Organic carrier for solar cell slurry and preparation method of organic carrier

A technology of solar cells and organic carriers, applied in applications, circuits, photovoltaic power generation, etc., can solve the problems that the aluminum paste has a large impact and cannot be completely solved, and achieves the effects of not being easy to resin agglomeration, not easy to scratch, and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] 1. First, the components of the organic solvent: 15% terpineol, 51% diethyl butyl ether, 10% diethylene glycol butyl ether acetate, and 10% ethylene glycol phenyl ether are formulated into solvents and then added to the stirring reactor. And heated to 55°C at a stirring rate of 30 rev / min;

[0026] 2. Then 4.5% Span-85, 2% ethyl cellulose, 4% CAB-381-20, 3.5% phenolic resin, under the condition that the stirring rate is 50 rpm and the temperature in the reactor is 55°C, Put into the stirred reactor;

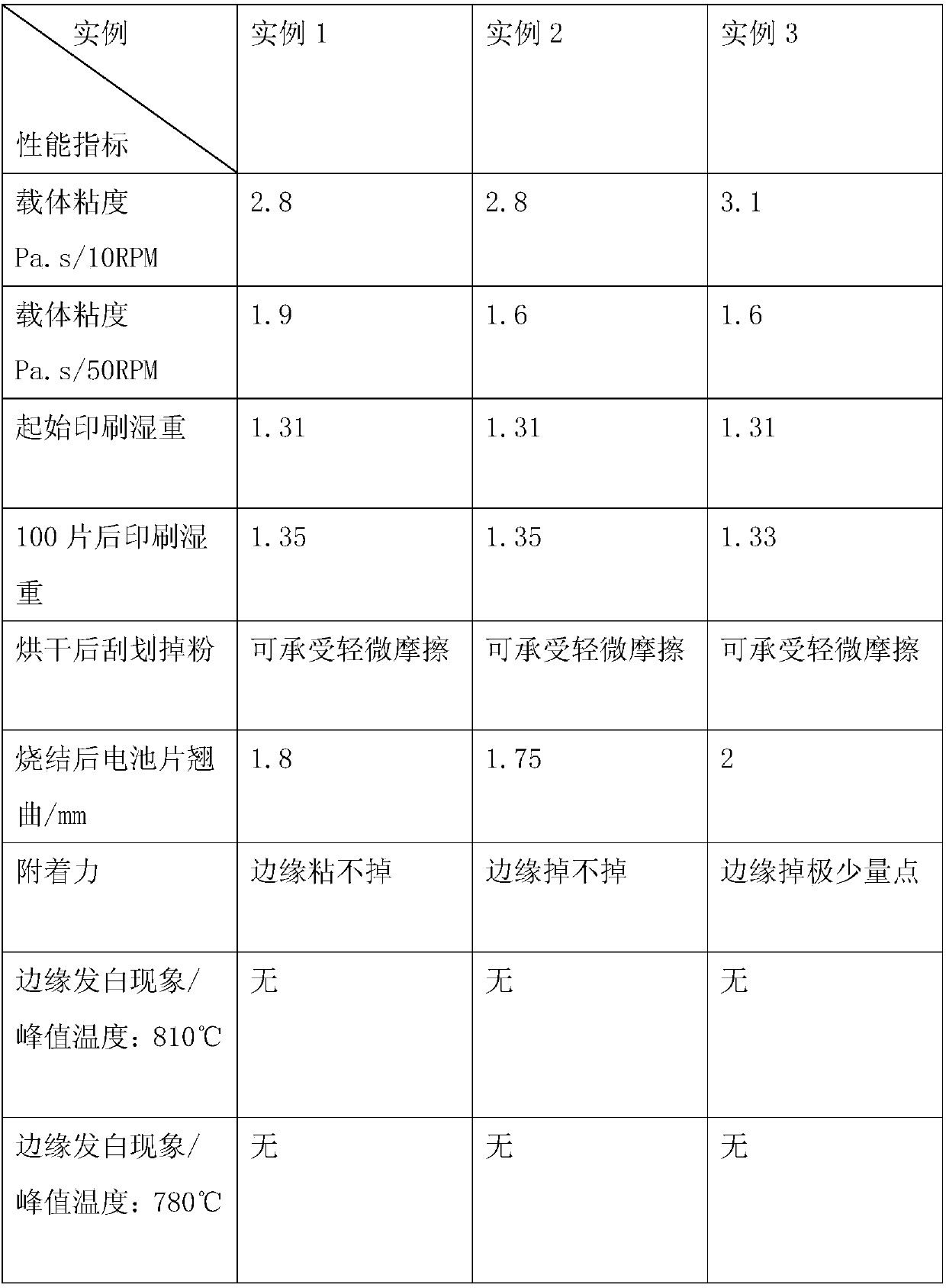

[0027] 3. Then heat up to 90°C under stirring and cook at constant temperature for 2 hours. After the components in the stirred reactor are completely dissolved and dispersed evenly, filter with a 200-mesh screen while it is hot, and obtain evenly dispersed The organic carrier used for the aluminum paste on the back of solar crystalline silicon cells, the specific performance parameters are shown in Table 1.

example 2

[0029] 1. First, the components of the organic solvent: 10% terpineol, 42% diethyl ether butyl ether, 20% diethylene glycol butyl ether acetate, 10% alcohol ester twelve, and 5% tributyl citrate are prepared The solvent is then added to the stirred reactor, and heated to above 50°C at a stirring rate of 30 rpm;

[0030] 2. Then add 3.5% Span-85, 0.8% lecithin, 2% ethyl cellulose, 2.2% CAB-381-20, 1% CAB-381-2BP, 3% phenolic resin, 0.5% polyaldehyde resin in Stirring speed is 50 rpm and the temperature in the reactor is 55°C, put it into the stirred reactor;

[0031] 3. Then heat up to 90°C under stirring and cook at constant temperature for 2 hours. After the components in the stirred reactor are completely dissolved and dispersed evenly, filter with a 200-mesh screen while it is hot, and obtain evenly dispersed The organic carrier used for the aluminum paste on the back of solar crystalline silicon cells, the specific performance parameters are shown in Table 1.

example 3

[0033] 1. First, the components of the organic solvent: 15% terpineol, 45% diethyl butyl ether, 10% diethylene glycol butyl ether acetate, 10% alcohol ester twelve, 5% tributyl citrate, benzene 3.5% methanol is prepared as a solvent, then added to the stirred reactor, and heated to above 50°C at a stirring rate of 30 rpm;

[0034] 2. Then mix 3.5% Span-85, 2% ethyl cellulose, 2% CAB-381-20, 3.5% phenolic resin, and 0.5% polyaldehyde resin at a stirring rate of 50 rpm and a high temperature in the reactor Put it into the stirred reactor at 55°C;

[0035] 3. Then heat up to 90°C under stirring and cook at constant temperature for 2 hours. After the components in the stirred reactor are completely dissolved and dispersed evenly, filter with a 200-mesh screen while it is hot, and obtain evenly dispersed The organic carrier used for the aluminum paste on the back of solar crystalline silicon cells, the specific performance parameters are shown in Table 1.

[0036] Table 1:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com