Scratch hardness reference device

A reference device and Leeb hardness technology, which is applied in the direction of testing the hardness of materials, etc., can solve the problems of poor long-term stability and low measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

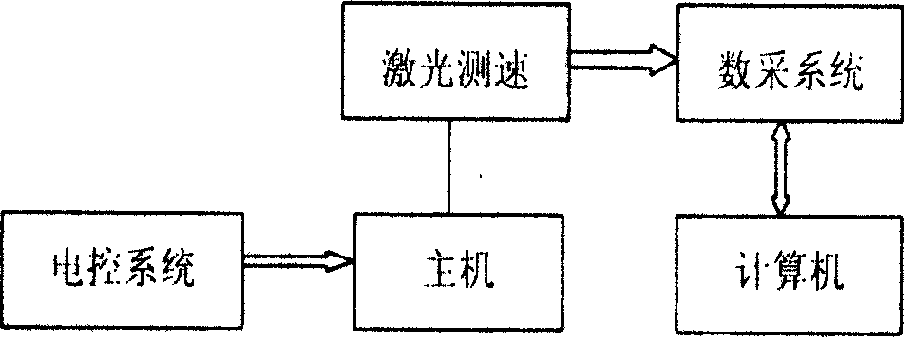

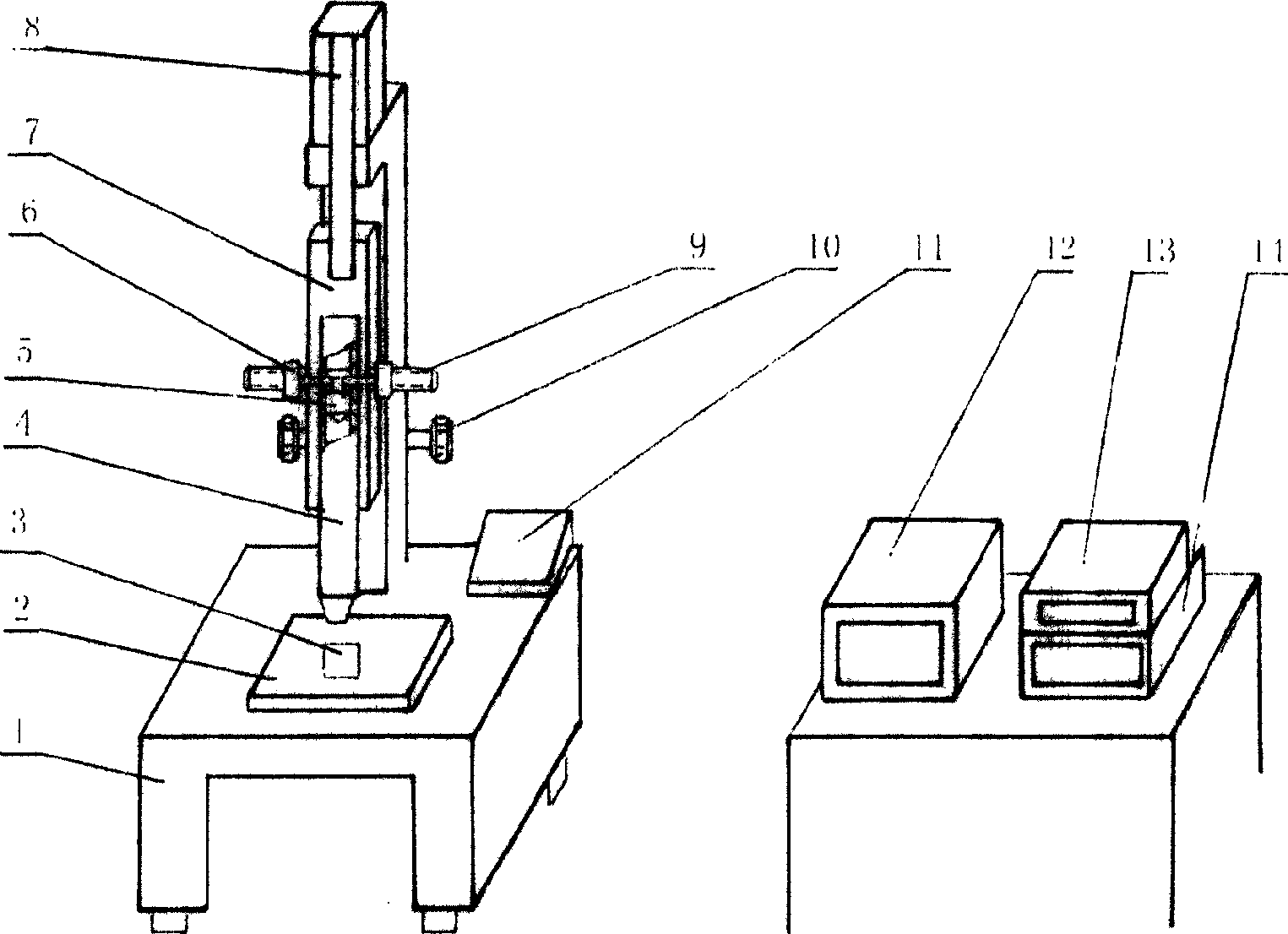

[0020] The present invention is a device with a high degree of automation integrating optical, mechanical and electrical systems, and is composed of a host, an impact body, an electric control system, a laser Doppler speed measurement system, a data acquisition system, and a data processing system. For the structure diagram, see figure 2 .

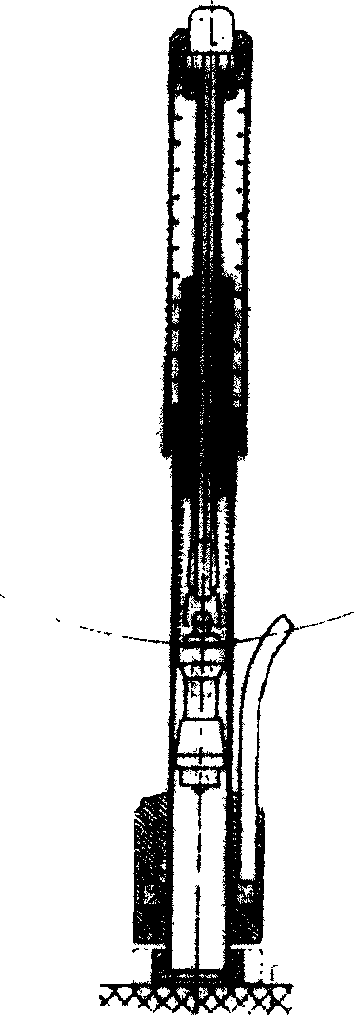

[0021] The main engine consists of a base (1), a worktable (2), a guide cylinder (4), an impact body (5), an impact body release clamping mechanism (6), a lifting guide rail (7), a screw rod (9) and a lifting hand wheel (10) and so on. Its base weighs 400 kg, is firm and stable, and meets the requirements of the Leeb hardness dynamic test. The lifting mechanism and the clamping mechanism are used to release the D-type impact body and the G-type impact body for the verification of the Leeb hardness HLD and HLG scales. The mass of the impact body (5) is 5.5g±0.05g for type D and 20g±0.05g for type G. There is a step on the top, which is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com