Environment-friendly water-based paint and preparation method thereof

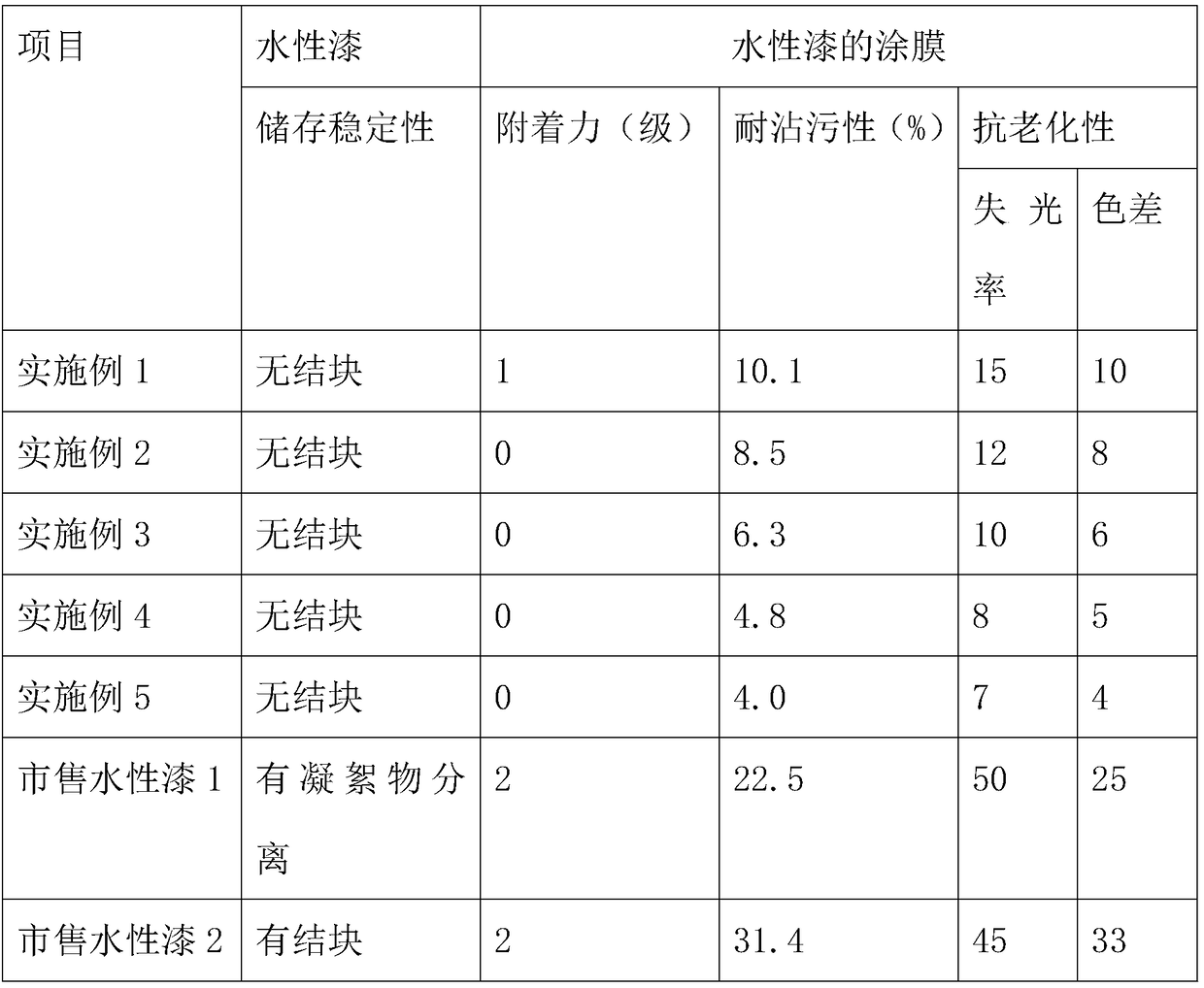

A water-based paint, environmental protection technology, applied in the direction of coating, etc., can solve the problems of affecting the surface smoothness of the coating film, reducing the physical properties of the water-based paint, and poor stain resistance of the coating film, so as to improve the stain resistance and be suitable for Effect of mass production and improvement of aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An environmentally friendly water-based paint, comprising the following components in parts by mass: 15 parts of water, 10 parts of hydroxyacrylic resin, 7 parts of silicone-modified polysiloxane emulsion, 10 parts of pigment, 5 parts of dispersant, defoaming agent 2 parts of agent, 1 part of leveling agent;

[0028] The dispersant is a composite dispersant, and the composite dispersant is composed of rutile nano-titanium dioxide and talc powder; the mass ratio of the rutile nano-titanium dioxide and talc powder is 3:1.

[0029] The preparation method of described environment-friendly water-based paint, comprises the steps:

[0030] (1) Add the water, hydroxyacrylic resin, and silicone-modified polysiloxane emulsion in parts by mass to a mixer, and stir for 1 hour at a rotating speed of 800 r / min to obtain a mixed solution;

[0031] (2) Add the pigment and the dispersant of the mass parts in the said mixed liquid successively, continue to stir 0.5h under 400r / min, obta...

Embodiment 2

[0035] An environmentally friendly water-based paint, comprising the following components by mass parts: 25 parts of water, 20 parts of hydroxyl acrylic resin, 12 parts of silicone modified polysiloxane emulsion, 15 parts of pigment, 7 parts of dispersant, defoaming agent 4 parts of agent, 3 parts of leveling agent;

[0036] The dispersant is a composite dispersant, and the composite dispersant is composed of rutile nano-titanium dioxide and talc powder; the mass ratio of the rutile nano-titanium dioxide and talc powder is 4:1.

[0037] The preparation method of described environment-friendly water-based paint, comprises the steps:

[0038] (1) Add the water, hydroxyacrylic resin, and silicone-modified polysiloxane emulsion in parts by mass to a mixer, and stir for 2 hours at a rotating speed of 1000 r / min to obtain a mixed solution;

[0039] (2) Add the pigment and the dispersant of the mass parts in the said mixed liquid successively, continue to stir 1h under 500r / min, obt...

Embodiment 3

[0043] An environmentally friendly water-based paint, comprising the following components in parts by mass: 17 parts of water, 16 parts of hydroxyacrylic resin, 10 parts of silicone-modified polysiloxane emulsion, 12 parts of pigment, 5 parts of dispersant, defoaming agent 3 parts of agent, 2 parts of leveling agent;

[0044] The dispersant is a composite dispersant, and the composite dispersant is composed of rutile nano-titanium dioxide and talc powder; the mass ratio of the rutile nano-titanium dioxide and talc powder is 3:1.

[0045] The preparation method of described environment-friendly water-based paint, comprises the steps:

[0046] (1) Add the water, hydroxyacrylic resin, and silicone-modified polysiloxane emulsion in parts by mass to a mixer, and stir for 1.5 h at a rotating speed of 900 r / min to obtain a mixed solution;

[0047] (2) Add the pigment and the dispersant of the mass parts in the said mixed liquid successively, continue to stir 0.7h under 450r / min, obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com