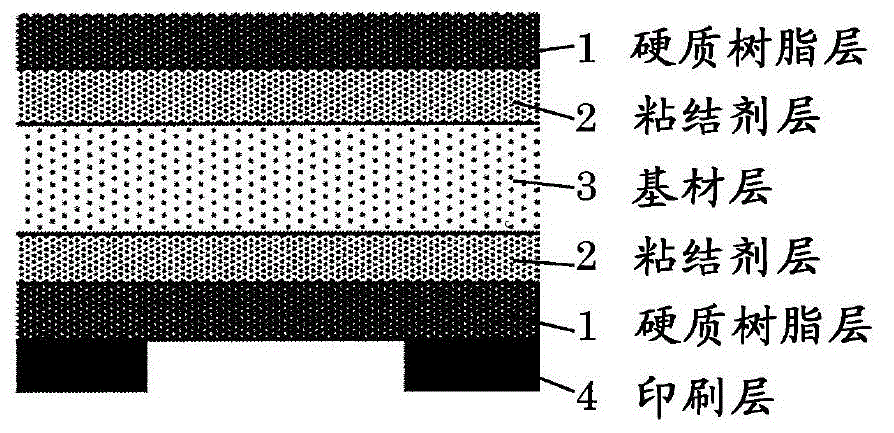

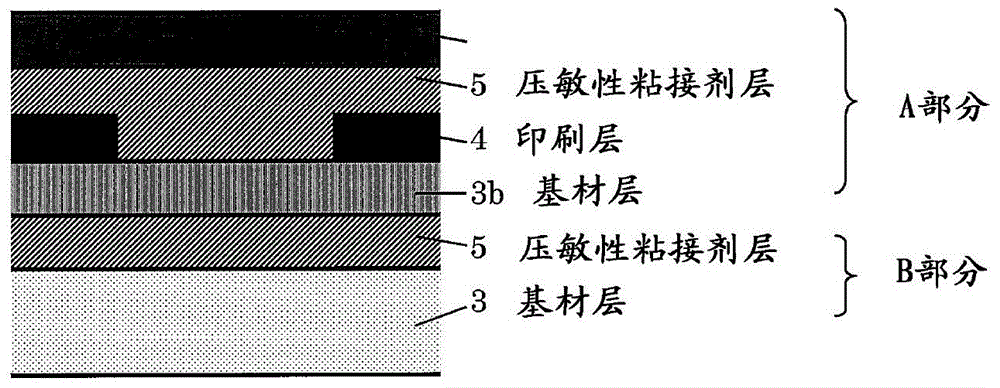

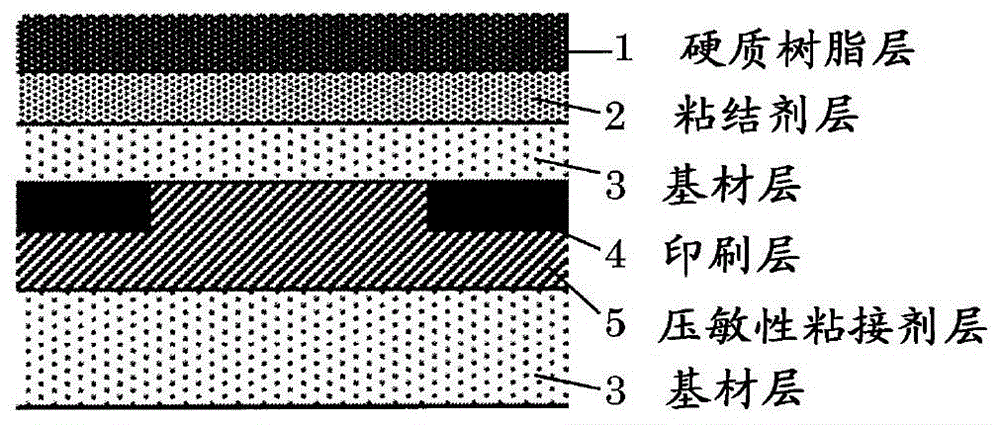

Resin laminate

A laminated body, resin layer technology, applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the difference in wear resistance, scratch resistance, hindered transparency, difficult to distinguish the surface, etc. problem, to achieve the effect of excellent processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] (Preparation of hard resin layer)

[0095] Dipentaerythritol hexaacrylate: 85 parts by weight and PMMA: 15 parts by weight were heated and kneaded to 110°C, and then 1-hydroxycyclohexyl phenyl ketone: 2.5 parts by weight as a photopolymerization initiator was mixed to obtain a curable resin combination.

[0096] Next, using a roll coater, the curable resin composition was cast (cast) on the peeled PET so that the thickness became 0.15 mm, and another peeled PET was laminated on the casted PET. After curable resin composition is on, use the high-pressure mercury lamp of 30W / cm, with 4000mJ / cm 2 The accumulated exposure dose is cured, and the peeled PET is removed by complete peeling to obtain a sheet-shaped hard resin layer with a predetermined thickness. The tensile elastic modulus and total light transmittance of the obtained hard resin layer were measured. The results are shown in Table 1.

[0097] (Manufacturing of resin laminates)

[0098] Polycarbonate (PC-115...

Embodiment 2

[0100] Except having made the compounding composition into the weight ratio shown in Table 1, it carried out similarly to Example 1, and obtained the hard resin layer and the resin laminated body. Table 1 shows the evaluation results of the molded articles obtained.

Synthetic example 1

[0102] 400 ml of 2-propanol (IPA) as a solvent and 5% tetramethylammonium hydroxide aqueous solution (TMAH aqueous solution) as a basic catalyst were placed in a reaction vessel equipped with a stirrer, a dropping funnel, and a thermometer. 150 ml of IPA and 126.9 g of 3-methacryloxypropyltrimethoxysilane (MTMS: Dow Corning Toray Silicone Co., Ltd. SZ-6030) were added to the dropping funnel, and the reaction vessel was stirred at room temperature for 30 minutes. A solution of MTMS in IPA was added dropwise. After the dropwise addition of MTMS was completed, the mixture was stirred for 2 hours without heating. After stirring for 2 hours, the solvent was removed under reduced pressure and dissolved in 500 ml of toluene. The reaction solution was washed with saturated brine until it became neutral, and then dehydrated with anhydrous magnesium sulfate. Anhydrous magnesium sulfate was filtered off and concentrated to obtain 86 g of a cage-type silsesquioxane compound having metha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com