A kind of ceramic filter purification material and preparation method thereof

A purification material and ceramic filtration technology, applied in ceramic products, chemical instruments and methods, separation methods, etc., can solve problems such as small drag coefficient, and achieve the effects of good taste, fresh air and multiple functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

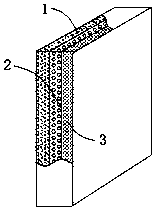

[0021] Grind various materials separately, the main material kaolin is mixed in a ratio of 70-80%, and the auxiliary materials crystalline quartz, clay, coconut shell activated carbon, borax powder, foaming agent, titanium oxide, zirconia, borax powder, etc. are mixed in a ratio of 20-80%. 30%, the main ingredients and auxiliary materials are mixed to form the primary filter layer 1 whose main components are kaolin, borax powder, foaming agent, clay and crystalline quartz, and the main ingredients and auxiliary materials are mixed to form kaolin, rare earth and The sterilization layer 2 of the cold catalyst, the main material and the auxiliary material are mixed into an electrolytic adsorption layer 3 whose main components are kaolin, tourmaline, radium stone titanium oxide, zirconia, coconut shell activated carbon, foaming agent, and catalyst. The primary filter layer, the sterilization layer and the electrolytic adsorption layer are tightly bonded together, mixed at a low tem...

Embodiment 2

[0029]Grind various materials separately, the main material kaolin is mixed with 30-50%, auxiliary materials crystalline quartz, coconut shell activated carbon, catalyst, magnesium-rich tourmaline spar, radium stone, titanium oxide, zirconium oxide, borax powder, etc. The input ratio is 50-70%, of which the coconut shell activated carbon accounts for the highest proportion in the auxiliary materials, which is molded at low temperature, made into 1-3mm diameter balls by rolling machine, and fired at high temperature to make spherical ceramic particles, which are used to absorb formaldehyde in the air, Benzene, TOVC and other harmful gases;

[0030] The preparation method of the ceramic filter purification material comprises the following process steps:

[0031] Its main material and its auxiliary materials are ground and screened with a 130 mesh screen;

[0032] Take half of the main ingredients and auxiliary materials and grind them finely to 1-3 micron particles;

[0033] K...

Embodiment 3

[0037] Grind various materials separately, the main material kaolin is mixed with a ratio of 50-70%, auxiliary materials crystalline quartz, tourmaline, magnesium-rich tourmaline spar, radium stone, clay, borax powder, catalyst, titanium oxide, zirconium oxide, The mixing ratio of borax powder and the like is 30-50%. Among them, the material with the highest proportion in the auxiliary materials is tourmaline. The main material and auxiliary materials are mixed to form kaolin, borax powder, foaming agent, clay and crystalline quartz. The primary filter layer, the main material and auxiliary materials are mixed to form a sterilization layer whose main components are kaolin, rare earth and cold catalyst, and the main materials and auxiliary materials are mixed to form a main component of kaolin, tourmaline, radium stone titanium oxide, oxide Zirconium, coconut shell activated carbon, foaming agent, electrolytic adsorption layer of catalyst, the primary filter layer, sterilizing l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com