Garage embedding fiber covering material

A covering material and fiber technology, applied in the field of landfill fiber covering material, can solve the problems of enterprise odor, environment pollution, untreated, etc., and achieve the effect of less equipment investment, purification of the environment, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

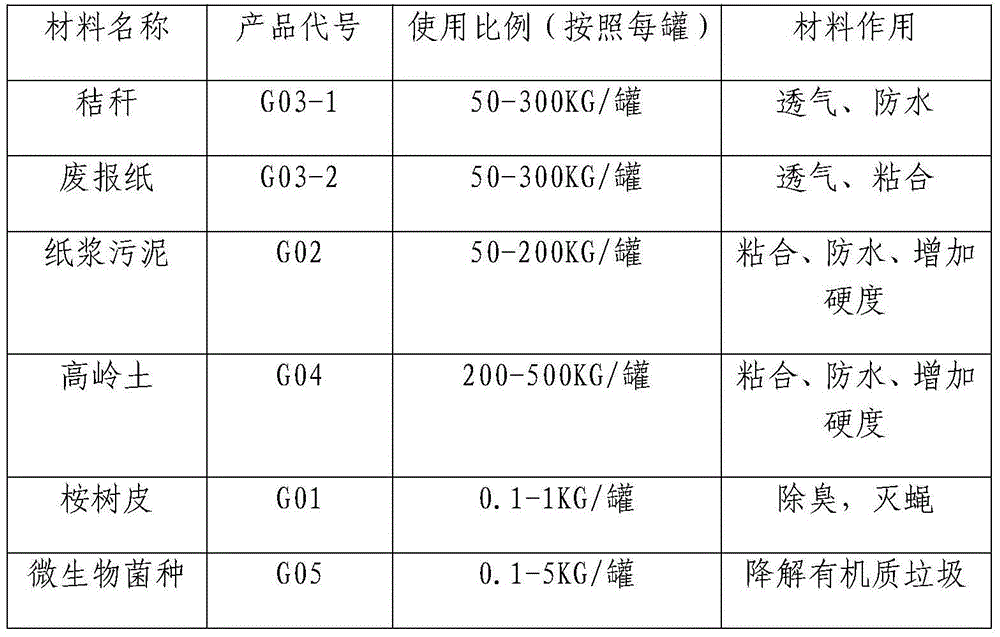

[0047] Material details: as in Table 1

[0048] Table 1

[0049]

[0050] Wherein the microbial strain described in is a spore strain solution, wherein each gram of the microbial strain solution contains more than 1 billion microorganisms, and the strain is MW011 strain.

[0051] The production method is:

[0052] 1. Grind straw and eucalyptus bark into powder, and make paper into pulp;

[0053] 2. Then mix the above-mentioned amounts of straw, eucalyptus bark, paper, and pulp sludge, and add water to make a paste mixture, then adjust the pH value of the paste mixture to 5.0-9.0, and then add the above-mentioned amount of microbial strain solution , stir evenly to make a mixture containing microorganisms;

[0054] 3. Before use, add kaolin into the mixture containing microorganisms according to the above ratio, and stir evenly to make the landfill fiber covering material.

[0055] When in use, make a paste of landfill fiber covering material according to the above step...

Embodiment 2

[0058] Material details: as shown in Table 2

[0059] Table 2

[0060] material name product code Use ratio (according to each can) material effect straw G03-1 100-200KG / can breathable, waterproof waste newspaper G03-2 100-200KG / can Adhesive, breathable pulp sludge G02 115-125KG / can waterproof, increased hardness Kaolin G04 275-400KG / can waterproof, increased hardness Eucalyptus bark G01 0.3-0.5KG / can Deodorizing, killing flies, Microbial strain G05 0.8-1KG / can Degradation of organic waste

[0061] Wherein the microbial strain described in is a spore strain solution, wherein each gram of the microbial strain solution contains more than 1 billion microorganisms.

[0062] Its preparation method comprises the following steps:

[0063] 1. Microbial strain production, the steps are as follows:

[0064] (1) Preparation of strain suspension, shake the strain evenly or use glass beads to break up, and gr...

Embodiment 3

[0079] Material details: as shown in Table 3

[0080] table 3

[0081] material name product code Use ratio (according to each can) material effect straw G03-1 100-200KG / can breathable, waterproof waste newspaper G03-2 100-200KG / can Adhesive, breathable pulp sludge G02 115-125KG / can waterproof, increased hardness Kaolin G04 275-400KG / can waterproof, increased hardness Eucalyptus bark G01 0.3-0.5KG / can Deodorize, kill flies Microbial strain G05 0.8-1KG / can Degradation of organic waste

[0082] [0082] Wherein the microbial strain described in is a spore strain solution, wherein each gram of the microbial strain solution contains more than 1 billion microorganisms.

[0083] Its preparation method comprises the following steps:

[0084] 1. Microbial strain production, the steps are as follows:

[0085] (1) Preparation of strain suspension, shake the strain evenly or use glass beads to break up, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com