High-solid automobile finish varnish and preparation method thereof

A high-solid varnish technology, applied in coatings and other directions, can solve problems such as poor leveling, lower gloss, and increased costs, and achieve good weather resistance, increase construction solids, and reduce VOC emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

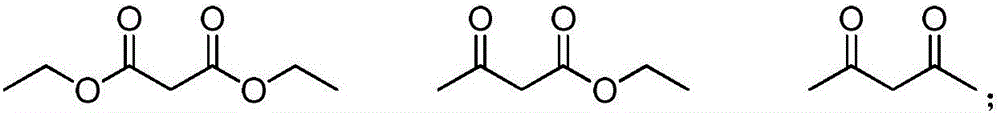

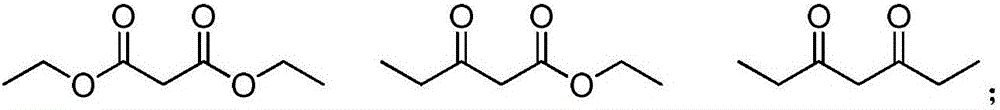

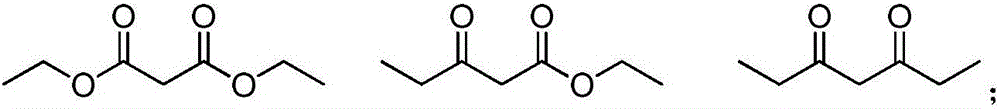

Image

Examples

preparation example Construction

[0026] Preparation of polyester resin A containing special functional groups: 416 parts of neopentyl glycol, 582 parts of dimethyl malonate and 2 parts of DBTO mixture were placed in a four-necked flask equipped with a stirrer and a condenser, Stir and heat up to 105°C under a nitrogen atmosphere, and continue to heat up to 190°C. Then 20 parts of hexane was added, and the methanol produced was removed by azeotropic distillation. Cool down to 160 DEG C and add 165 parts of xylenes subsequently, obtain polyester resin A containing special functional group, this resin non-volatile matter is 80.0%, acid value 0.3, hydroxyl content 1.88% (accounting for resin weight), number-average molecular weight 2450, activity The hydrogen equivalent is 245 (calculated according to the resin design structure, the same below).

[0027] Preparation of polyester resin B containing special functional groups: 216 parts of dimethylolcyclohexane, 158 parts of 1,6-hexanediol, 320 parts of dimethyl ma...

Embodiment

[0032] The weight percentages of the resins prepared in Examples 1-4 and Comparative Examples 1-2 are shown in Table 1, and they were formulated into varnishes with a solid content of 55-60% in the original paint.

[0033] The preparation process of the varnish is as follows: after cleaning the equipment with trimethylbenzene to confirm the cleanliness before feeding, put component a, component b, component c and component d into the main tank in sequence, and stir at 1000±100rpm for 1 hour until all components are mixed evenly , then add the catalyst, additives and solvent trimethylbenzene sequentially under the stirring state, stir at 500±50rpm for 30min, QC detects that the fineness of the varnish is <5μm, and sprays the plate (tinplate plate, 20×20cm) to check whether the varnish has shrinkage cavities, such as fine If the degree and shrinkage condition are qualified, it will be packaged and discharged.

[0034] Then, a single-layer varnish film with a thickness of 23±2μm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com