Bottom plate of improved table tennis bat and table tennis bat

An improved technology for table tennis rackets, applied to rackets, sports accessories, etc., which can solve the problems of heavy weight of table tennis rackets, influence on power generation, failure to effectively increase hitting friction and rotation speed, etc., to improve flatness and friction and rotation speed, material cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Specific preparation of raw materials and ratio

[0036] Improved table tennis racket of the present invention, its bottom plate 1 comprises preparation raw material according to weight proportion:

[0037] Modified polypropylene is 85 parts; glass fiber is 14 parts; azodicarbonamide is 0.25 parts; phthalate is 0.5 parts; carbon black is 0.15 parts.

[0038] 2. Preparation method

[0039] The preparation method of the bottom plate 1 of the improved table tennis racket of this embodiment is to use modified polypropylene (CSR-6000G115) as the main material, glass fiber is used as traction, azodicarbonamide is used for foaming, and phthalate Enhanced plasticity, plus carbon black for coloring.

[0040] It specifically includes the following steps: 1), pretreatment: before plasticizing, the modified polypropylene is dried for 6-8 hours, and the temperature range is controlled at 70-80°C during drying; the function of this step is to eliminate the modified polypropylene...

Embodiment 2

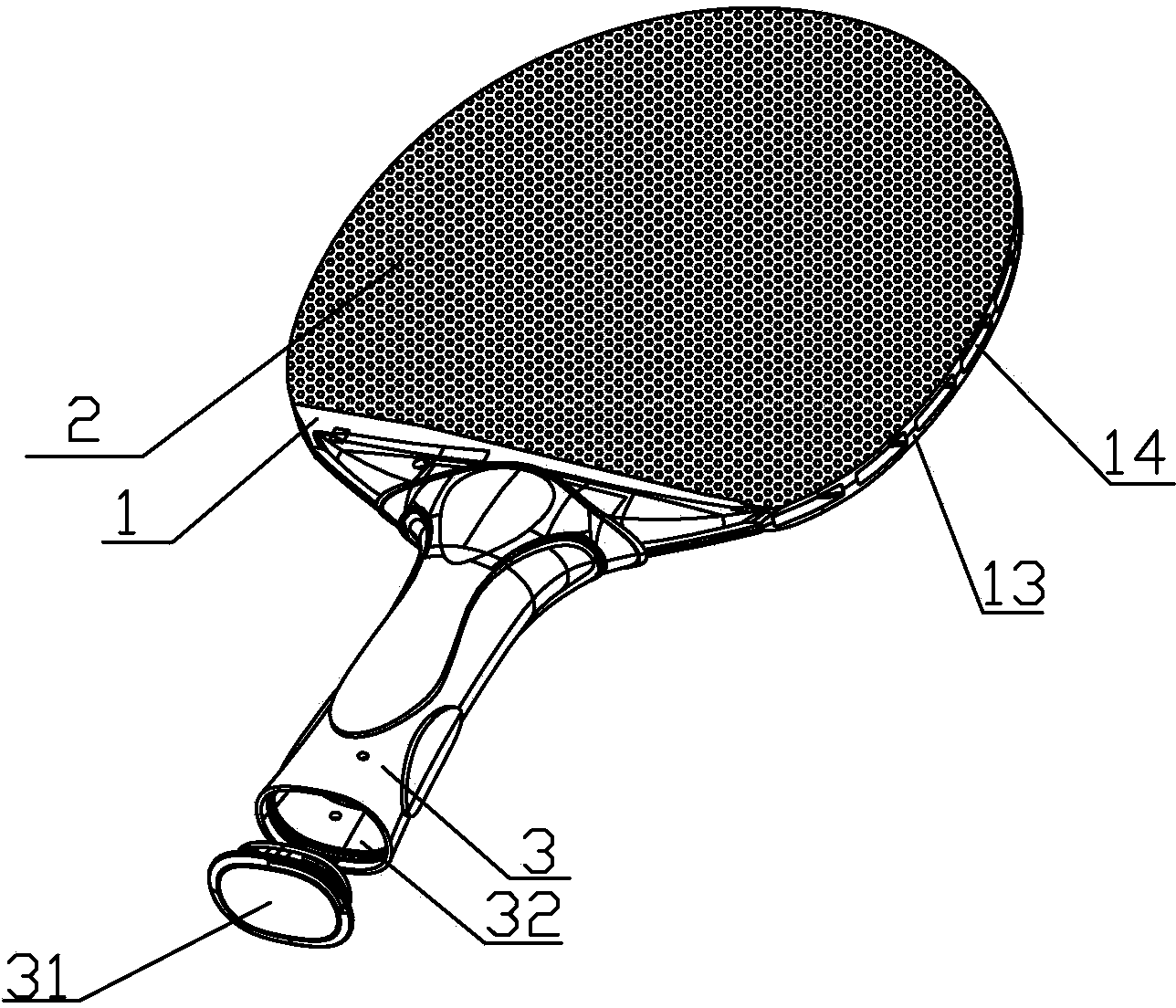

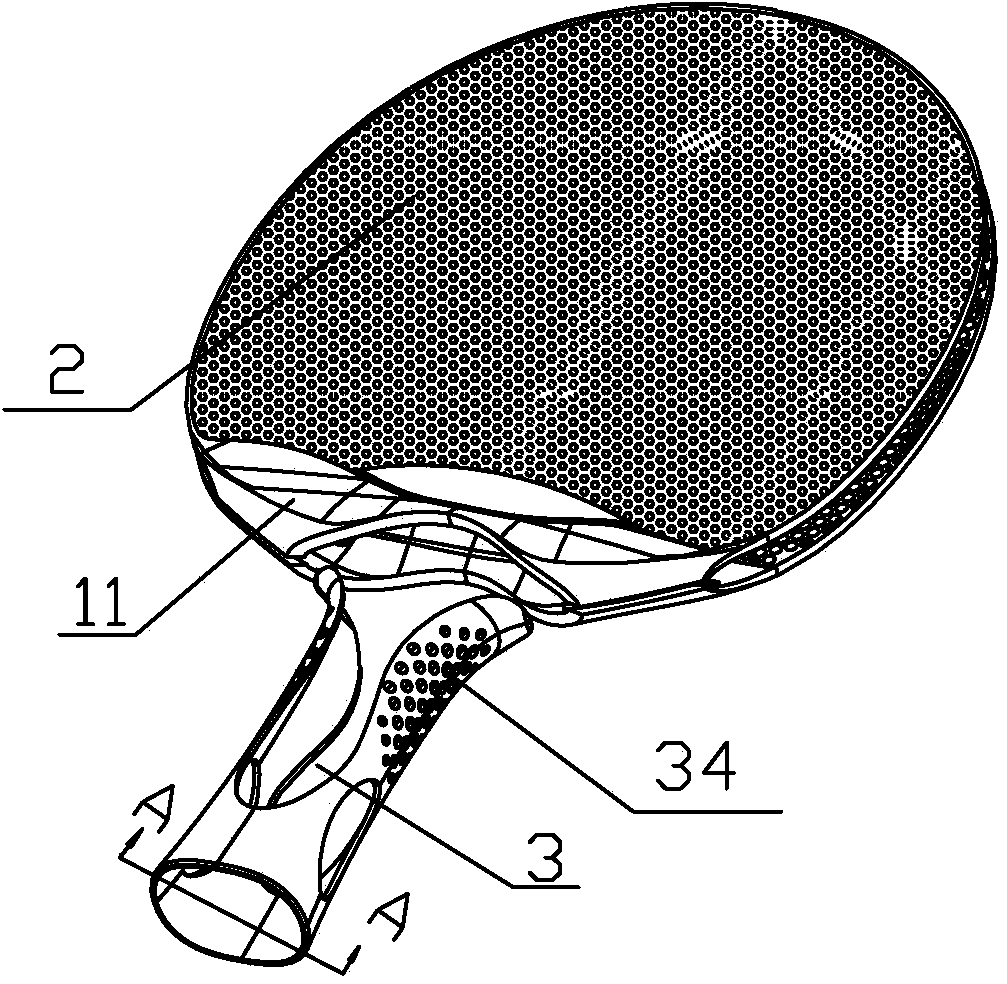

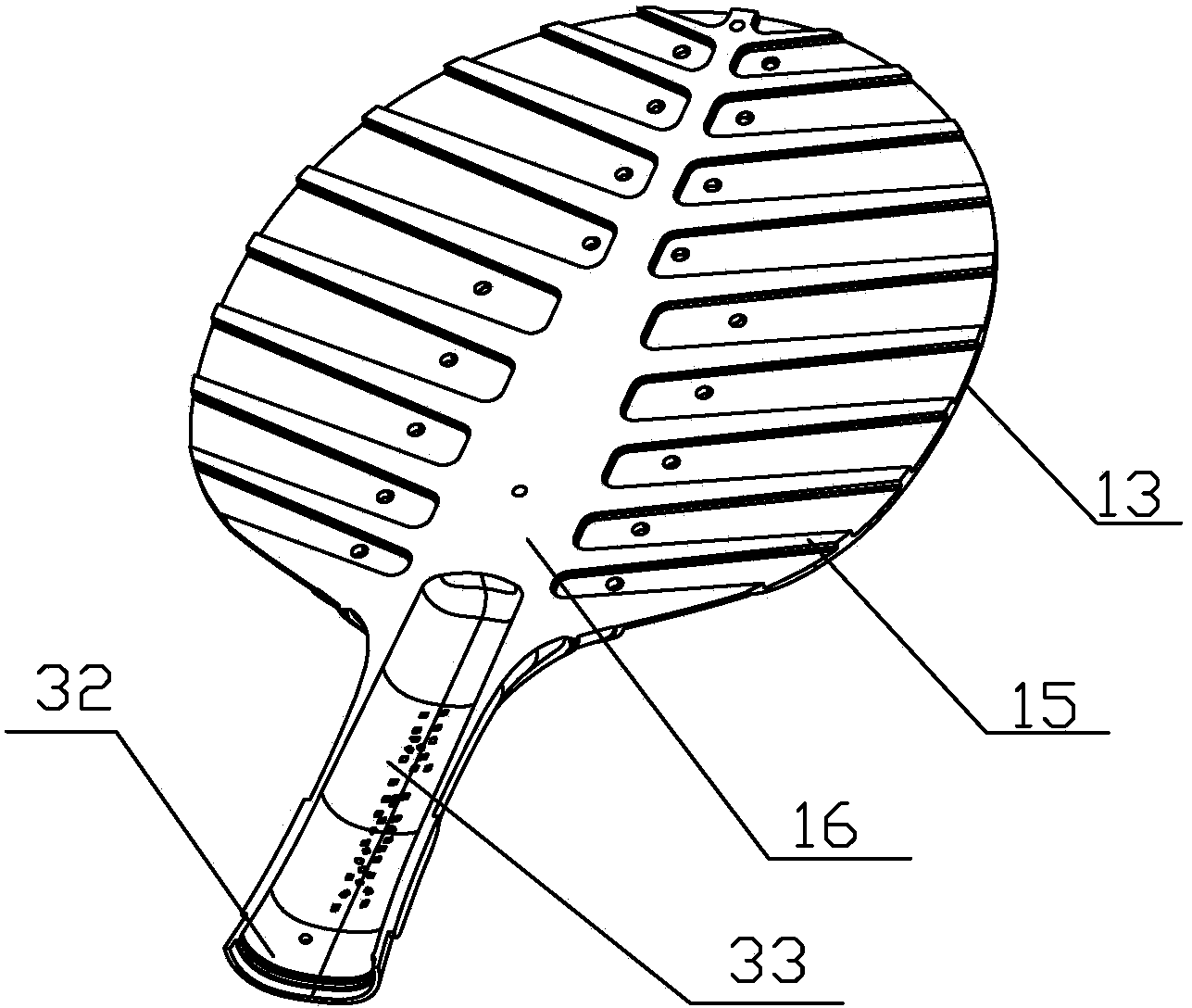

[0045] Such as Figure 1-4As shown, the improved table tennis racket of the present invention includes a base plate 1, an elastic panel 2 and a handle 3 positioned on the base plate 1, and the base plate 1 includes a first plane 11 parallel to each other, a second plane 12 and a first plane 12 for connecting the first The outer facade 13 of the plane 11 and the second plane 12, the outer facade 13 is provided with several blind holes 14 extending to the inside of the bottom plate 1, and ribs 15 are formed between adjacent blind holes 14; the inner bottom plate 1 A main rib 16 is arranged along the axial direction of the handle 3, and the ribs 15 and the main rib 16 are connected as an integral structure, and they serve as important bearing force positions for table tennis rackets. As a specific embodiment, the ribs 15 and the main ribs 16 jointly form a fishbone structure. Of course, another situation is also allowed, the main rib 16 is located at the center of the bottom pla...

Embodiment 3

[0049] Such as Figure 5-7 As shown, in order to enhance the adhesion between the racket bottom plate 1 and the elastic panel 2, the bottom plate 1 is provided with a number of evenly arranged concave holes 17, and the concave holes 17 are attached to the elastic panel 2 together. The elastic panel 2 and the handle surface 34 of the present invention are all made of TPR (thermoplastic rubber material) material, through the secondary processing of the abrasive tool, the concave holes 17 are filled with TPR material, so that the elastic panel 2 and the racket bottom plate 1 Combine more closely. Another important improvement point of the present invention: the elastic panel 2 can also be provided with several concave holes 17 arranged evenly. In addition to enhancing the combination of the racket bottom plate 1 and the elastic panel 2, the concave hole 17, please refer to Figure 6 . More importantly, it can effectively improve the friction, rotation speed and rebound speed g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com