Automotive waterborne floating-coat coating and preparation method thereof

A water-based, automotive technology, applied in the field of coatings, which can solve problems such as patented technology or lack of technical documents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A water-based intermediate coating for automobiles, which includes component A and component B, wherein component A includes: 20% of water-based polyester resin, 25% of water-based epoxy resin, and 20% of water-soluble pigment in parts by weight , talcum powder 3%, calcium carbonate 15%, water-based polyurethane defoamer 0.1%, water-based methyl etherified amino resin 0.4%, fumed silica anti-settling agent 0.2%, leveling agent 0.2%, wetting agent 0.7%, Anti-flash rust agent 1.2%, deionized water 14.2%; B component is a blocked water-based isocyanate curing agent; the weight ratio of A component and B component is 11:1.

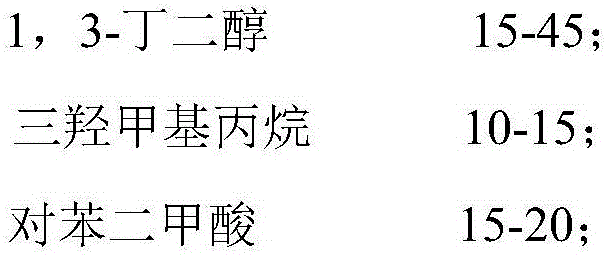

[0027] Wherein, in the water-based polyester resin, according to parts by weight, including:

[0028]

[0029] Among them, the leveling agent is BYK-333, the wetting agent is BYK-345, and the anti-flash rust agent is CORV609B.

[0030] The preparation method of the above-mentioned automobile water-based intermediate coating is: in the feed tank unde...

Embodiment 2

[0033] A water-based intermediate coating for automobiles, which includes component A and component B, wherein component A includes: 25% of water-based polyester resin, 30% of water-based epoxy resin, and 15% of water-soluble pigment in parts by weight , talcum powder 5%, calcium carbonate 18%, water-based polyurethane defoamer 0.2%, water-based methyl etherified amino resin 0.5%, fumed silica anti-settling agent 0.3%, leveling agent 0.4%, wetting agent 1%, Anti-flash rust agent 1%, deionized water 3.6%; B component is a blocked water-based isocyanate curing agent; the weight ratio of A component and B component is 13:1.

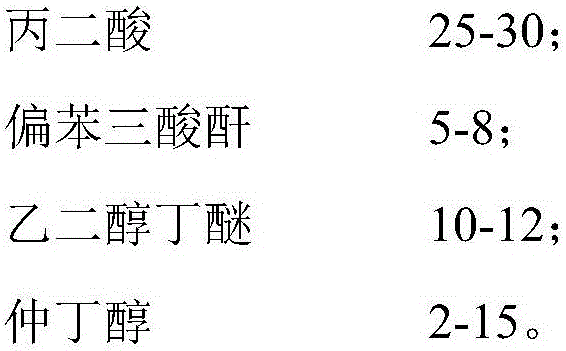

[0034] Wherein, in the water-based polyester resin, according to parts by weight, including:

[0035]

[0036] Among them, the leveling agent is BYK-333, the wetting agent is BYK-348, and the anti-flash rust agent is CORB.

[0037] The preparation method of the above-mentioned automobile water-based intermediate coating is: in the feed tank under the pro...

Embodiment 3

[0040] A water-based intermediate coating for automobiles, which includes component A and component B, wherein component A includes: 30% of water-based polyester resin, 30% of water-based epoxy resin, and 15% of water-soluble pigment in parts by weight , talcum powder 3%, calcium carbonate 15%, water-based polyurethane defoamer 0.2%, water-based methyl etherified amino resin 0.5%, fumed silica anti-settling agent 0.5%, leveling agent 0.4%, wetting agent 1%, Anti-flash rust agent 1.5%, deionized water 0.7%; B component is a blocked water-based isocyanate curing agent; the weight ratio of A component and B component is 14:1.

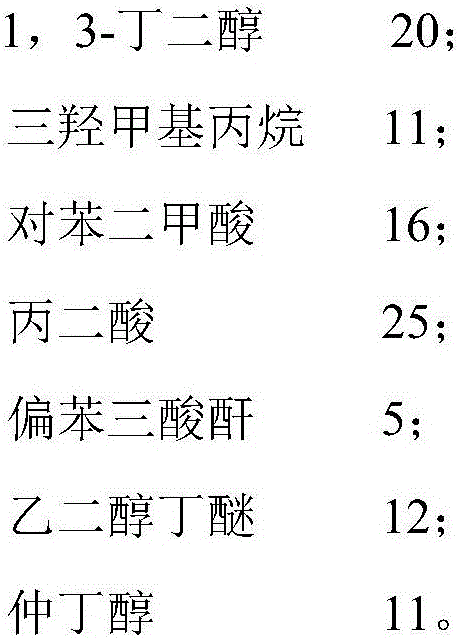

[0041] Wherein, in the water-based polyester resin, according to parts by weight, including:

[0042]

[0043] Among them, the leveling agent is BYK-420, the wetting agent is BYK-345, and the anti-flash rust agent is CORB.

[0044] The preparation method of the above-mentioned automobile water-based intermediate coating is: in the feed tank under the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com