Treatment process of polyester double-layer side-stretch fabric

A processing technology and four-way elastic technology, which is applied in the processing of textile materials, continuous processing of textile materials, and equipment configuration for processing textile materials, etc., can solve the problems of high cost, unfavorable production enterprises, and large temperature changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

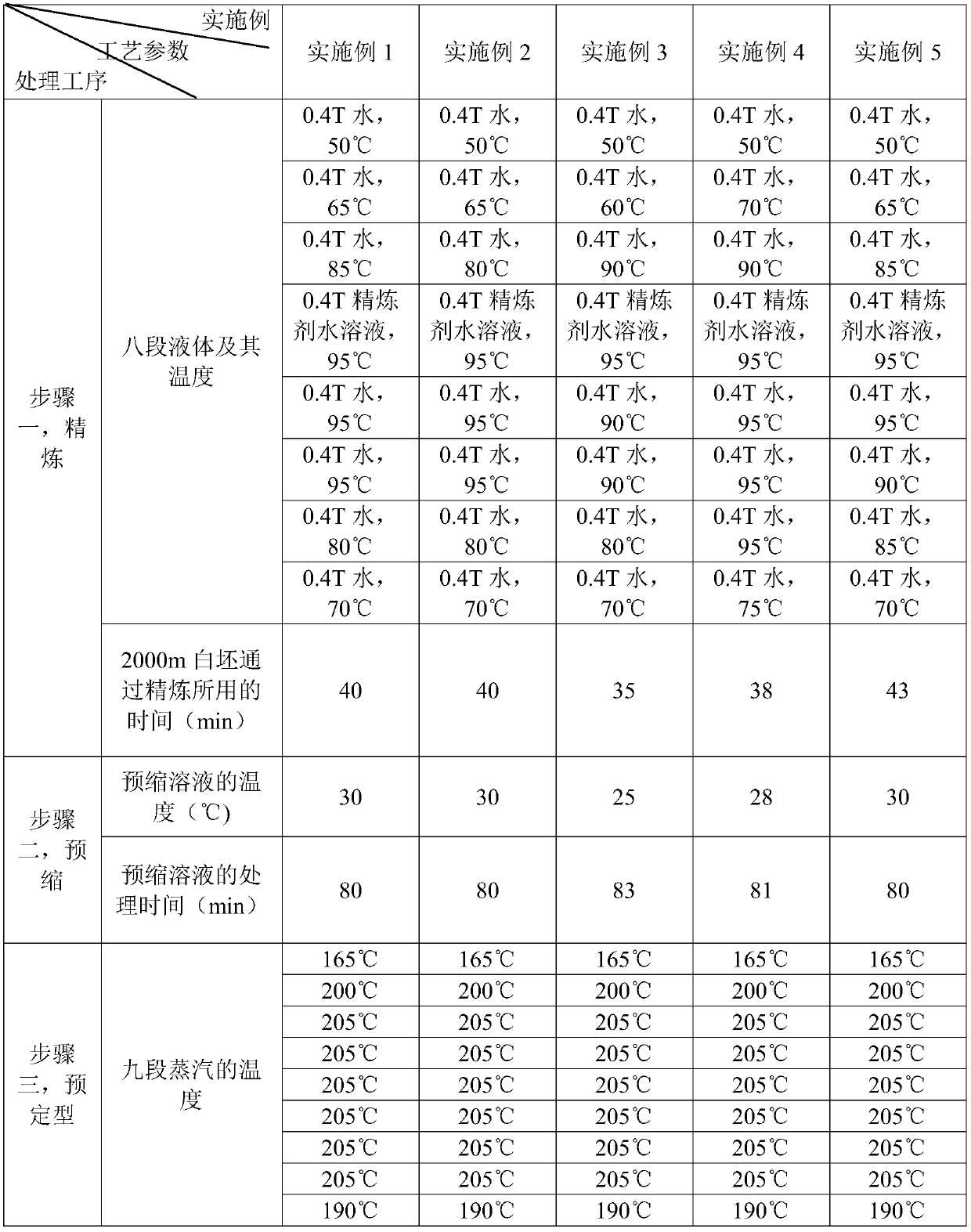

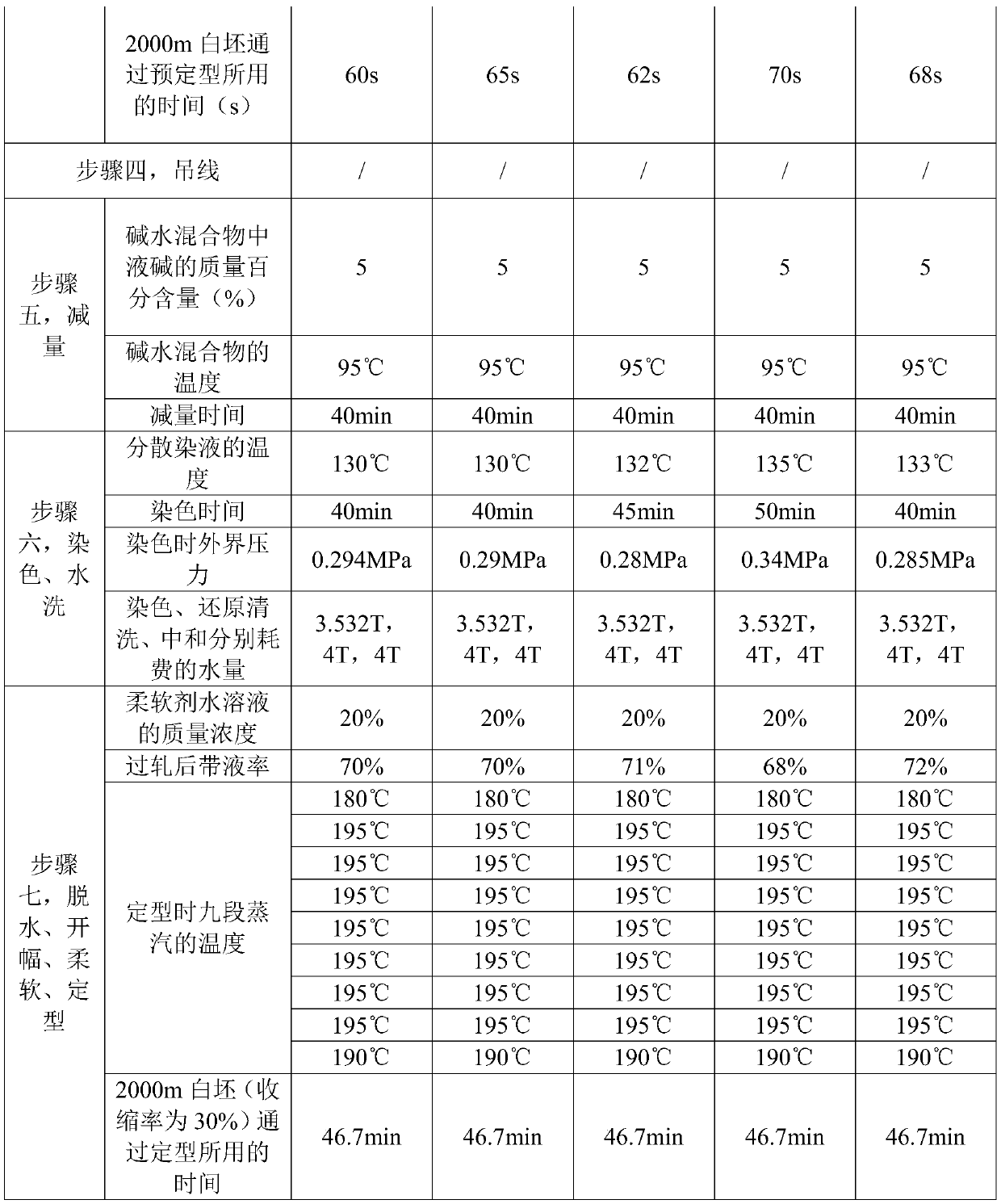

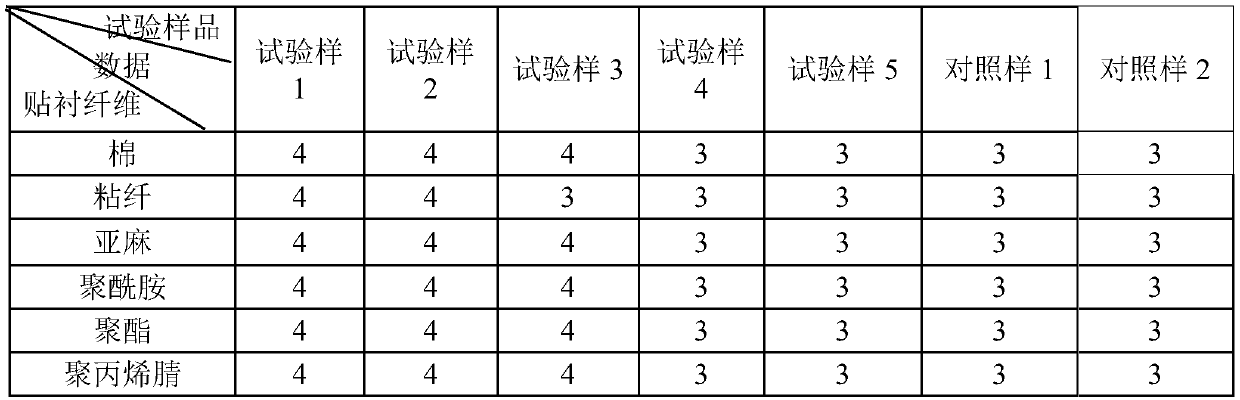

[0066] Embodiment 1-5: a kind of processing technology of polyester double-layer four-way stretch fabric, comprises the following steps:

[0067] Step 1, refining: the blank with a length of 2000m (the yarn is obtained by wrapping a polyester yarn with a fineness of 70D on the outside of a spandex yarn with a fineness of 40D, and the blank is obtained from the yarn along the warp direction and Weaving in the weft direction) successively passes through the eight-stage liquid (0.4T in use) for refining treatment, and the temperature of the eight-stage liquid is 50°C-65°C-85°C-95°C-95°C-95°C-80°C ℃-70℃; in the eight-stage liquid, except the fourth stage is the refining agent aqueous solution, the rest are all clear water, and the blank with a length of 2000m needs a total of 35-43min to go through the entire refining process;

[0068] Step 2, pre-shrinking: place the refined blank in a pre-shrinking solution for 25-30 minutes, and the temperature of the pre-shrinking solution is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com