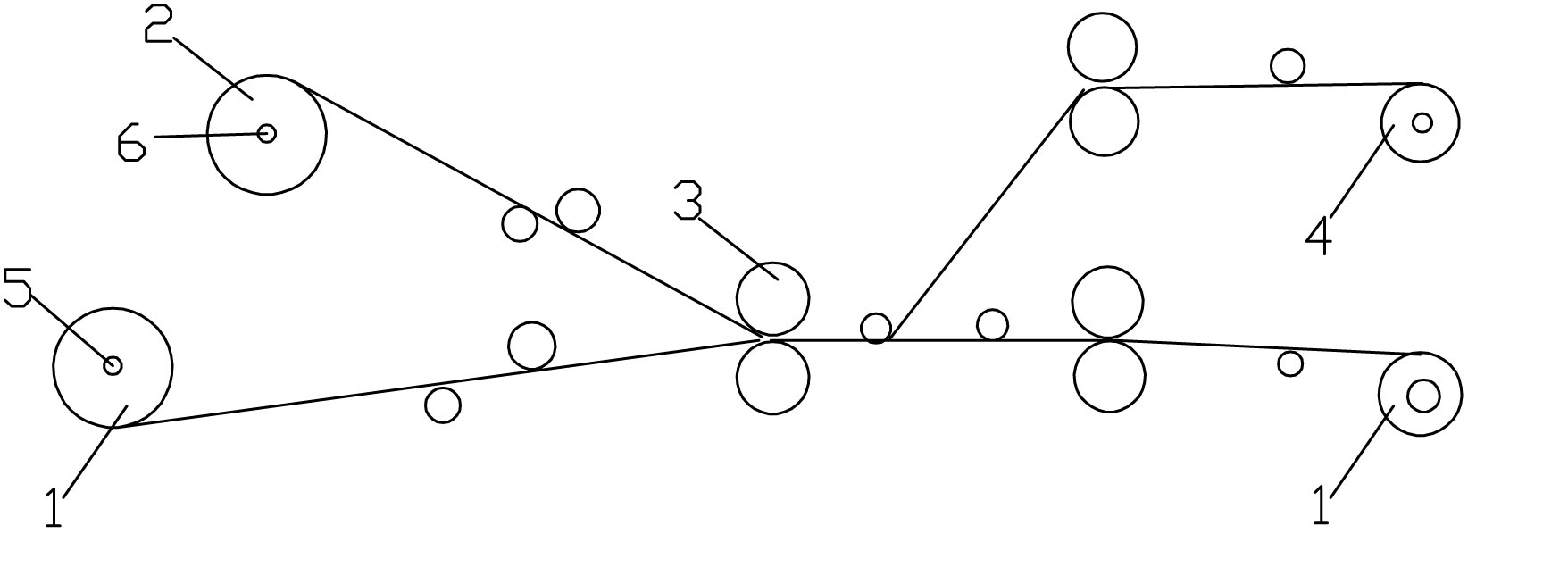

[0020] According to the material and temperature requirements, select the single-sided adhesive tape roll 2 with suitable backing. The double-sided tape with release paper can also be used for the tape roll 2, and the graphite tape is composited on one adhesive surface, and the other adhesive surface is used for installation. The base film of the tape can be polyester or polyimide, and the pressure-sensitive adhesive of the tape can be acrylic or natural rubber pressure-sensitive adhesive.

[0021] Base film and pressure sensitive adhesive thicknesses are adjusted as needed.

[0022] The width of tape coil 2 is selected according to actual needs. Generally, it is equivalent to the width of the tape roll 2.

[0023] Graphite coil thickness, width and actual product needs to be set, flexible graphite coil density not less than 1.0g / cm 3 .

[0024] Such as figure 1 Among them, the manufacturing method of thermally and electrically conductive graphite foil comprises the follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com