Composition for making a drilling fluid a non-invasive drilling fluid

A non-invasive, drilling fluid technology, applied in the field of the composition used to make the drilling fluid a non-invasive drilling fluid, which can solve the problems of pressure transmission and fluid loss, not having the strength of the sealing hole throat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

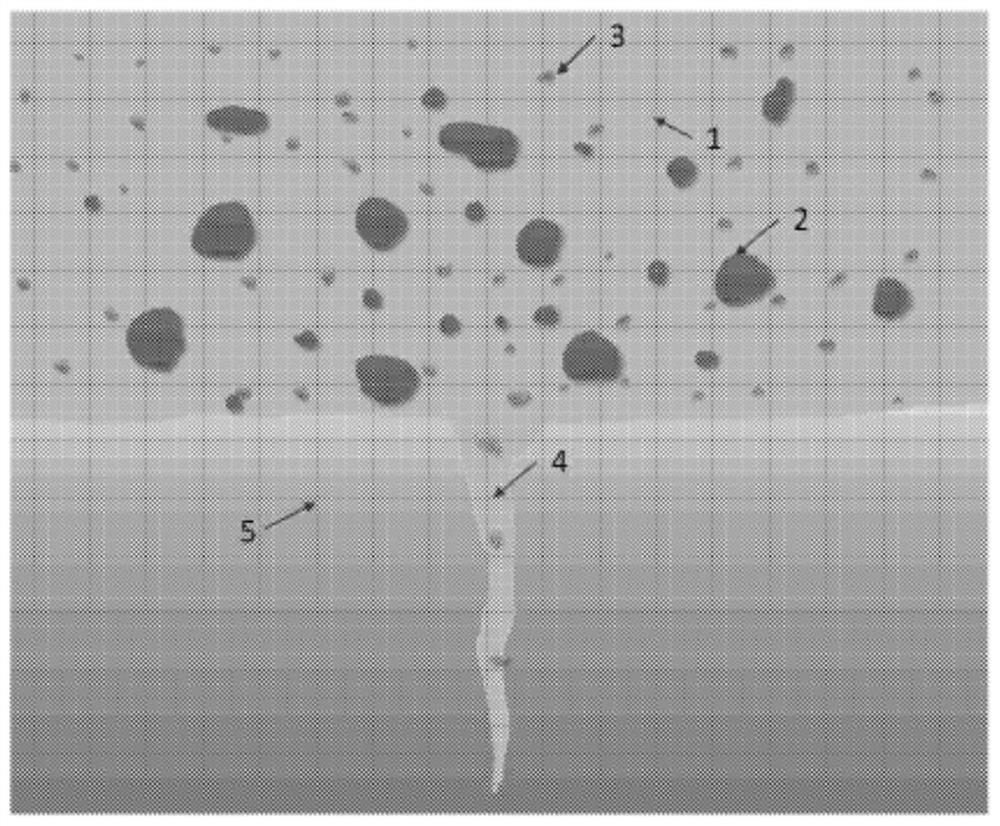

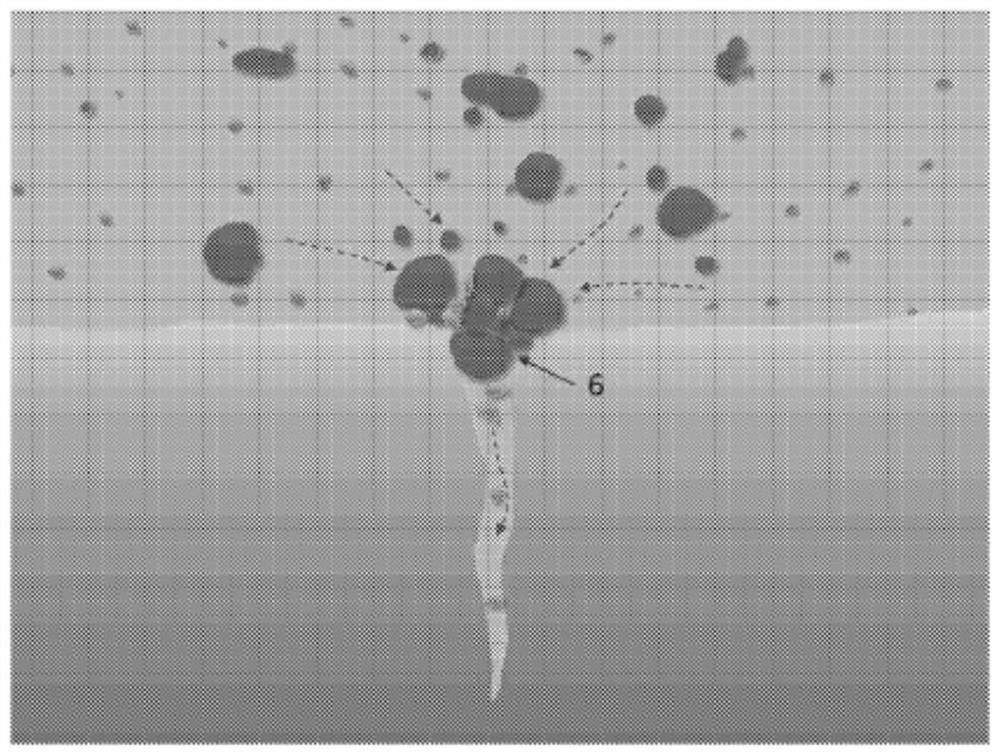

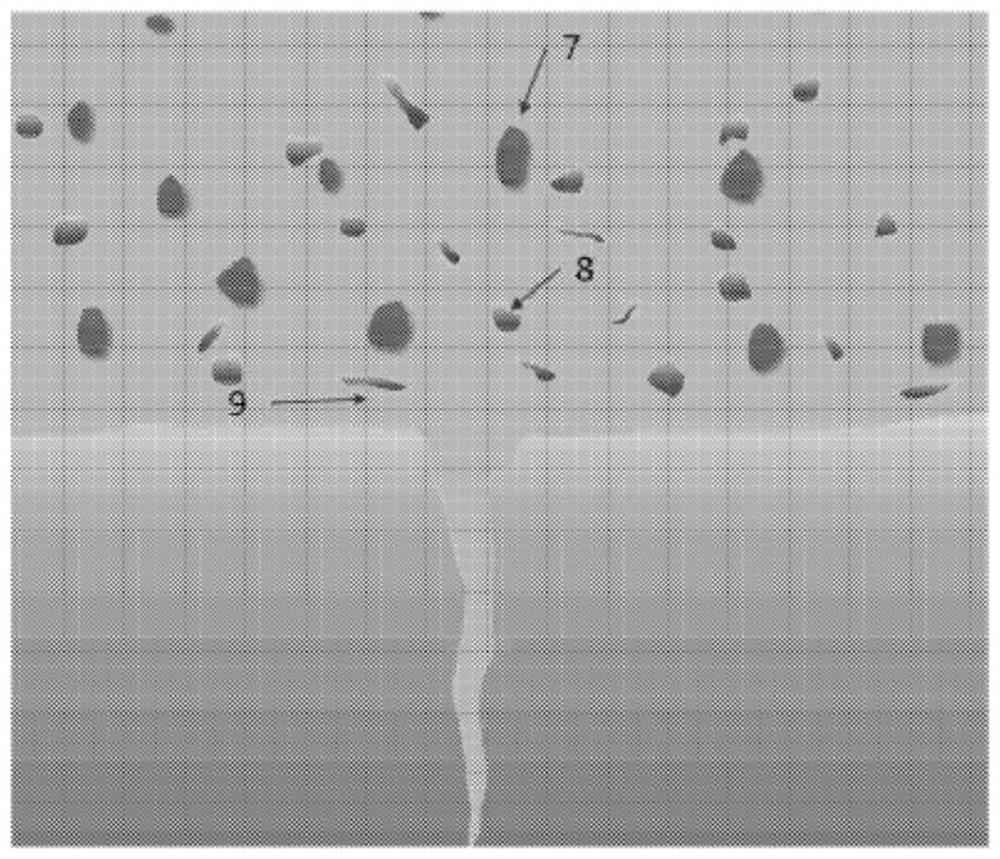

Image

Examples

Embodiment 1

[0072] Example 1: Addition of non-invasive drilling fluid Composition 1 to a water-based fluid wherein the following components were ground, dried and sieved:

[0073] Almond shell powder (100 mesh): 75% (component 1)

[0074] Capers seed powder (100 mesh): 25% (component 2)

Embodiment 2

[0075] Example 2: Addition of non-invasive drilling fluid Composition 2 to a water-based fluid wherein the following components were ground, dried and sieved:

[0076] Almond shell powder (100 mesh): 75% (component 1)

[0077] Capers seed powder (100 mesh): 5% (component 2)

[0078] ·Coffee shell (120 mesh): 20% (component 3)

Embodiment 3

[0079] Example 3: Addition of non-invasive drilling fluid Composition 3 to a water-based fluid wherein the following components were ground, dried and sieved:

[0080] Almond shell powder (100 mesh): 90% (component 1)

[0081] Sour bean powder (100 mesh): 10% (component 2)

[0082] Table 1: Important properties of the drilling fluids of Examples 1 to 3. BHR is before hot rolling, AHR is after hot rolling.

[0083]

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com