Preparation method and application of bio-based modified polyurethane resin

A polyurethane resin and bio-based technology, which is applied in the field of polyurethane resin preparation for synthetic leather, can solve problems such as weak bonding strength, and achieve the effect of improving easy delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

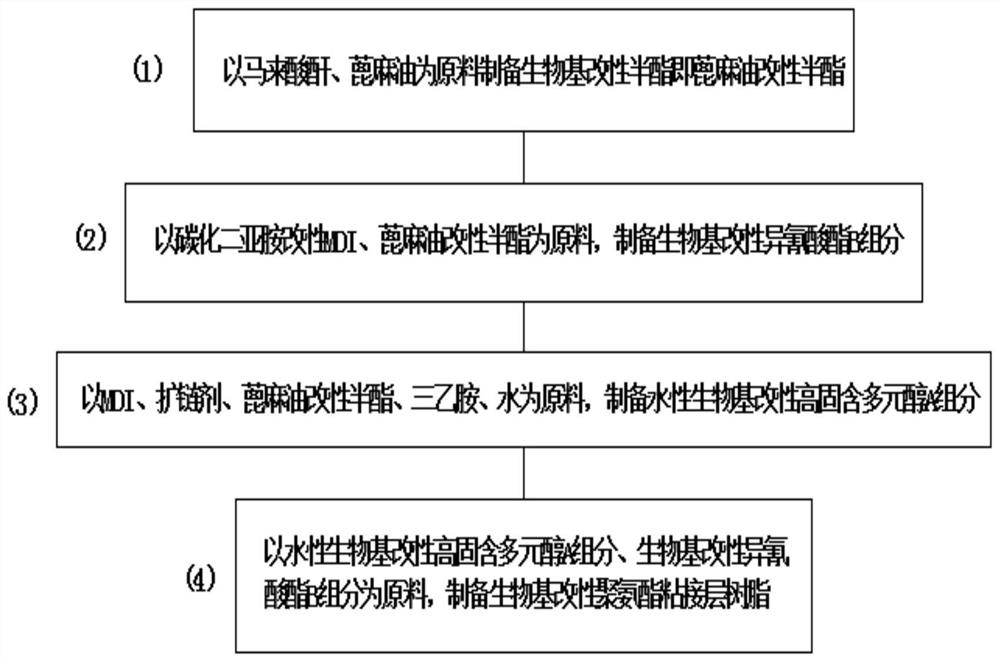

[0055] Such as figure 1 Shown, a kind of preparation method of bio-based modified polyurethane resin comprises the following steps:

[0056] (1), preparation of castor oil modified half ester:

[0057] Using maleic anhydride and castor oil as raw materials, add maleic anhydride and castor oil to the anti-vessel according to the molar ratio of 1.35:1-1.35:1.05 (the reaction of these two raw materials is basically an equimolar ratio reaction, and the numerical ratio range cannot be large) The reaction is carried out until the acid value detected in the reaction vessel is stable, and the bio-based modified half-ester is obtained, that is, the castor oil modified half-ester. The molecular structural formula of the prepared castor oil-modified half-ester is:

[0058]

[0059] In the molecular structural formula of castor oil modified half ester, The specific structure is

[0060]

[0061] (2), preparation of bio-based modified isocyanate B component:

[0062] Take by wei...

Embodiment 1

[0080] A preparation method of bio-based modified polyurethane resin, comprising the steps of:

[0081] (1) Preparation of bio-based modified half-esters

[0082] Add castor oil into the reaction bottle, dehydrate at 100°C and -0.095MPa for 2 hours, cool to 60°C, then add maleic anhydride at a molar ratio of 1.35 / 1, stir until all solids are dissolved, then heat up to 78°C for 6 hours until the detected acid value is basically stable, that is, the bio-based modified half-ester, ie castor oil-modified half-ester, is prepared. The hydroxyl value of the obtained castor oil modified half ester is 105mgKOH / g, and the acid value is 52.5mgKOH / g;

[0083] (2) Preparation of bio-based modified isocyanate B component

[0084]First, the temperature of the reaction flask is set to 55° C., and in parts by mass, 60 parts of carbodiimide modified MDI and 100 parts of castor oil modified half esters obtained in step (1) are added to the reaction flask, and the temperature is raised to Stir...

Embodiment 2

[0091] A preparation method of bio-based modified polyurethane resin, comprising the steps of:

[0092] (1) Preparation of bio-based modified half-esters

[0093] Add castor oil into the reaction bottle, dehydrate at 110°C and -0.09MPa for 3 hours, cool to 65°C, then add maleic anhydride at a molar ratio of 1.35 / 1.05, stir until all solids are dissolved, then heat up to 82°C for 4 hours , until the detected acid value is basically stable, and the bio-based modified half-ester, that is, the castor oil-modified half-ester, is prepared. The hydroxyl value of the castor oil modified half ester obtained is 106mgKOH / g, and the acid value is 53mgKOH / g;

[0094] (2) Preparation of bio-based modified isocyanate B component

[0095] First, the temperature of the reaction flask is set to 65° C., and in parts by mass, 84.5 parts of carbodiimide modified MDI and 100 parts of castor oil modified half esters prepared in step (1) are added to the reaction flask, and the temperature is raise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com