Scratch hardness test method

A test method and technology of scratch hardness, applied in the direction of testing material hardness, etc., can solve the problems of insufficient accuracy of scratch hardness measurement, large measurement error, and material damage around the test piece, so as to achieve good popularity and test error Small and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

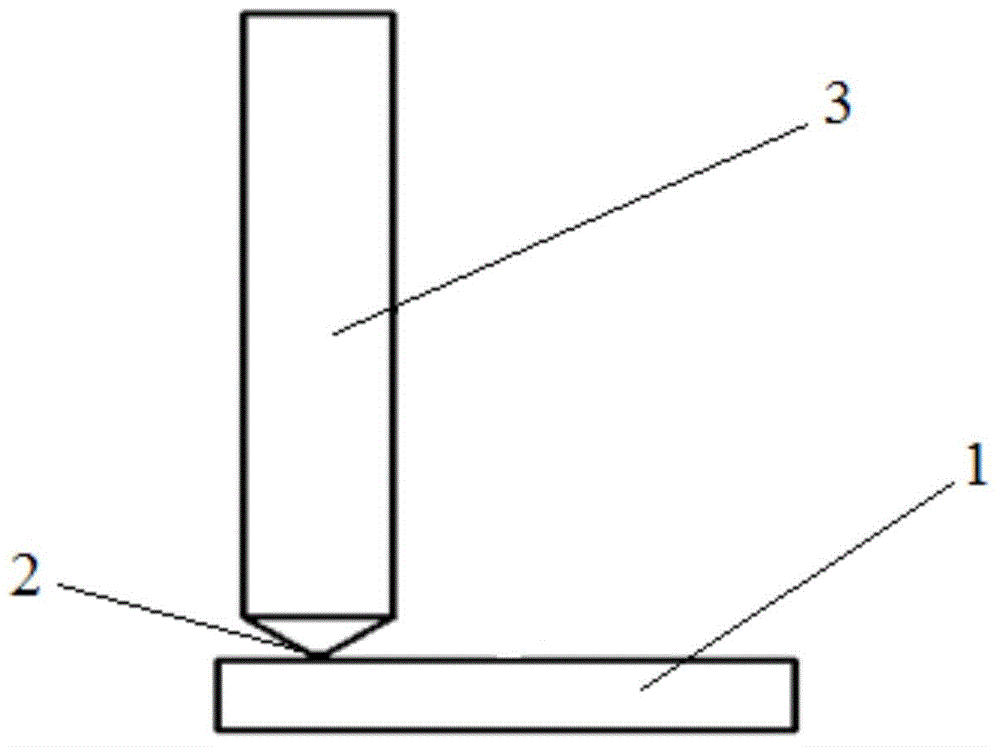

[0037] Such as figure 1 Shown, a kind of scratch hardness test method, this test method specifically comprises the following steps:

[0038] (1) Clean the sample 1 to be tested and dry it;

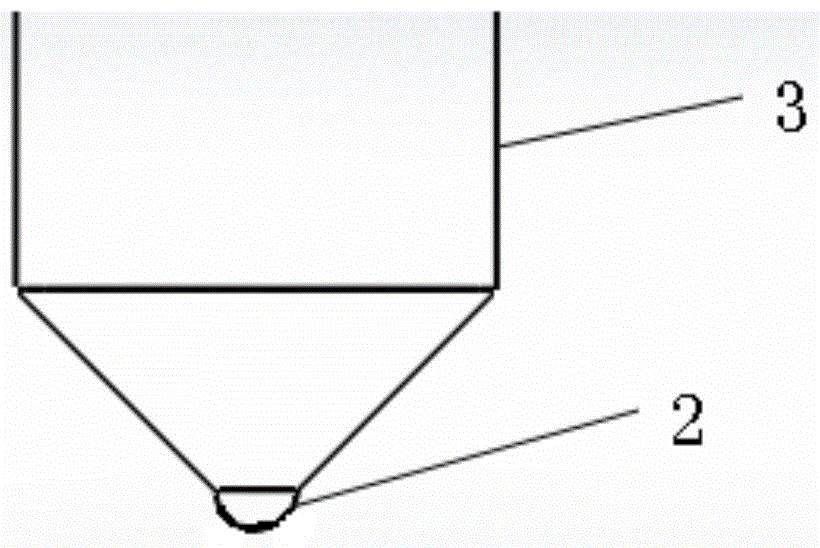

[0039] (2) Fix the sample 1 to be tested on the base of the testing machine, and fix the contact pin 3 provided with the indenter 2 on the fixture of the testing machine, adjust the direction of the stylus so that the indenter 2 is perpendicular to the test machine Surface of sample 1;

[0040] (3) Set the pressure P and the scratching speed of the indenter 2 on the surface of the sample 1 to be tested by the testing machine;

[0041] (4) Turn on the power and carry out the scratch test;

[0042] (5) After the scratch test is finished, measure the scratch width at 3-5 places on the surface of the sample to be tested 1, and get the average value W of the scratch width;

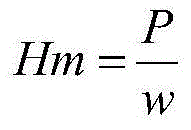

[0043] (6) Calculate the scratch hardness value according to the average value of the scratch width product and the p...

Embodiment 2

[0052] The scratch hardness test method of the present embodiment specifically comprises the following steps:

[0053] (1) Clean the sample 1 to be tested and dry it;

[0054] (2) Fix the sample 1 to be tested on the base of the testing machine, and fix the contact pin 3 provided with the indenter 2 on the fixture of the testing machine, adjust the direction of the stylus so that the indenter 2 is perpendicular to the test machine Surface of sample 1;

[0055] (3) Set the pressure P and the scratching speed of the indenter 2 on the surface of the sample 1 to be tested by the testing machine;

[0056] (4) Turn on the power and carry out the scratch test;

[0057] (5) After the scratch test is finished, measure the scratch width at 3-5 places on the surface of the sample to be tested 1, and get the average value W of the scratch width;

[0058] (6) Calculate the scratch hardness value according to the average value of the scratch width product and the pressure P, the formula ...

Embodiment 3

[0067] The scratch hardness test method of the present embodiment specifically comprises the following steps:

[0068] (1) Clean the sample 1 to be tested and dry it;

[0069](2) Fix the sample 1 to be tested on the base of the testing machine, and fix the contact pin 3 provided with the indenter 2 on the fixture of the testing machine, adjust the direction of the stylus so that the indenter 2 is perpendicular to the test machine Surface of sample 1;

[0070] (3) Set the pressure P and the scratching speed of the indenter 2 on the surface of the sample 1 to be tested by the testing machine;

[0071] (4) Turn on the power and carry out the scratch test;

[0072] (5) After the scratch test is finished, measure the scratch width at 3-5 places on the surface of the sample to be tested 1, and get the average value W of the scratch width;

[0073] (6) Calculate the scratch hardness value according to the average value of the scratch width product and the pressure P, the formula i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com