Preparation method of high-strength high-elasticity wear-resistant CuNiSn alloy material through vacuum induction melting

A technology of vacuum induction melting and alloy materials, applied in metal material coating process, fusion spraying, coating, etc., can solve the problems of complex preparation process, serious surface oxidation, high expansion coefficient, etc., and achieve reasonable material composition, The effect of low production cost and high degree of alloying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

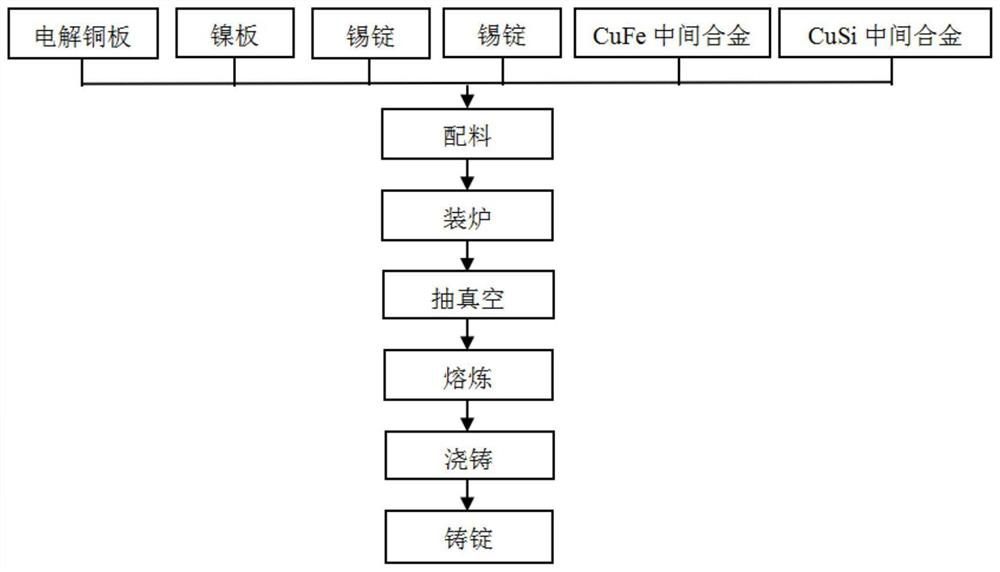

[0033] A method for preparing a vacuum induction melting high-strength, high-elasticity and wear-resistant CuNiSn alloy material, comprising the following steps:

[0034] (1) Ingredients: In terms of mass percentage, the percentage content of each element is: Ni: 5%, Sn: 5%, Fe: 0.01%, Al: 0.5%, Si: 0.3%, Cu is the balance: 89.19% ;

[0035] (2) Furnace loading: use one-time feeding method, put the prepared alloy material into the graphite crucible, close the furnace cover, close the vent valve, and clean the observation window;

[0036] (3) Vacuuming: Turn on the mechanical pump, open the low vacuum baffle valve and evacuate, and when the vacuum pressure P in the furnace is 0.08MPa, turn on the Roots pump;

[0037] (4) Melting: When vacuuming until P is 10Pa, heat intermittently to 1250°C. After the raw materials in the crucible start to melt, reduce the power of the equipment, open the argon filling valve, and slowly fill the furnace with high-purity argon. When the intern...

Embodiment 2

[0041] A method for preparing a vacuum induction melting high-strength, high-elasticity and wear-resistant CuNiSn alloy material, comprising the following steps:

[0042] (1) Ingredients: by mass percentage, the percentage content of each element is: Ni: 6%, Sn: 6%, Fe: 0.02%, Al: 1%, Si: 0.5%, Cu: 86.48%;

[0043] (2) Furnace loading: use one-time feeding method, put the prepared alloy material into the graphite crucible, close the furnace cover, close the vent valve, and clean the observation window;

[0044] (3) Vacuuming: Turn on the mechanical pump, open the low vacuum baffle valve and evacuate, and when the vacuum pressure P in the furnace is 0.07MPa, turn on the Roots pump;

[0045] (4) Melting: When vacuuming until P is 9Pa, heat intermittently to 1350°C. After the raw materials in the crucible start to melt, reduce the power of the equipment, open the argon filling valve, and slowly fill the furnace with high-purity argon. When the internal pressure rises to -0.08Mpa, ...

Embodiment 3

[0049] A method for preparing a vacuum induction melting high-strength, high-elasticity and wear-resistant CuNiSn alloy material, comprising the following steps:

[0050] (1) Ingredients: by mass percentage, the percentage content of each element is: Ni: 7%, Sn: 7%, Fe: 0.03%, Al: 2%, Si: 0.7%, Cu: 83.27%;

[0051] (2) Furnace loading: use one-time feeding method, put the prepared alloy material into the graphite crucible, close the furnace cover, close the vent valve, and clean the observation window;

[0052] (3) Vacuuming: Turn on the mechanical pump, open the low vacuum baffle valve and evacuate, and when the vacuum pressure P in the furnace is 0.086MPa, turn on the Roots pump;

[0053] (4) Melting: When vacuuming until P is 8Pa, heat intermittently to 1450°C. After the raw materials in the crucible start to melt, reduce the power of the equipment, open the argon filling valve, and slowly fill the furnace with high-purity argon. When the internal pressure rises to -0.08Mp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com