Low-cost production process for as-cast high-elongation nodular cast iron

A high elongation, nodular cast iron technology, applied in the field of casting, can solve the problems of wasting energy, prolonging the production cycle, increasing the production cost, etc., and achieve the effect of expanding the selection range, shortening the production cycle, and preventing shrinkage cavities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

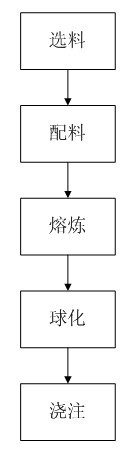

Method used

Image

Examples

Embodiment 1

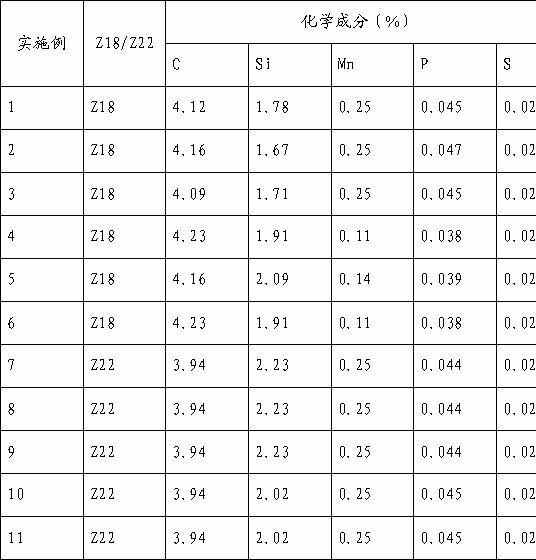

[0027] A) Material selection, select the Z18 cast new iron produced by Xuzhou Iron and Steel Plant in Jiangsu Province, China, and the weight percentage of the chemical composition is shown in Table 1;

[0028] B) batching, with step A) the selected Z18 cast newborn iron, the nodular cast iron pouring riser of this kind of molten iron is return charge, is C0.12-0.6, Si0.12-0.6, Si0.12-0.6, with the weight percentage of contained chemical composition Ordinary carbon steel of Mn0.35-0.65 is used as steel scrap; the mass percentage of each component is 45% new iron, 25% recycled materials, and 30% scrap steel;

[0029] C) Smelting: use 5T / h hot blast furnace cupola for smelting, put the prepared material into the furnace for smelting, melt it into molten iron and heat up to 1650°C, add 3.5-4.8% carburizing agent by mass, 0.6-2.5 % mass percentage is ferrosilicon No. 75 ferrosilicon alloy with a silicon content of 72.0-80.0% as defined in the Chinese national standard GB2272-87, w...

Embodiment 2

[0033] Take casting as an example to produce jack caps, tabs and other castings for Changshu Auto Parts Co., Ltd. in Jiangsu Province, China.

[0034] A) material selection, select the Z18 casting fresh iron of the chemical composition shown in Table 1 produced by Xuzhou Iron and Steel Works, Jiangsu Province, China;

[0035] Batching, the return charge adopts this kind of molten iron, the ductile iron pouring cap and the scrap casting each account for 50%, and the mass percentage of each component is 25% of new iron, 20% of return charge, and 50% of scrap steel;

[0036] B) Melting and spheroidizing are the same as in Example 1, the amount of nodulizer added is 1.6% of the molten iron, and high-elongation nodular cast iron with an elongation of 22.9% is obtained. All the other are the same as the description of embodiment 1.

Embodiment 3

[0038] Take the casting as an example of the half shaft sleeve casting of Changshu Machinery General Factory in Changshu City, Jiangsu Province, China.

[0039] A) material selection, select the Z18 casting fresh iron of the chemical composition shown in Table 1 produced by Xuzhou Iron and Steel Works, Jiangsu Province, China;

[0040] B) batching, the recycled material adopts the scrap casting recycling material of this kind of molten iron, and the mass percentage of each component is 37.5% of newborn iron, 20% of recycled material, and 42.5% of steel scrap;

[0041] C) Melting and spheroidizing are the same as in Example 1, the addition of the spheroidizing agent is 1.7% of the amount of molten iron, and high elongation ductile iron with an elongation of 18.7% is obtained. All the other are the same as the description of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com