Electric motor with torque sensor

A torque sensor and motor technology, applied in the field of motors, can solve problems such as the influence of test accuracy fluctuations, achieve the effects of reducing installation space, avoiding conversion errors, and improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

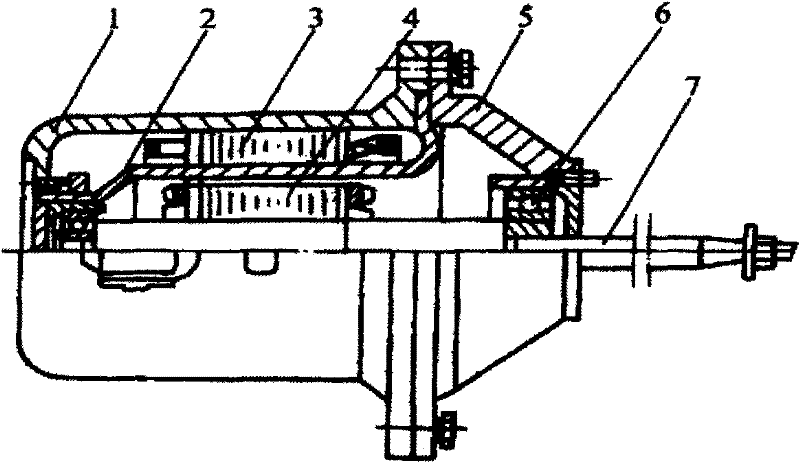

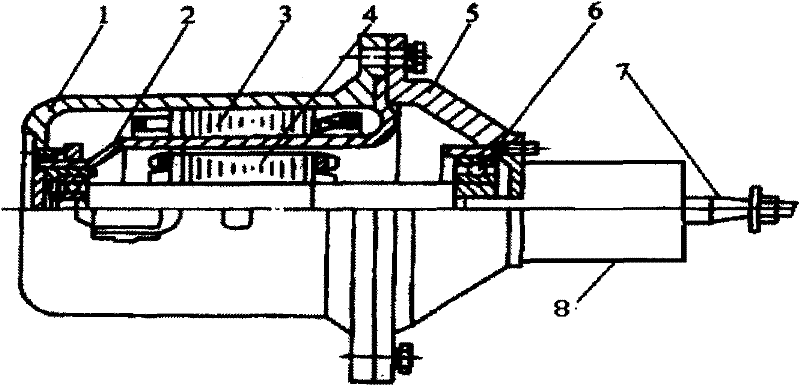

[0022] Such as figure 2 As shown, the motor with torque sensor of the present invention includes a motor shaft 7 and a motor front cover 5 . A torque sensor 8 is sleeved on the outwardly extending end of the motor shaft 7, and the rear end of the housing of the torque sensor is fixedly connected to the front end cover 5 of the motor. connect.

[0023] When the motor is working, the torque sensor 8 rotates together with the motor shaft 7, and simultaneously tests the working torque on the motor shaft 7. And its shell 10 is then fixed together with the motor front end cover 5, does not rotate with the motor rotating shaft 7. There is a pair of rolling bearings 11 between the housing 10 and the motor shaft 7 so that they can rotate relative to each other without affecting each other.

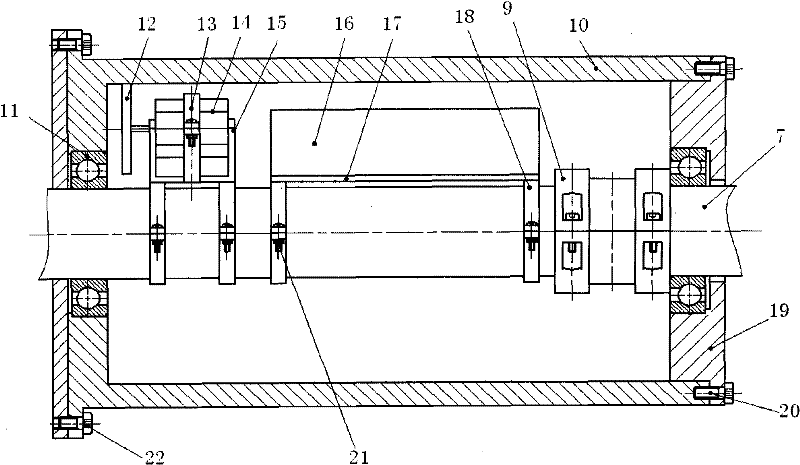

[0024] Such as image 3 As shown, the torque sensor 8 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com