Patents

Literature

32results about How to "Not prone to shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of cast state high extension rate ductile iron

InactiveCN1948534AShorten the production cycleEnhanced self-expanding and refilling capabilitiesChemical compositionSilicon alloy

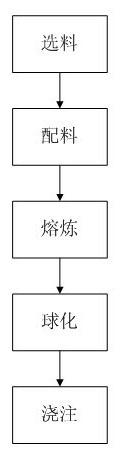

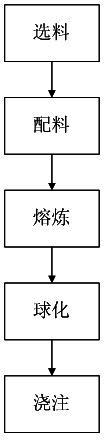

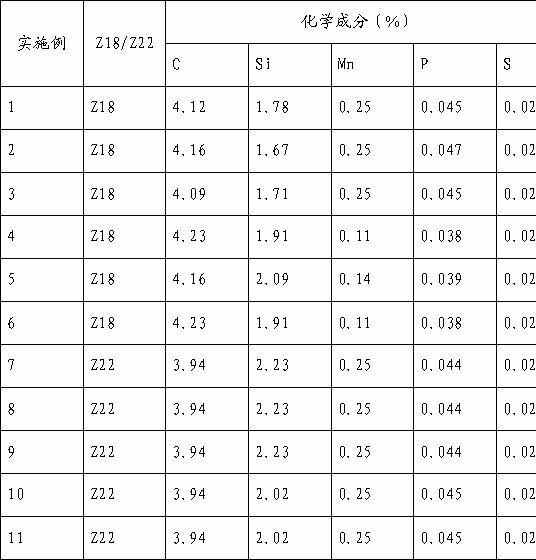

A method to produce as-cast spheroidal graphite iron with high elongation percentage is disclosed, which belongs to the field of casting technique. Steps of the method are as follows: One of foundry pigs such as Z18 or Z22 is taken as material. Based on weight proportion, there are 35-95% pig iron of Z18 or Z22, returns<55%, scrap steel <12% and 0.6-2.5% ferro-silicon. Prepared materials are melted in furnace and nodularized by shocking, in which the addition of nodularizer is 1.4-1.8% of weight of melted iron. Nodularizer is covered and compacted with 75 size ferro-silicon which is 0.3-0.5% of melted iron. The 75 size ferro-silicon is inoculated again before discharging melted iron to nodularize. Weight proportion of chemical constitution of nodularized melted iron is C3.5-4 %,Si2.6-3.2%,Mn0.15-0.5%,P<=0.06%,S<=0.03%. Nucleating agent is used for instantaneous inoculation when extending cast, which can get as-cast spheroidal graphite iron with high elongation percentage. The method can lower cost, shorten production cycle of casts and extend preferred range of materials. Casts are not tend to get shrinkage voids. None or small quantity of ferro-silicon alloy is added in furnace rear, which can save cost.

Owner:CHAGNSHU QIANJINDING CASTING

Molding sand for casting

ActiveCN106040965AImprove high temperature resistanceImprove acid and alkali corrosion resistanceFoundry mouldsFoundry coresAdhesiveOlivine

The invention discloses molding sand for casting. The molding sand for casting comprises the following raw materials in parts by weight: 35-40 parts of chromite sand, 40-45 parts of ceramsite, 0.2-1 part of adhesive, 20-30 parts of silica sand, 5-10 parts of white sand, 18-25 parts of magnesium sand, and 3-6 parts of olivine sand. The molding sand for casting uses the silica sand, the magnesium sand, the white sand and the olivine sand as main components of raw sand; the expansion coefficients of the white sand and the magnesium sand are lower during heating; the white sand, the magnesium sand and the silica sand are mixed as the the raw sand of the molding sand for casting; the expansion coefficient of the silica sand is reduced; the structure stability is improved; the casting condensation speed is uniform; condensed castings are not easy to generate cracks and shrinkage holes in surfaces; the ceramsite is added to improve the high-temperature resistance and the acid-alkali erosion resistance of the molding sand, and can be recycled; and a little adhesive is added to enhance the viscosity of the molding sand for casting.

Owner:HEFEI JAC CASTING

Production process of high-elongation nodular cast iron being as cast condition

The invention discloses a production process of high-elongation nodular cast iron being as cast condition. The production process comprises the following steps: sorting; burdening: taking materials by weight percentage as follows: 35-45% of cast iron Z18 or Z22, less than 35% of foundry returns and 30-55% of steel scraps; melting: putting burdened materials into a furnace for melting, melting the materials into molten iron, rising the temperature of the molten iron to be 1600-1650 DEG C, carburetting and complementing silicon; then conducting desulfuration process; complementing oxygen and reducing manganese and conducting dephosphorization process; finally carrying out on-the-spot chemical contents analysis, adjusting the chemical contents, conducting the next operation after the chemical contents are qualified; balling by utilizing pour-over method; and breeding instantly by adopting an inoculant when in casting so as to obtain the high-elongation nodular cast iron being as cast condition. According to the high-elongation nodular cast iron being as cast condition provided by the invention, the cost is lowered, the production period of a cast is shortened; the sorting range of the raw materials of the nodular cast iron is enlarged; the cast can not shrink easily; and the cost is saved, silicon iron alloy does not need to be added or is little added after the casting treatment.

Owner:CHAGNSHU QIANJINDING CASTING

Low-cost production process for as-cast high-elongation nodular cast iron

The invention discloses a low-cost production process for as-cast high-elongation nodular cast iron. The method comprises the following steps of: selecting materials; burdening, namely preparing 20 to 45 weight percent of Z18 or Z22 new cast iron, less than 55 weight percent of foundry returns and 30 to 55 weight percent of scrape steel; smelting, namely feeding the prepared materials into a furnace and smelting; nodulizing, namely nodulizing by a nodularizing process; and performing instantaneous inoculation by using an inoculant during casting and purifying simultaneously to obtain the as-cast high-elongation nodular cast iron. The nodular cast iron which is obtained by the low-coast production process for the as-cast high-elongation nodular cast iron is the as-cast high-elongation nodular cast iron, middle and high-temperature ferritizing annealing is not needed, and the elongation can reach over 10 percent; and a large amount of scrape steel materials and foundry returns are used, so that cost is reduced, and the production cycle of a cast is shortened; the selection range of the ductile iron raw materials is widened; the sinkhole of the cast is avoided; cost is saved; and few ferro-silicon alloy or no ferro-silicon alloy is added into a furnace rear.

Owner:CHAGNSHU QIANJINDING CASTING

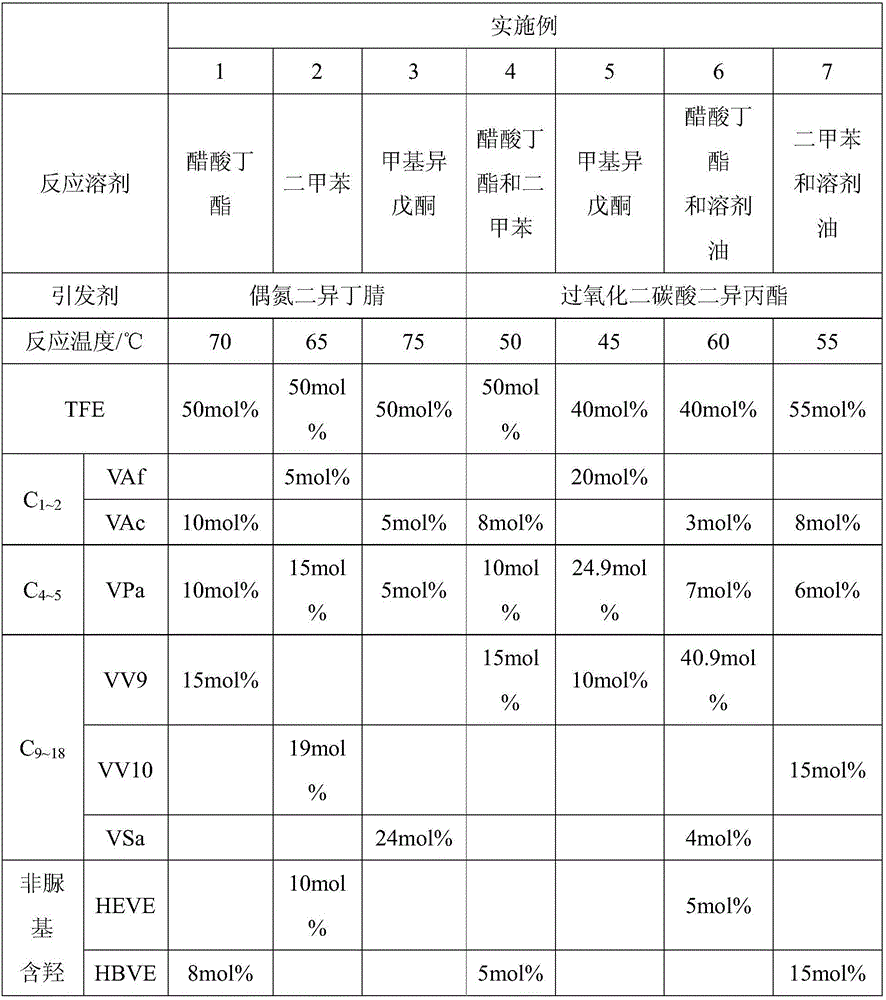

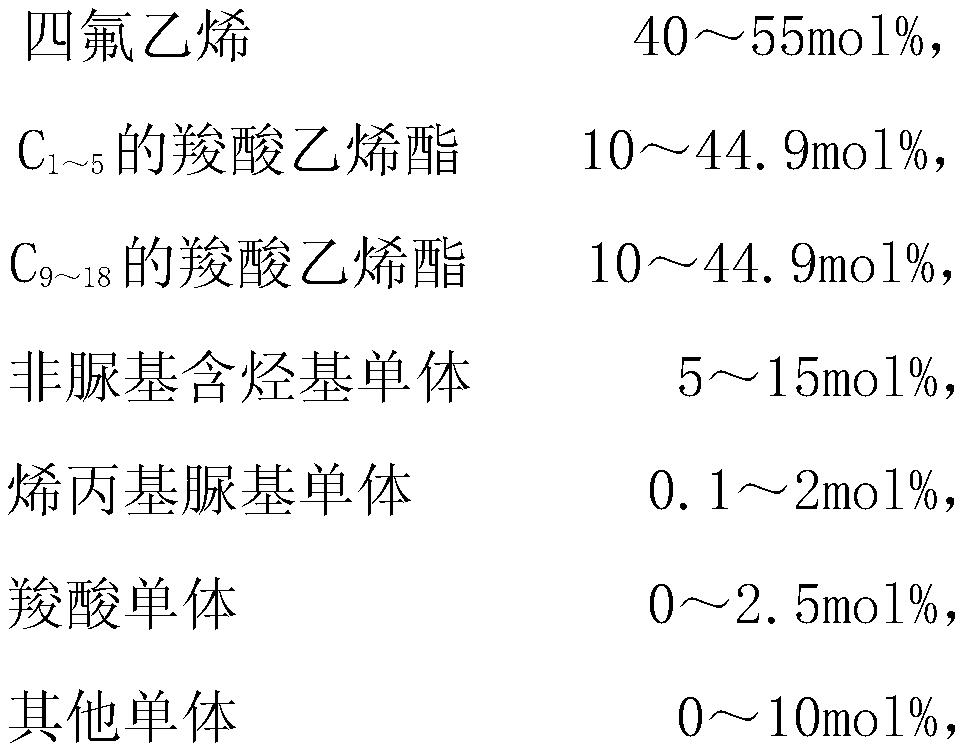

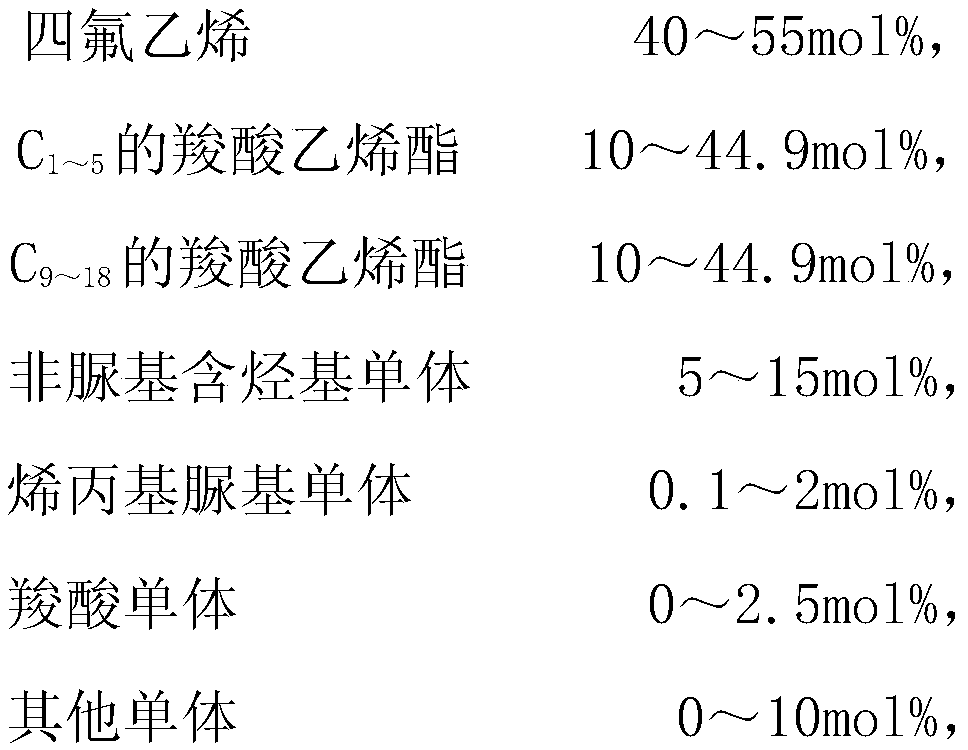

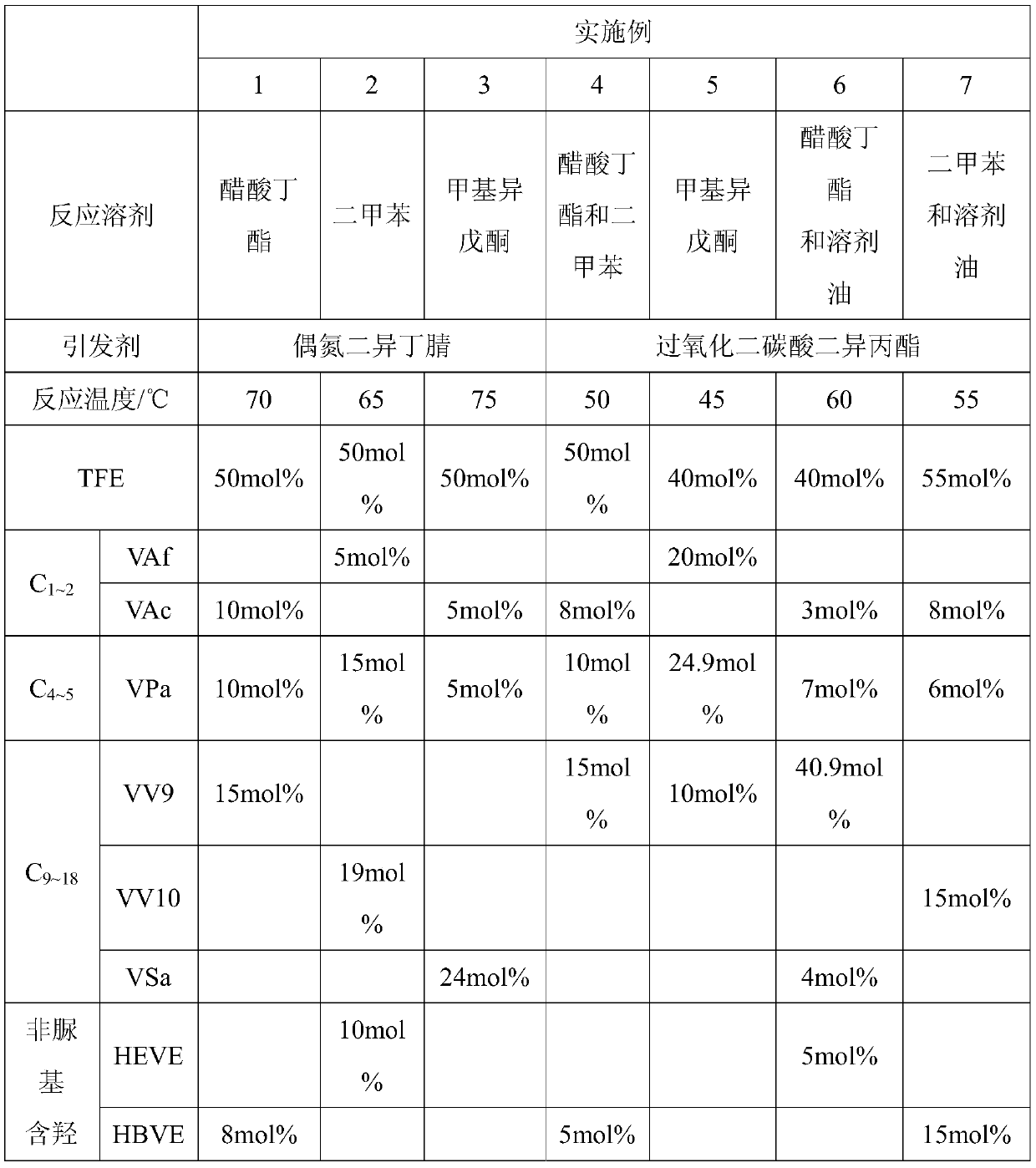

Tetrafluoroethylene copolymer resin for coating and preparation method thereof

ActiveCN106674407AGood dispersion and wettabilityImproved post-processing performanceCoatingsFiberTetrafluoroethylene

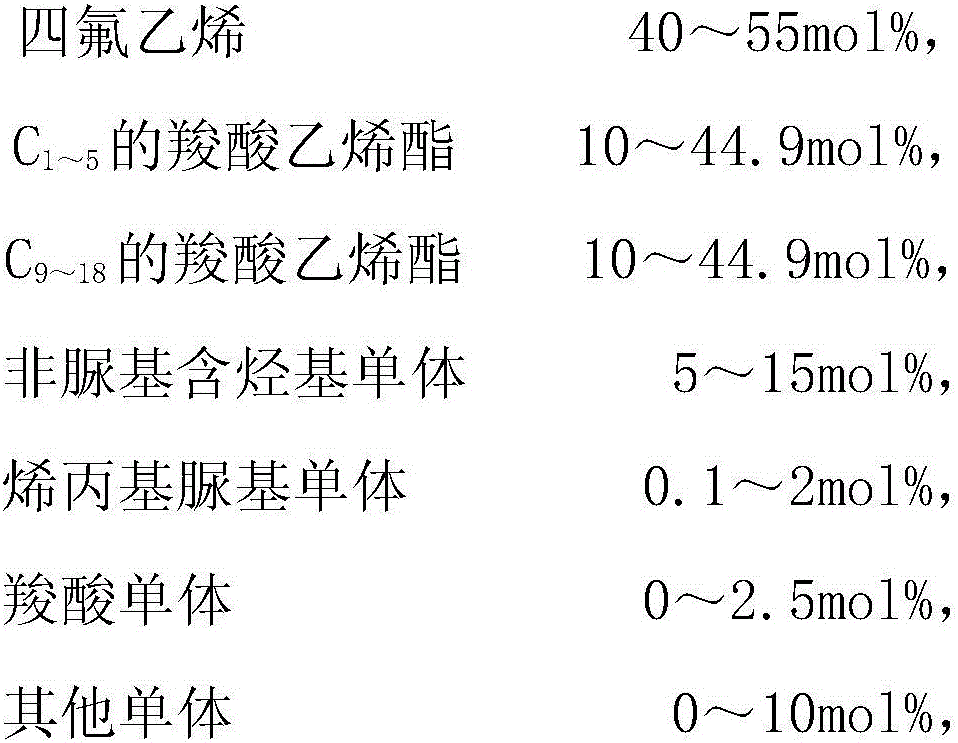

The invention discloses tetrafluoroethylene copolymer resin for coating and a preparation method thereof. The tetrafluoroethylene copolymer resin is prepared from the following components in mol fractions: 40-55mol% of tetrafluoroethylene, 10-44.9mol% of C1-5 vinyl carboxylate, 10-44.9mol% of C9-18 vinyl carboxylate, 5-15mol% of non-carbamido hydroxyl containing monomer, 0.1-2mol% of allyl carbamido monomer, 0-2.5%mol% of carboxylic monomer and 0-10mol% of other monomers, wherein the C1-5 vinyl carboxylate is composed of C1-2 vinyl carboxylate and C4-5 branched vinyl carboxylate of which the mol ratio is 1:(0.1-10). The tetrafluoroethylene copolymer resin for coating disclosed by the invention has a good dispersion wetting property with a pigment, has good consistency with a curing agent and can be dissolved in a pure petroleum based solvent, coating prepared from the tetrafluoroethylene copolymer resin has good weather resistance and solvent resistance and is not easy to produce yellow stain, and the tetrafluoroethylene copolymer resin is not easy to crack or flake when used for surface coating of a fiber substrate.

Owner:QUZHOU FLUORIDE & SILICON RES INST

Metal printing UV varnish and coating method thereof

InactiveCN107227100AImprove protectionHigh glossPretreated surfacesPolyurea/polyurethane coatingsTripropylene glycolPolymer science

The invention relates to the field of printing, and discloses a metal printing UV varnish and a coating method thereof. The UV varnish comprises the following components in percentage by mass: 30-60% of photocuring resin prepolymer, 30-60% of active monomer, 5-15% of photoinitiator and 0-15% of additive. The photocuring resin prepolymer is composed of at least one of a modified epoxy acrylic resin, a modified polyurethane acrylic resin and diallyl phthalate. The active monomer is composed of at least one of ethoxy acrylate, hexanediol diacrylate, acryloylmorpholine, trihydroxy acrylate, hydroxyethyl methacrylate and tripropylene glycol diacrylate. The UV varnish has the advantages of favorable leveling property, favorable gloss, favorable adhesive force and high photocuring efficiency. When being matched with the specific coating method disclosed by the invention, the UV varnish can not easily produce blisters, cratering, particles or other apparent defects.

Owner:HANGZHOU CPMC

Molding sand

InactiveCN107598071ASmall expansion coefficientIncrease stickinessFoundry mouldsFoundry coresSodium BentoniteRosin

The invention relates to molding sand. The molding sand is characterized by comprising the following components in parts by weight: 15-25 parts of clay sand, 15-25 parts of quartz sand, 20-25 parts ofwhite sand, 20-25 parts of magnesia, 8-15 parts of bentonite, 5-8 parts of zeolite powder, 3-6 parts of rosin, 2-5 parts of gypsum powder, 5-10 parts of pulverized coals, 25-35 parts of binding agent, 10-15 parts of hardening agent, 5-10 parts of starch, and 10-13 parts of water. Compared with the prior art, the clay sand is adopted as the raw materials, so that the binding performance is prominent; and the molding sand is simple in manufacturing, low in cost and suitable for secondary utilization after recovery, and greatly reduces the use cost. When the white sand and the magnesia are heated, the expansion coefficient is lower; the white sand and the magnesia are mixed with the quartz sand as raw sand for casting the molding sand, so that the expansion coefficient of the quartz sand isreduced, the condensation speed of castings is uniform, and the surfaces of the condensed castings are not easy to generate cracks and shrunk holes; and the pulverized coals and the clay can be addedto improve viscosity of the cast molding sand.

Owner:JIANGSU MINJIANG MINING CO LTD

Foundry process of multiway valve casting

The invention discloses a foundry process of a multiway valve casting. The foundry process comprises the steps of mold making, main core and small core making, modeling, pouring and cleaning inspecting. The main core and small core making step comprises the concrete steps of using foundry sand to make a main core and a small core; using a steel material as core bars; and assembling the main core and the small core together through a binding agent. The pouring step comprises the concrete steps of preheating a casting mold obtained after modeling, wherein the preheating temperature is 80-100 DEGC; then, spraying a heat resistant agent on the inner surface of the preheated casting mold; conducting heat preservation for the sprayed casting mold, wherein the heat preservation temperature is 200-280 DEG C, and the heat preservation time is 10-20 minutes; and finally, pouring pouring liquid into a mold cavity. By preheating and spraying of the heat resistant agent, the casting mold has strong flexibility and is not easy to break in the pouring process, and meanwhile, the uniform pouring and cooling is ensured. Thus, the obtained casting is not easy to produce shrinkage cavities, shrinkage porosity and internal porosity.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

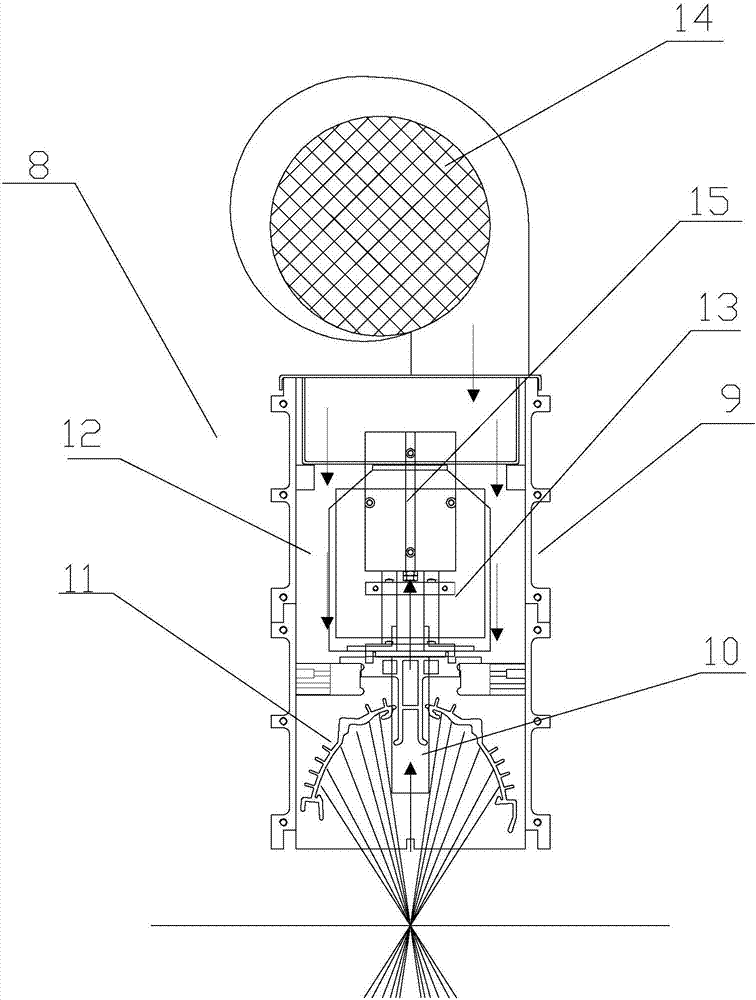

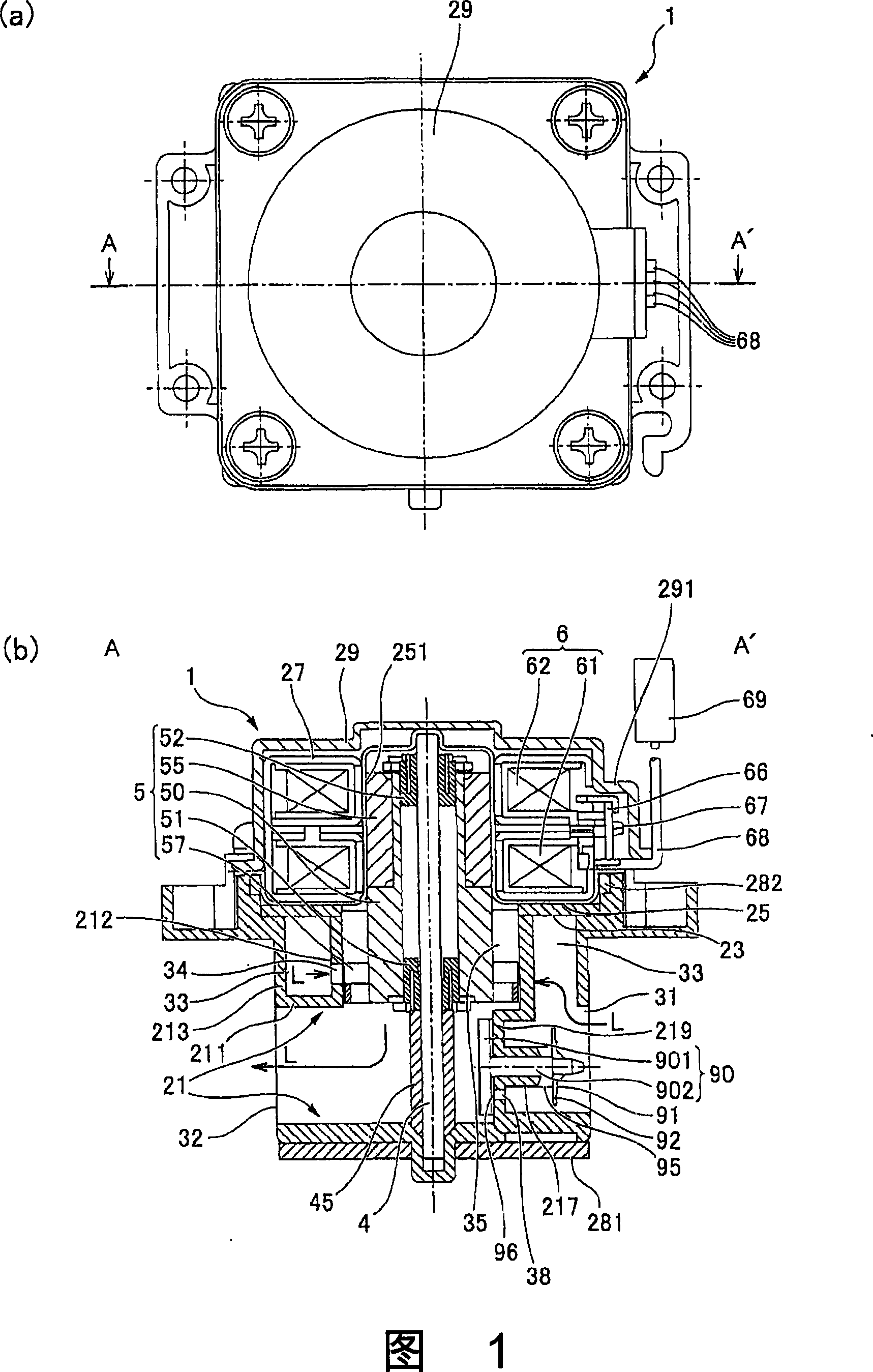

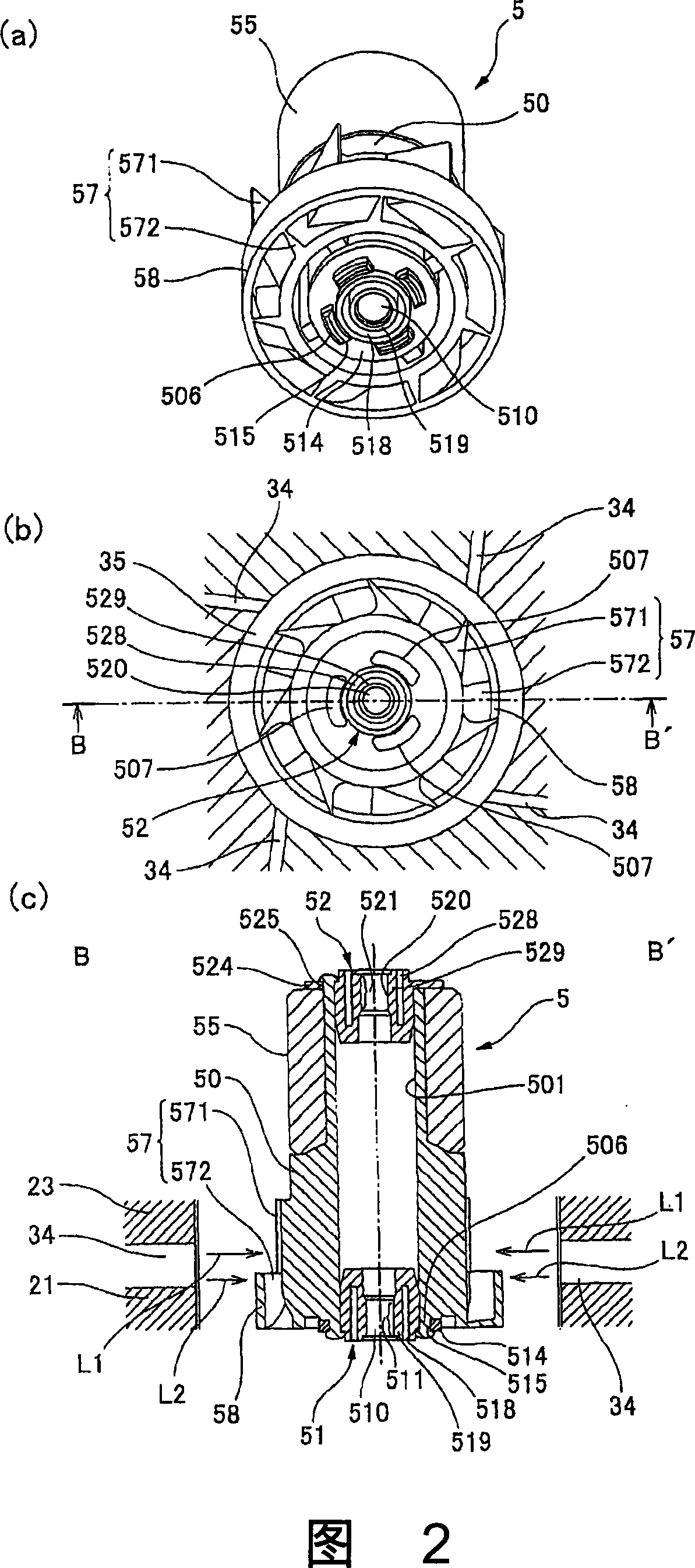

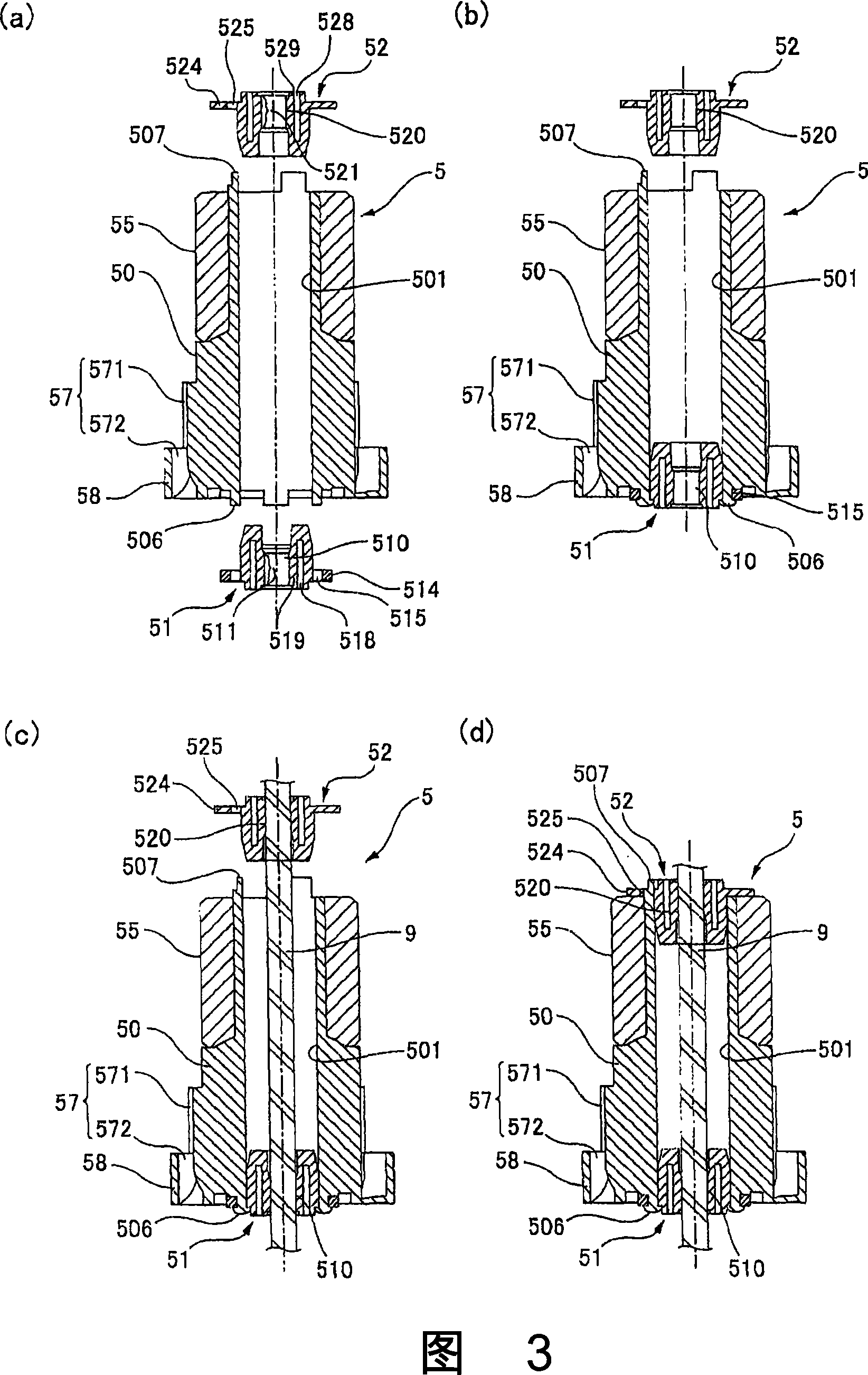

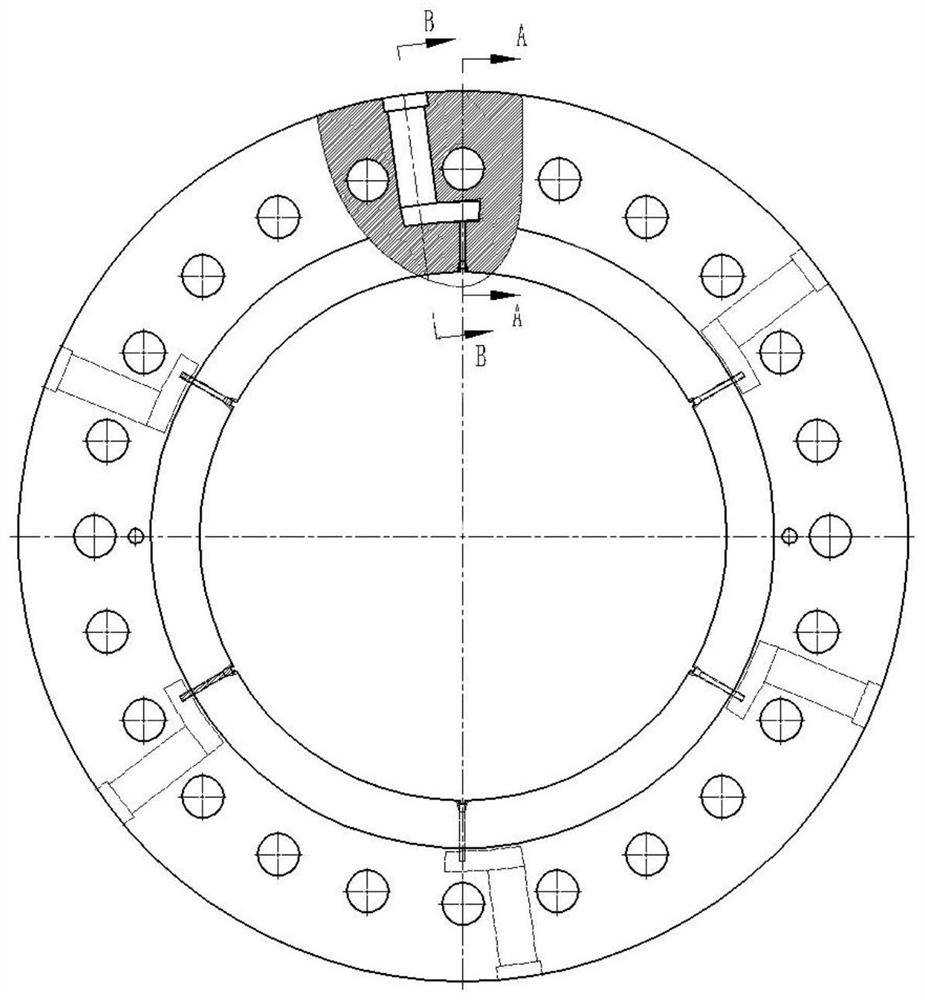

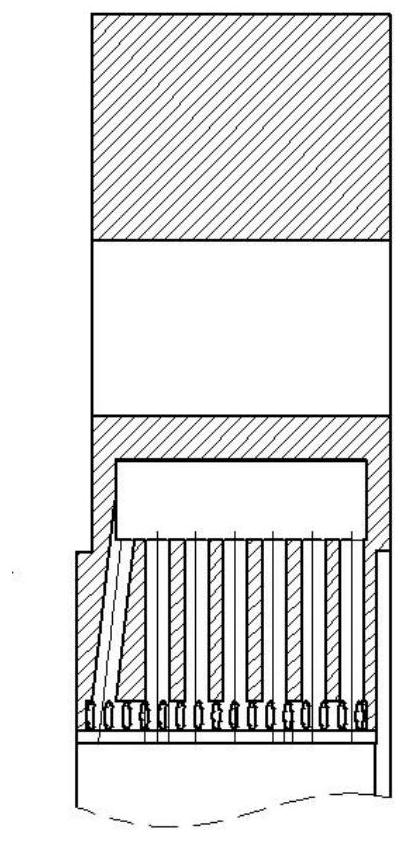

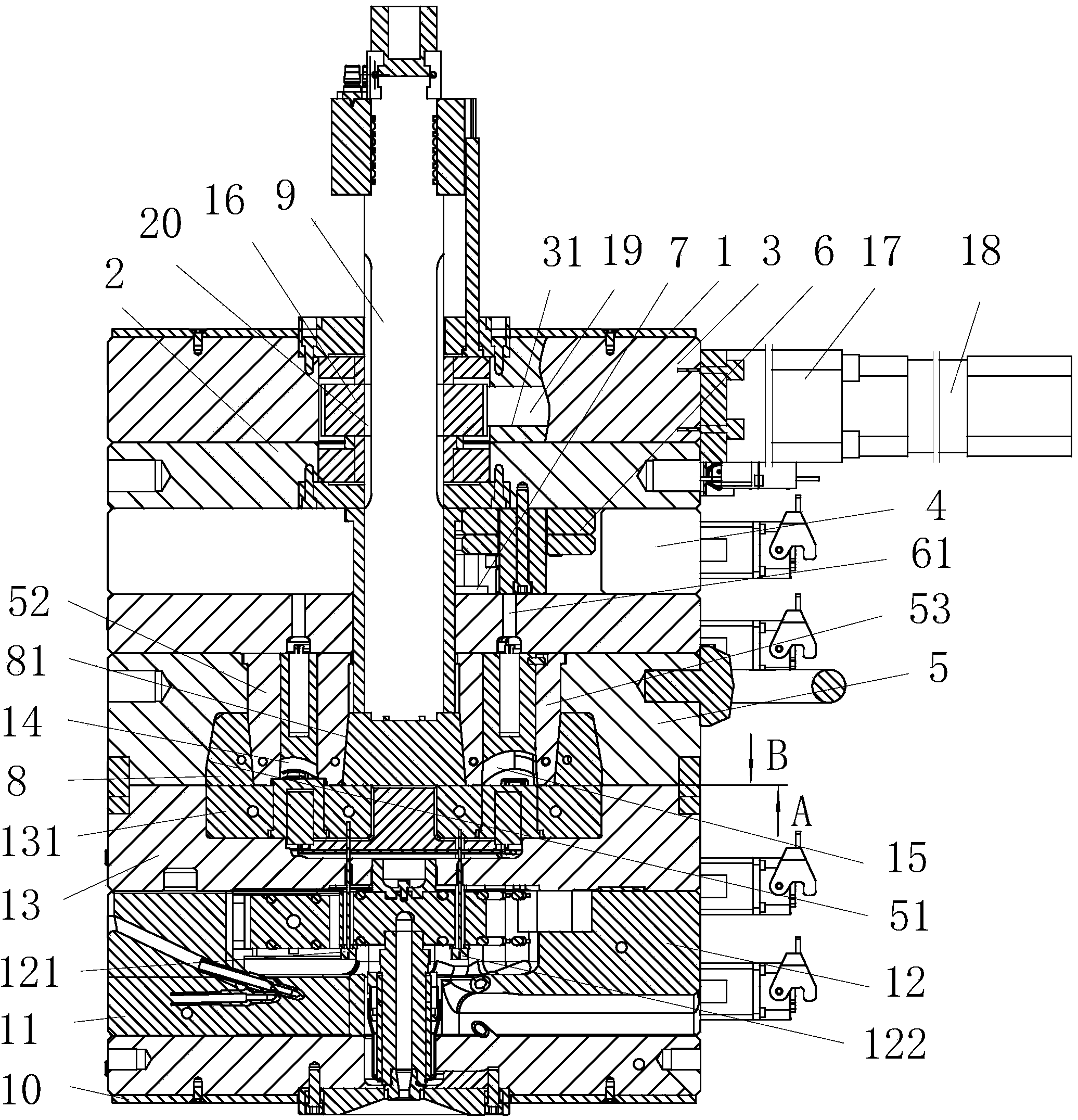

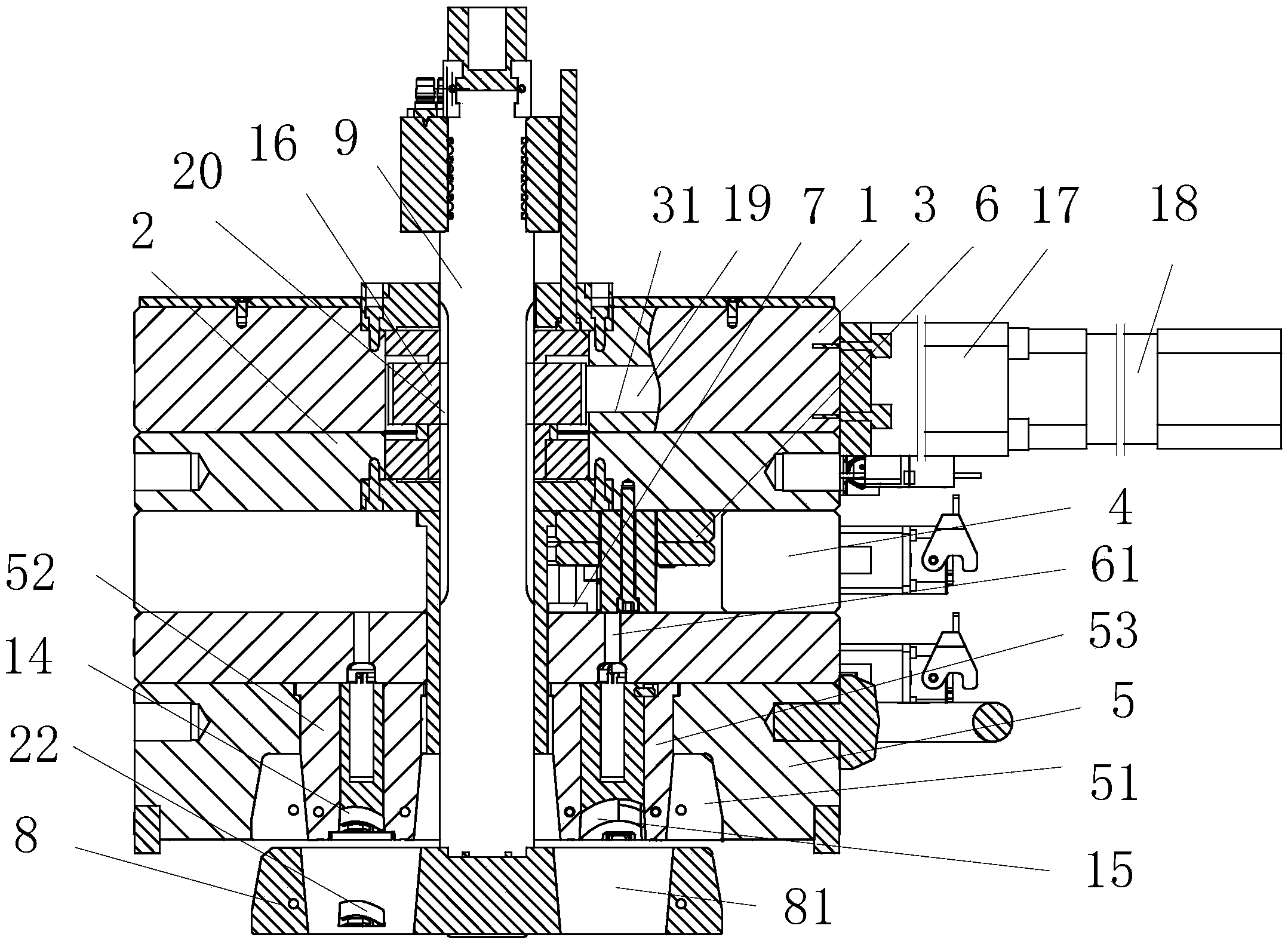

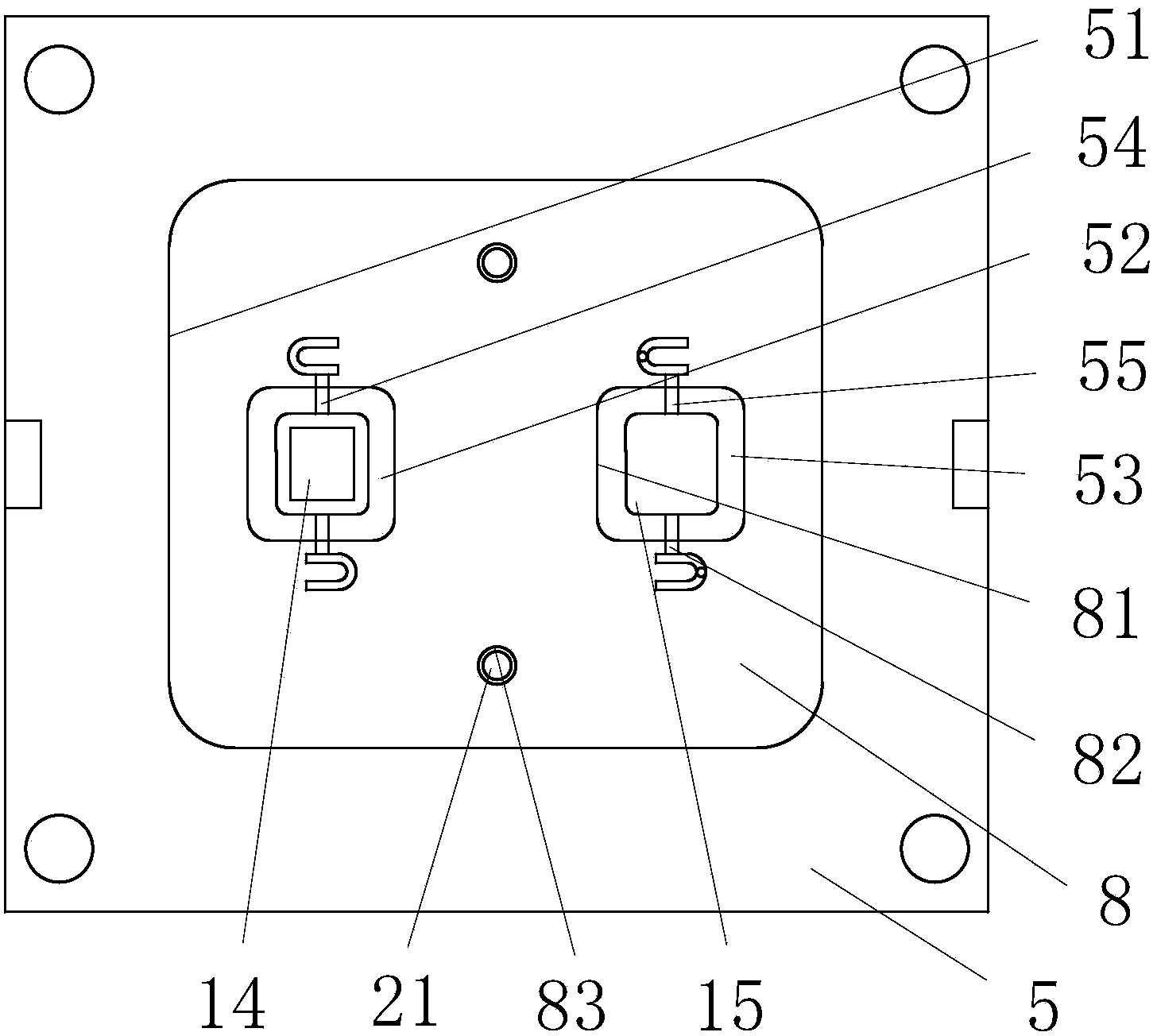

Hydraulic power generating device and manufacturing method therefor

ActiveCN101046186AAvoid noiseNot prone to shrinkageFinal product manufactureMachines/enginesWater turbineEngineering

To provide a hydraulic power generating device capable of preventing rotation vibration and rotation noise when a water turbine for power generation is rotated. In a water turbine 5 for power generation of a hydraulic power generating device, a first blade 571 and second blade 572 are formed in an area adjacent to each other in an axial line direction. The outer peripheral ends of the second blades 572 are coupled by a cylindrical plate 58. Four ejection ports 34 are opened to a direction astride both the first blade 571 and cylindrical plate 58. A part of water ejected through an ejection port 34 directly collides with the first blade 571. The rest continuously collides with the outer end surface of the cylindrical plate 58 from each direction. Thus, aligning action is exerted to the water turbine 5 for power generation. The number of ejection ports 34 and the number of blades 57 are prime to each other. Since timings at which four first blades 571 come nearest to the ejection ports 34 respectively are deviated, water ejected through the ejection port 34 is prevented from intensely colliding with two or more blades 57 at the same time.

Owner:SANKYO SEIKI MFG CO LTD

Motor casing casting material

The invention discloses a motor casting material, and belongs to the field of casting materials. The material comprise, by weight, 3.0-3.4% of carbon, 1.8-2.0% of silicon , 0.8-1.1% of manganese, 0.01-0.03% of phosphorus, 0.02-0.04% of sulphur, 0.03-0.05% of magnesium, 0.03-0.05% of strontium, 0.03-0.05% of vanadium, 0.02-0.03% of tungsten, 0.01-0.02% of zirconium, 0.02-0.04% of tin, 0.1-0.2% of titanium, 0.3-0.5% of copper, 0.1-0.15% of chrome, 0.25-0.35% of misch metal, and the balance iron. Strength, hardness and corrosion resistance of gray cast iron prepared through the motor casing casting material are high, and during casting, shrinkage cavities are not prone to being formed; the rate of finished products is high, the machining characteristic of the gray cast iron is good, machining is convenient, and the gray cast iron is not prone to deformation. Vibrating and acoustic characteristics of a prepared motor casing are good, and the service life is long.

Owner:FUNAN COUNTY FENJIN MACHINERY MFG

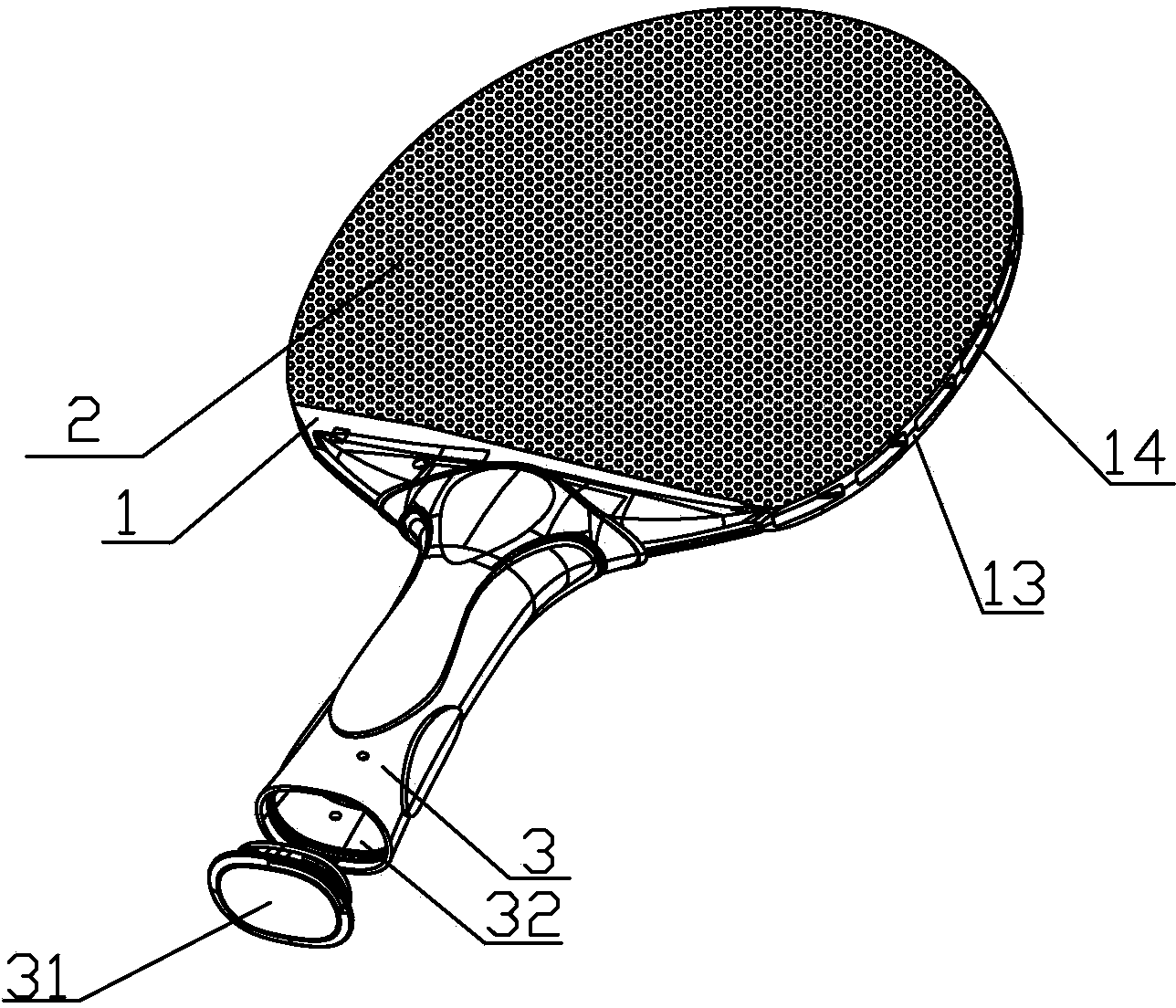

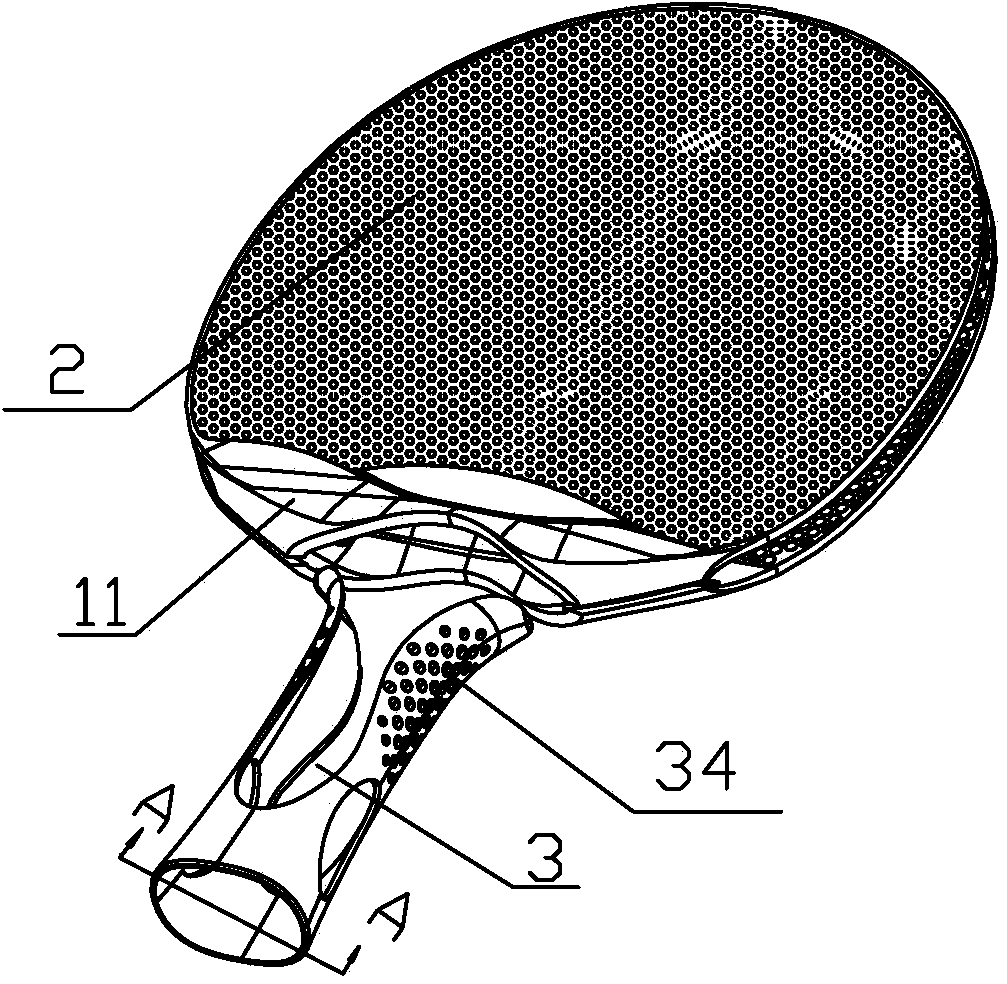

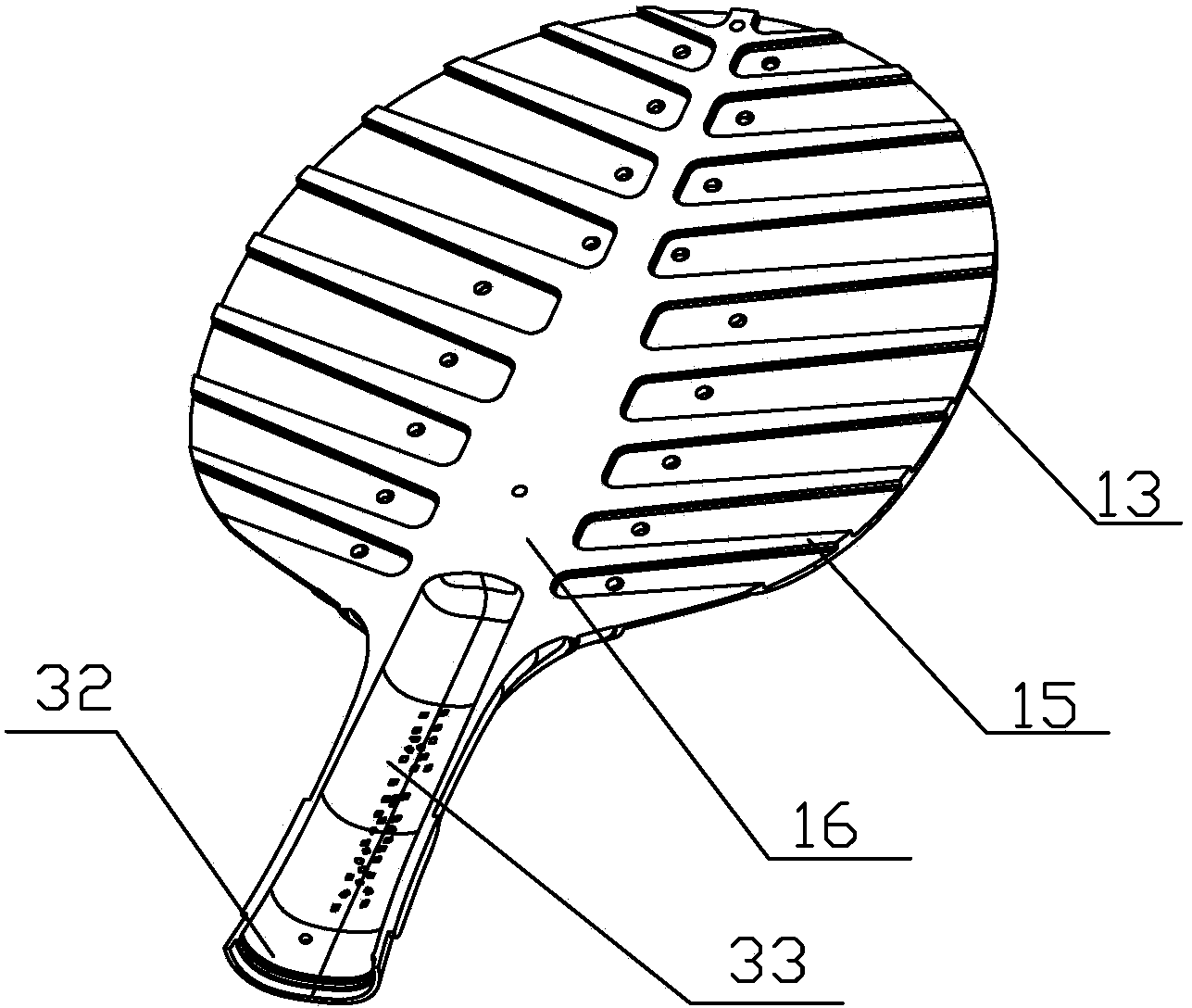

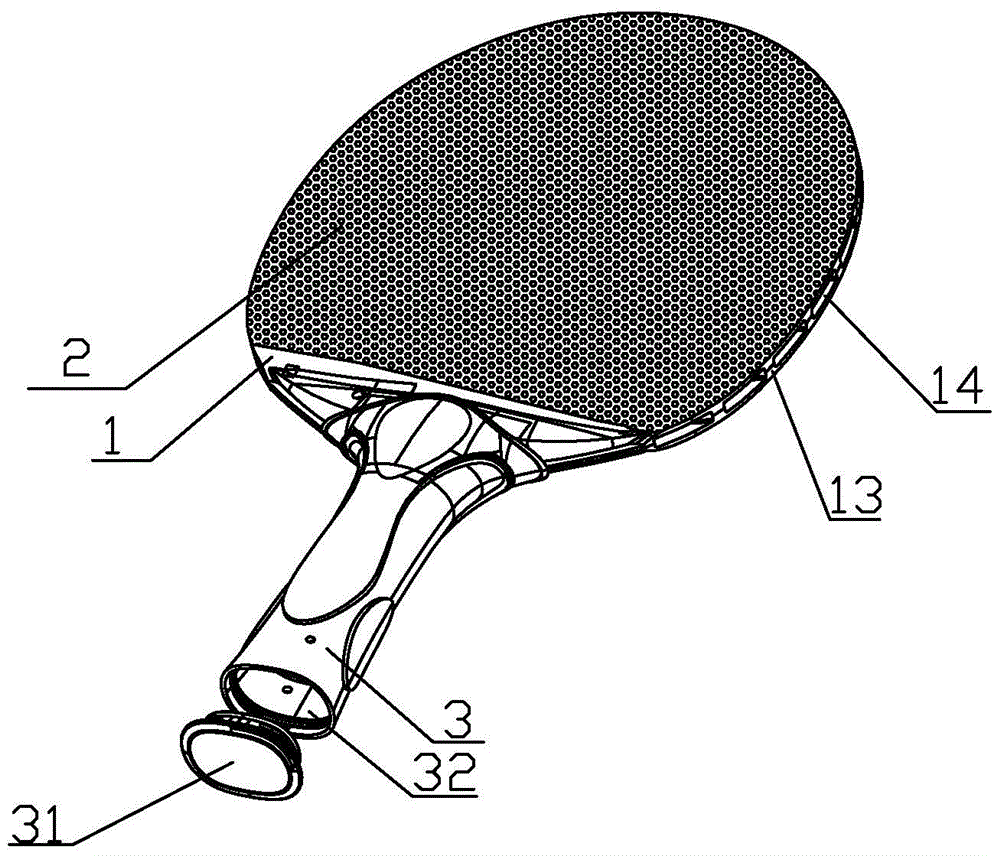

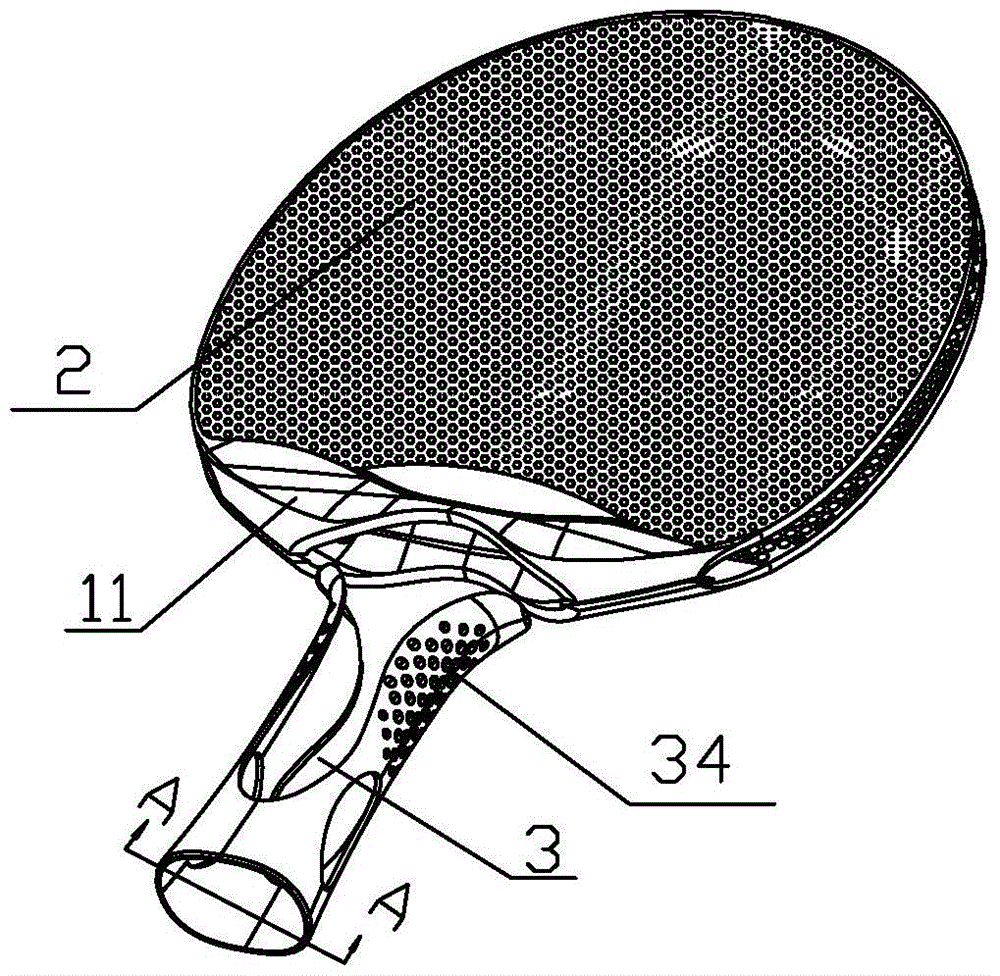

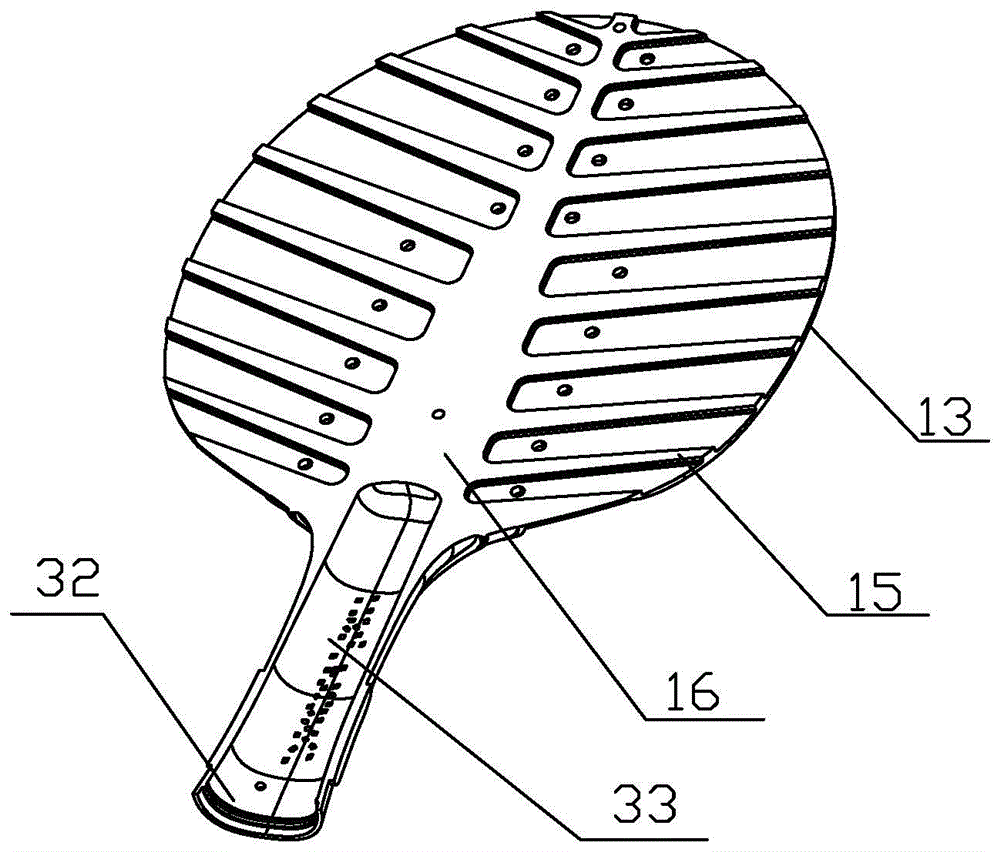

Bottom plate of improved table tennis bat and table tennis bat

The invention discloses a bottom plate of an improved table tennis bat and the table tennis bat. The bottom plate of the improved table tennis bat adopts a special material, so that the table tennis bat is impact-resistant, ageing-resistant and better in rigidity; the bottom plate of the improved table tennis bat adopts a fish bone structure to realize the partially hollow effect of the bat bottom plate, and the whole weight of the table tennis bat is reduced; a plurality of concave holes are uniformly distributed in an elastic bottom panel and the bottom plate of the table tennis bat, the contact surface between the table tennis bat and a table tennis is enlarged by the concave hole structure, and most important, the friction and the rotating speed which are produced by the bat to the table tennis when the table tennis is hit in the table tennis sport are improved.

Owner:GUANGZHOU DOUBLE FISH SPORTS GOODS GRP

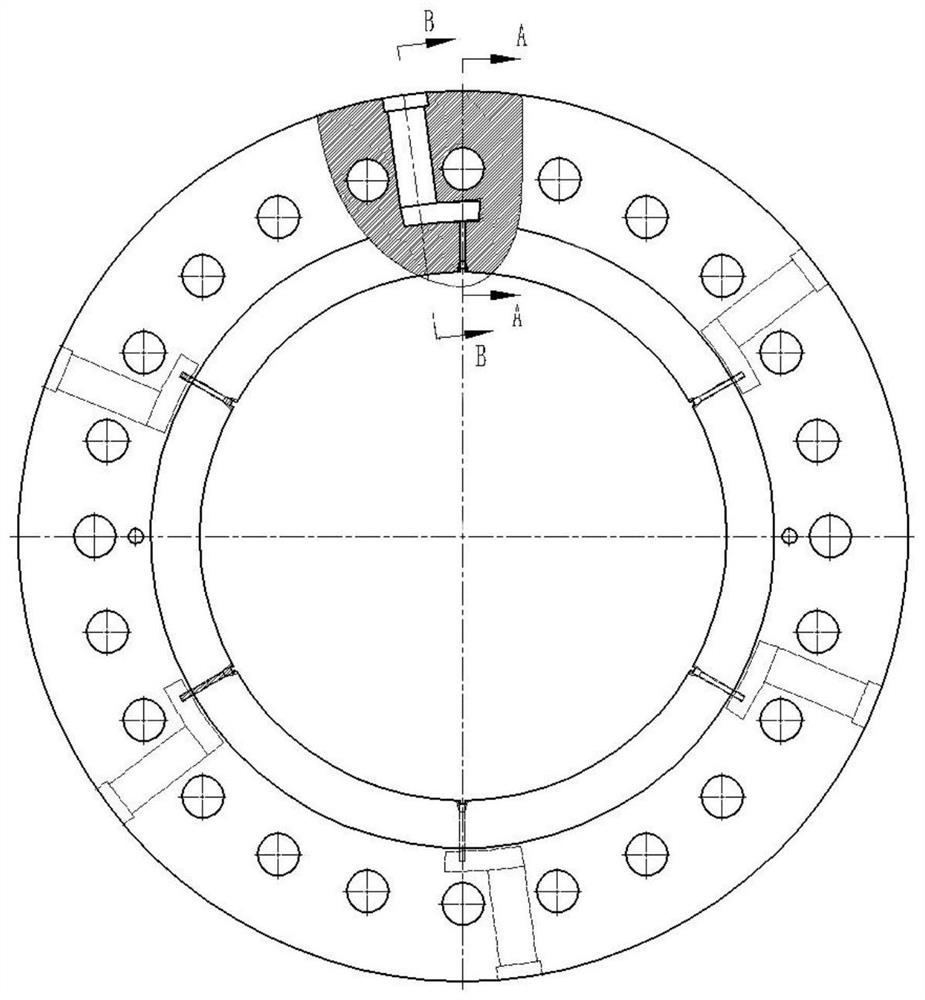

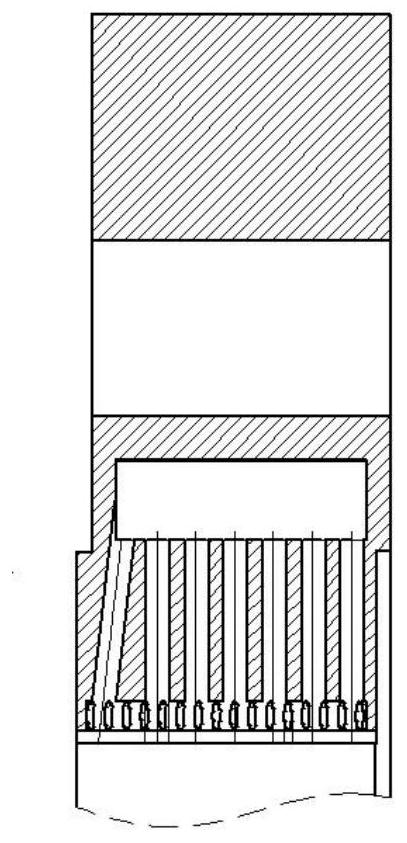

Welding forming method for water inlet and outlet flow channels of outer ring of heat exchange honeycomb structural part

ActiveCN112338446AMeet welding strength requirementsSmall thermal deformationSoldering apparatusWelding/soldering/cutting articlesThermal deformationEngineering

The invention belongs to the technical field of precision machining, and discloses a welding forming method for water inlet and outlet flow channels of an outer ring of a heat exchange honeycomb structural part. A workpiece is decomposed into several parts, a fan-shaped groove is machined and formed in the outer ring in a line cutting mode, and then a butt joint oblique joint and a limiting sinking table which are used for brazing are milled on the fan-shaped groove so as to position an insert and increase the brazing area, so that the welding strength is improved; and then the insert, an upper cover plate and a lower cover plate are independently machined. According to the corresponding assembling steps, the insert and the butt joint oblique joint of the fan-shaped groove are welded together through brazing treatment so as to reduce the deformation of large-depth fusion welding; and the upper cover plate, the lower cover plate and an insert boss are welded to the limiting sinking table of the fan-shaped groove through an argon arc welding process. Meanwhile, the welding strength between the fan-shaped groove and the upper cover plate and the welding strength between the fan-shapedgroove and the lower cover plate can be ensured by locally adopting argon arc welding fusion welding. The workpiece can meet the welding strength requirement, in addition, due to the fact that overall slow heating is adopted in the welding process, the thermal deformation of the workpiece is small, and the situation that the workpiece is twisted and deformed is effectively avoided.

Owner:XIAN YUANHANG VACUUM BRAZING TECH

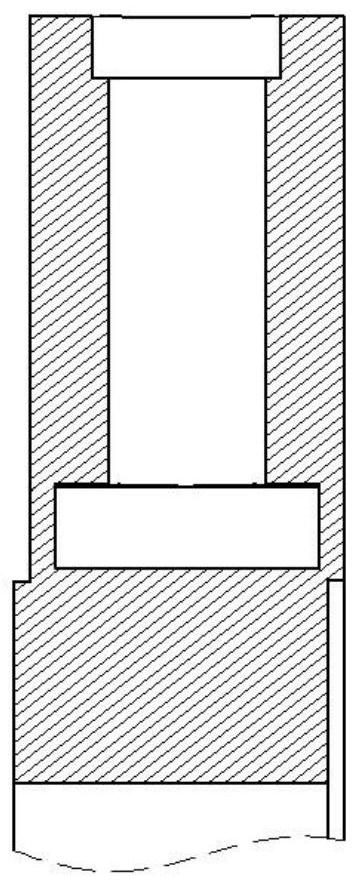

Lens injection molding mould and injection molding method

The invention relates to the field of injection molding moulds and aims to provide a lens injection molding mould and an injection molding method. The lens injection molding mould comprises a movable mould and a fixed mould, wherein the movable mould comprises a bottom heat insulation plate, a base plate, a fixing plate, a mould leg, a movable mould plate with two movable mould cores, a pushing plate with an ejector pin, a pushing oil cylinder, a supporting plate, a pushing rod and a pushing rod rotation device; two through holes which are respectively matched with the movable mould cores are formed in the supporting plate; a counter bore matched with the supporting plate is formed in the front end face of the movable mould plate; the front end of the pushing rod is connected with the supporting plate; the fixed mould comprises a surface heat insulation plate, a panel, a hot runner mounting plate with two needle valve type hot runners and a fixed mould plate with a fixed mould core; the first movable mould core and the fixed mould core form a primary cavity in an enclosing manner; the second movable mould core and the fixed mould core form a secondary cavity in an enclosing manner; and the size of the secondary cavity is greater than that of the primary cavity. The defects of shrinkage cavity, bubbles, deformation after demoulding and the like are not easily generated when the lens injection molding mould is used for injection molding; the cooling time is short after injection molding; and the production efficiency is relatively high.

Owner:宁波雷邦机械科技有限公司

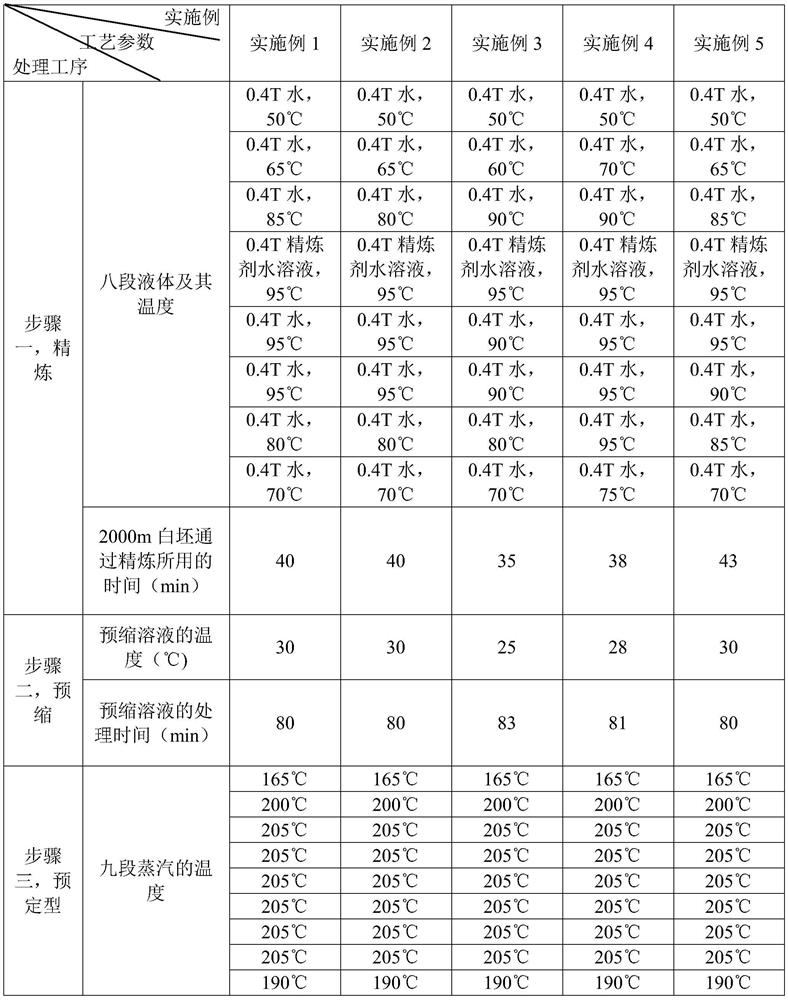

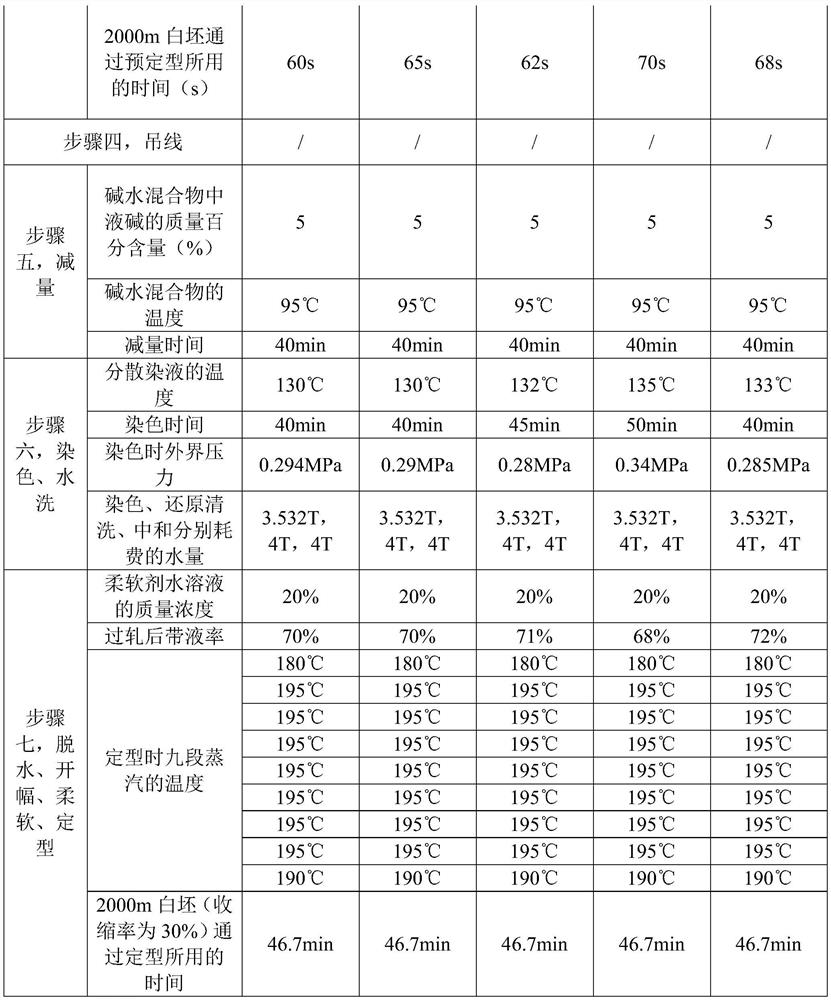

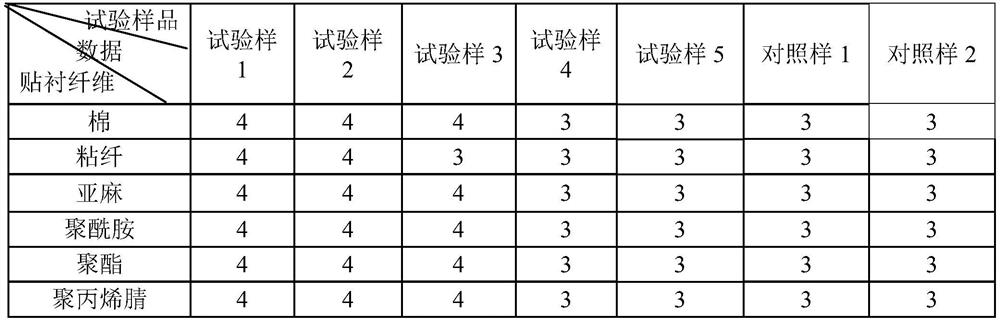

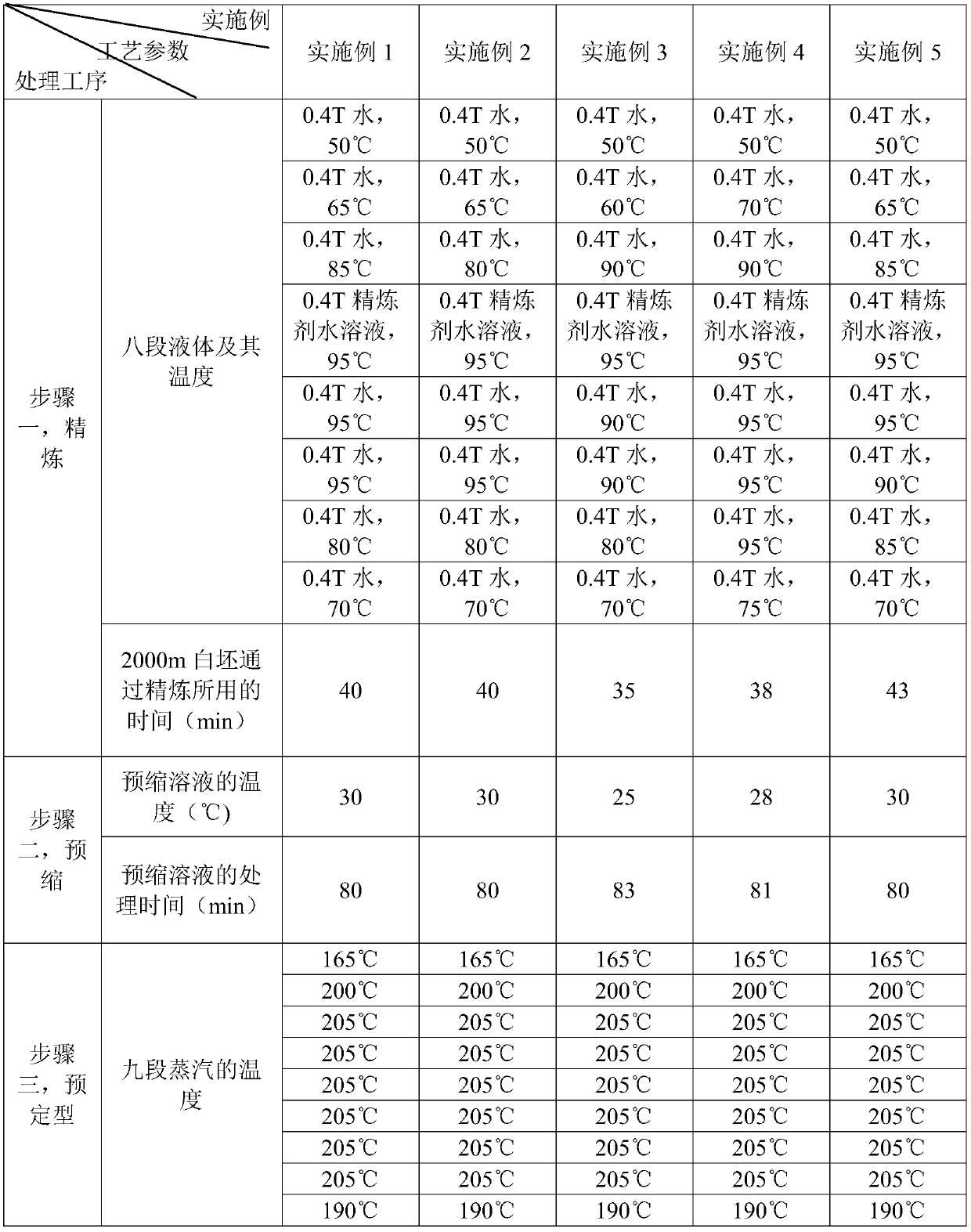

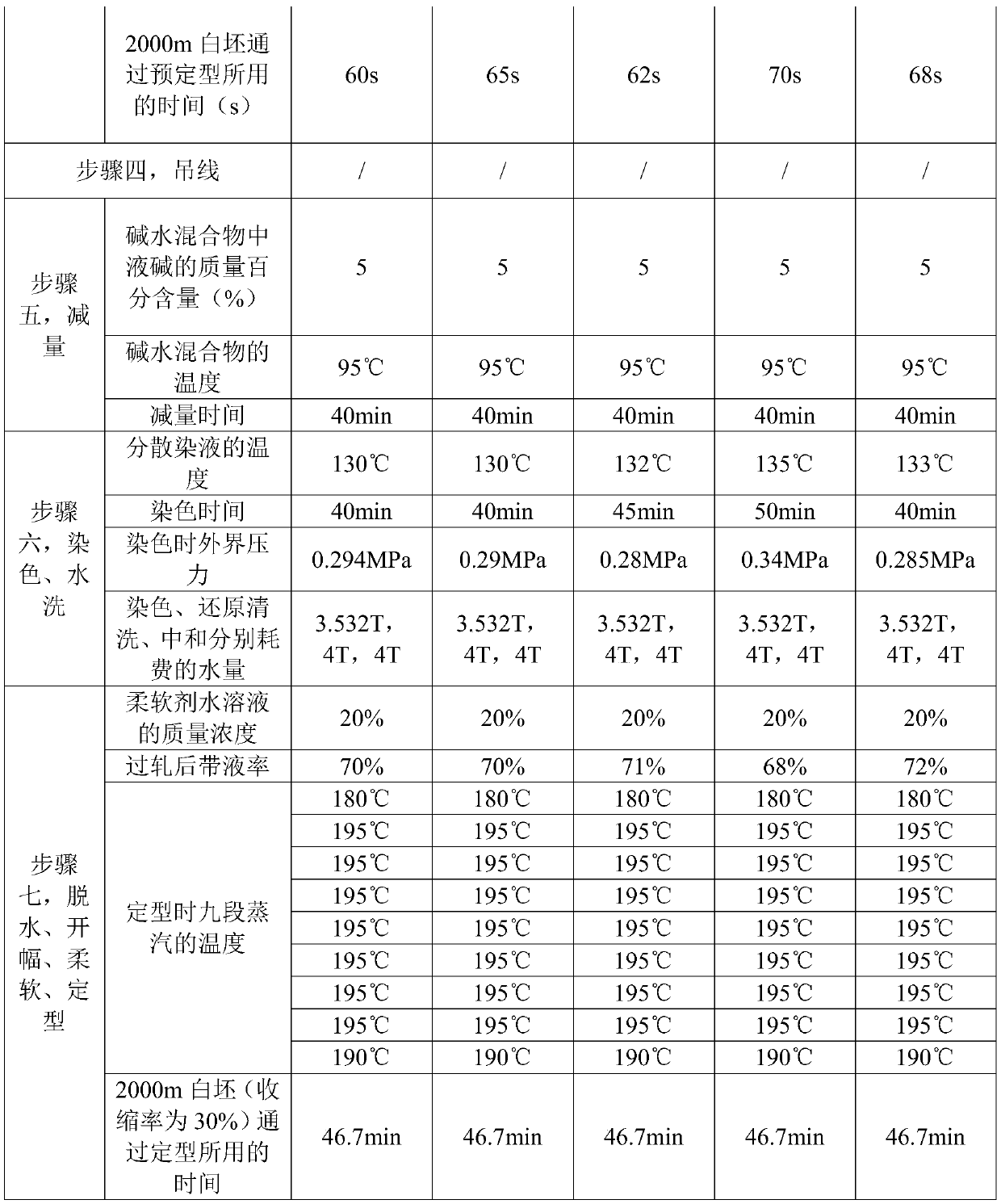

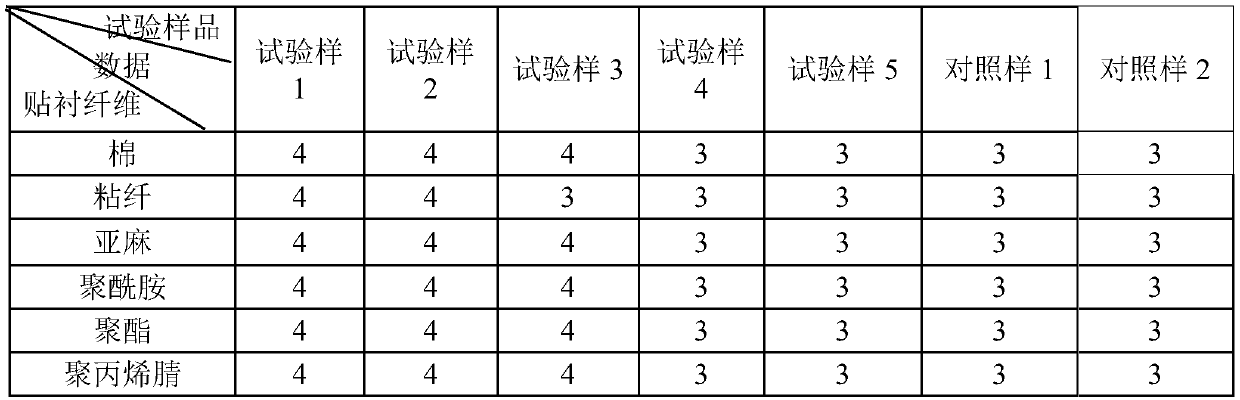

A processing technology of polyester double-layer four-way stretch fabric

ActiveCN111020794BThick textureIncrease the difficulty of the processSucessive textile treatmentsHeating/cooling textile fabricsPolyesterAlkaline water

The invention discloses a processing technology for a polyester double-layer four-way elastic fabric, and relates to the technical field of fabric processing. The treatment process is based on the blank length of 2000m, including the following steps: Step 1, refining; Step 2, pre-shrinking: the refined blank is placed in a pre-shrinking solution for pre-shrinking treatment for 25-30min, and the pre-shrinking solution The temperature is 80-83°C; Step 3, pre-setting; Step 4, hanging wire; Step 5, weight reduction: reduce the pre-shaped blank in the alkali-water mixture; Step 6, dyeing, washing; Seventh, dehydration, opening width, softness, and setting to obtain polyester double-layer four-way stretch fabric. The invention can make the obtained polyester double-layer four-way stretch fabric have the advantages of soft hand feeling and moderate gram weight, and it is also beneficial to make it have good physical indicators such as good soaping fastness; more importantly, the invention is beneficial to saving Reduce energy consumption and reduce processing costs for polyester double-layer four-way stretch fabrics.

Owner:HANGZHOU ZHUODA PRINTING & DYEING CO LTD

Treatment process of polyester double-layer side-stretch fabric

ActiveCN111020794ANot easy to removeWay to increaseSucessive textile treatmentsHeating/cooling textile fabricsPolyesterAlkaline water

The invention discloses a treatment process of a polyester double-layer side-stretch fabric, and relates to the technical field of fabric processing. Based on the length of 2000m of gray cloth, the treatment process comprises the following steps: S1, refining; S2, preshrinking, namely, placing the refined gray cloth in a preshrinking solution for preshrinking treatment for 25-30 min, wherein the temperature of the preshrinking solution is 80-83 DEG C; S3, pre-shaping; S4, line hanging; S5, decrement, namely, carrying out decrement treatment on the pre-shaped gray cloth in an alkaline-water mixture; S6, dyeing and washing; and S7, dewatering, scutching, softening and shaping, thus obtaining the polyester double-layer side-stretch fabric. The obtained polyester double-layer side-stretch fabric has the advantages of being soft in hand feeling and moderate in gram weight, meanwhile, the obtained polyester double-layer side-stretch fabric has the physical indexes such as good soaping fastness, more importantly, the energy consumption is favorably reduced, and the treatment cost of the polyester double-layer side-stretch fabric is favorably reduced.

Owner:HANGZHOU ZHUODA PRINTING & DYEING CO LTD

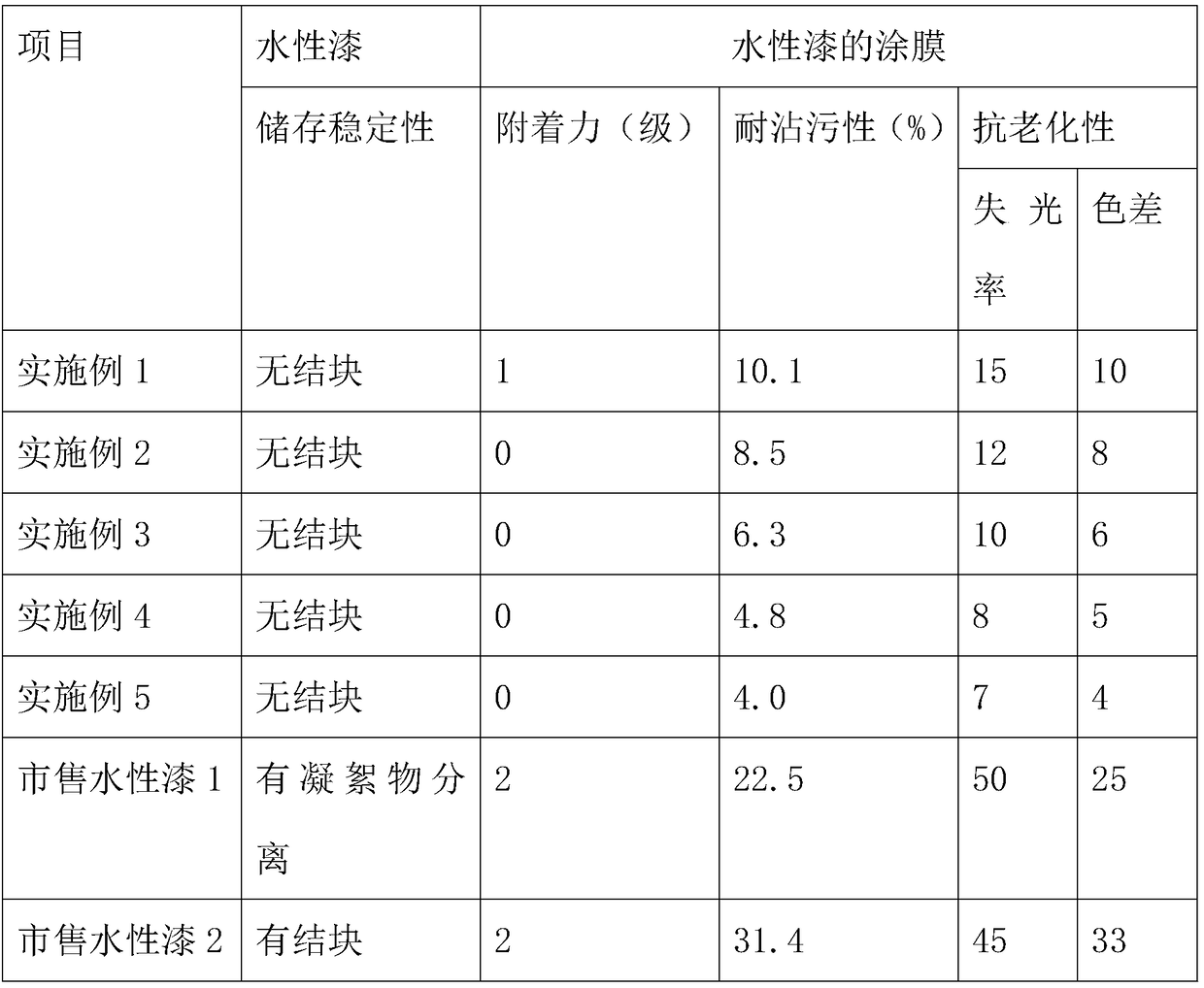

Environment-friendly water-based paint and preparation method thereof

The invention provides an environment-friendly water-based paint and a preparation method thereof. The environment-friendly water-based paint comprises the following components in parts by weight: 15-25 parts of water, 10-20 parts of hydroxy acrylic resin, 7-12 parts of organic silicon modified polysiloxane emulsion, 10-15 parts of pigment, 5-7 parts of a dispersing agent, 2-4 parts of a de-foaming agent and 1-3 parts of a flatting agent. The preparation method comprises the following steps: adding water, hydroxy acrylic resin and organic silicon modified polysiloxane emulsion into a stirrer and stirring, thereby acquiring a mixed solution; adding pigment and the dispersing agent into the mixed solution in turn, and continuing to stir, thereby acquiring a mixed slurry; grinding the slurrytill the fineness of the mixed slurry is controlled within 20-30mum, thereby acquiring a ground material; putting the ground material into a paint mixing tank, adding the de-foaming agent and the flatting agent in turn, and stirring, thereby acquiring the environment-friendly water-based paint. The environment-friendly water-based paint provided by the invention has the advantages that the surfacetension of the water-based paint in water is greatly reduced, the adhesive force of water-based paint coating to the substrate is enhanced, shrinking cavities are difficult to form on the coating, the surface evenness of the coating is improved and the stain resistance of the coating is greatly enhanced.

Owner:成都道立福科技有限公司

Molding sand for castings

InactiveCN107671233AUniform condensation rateIncrease stickinessFoundry mouldsFoundry coresSodium BentoniteGypsum

The invention relates to molding sand for castings. The molding sand for castings is characterized by being composed of, by weight, 15-25 parts of clay sand, 15-25 parts of quartz sand, 20-25 parts ofglass beads, 20-25 parts of magnesite, 8-15 parts of bentonite, 5-8 parts of zeolite powder, 3-6 parts of titanium dioxide, 2-5 parts of gypsum powder, 5-10 parts of pulverized coal, 25-35 parts of abinder, 10-15 parts of a hardener, 5-10 parts of a coupling agent and 10-13 parts of water. Compared with the prior art, the molding sand for castings is advantageous in that by adopting the clay sand as raw materials, the adhesive property of the molding sand is prominent; and the molding sand for castings is easy to manufacture, low in cost and suitable for secondary utilization after recycling, and using cost is greatly reduced. The glass beads and the magnesite have small expansion coefficients when heated, the glass beads, the magnesite and the quartz sand are mixed to serve as crude sand of the molding sand for castings, the expansion coefficient of the quartz sand is reduced, and thus the condensing rate of castings is uniform, and the surfaces of condensed castings are not prone to cracking and cavity shrinkage. By adding the pulverized coal and the clay, the viscidity of the molding sand for castings can be enhanced.

Owner:JIANGSU MINJIANG MINING CO LTD

Automobile rear axle dipping paint

InactiveCN108610893ANot prone to pinholesNot prone to shrinkageCellulose coatingsPolyurea/polyurethane coatingsChemistryCarbon black

The invention relates to automobile rear axle dipping paint which is prepared from the following raw materials in parts by weight: 50-60 parts of organosilicon modified epoxy resin, 40-50 parts of deionized water, 15-20 parts of water-based polyurethane resin, 10-15 parts of cellulosic resin, 8-10 parts of polyester polyol, 3-5 parts of nano tin oxide, 1-1.5 parts of silicon dioxide nanoparticle,1-1.5 parts of a wetting dispersing agent, 0.5-1.5 parts of a flatting agent, 1-5 parts of a defoaming agent, 0.5-1 part of a thickening agent, 0.1-1 part of an emolsifier, 10-15 parts of modified white carbon black and 10-20 parts of pigment and filler. The dipping paint can achieve locking after a certain time and forms a relatively hard external protective film on the surface quickly; the impedance ability and breakdown resistance of a film layer are improved; and a paint material at the top has a good covering effect.

Owner:ZHUCHENG CITY FURI MACHINERY

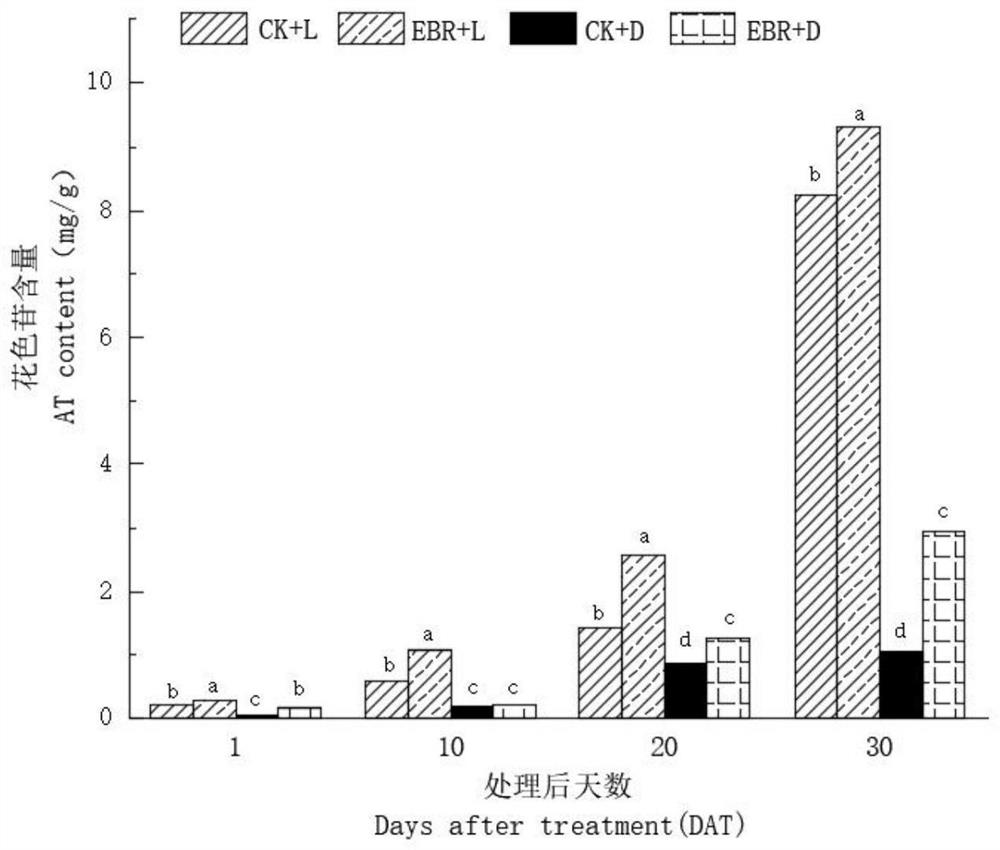

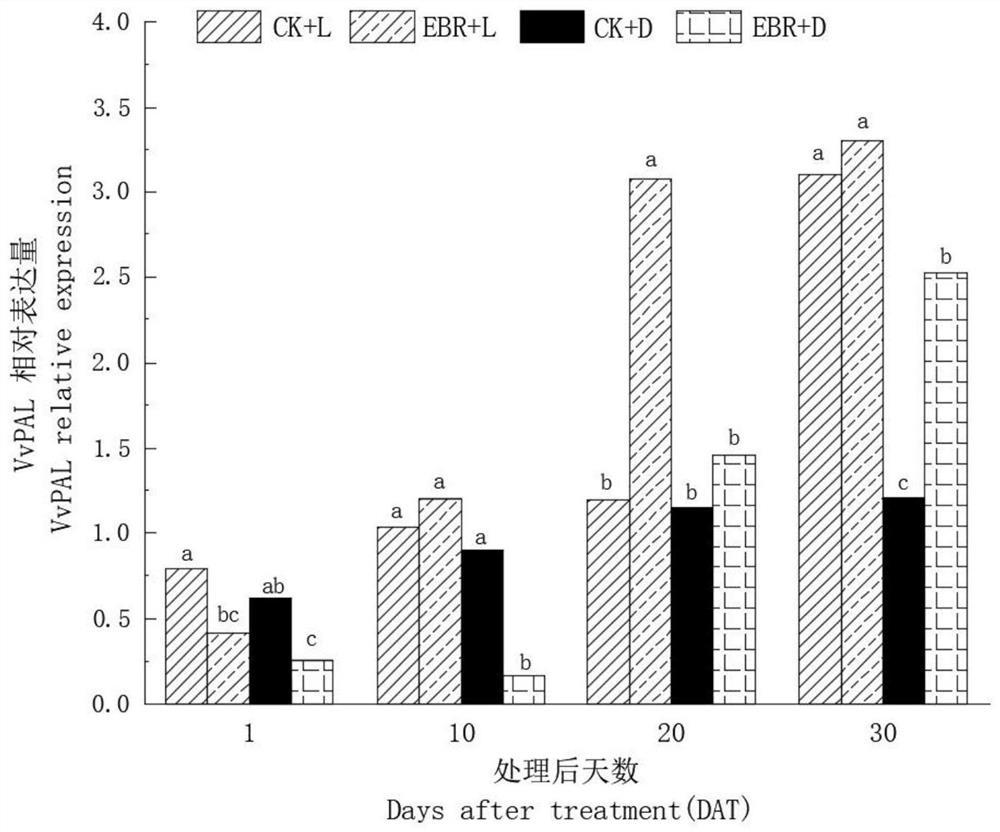

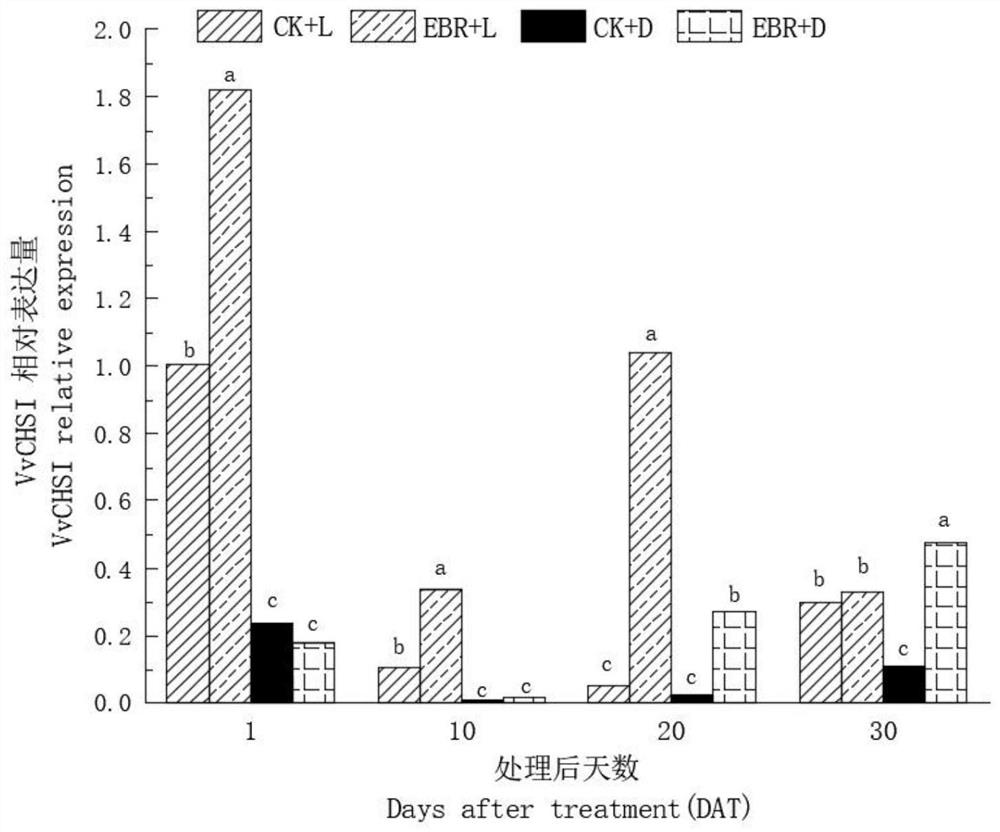

Method for increasing anthocyanin content in grape pericarp in vitro

PendingCN113973639AHigh color transfer efficiencyHigh in sugarCultivating equipmentsHorticulture methodsVitis viniferaAgronomy

The invention discloses a method for increasing the content of anthocyanin in grape pericarp in vitro, and relates to the technical field of grape fruit treatment. The method comprises the steps: picking grape clusters at the initial stage of grape coloring; placing the grape clusters on a tray and then placing the tray in an artificial climate incubator; preparing an EBR solution; spraying the EBR solution to the grape clusters; and creating a culture environment for the grape clusters through an artificial climate culture box filled with a culture solution, wherein the grape clusters are subjected to light treatment with the light intensity of 80%. By adopting the method disclosed by the invention, the coloring efficiency of the grape fruits is high, and the surfaces are not easy to shrink and are not easy to pollute; according to the method, the EBR plays a crucial role in the accumulation process of the anthocyanin of the grape fruits, EBR treatment can improve the sugar content of the grape fruits, promote accumulation of the anthocyanin and enable the fruits to turn color and mature in advance, and illumination adopted by the method is an important environmental factor influencing the growth and development of the grapes and is crucial to the formation of the anthocyanin; the distribution of plant anthocyanin can be directly influenced.

Owner:NORTHWEST A & F UNIV

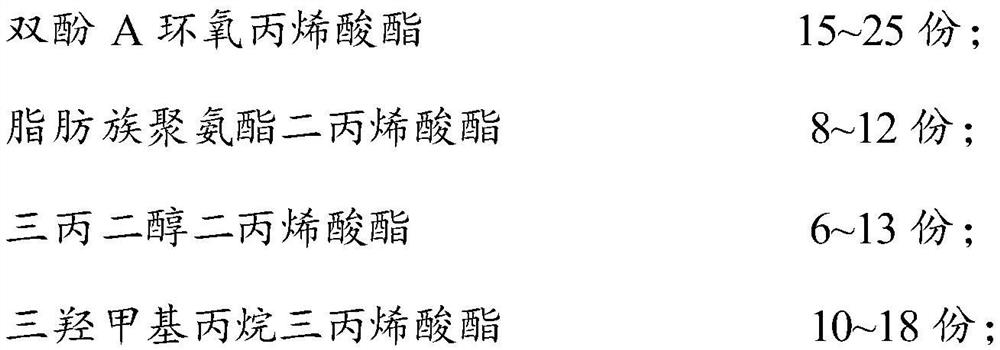

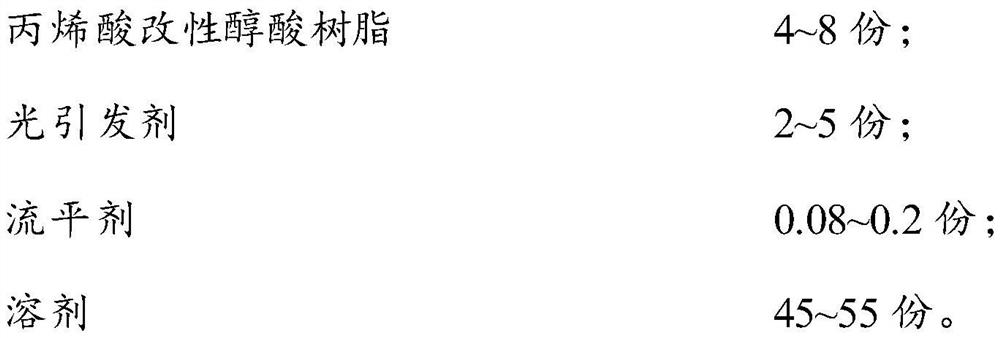

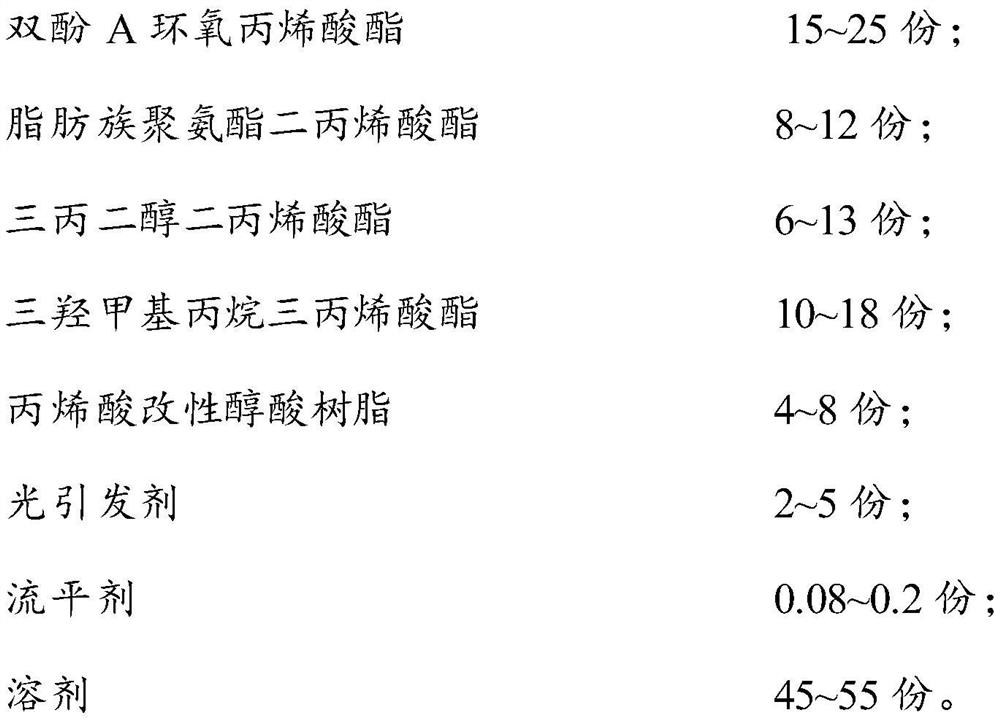

A kind of UV curing vacuum coating wrinkle primer and preparation method thereof

ActiveCN110591512BLow costImprove adhesionAntifouling/underwater paintsPaints with biocidesTripropylene glycolPolymer science

The application discloses a UV-curable vacuum coating wrinkle primer and a preparation method thereof, which comprises the following components in parts by weight: 15-25 parts of bisphenol A epoxy acrylate; 8-12 parts of aliphatic polyurethane diacrylate 6-13 parts of tripropylene glycol diacrylate; 10-18 parts of trimethylolpropane triacrylate; 4-8 parts of acrylic modified alkyd resin; 2-5 parts of photoinitiator; 0.08-0.2 parts of leveling agent parts; solvent 45 to 55 parts. Through the reasonable matching of various components, the cured coating can take into account the advantages of ordinary UV paint such as energy saving, environmental protection, high efficiency, and economy, and has low curing energy and good wrinkle decoration effect.

Owner:HUNAN SOKAN NEW MATERIAL

High-quality gray cast iron for automobile flywheel housing

The invention discloses high-quality gray pig iron for an automobile flywheel shell, and relates to cast iron. The high-quality gray pig iron comprises, by weight percent, 3.1% to 3.5% of carbon, 1.7% to 2.0% of silicon, 0.9% to 1.2% of manganese, 0.02% to 0.04% of phosphorus, 0.03% to 0.06% of sulphur, 0.03% to 0.05% of magnesium, 0.02% to 0.04% of strontium, 0.05% to 0.1% of vanadium, 0.1% to 0.2% of titanium, 0.3% to 0.5% of copper, 0.1% to 0.15% of chromium, 0.2% to 0.3% of mixed rare earth and the balance iron. The prepared high-quality gray pig iron has the higher strength, hardness and corrosion resistance, and is good in machining characteristic; during casting, shrinkage holes are not prone to generating, the obtained yield is high, the manufactured flywheel shell is good in vibration and acoustic characteristics, and the service life is longer.

Owner:安徽伟晔机械有限公司

Base plate of improved table tennis racket and table tennis racket thereof

Owner:GUANGZHOU DOUBLE FISH SPORTS GOODS GRP

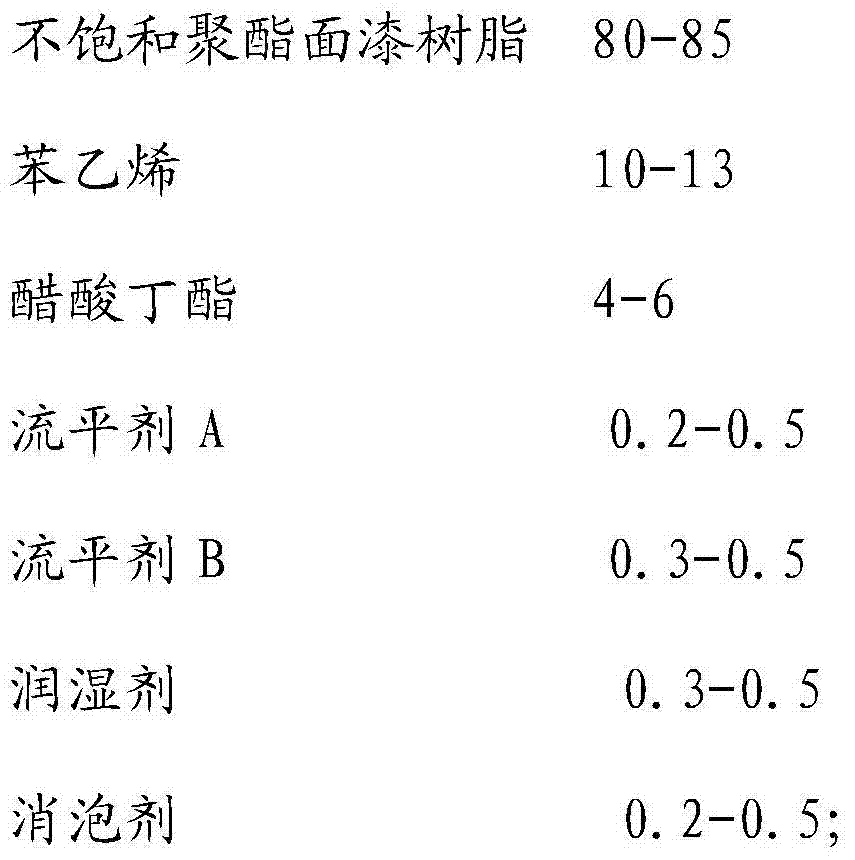

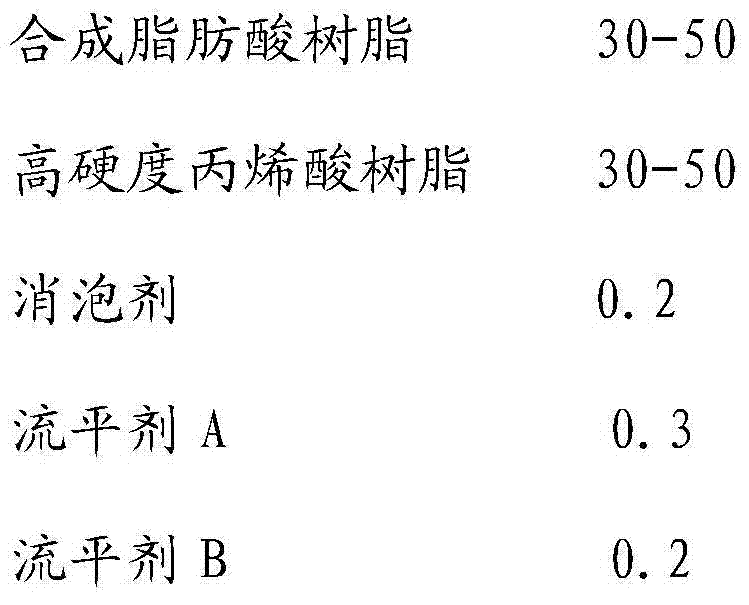

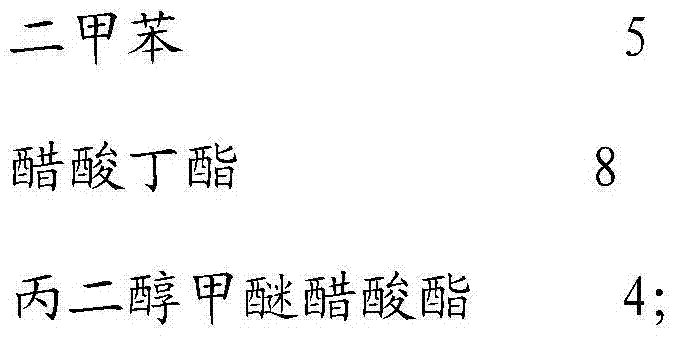

Unsaturated polyester modified polyurethane high-gloss top-coat paint and preparation method and using method thereof

InactiveCN102533095BHigh hardnessImprove fullnessPolyurea/polyurethane coatingsAcrylic resinPliability

Provided is unsaturated polyester modified polyurethane high-gloss top-coat paint. The weight ratio of components in raw material formula is that unsaturated polyester main paint: polyurethane main paint: polyurethane curing agent: blue water: clear water: diluents = 100:100:100:0.8:0.8:80. The unsaturated polyester main paint is prepared, by the following weight ratio, unsaturated polyester finish paint resin 80-85, styrene 10-13, butyl acetate 4-6, flatting agent A 0.2-0.5, flatting agent B 0.3-0.5, wetting agent 0.3-0.5 and defoaming agent 0.2-0.5. The unsaturated polyester finish paint resin is air-seasoning unsaturated polyester finish paint resin. The flatting agent A is an acrylate flatting agent. The flatting agent B is an organic silicon flatting agent. The polyurethane main paint is prepared, by the following weight ratio, synthetic fatty acid resin 30-50, high-hardness acrylic resin 30-50 and the like. The unsaturated polyester modified polyurethane high-gloss top-coat paint has the advantages of being high in hardness, good in fullness, strong in adhesion, good in flexibility, easy to polish and the like.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Preparation method of environment-friendly molding sand for casting

InactiveCN108356211AUniform condensation rateAvoid crackingFoundry mouldsFoundry coresAdhesiveGraphite

The invention discloses a preparation method of environment-friendly molding sand for casting. The molding sand is mainly prepared from aggregate and an adhesive which are uniformly mixed according tothe mass ratio of (95-118): (5-8). The aggregate is composed of the following components including, by weight, 45-56 parts of CRT screen glass treatment product, 25-30 parts of graphite sand, 16-20 parts of zircon sand and 9-12 parts of pitchstone powder, wherein the preparation method of the CRT screen glass treatment product includes the following steps that (1) recycled CRT screen glass is smashed till the grain diameter is 3 mm or below; (2) smashed CRT screen glass is continuously stirred for 5 minutes or above, and then granular screen glass is obtained; and (3) the granular screen glass is sieved. By means of the preparation method of the environment-friendly molding sand for casting, the obtained molding sand is high in mechanical strength, good in thermo-chemical stability, remarkable in adhesive property and good in breathability, the condensation speed of a cast part is uniform, the surface of the cast part after condensation is finished is not prone to cracking and formingshrinking holes, and the preparation method is particularly suitable for manufacturing cast parts which are high in quality requirement.

Owner:FOSHAN GAOMING LIGANG PRECISION CASTING CO LTD

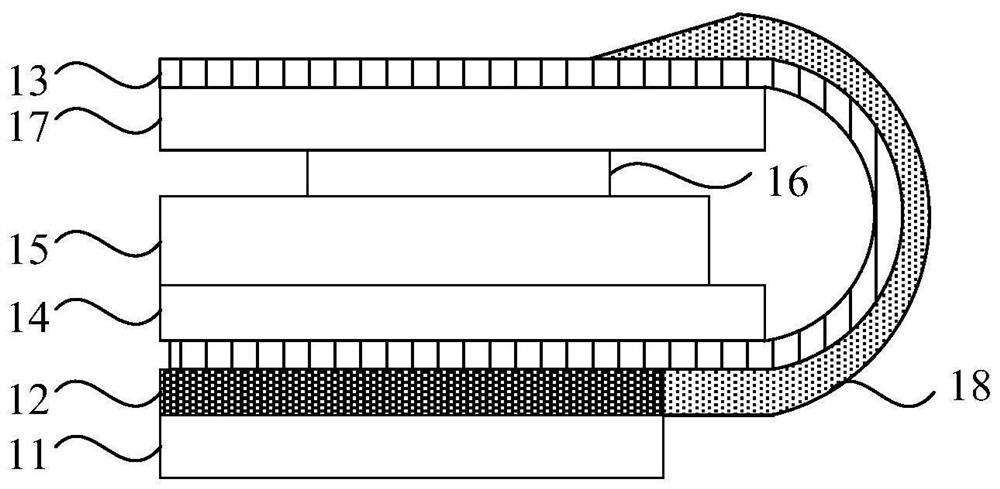

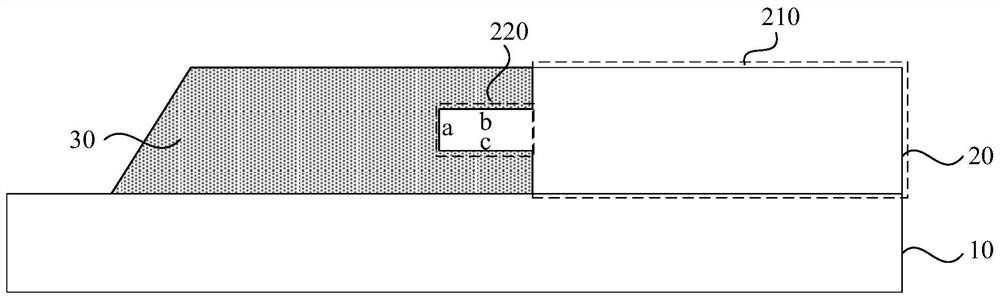

Display device and preparation method thereof

PendingCN113823195AIncrease the restrictive effectNot prone to shrinkagePolarising elementsIdentification meansEngineeringOptics

The embodiment of the invention discloses a display device and a preparation method thereof. The display device comprises a display panel; a polarizing layer which is located on one side of the display panel, and the polarizing layer comprises a main body part and an extending part; a protection layer, the protection layer and and the polarization layer are located on the same side of the display panel, the protection layer is located on the side, facing the extending part, of the main body part, the extending part comprises a side surface close to the side of the protection layer, a lower surface close to the side of the display panel and an upper surface away from the side of the display panel, and the protection layer makes contact with the side surface of the extending part, and contacts at least one of the upper surface and the lower surface of the extension part. According to the technical scheme provided by the embodiment of the invention, the extending part of the polarization layer extends into the protection layer, so that the protection layer is in contact with at least one of the upper surface and the lower surface of the extending part while being in contact with the side surface of the extending part, and the contact area between the polarization layer and the protection layer is increased, therefore, the polarization layer is not easy to shrink inwards, and the stripping phenomenon of the film layer can be improved.

Owner:HEFEI VISIONOX TECH CO LTD

A kind of tetrafluoroethylene copolymer resin for coating and preparation method thereof

ActiveCN106674407BGood dispersion and wettabilityImproved post-processing performanceCoatingsFiberTetrafluoroethylene

Owner:QUZHOU FLUORIDE & SILICON RES INST

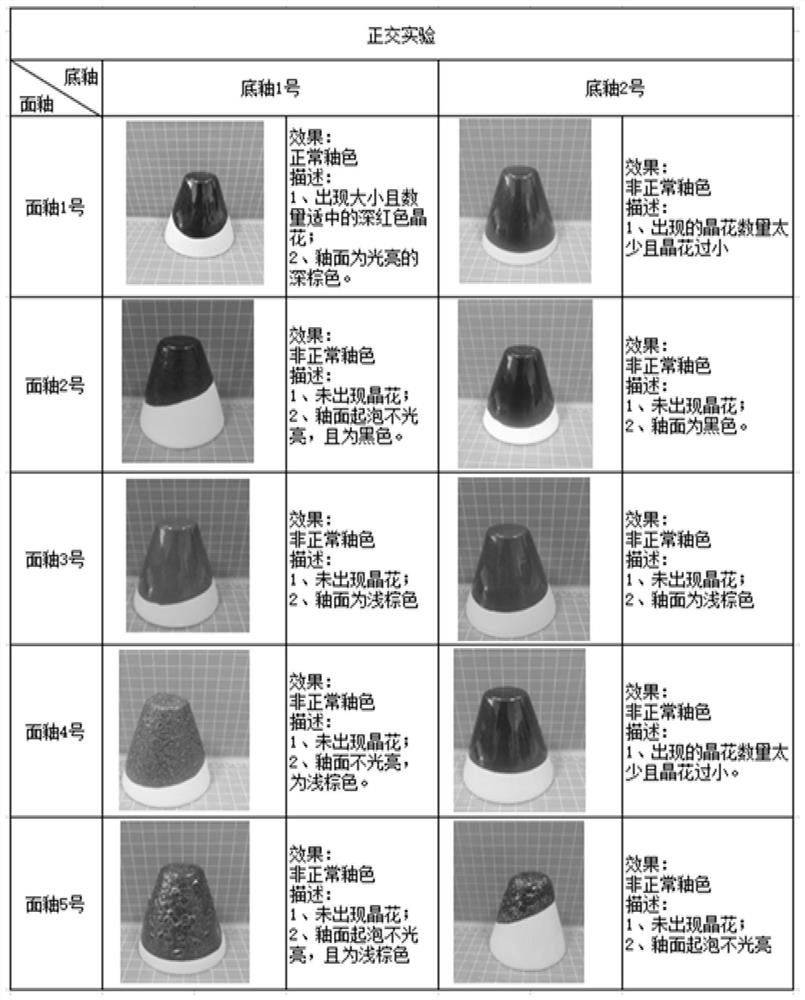

Formula of special tianmu glaze for sanitary ceramics and glazing method

ActiveCN113912293AColor personalizationNot prone to rolling glazeCeramic materials productionGlazeAluminium oxides

The invention discloses a formula of a special tianmu glaze for sanitary ceramics and a glazing method. The special tianmu glaze comprises a ground glaze and a cover glaze, and the ground glaze and the cover glaze are both prepared from silicon dioxide, aluminum oxide, iron oxide, titanium dioxide, calcium oxide, magnesium oxide, potassium oxide, sodium oxide and zinc oxide. The invention also provides the glazing method adapted to the formula of the special tianmu glaze for the ceramics. Through the method, the special tianmu glaze can smoothly applied to a sanitary ceramic green body, a stable glazing color is generated, the defects of glaze rolling, glaze shrinkage and the like are reduced, and the phenomenon that a glaze surface falls off is reduced.

Owner:福建良瓷科技有限公司

Welding forming method of the outer ring inlet and outlet water channel of the heat exchange honeycomb structure

ActiveCN112338446BMeet welding strength requirementsSmall thermal deformationSoldering apparatusWelding/soldering/cutting articlesButt jointThermal deformation

The invention belongs to the technical field of precision machining, and discloses a welding and forming method for the inlet and outlet water channels of the outer ring of the heat exchange honeycomb structure. The butt joint and limit sinking are used for brazing to position the insert and increase the brazing area, thereby improving the welding strength; then the insert, upper cover and lower cover are processed separately. According to the corresponding assembly steps, brazing is used to weld the insert and the fan-shaped groove butt joint to reduce the deformation of large-depth welding; the upper cover, the lower cover and the insert are convexly welded by argon arc welding. The platform is welded to the limit sunken platform of the fan-shaped groove. At the same time, partial welding with argon arc welding can ensure the welding strength between the fan-shaped groove and the upper and lower cover plates. Not only can the workpiece meet the welding strength requirements, but also the thermal deformation of the workpiece is small due to the slow heating of the whole during the welding process, effectively avoiding the distortion and deformation of the workpiece.

Owner:XIAN YUANHANG VACUUM BRAZING TECH

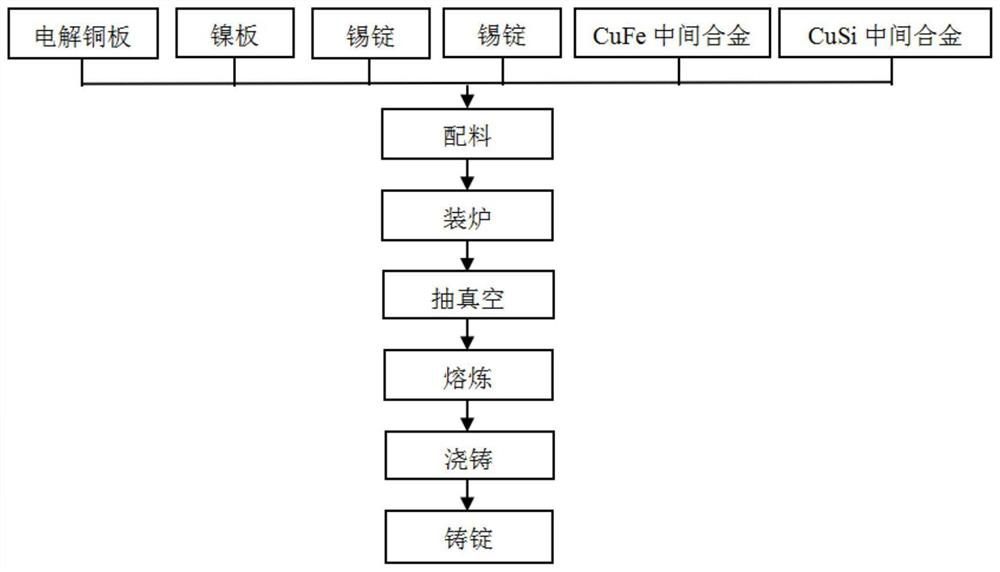

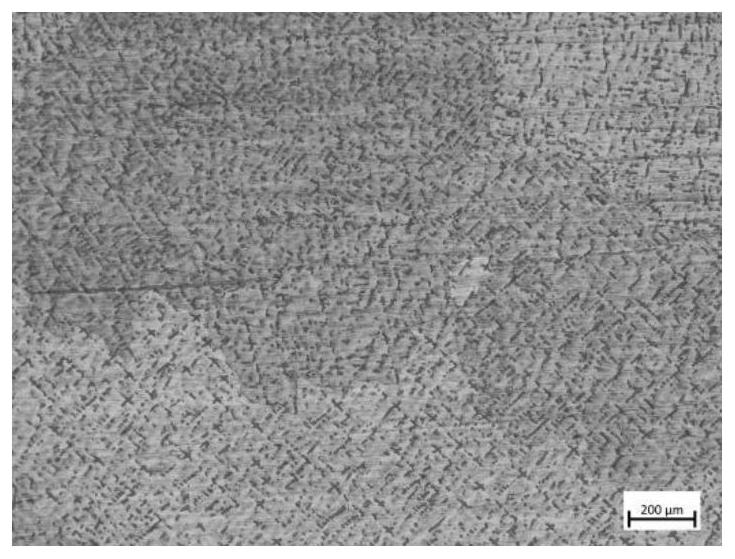

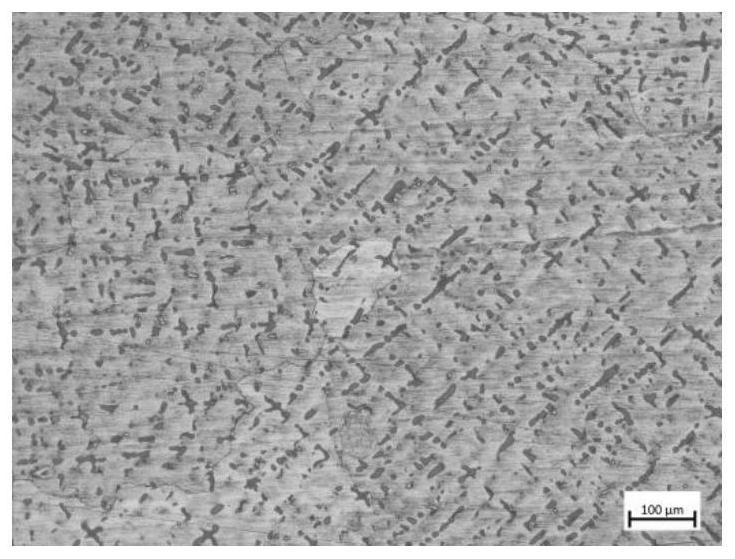

Preparation method of high-strength high-elasticity wear-resistant CuNiSn alloy material through vacuum induction melting

PendingCN114381622ANo reverse segregationUniform tissueMolten spray coatingThermal dilatationMicro arc oxidation

The invention provides a preparation method of a high-strength high-elasticity wear-resistant CuNiSn alloy material through vacuum induction melting, and belongs to the technical field of non-ferrous metal alloy preparation. Comprising the following steps: (1) burdening; (2) charging; (3) vacuumizing; (4) smelting; (5) casting; (6) discharging; the CuNiSn alloy is prepared by adopting a vacuum induction melting method, the material composition is reasonable, the structure is uniform, the alloying degree is high, no obvious structure defect exists, no impurity exists, and after a small amount of Fe, Si and Al is added, the material strength is improved, the wear resistance is improved, grains are refined, and no reverse segregation of Sn exists in the structure; the nano carbon sphere micro-arc oxidation coating is sprayed on the surface of the CuNiSn alloy, so that the strength of the alloy is improved, the friction coefficient is obviously reduced, and the wear resistance of the alloy is obviously improved; the negative thermal expansion material is added into the alloy liquid, so that the expansion coefficient of the CuNiSn alloy material can be reduced, the defects of shrinkage porosity and shrinkage cavity are not easy to generate during casting, and the alloy has no obvious structure defect.

Owner:SIRUI ADVANCED COPPER ALLOY CO LTD

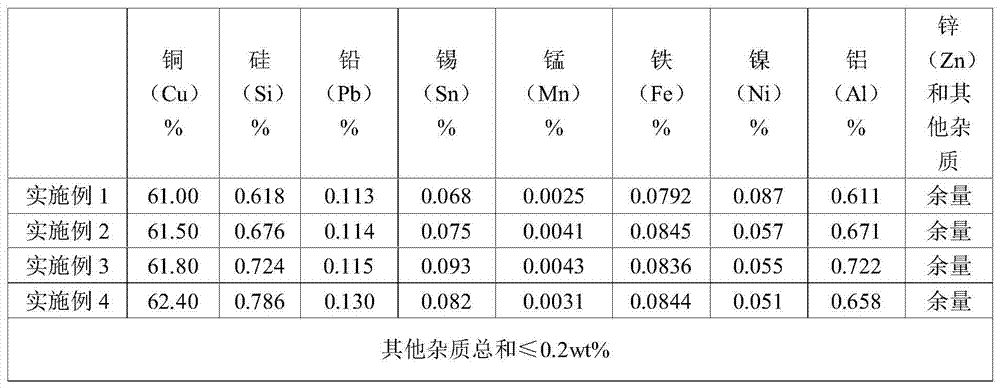

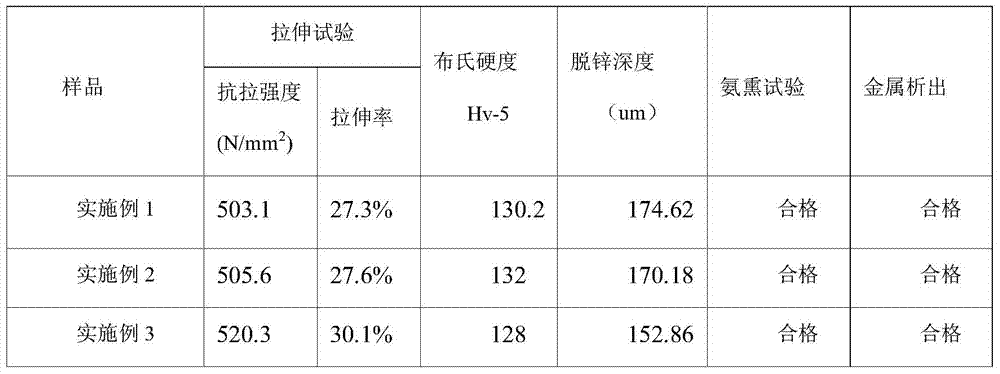

A kind of easy processing silicon brass alloy and preparation method thereof

Owner:JOMOO KITCHEN & BATHROOM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com