Bi-component high-temperature resistant alcohol-soluble ink binder, preparation method and application thereof

A technology of ink binder and high temperature resistance, applied in ink, application, household appliances, etc., can solve the problems of high solvent residue, poor pigment dispersion and wettability, narrow range of printing substrates, etc., and achieve good dispersion and wettability , a wide range of printing substrates, and good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

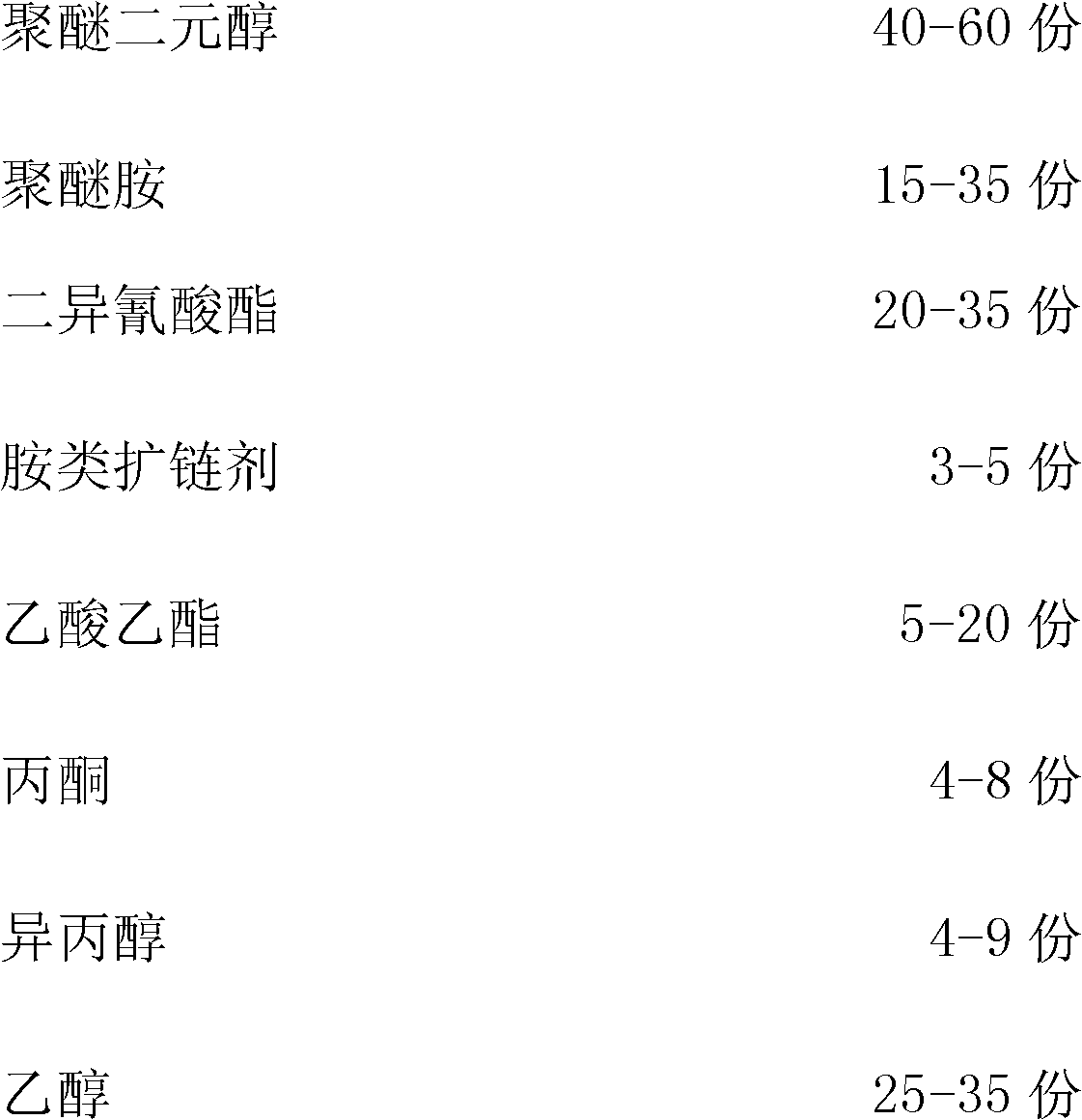

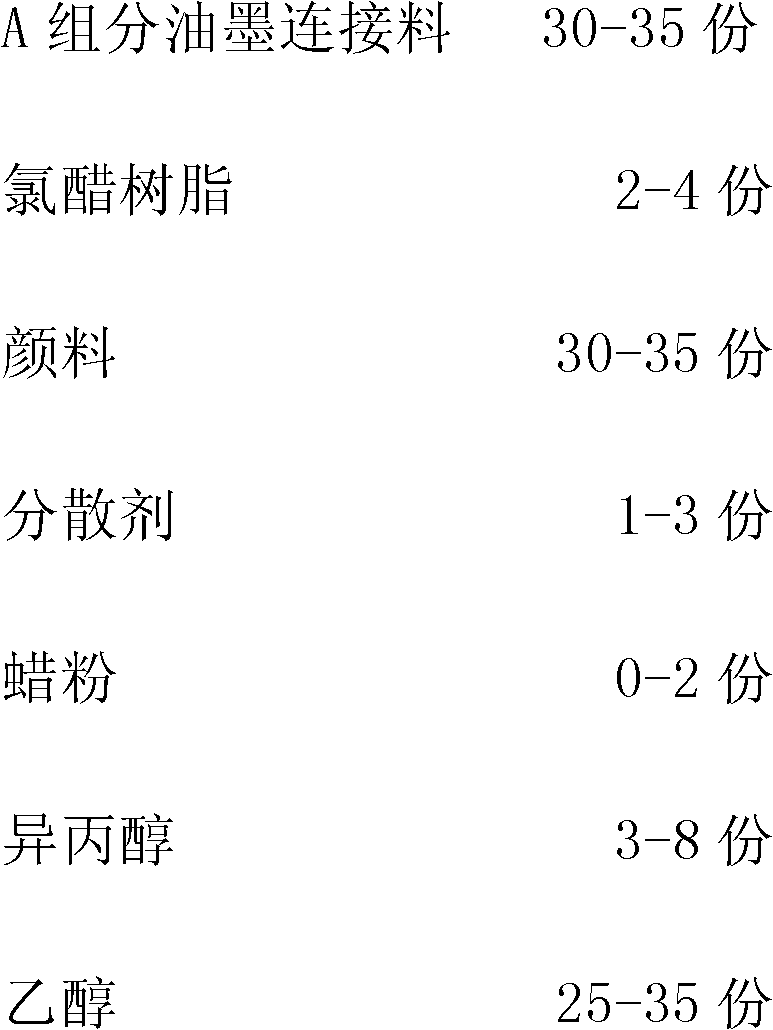

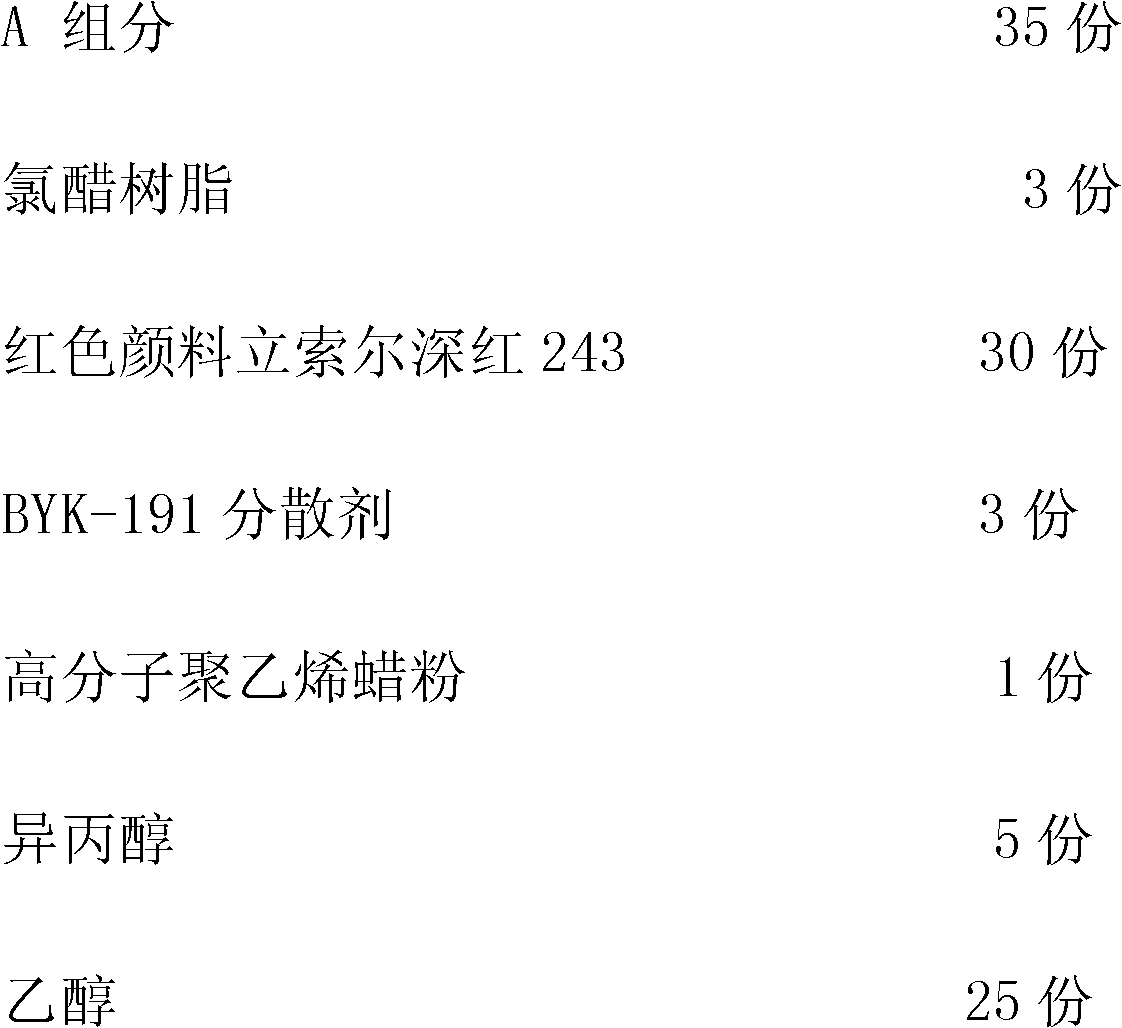

[0027] The amino-terminated polyurethane prepolymer solution containing urea groups in component A is polymerized by solution polymerization of polyetheramine, polyether diol, diisocyanate, and amine chain extender. The specific preparation method is as follows:

[0028] Put 60 parts of polyether glycol DL1000 (commercially available) into the reaction kettle at room temperature, vacuum dehydration at 90-100℃ for 1-2 hours, take a sample to determine the moisture content, when the moisture content is less than 0.08%, stop dehydration and cool to 40-45℃ and maintain this temperature range, turn on the stirring, add 10 parts of ethyl acetate and 30 parts of liquefied MDI (diphenylmethane diisocyanate) in turn while stirring. After the temperature stabilizes, slowly increase the temperature to 70 Reaction at ℃, after 2 hours, measure the NCO value (4%-6%), and lower the temperature to about 42℃, put in 25 parts of polyetheramine D230 (commercially available), 5 parts of diethylene t...

Embodiment 2

[0035] The amino-terminated polyurethane prepolymer solution containing urea groups in component A is polymerized by solution polymerization of polyetheramine, glycol, diisocyanate, and amine chain extender. The specific preparation method is as follows:

[0036] Put 60 parts of polyether glycol DL400 (commercially available) into the reaction kettle at room temperature, vacuum dehydration at 90-100℃ for 1-2 hours, take samples to determine the moisture content, when the moisture content is less than 0.08%, stop dehydration and cool to 40-45℃ and maintain this temperature range, turn on the stirring, add 8 parts of ethyl acetate and 30 parts of TDI (toluene diisocyanate) sequentially while stirring. After the temperature stabilizes, slowly increase the temperature to 70℃ for reaction, 2 After hours, measure the NCO value and lower the temperature to about 42°C. Put in 25 parts of polyetheramine D400 (commercially available), 3 parts of diethylene triamine, 6 parts of acetone, 9 p...

Embodiment 3

[0044] The amino-terminated polyurethane prepolymer solution containing urea groups in component A is polymerized by solution polymerization of polyetheramine, polyether diol, diisocyanate, and amine chain extender. The specific preparation method is as follows:

[0045] Put 30 parts of polyether glycol DL1000 and 30 parts of polyether polyol DL400 into the reaction kettle at room temperature, vacuum dehydration at 90-100℃ for 1-2 hours, take samples to determine the moisture content, when the moisture content is less than 0.08%, Stop dehydration, cool to 40-45℃ and maintain this temperature range, turn on stirring, add 15 parts of ethyl acetate and 25 parts of liquefied MDI sequentially while stirring. After the temperature stabilizes, slowly increase the temperature to 70℃ for reaction, 2. After hours, measure the NCO value and lower the temperature to about 42°C, put in 40 parts of polyetheramine D230, 4 parts of diethylenetriamine, 8 parts of acetone, 4 parts of isopropanol a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com