Display device and preparation method thereof

A technology for display devices and display areas, which is applied in the directions of identification devices, optics, instruments, etc., can solve the problems of lowering the yield rate of display devices and easy peeling of film layers, so as to improve the phenomenon of film layer peeling, enhance the limiting effect, reduce the The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

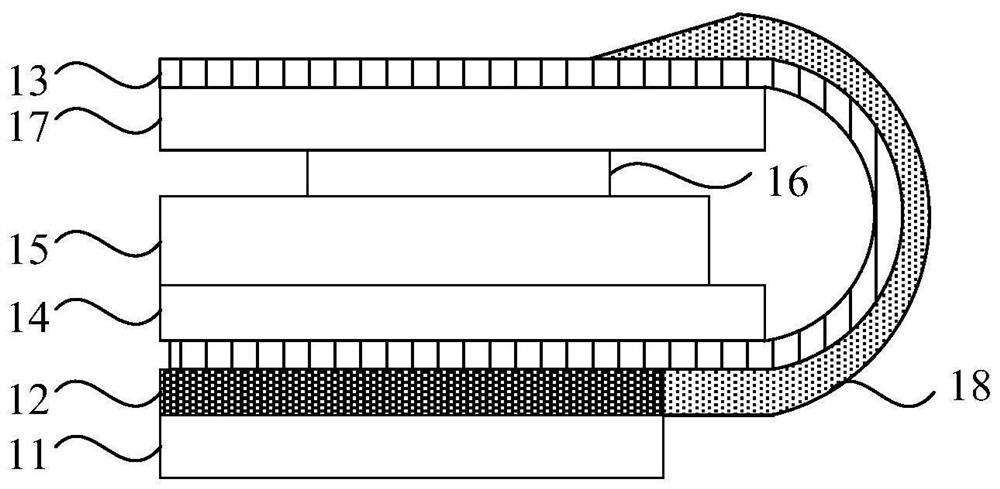

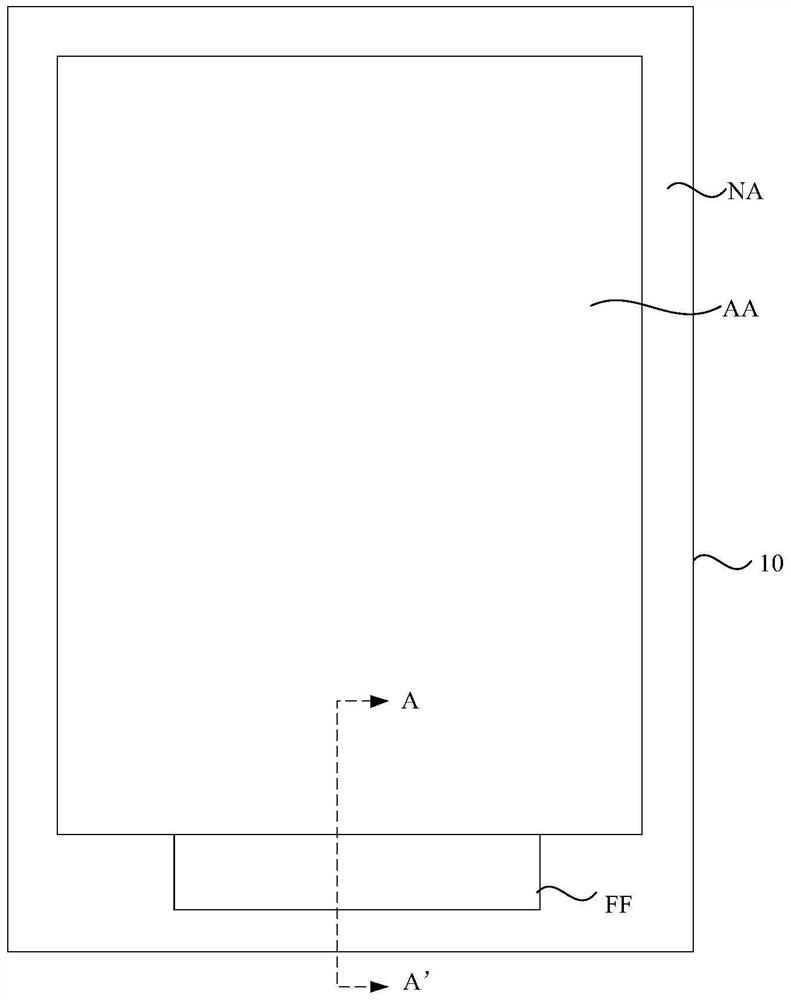

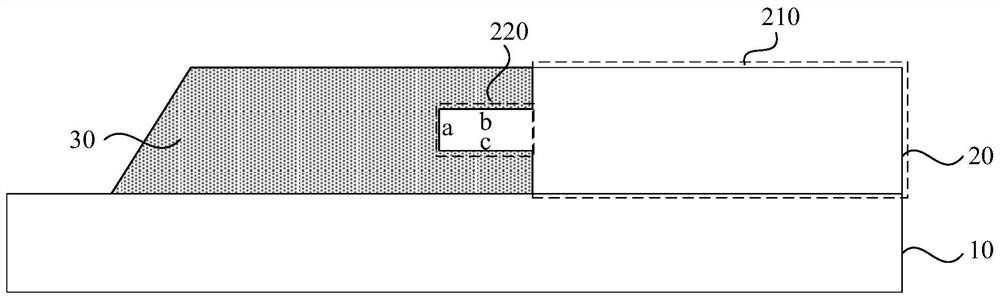

[0037] As mentioned in the background art, the existing display device has a problem of low yield after reliability test. The inventors have found through research that the reason for the above problems is that during the reliability test, the high temperature and high pressure environment causes some film layers to shrink inward, which leads to a large stress between the film layers arranged in the stack, and then the film layer peeling phenomenon. Exemplarily, figure 1 It is a schematic cross-sectional structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com