Manufacturing method for tin-phosphor bronze strip

A technology of tin phosphor bronze strips and preparation steps, which is applied in the field of preparation of tin phosphor bronze strips, can solve the problems of reverse segregation, poor bending performance of materials, and easy initiation of transverse bending cracks, etc., achieves increased diffusion speed, improved bending properties, and preparation Effects in simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

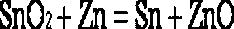

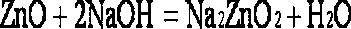

[0025] First weigh 100g of metaphosphoric acid and put it into a closed reactor, and at the same time, feed pure nitrogen from the bottom of the closed reactor, control the nitrogen feed rate to be 20mL / min, and replace the air in the closed reactor. Vacuumize to 120Pa, then heat to 200°C, react for 1h, and then introduce the reactants into -100°C cold trap, -125°C cold trap and -186°C liquid nitrogen cold trap respectively and let them stand for 20 minutes each, then collect phosphine Then take by weighing 100g tin oxide and 15g zinc powder respectively, put into tube furnace, pass into phosphine in tube furnace simultaneously, control phosphine feed rate to be 18mL / min, feed time is 12min, After the feeding is completed, react for 4 hours; after the above reaction is completed, add 10 mL of sodium hydroxide solution with a mass concentration of 1.6 mol / L to the tube furnace, stir and react for 3 hours, and then put the obtained reactant into a vacuum oven at 50 °C Dry in the...

example 2

[0027]First weigh 125g of metaphosphoric acid and put it into a closed reactor, and feed pure nitrogen from the bottom of the closed reactor at the same time. Vacuumize to 120Pa, then heat to 210°C, react for 1h, and then introduce the reactants into -95°C cold trap, -117°C cold trap and -168°C liquid nitrogen cold trap respectively, and let them stand for 23 minutes, then collect phosphine Then take by weighing 110g tin oxide and 18g zinc powder respectively, put into tube furnace, pass into phosphine in tube furnace simultaneously, control phosphine feed rate to be 19mL / min, feed time is 14min, After the feeding is completed, react for 5 hours; after the above reaction is completed, add 13 mL of sodium hydroxide solution with a mass concentration of 1.6 mol / L to the tube furnace, stir and react for 4 hours, and then put the obtained reactant into a vacuum oven at 55 °C Dry in medium for 2 hours to obtain dry matter; then weigh 40g of copper powder and 6g of sodium thiosulfat...

example 3

[0029] First weigh 150g of metaphosphoric acid and put it into a closed reactor, feed pure nitrogen from the bottom of the closed reactor at the same time, control the nitrogen feed rate to be 22mL / min, replace the air in the closed reactor, after the replacement is completed, Vacuumize to 120Pa, then heat to 220°C, react for 2 hours, then introduce the reactants into -90°C cold trap, -110°C cold trap and -160°C liquid nitrogen cold trap respectively, and let them stand for 25 minutes each, then collect phosphine Then take by weighing 120g tin oxide and 20g zinc powder respectively, put into tube furnace, pass into phosphine in tube furnace simultaneously, control phosphine feed rate to be 20mL / min, feed time is 15min, After the feeding is completed, react for 6 hours; after the above reaction is completed, add 15 mL of sodium hydroxide solution with a mass concentration of 1.6 mol / L to the tube furnace, stir and react for 5 hours, and then put the obtained reactant into a 60°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com