A kind of tetrafluoroethylene copolymer resin for coating and preparation method thereof

A technology of tetrafluoroethylene and copolymer, which is applied in the field of tetrafluoroethylene copolymer resin for coating and its preparation, can solve the problem that the compatibility between copolymer and curing agent and dispersant decreases, the dispersing and wetting of pigment is not ideal, and the The fluorine content of the copolymer is difficult to increase and other problems, so as to achieve the effects of not easy shrinkage, excellent solvent resistance and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

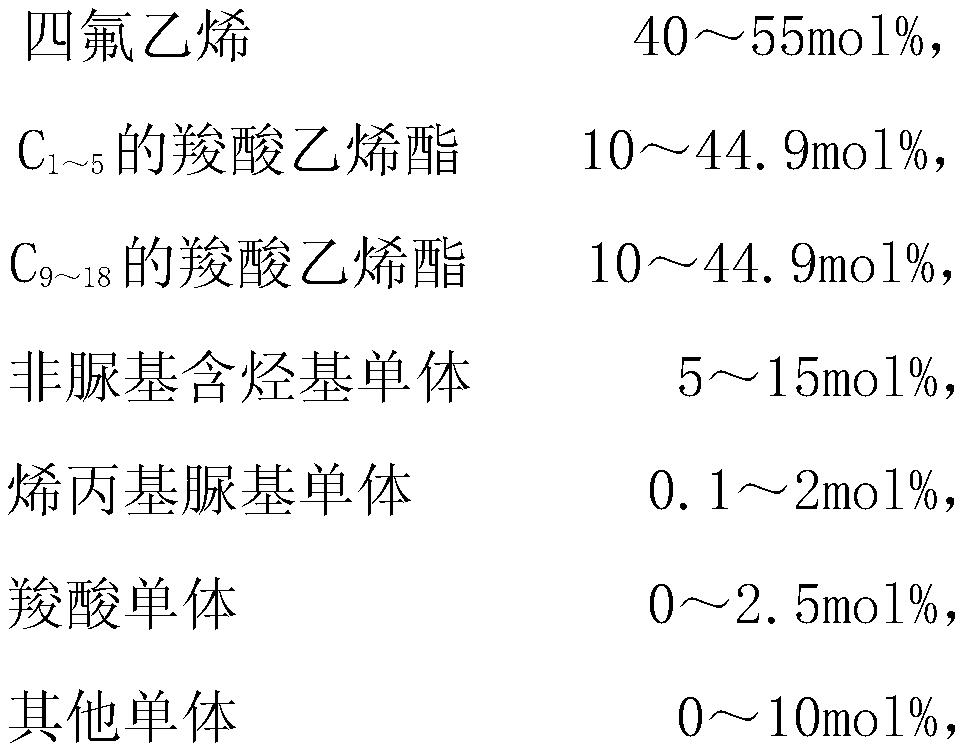

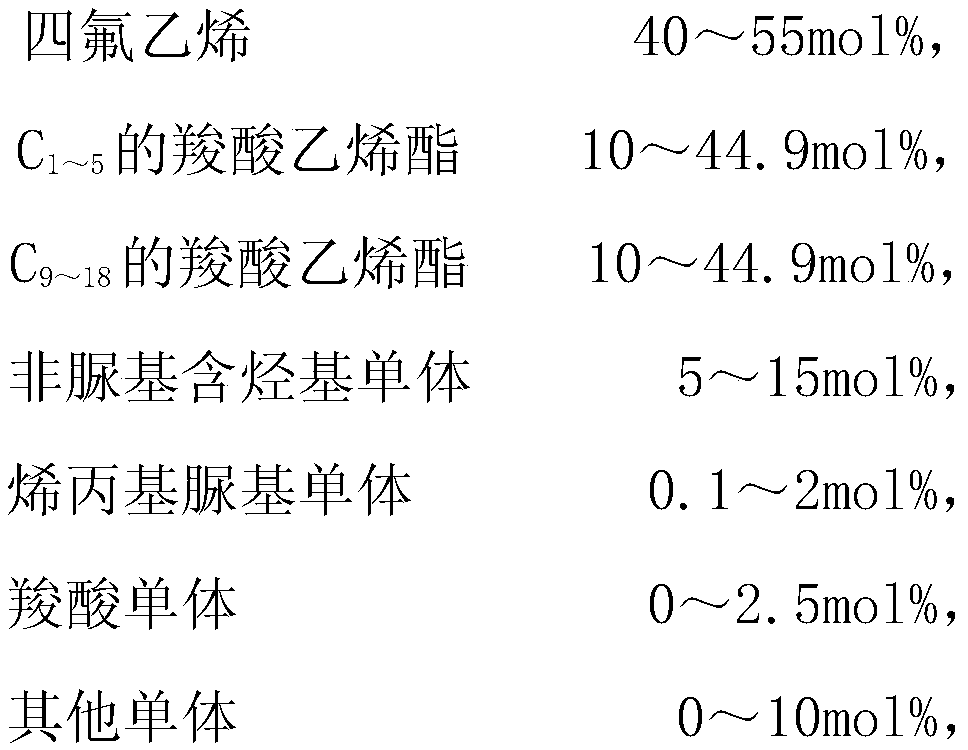

Method used

Image

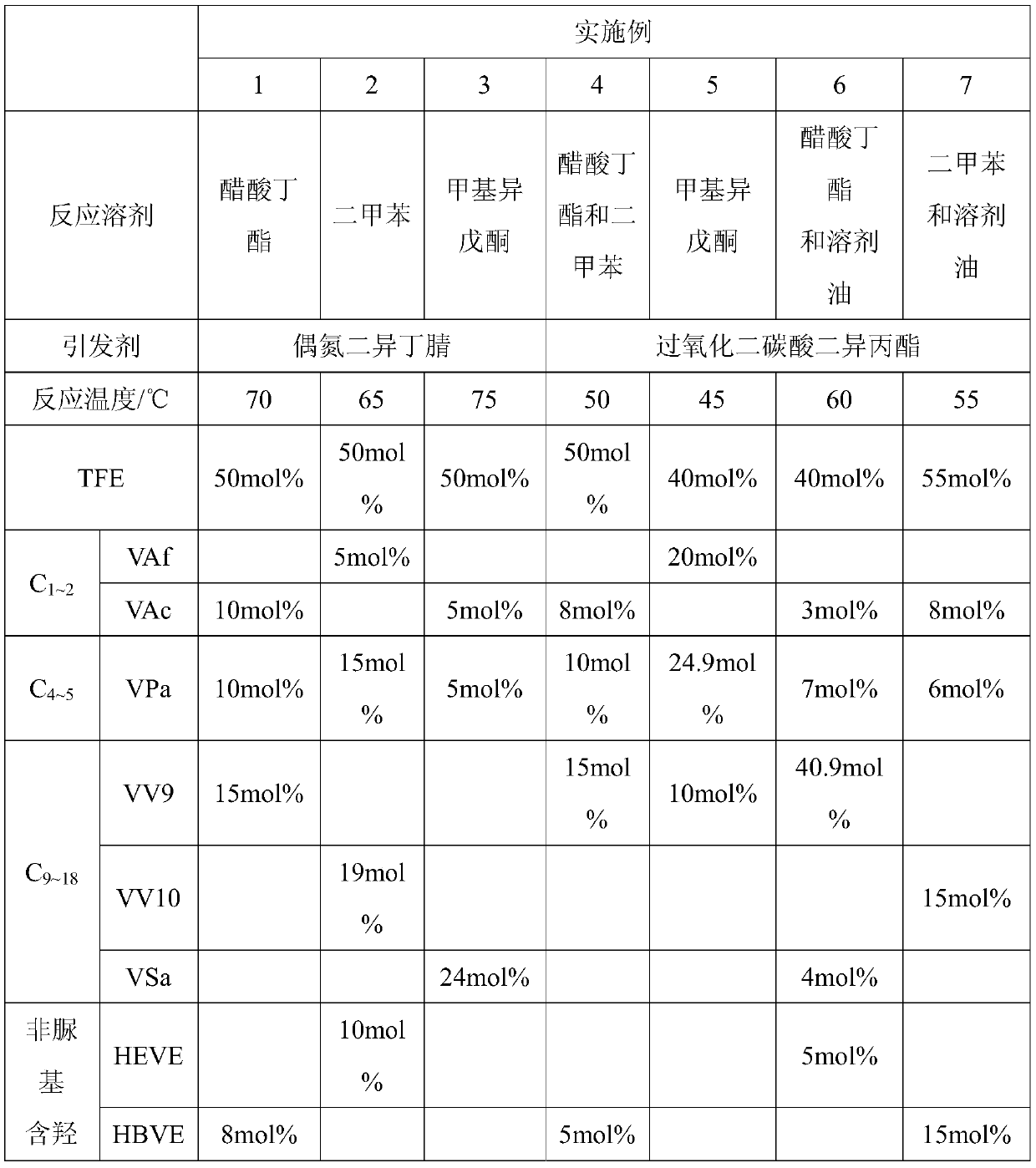

Examples

Synthetic example 1

[0040] Synthesis example 1 (CH 2 =CHCH 2 NHCONHCH 2 CH 3 Synthesis)

[0041] Add 450 g (10 mol) of H 3 NCH 2 CH 3 (purchased from Changzhou Aohua Chemical Co., Ltd.), 830g (10mol) of CH 2 =CHCH 2 NCO (purchased from Beijing Datian Fengtuo Chemical Technology Co., Ltd.), after 30 minutes of dropping, add a small amount of hydroquinone (purchased from Nanjing Xinhuayuan Chemical Co., Ltd.) polymerization inhibitor, and then heat up to 80 ° C for 8 hours , to obtain light yellow transparent liquid. Infrared analysis showed that the absorption peak of the isocyanate group disappeared completely.

Synthetic example 2

[0042] Synthesis example 2 (CH 2 =CHCH 2 NHCONHCH 2 CH 2 CH 2 CH 3 Synthesis)

[0043] In addition to 730g (10mol) of H 3 NCH 2 CH 2 CH 2 CH 3 (purchased from Changzhou Aohua Chemical Co., Ltd.) to replace 450g (10mol) of H 3 NCH 2 CH 3 Except, others are the same as Synthesis Example 1.

Synthetic example 3

[0044] Synthesis example 3 (CH 2 =CHCH 2 NHCONHCH 2 CH 2 Synthesis of OH)

[0045] In addition to 610g (10mol) of H 3 NCH 2 CH 2 OH (purchased from Shanghai Jinjinle Industrial Co., Ltd.) to replace 450g (10mol) of H 3 NCH 2 CH 3 Except, others are the same as Synthesis Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com