Hydraulic power generating device and manufacturing method therefor

A hydroelectric power generation device, one party's technology, applied in hydropower, electromechanical devices, final product manufacturing, etc., can solve problems such as rotation noise, shaft hole size error, shaft hole centering, etc., and achieve the effect of preventing rotation vibration and rotation noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Next, a hydroelectric power generation device to which the present invention is applied and a method of manufacturing the same will be described with reference to the drawings.

[0026] (the whole frame)

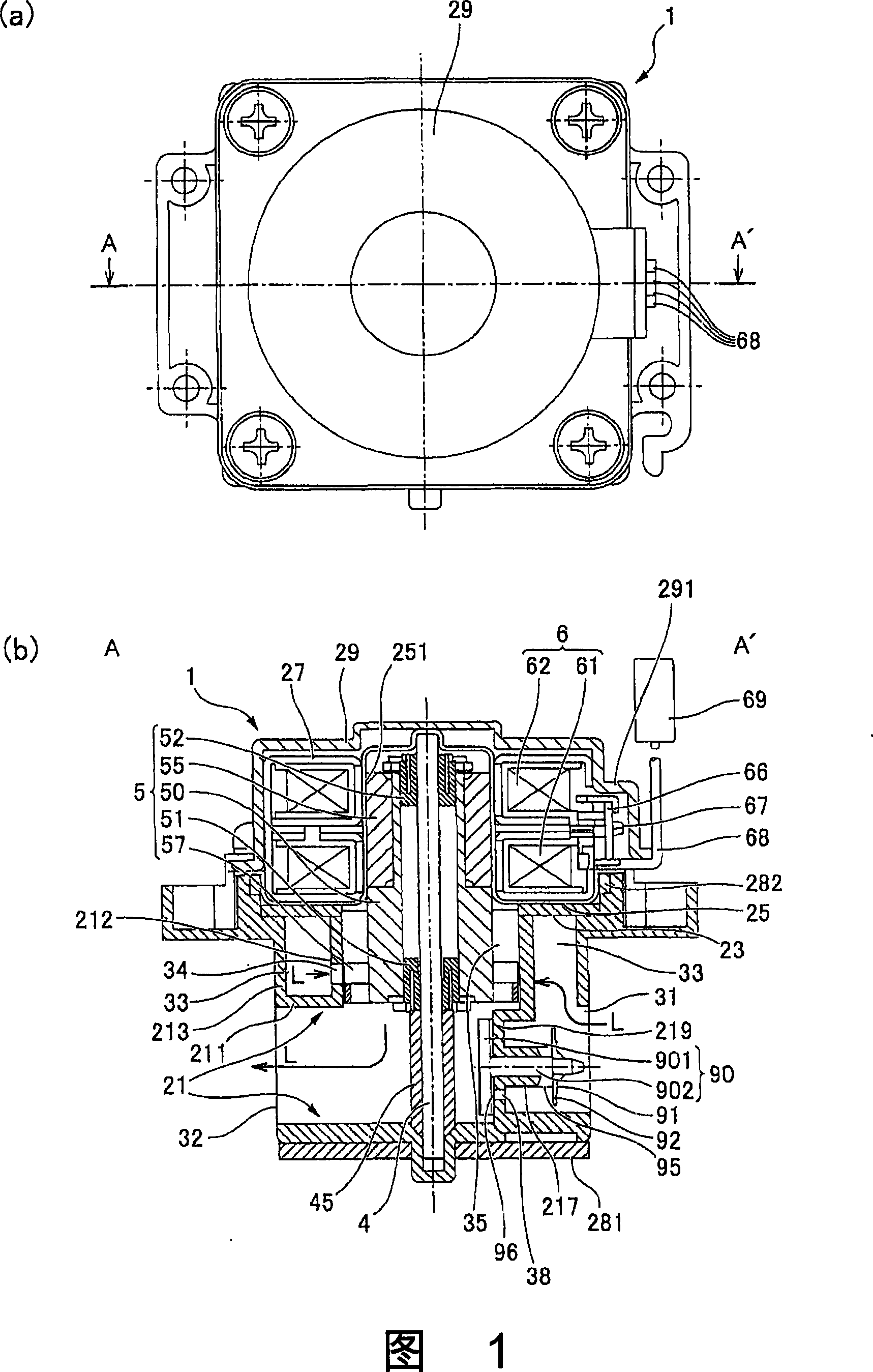

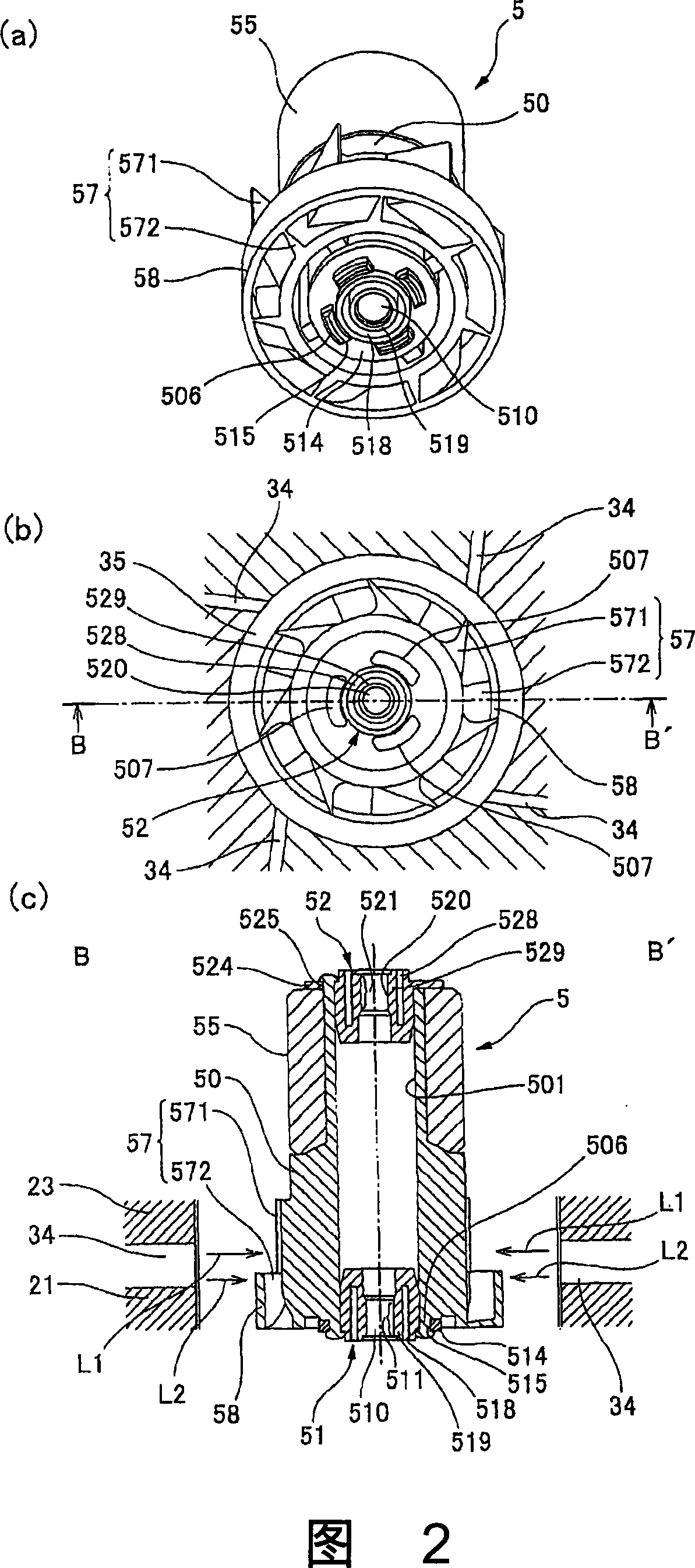

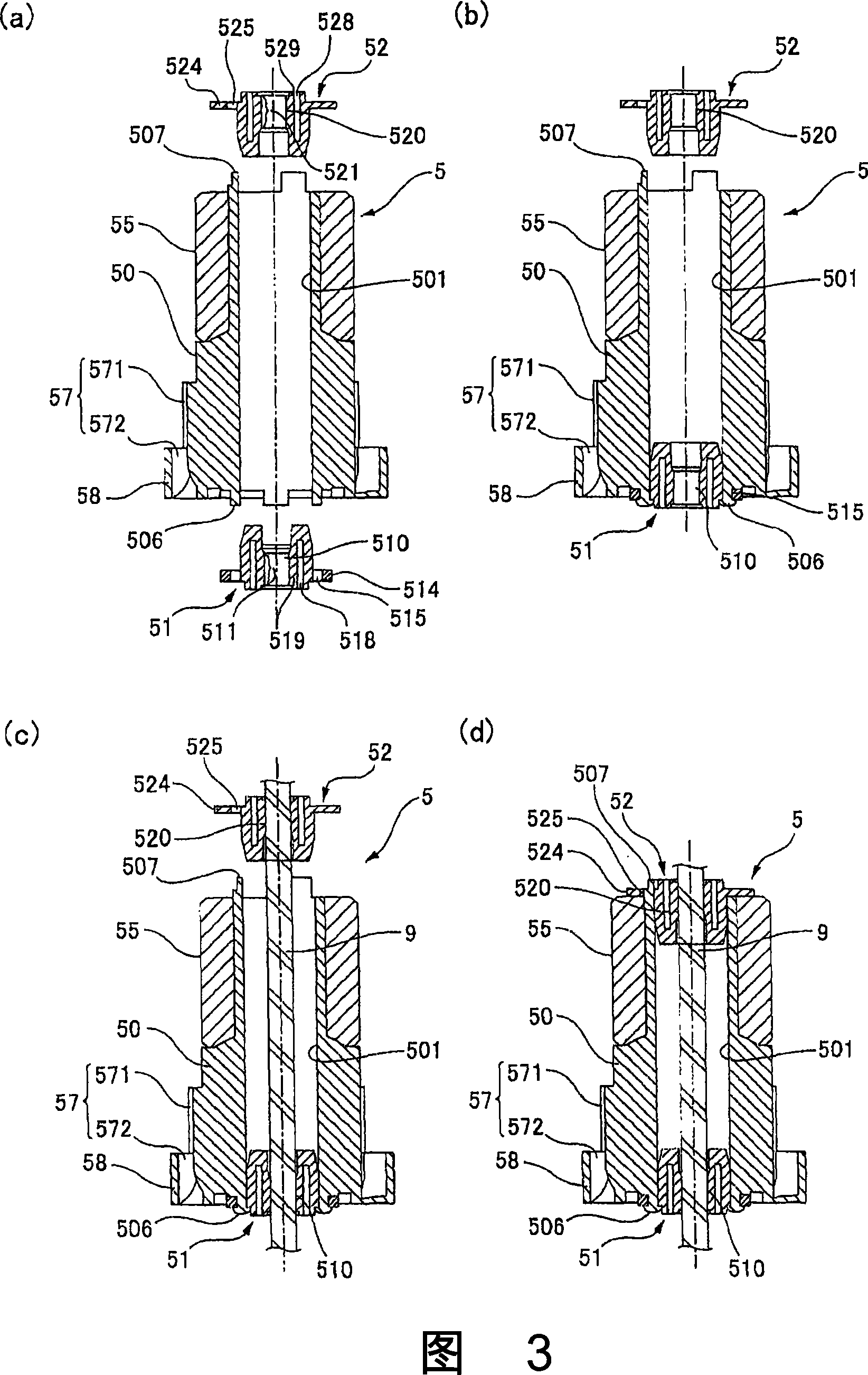

[0027]Fig. 1(a), (b) is a top view and A-A' sectional view of a hydroelectric power generation device to which the present invention is applied. The line A-A' does not pass through the position where the injection port is formed, and the left part of Fig. 1(b) also shows the injection port.

[0028] The hydroelectric power generation device 1 shown in Fig. 1 (a), (b) is a small hydroelectric power generation device arranged at a position in the middle of a water flow path, etc., and stores the electric power obtained by the hydroelectric power generation device 1, and uses the electric power Used in sensor circuits of automatic water faucets, etc. The hydroelectric power generation device 1 of this form has: a resin main body case 21 constituting a flow path describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com