Method for forming curing laminated film of siloxane resin compound

A technology of siloxane resin and composition, which is applied in the direction of coating, etc., can solve the problems of hindering the properties of the film, reducing the hardness of the film, forming wrinkles, etc., and achieving high insulation, high scratch hardness, and low dielectric constant Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

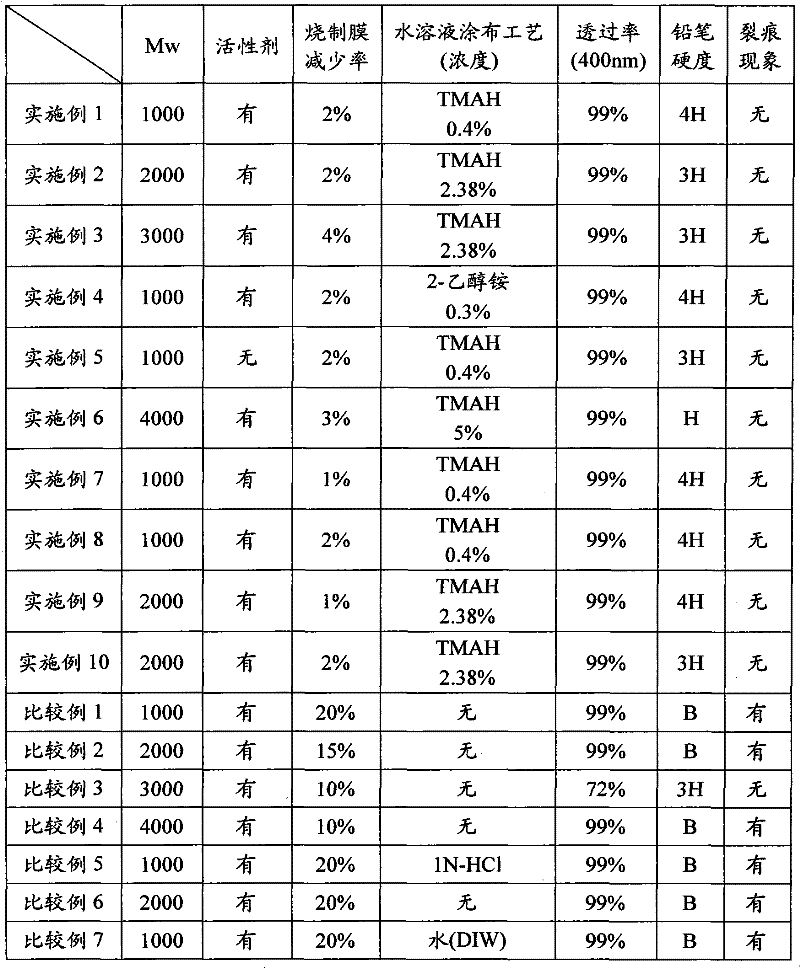

Examples

manufacture example 1

[0078]47.6g (0.35mol) methyltrimethoxysilane, 29.7g (0.15mol) phenyltrimethoxysilane, 4.83g (0.015mol) 3,3',4,4'-benzophenone tetracarboxylic acid The dianhydride was dissolved in 200 g of 3-methyl-3-methoxybutanol, and 34.2 g of distilled water was added with stirring at 45° C., followed by heating and stirring for 1 hour to perform hydrolysis and condensation. Thereafter, it was washed with water five or more times, and the ethyl acetate oil layer was recovered. Next, the ethyl acetate oil layer was concentrated and replaced with propylene glycol monomethyl ether acetate to obtain a 40% solution of a polycondensate of methylphenylsilsesquioxane.

[0079] The obtained siloxane resin was methylphenylsilsesquioxane (methyl:phenyl=7:3 molar ratio) having a weight average molecular weight (Mw) of 1,000.

[0080] The measurement of the weight average molecular weight (Mw) was performed using the following apparatus and conditions (for example, in the following examples, it measur...

manufacture example 2

[0085] In Production Example 1, except that the reaction temperature was changed from 45°C to 60°C, the same method as in Production Example 1 was carried out, thereby obtaining methylphenylsilsesquioxane (methylphenylsilsesquioxane) with a weight average molecular weight (Mw) of 2,000. base: phenyl = 7:3 molar ratio).

manufacture example 3

[0087] In Production Example 1, except that the reaction temperature was changed from 45°C to 60°C, and the reaction time was changed from 1 hour to 6 hours, the same method as in Production Example 1 was carried out, thereby obtaining formazan with a weight average molecular weight (Mw) of 4,000. phenyl silsesquioxane (methyl:phenyl=7:3 molar ratio).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com