Patents

Literature

82results about How to "Barrier infiltration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-retention and sand-fixing liquid mulching film and preparation method thereof

InactiveCN104804140AStrong water absorptionIncrease contactPlant protective coveringsCross-linkMoisture permeation

The invention relates to a water-retention and sand-fixing liquid mulching film and a preparation method thereof, and belongs to the technical field of agricultural production. The liquid mulching film comprises components in parts by weight as follows: 30-50 parts of ultrafine silica sol or nano-silica, 40-100 parts of carboxymethyl cellulose, 20-30 parts of N-isopropylacrylamide, 1-5 parts of ferrocene, 0.02-0.3 parts of a cross-linking agent and 0.4-1.2 parts of an initiator, wherein the solid content of the ultrafine silica sol is 10wt%-30wt%, and the particle size of silica is 1-100 nm. The liquid mulching film forms colloid easily with water, soil particles can be connected, structureless and dispersed sand soil is connected to form an elastic stable object, and a net-shaped film with good film performance and high strength is formed; one the one hand, surface pores of soil can be sealed, and soil moisture volatilization is blocked; on the other hand, moisture permeation is not inhibited, good water retention, soil moisture preservation and sand fixing functions are realized, and the performance of a desert and dry soil is improved effectively.

Owner:JIAXING GUOXING NEW MATERIAL TECH CO LTD

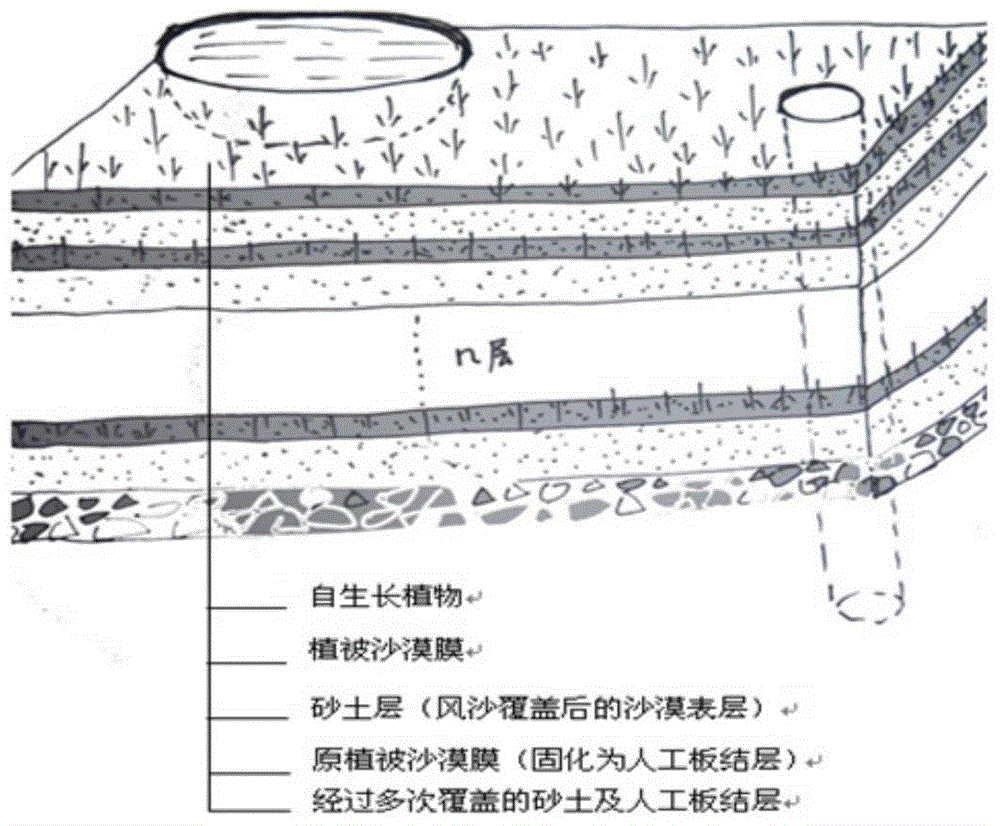

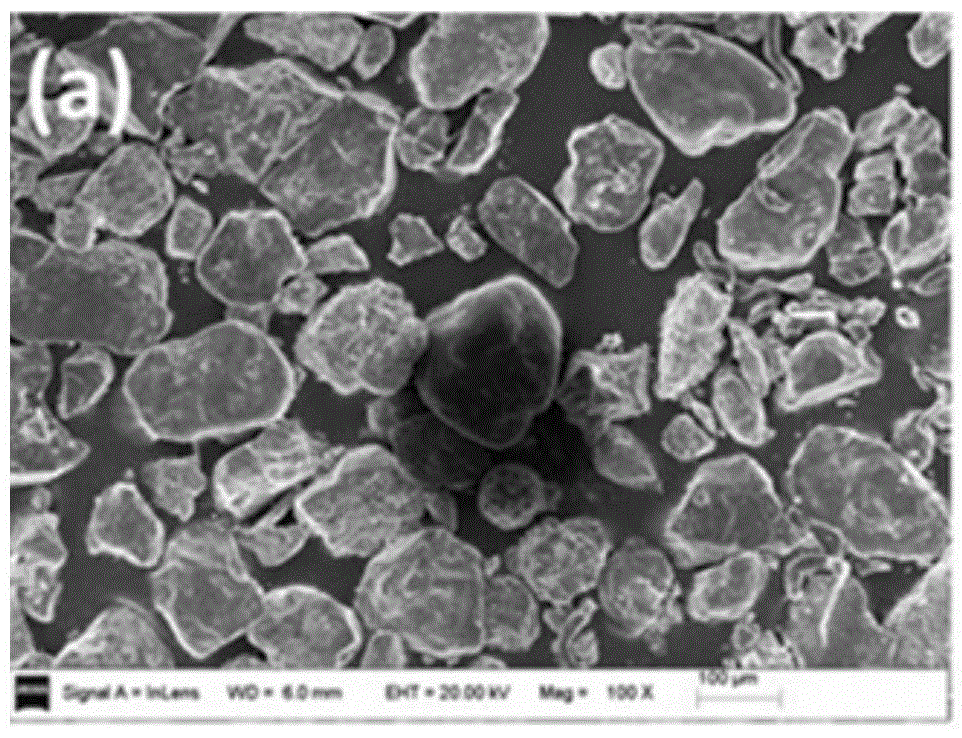

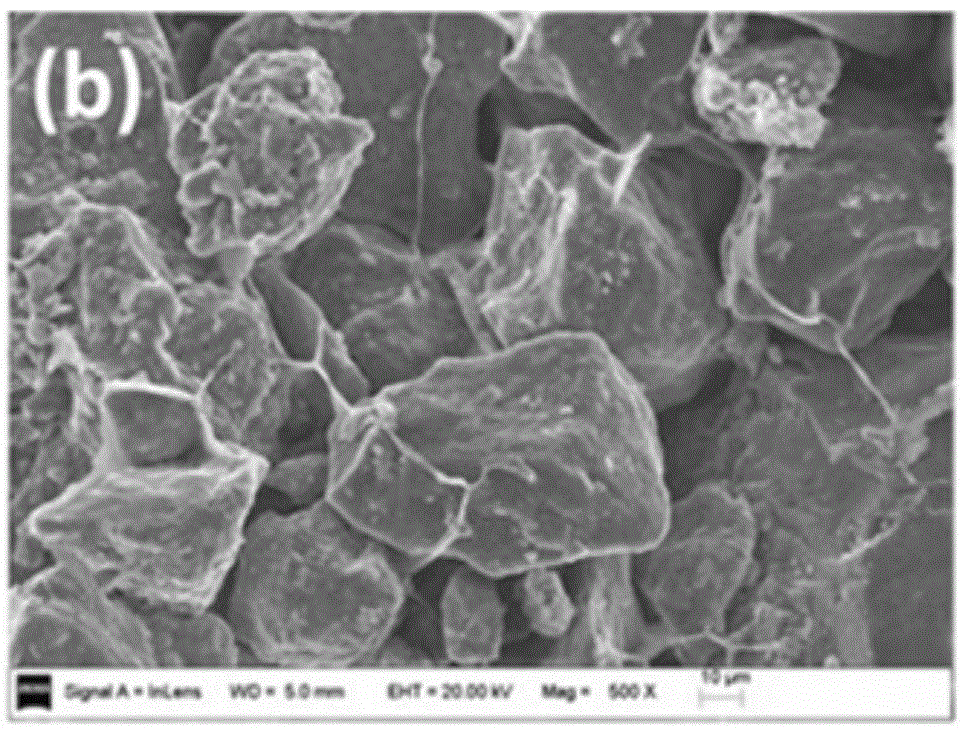

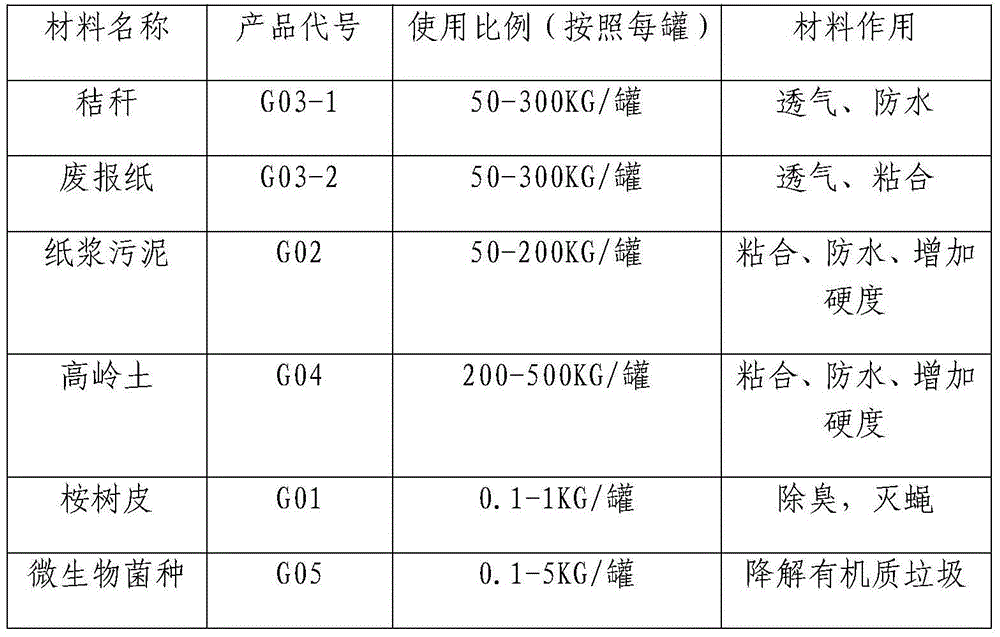

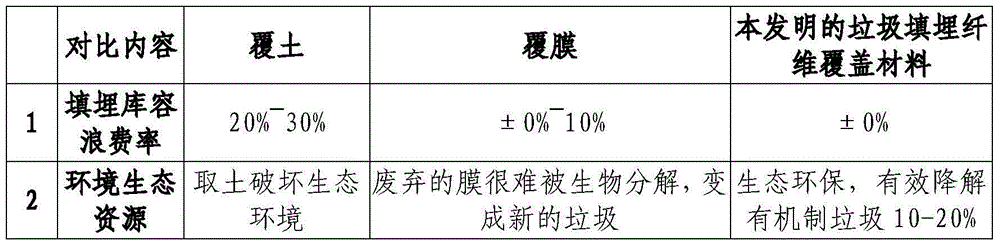

Garage embedding fiber covering material

The invention provides a garbage embedding fiber covering material which comprises the following components in parts by weight: 5-30 parts of straws, 5-30 parts of paper, 5-20 parts of pulp sludge, 20-50 parts of kaolin, 0.01-0.1 part of eucalyptus bark and 0.01-0.5 part of a microbial strain solution, wherein microbial strains are spore strains. After being used and dried, a coating of the garbage embedding fiber covering material provided by the invention has main dual effects of gas permeability and water guide; a core microbial technology for quickly degrading household garbage organic pollutants is uniquely added to quickly and effectively deodorize and kill flies for a long time; meanwhile, the garbage embedding fiber covering material has the necessary physical strength and flame resistance; moreover, by adding functional additives and grass seeds, operations such as deodorizing, fly killing and greening can be completed by one step in a spraying and covering process.

Owner:GUIZHOU OURUIXIN ENVIRONMENTAL PROTECTION TECH

Carburization prevention coating for ultralow carbon stainless steel casting

The invention discloses a carburization prevention coating for an ultralow carbon stainless steel casting. The carburization prevention coating is prepared by mixing 50 to 60 weight percent of white corundum powder, 5 to 10 percent of oxidant, 3 to 8 percent of sintering aid, 1 to 3 percent of organic binder, 2 to 5 percent of bentonite suspending agent, 0.2 to 0.4 percent of aid, and 28.8 to 38.2 percent of solvent; the granularity of the white corundum powder is less than or equal to 3 mu m, the granularity of the oxidant is less than or equal to 5 mu m, and the granularity of talcpowder isless than or equal to 5 mu m; the oxidant is one or more of potassium nitrate, potassium permanganate, potassium dichromate, and potassium chlorate; the sintering aid is one or more of talcpowder, feldspar powder, mica powder, and clay; and the organic binder is rosin or resin; and the solvent is ethanol or isopropanol, the concentration of ethanol is more than or equal to 95 percent, and the concentration of the isopropanol is more than or equal to 98 percent. The coating is poured into some ultralow carbon stainless steel castings of water turbine blades, and the thickness of a surface carburization layer of the ultralow carbon stainless steel casting on which the carburization prevention coating prepared according to the formula is poured is less than or equal to 3mm, and is obviously superior to that of the common coating.

Owner:SHENYANG RES INST OF FOUNDRY

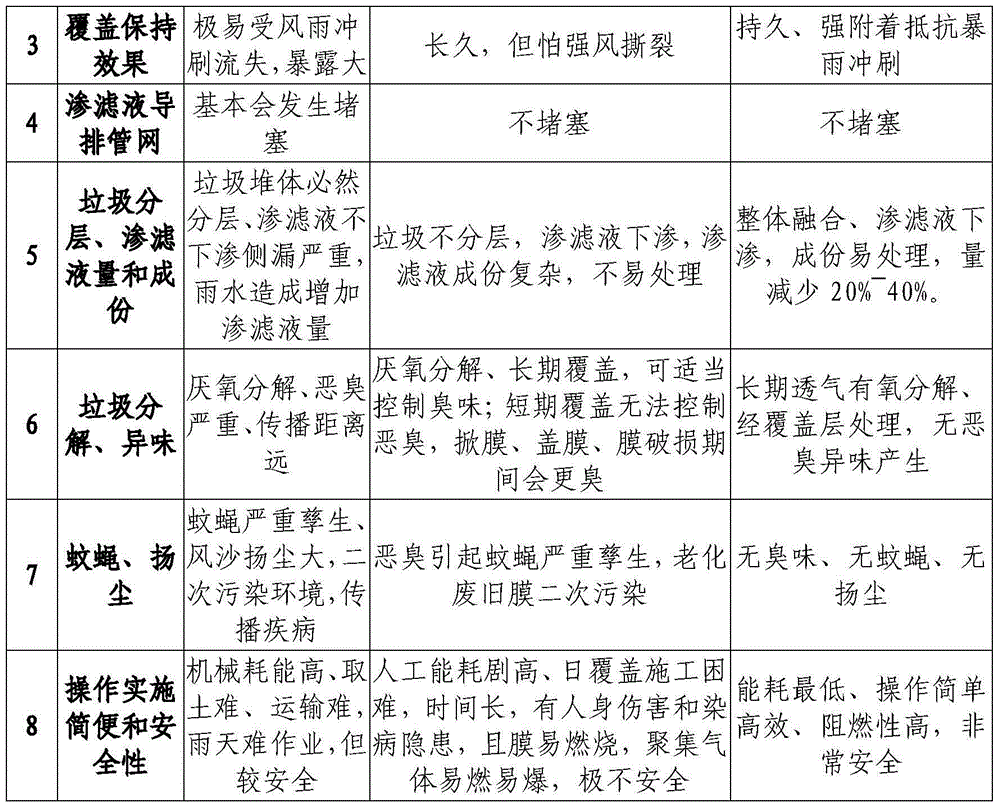

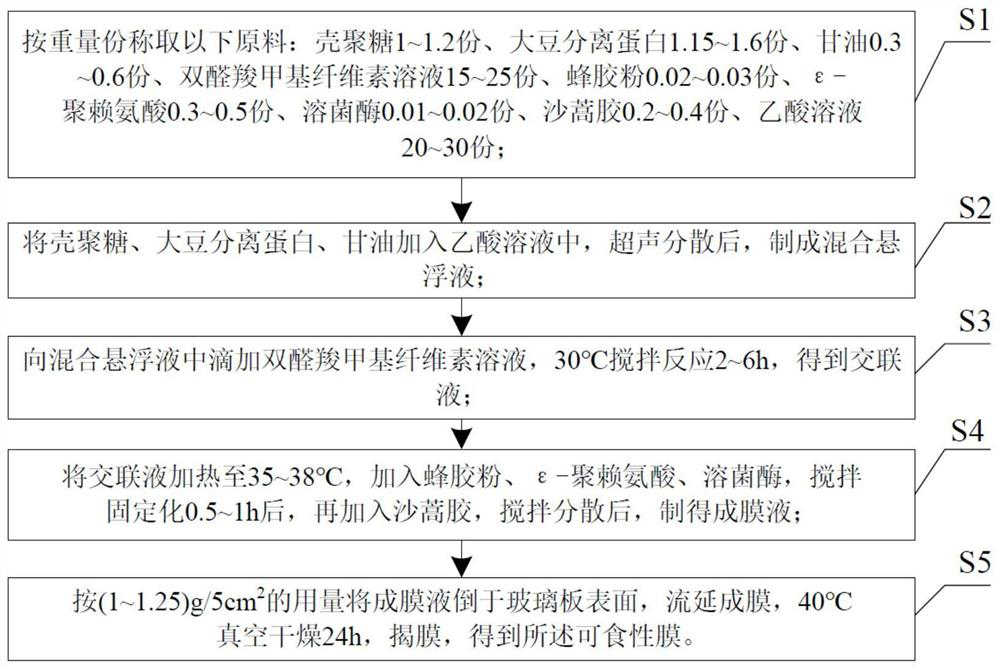

Treatment method for edible film for meat preservation

InactiveCN111635544ABarrier infiltrationAvoid churn dispersionMeat/fish preservation by coatingCelluloseBULK ACTIVE INGREDIENT

The invention discloses a preparation method of an edible film for meat preservation. The preparation method comprises the following steps: S1, weighing raw materials in parts by weight; S2, adding 1-1.2 parts of chitosan, 1.15-1.6 parts of soy isolate protein and 0.3-0.6 part of glycerol into 20-30 parts of an acetic acid solution, and performing ultrasonic dispersion to prepare a mixed suspension; S3, dropwise adding 15-25 parts of a dialdehyde carboxymethyl cellulose solution into the mixed suspension, and carrying out a stirring reaction at 30 DEG C for 2-6 h to obtain a cross-linking solution; S4, heating the cross-linking solution to 35-38 DEG C, adding 0.02-0.03 part of propolis powder, 0.3-0.5 part of epsilon-polylysine and 0.01-0.02 part of lysozyme, stirring and immobilizing for0.5-1 hour, then adding 0.2-0.4 part of artemisia desertorum gum, and stirring for dispersing to obtain a film forming solution; and S5, casting to form a film, carrying out vacuum drying at 40 DEG Cfor 24 hours, and uncovering the film. The dialdehyde carboxymethyl cellulose is used as a cross-linking agent, so that the compactness of the edible film is improved; epsilon-polylysine, lysozyme andthe like are further immobilized and enriched in a film structure, so loss and dispersion of active ingredients are avoided, and the shelf life and the storage time are remarkably prolonged.

Owner:BENGBU COLLEGE

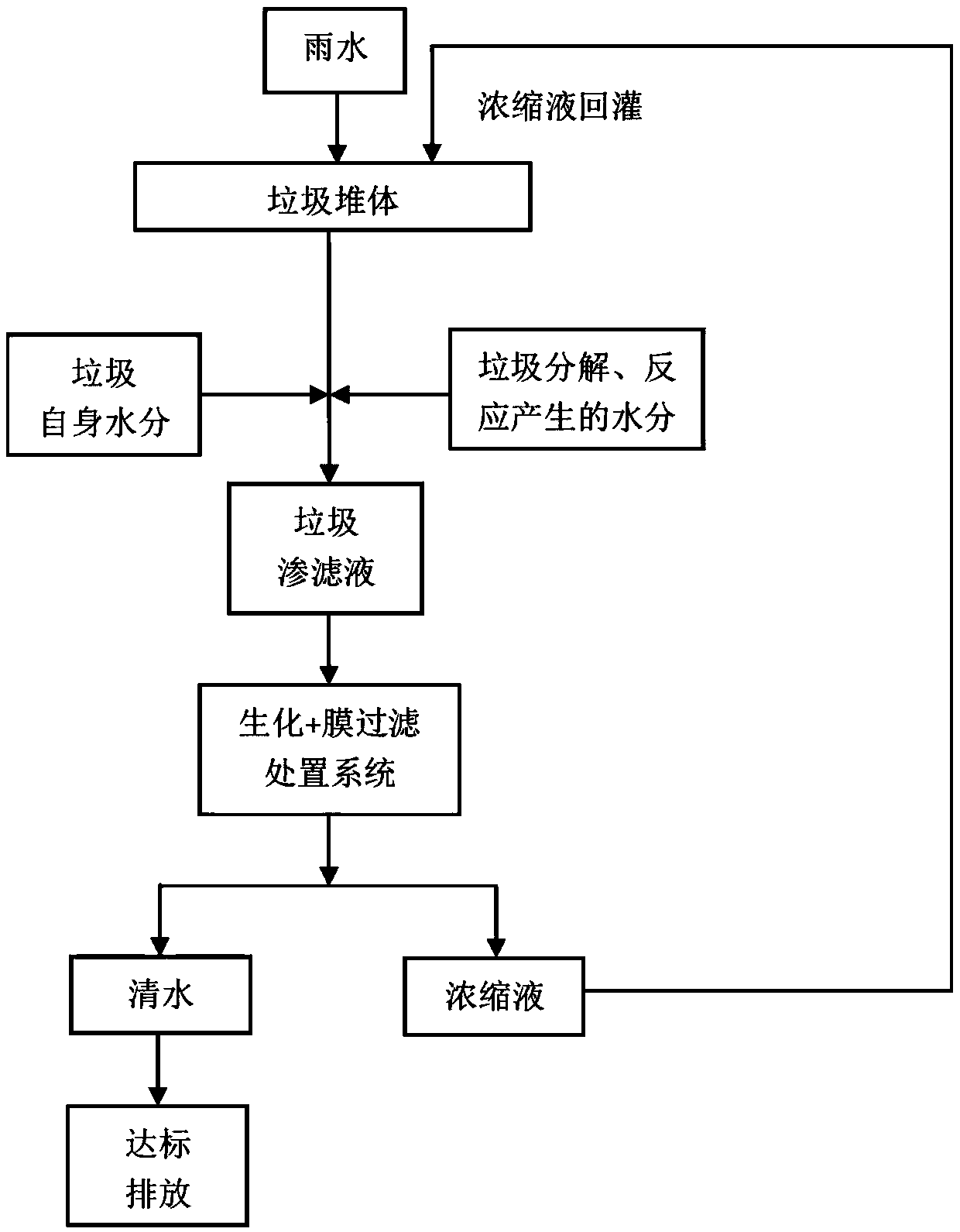

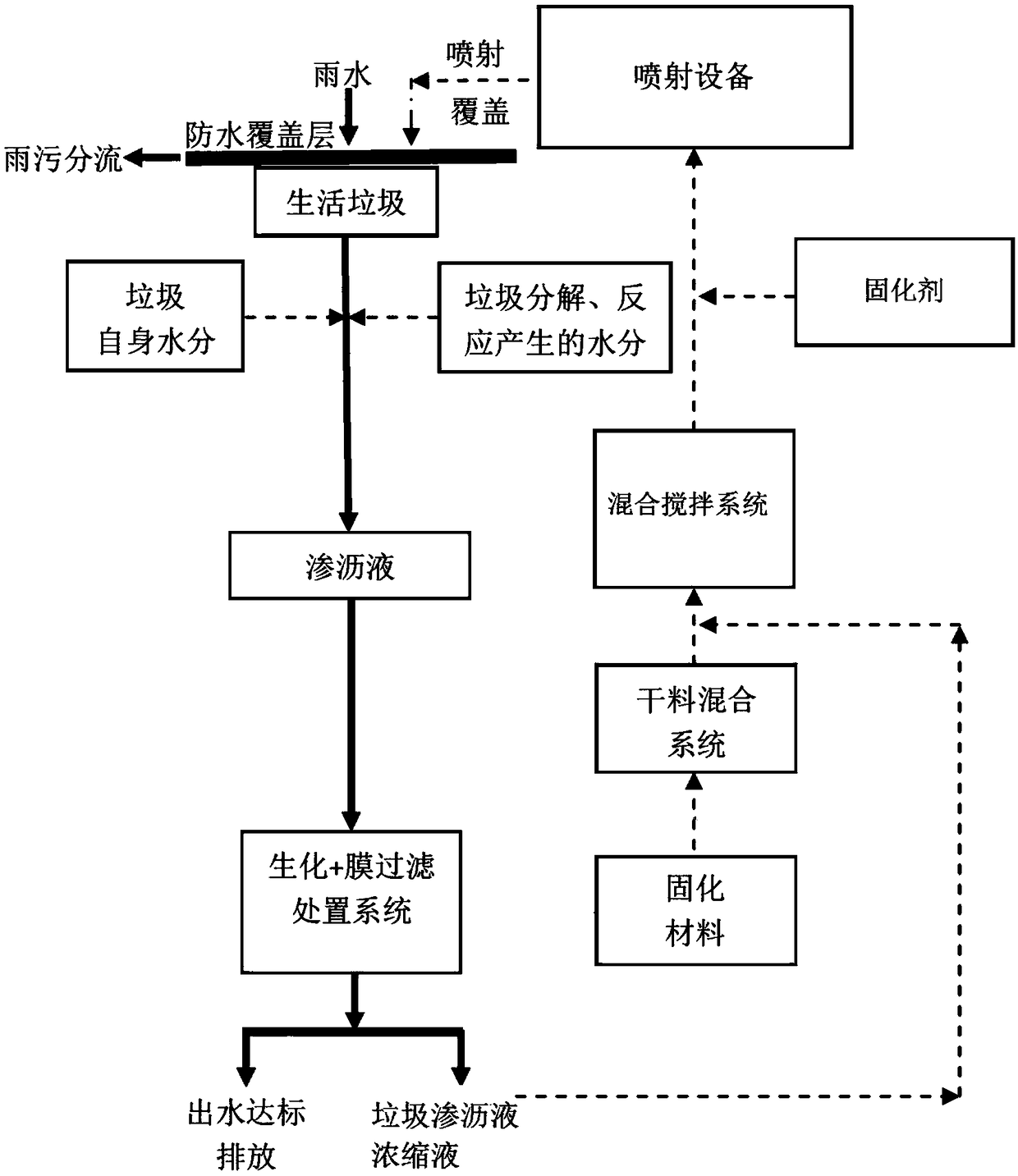

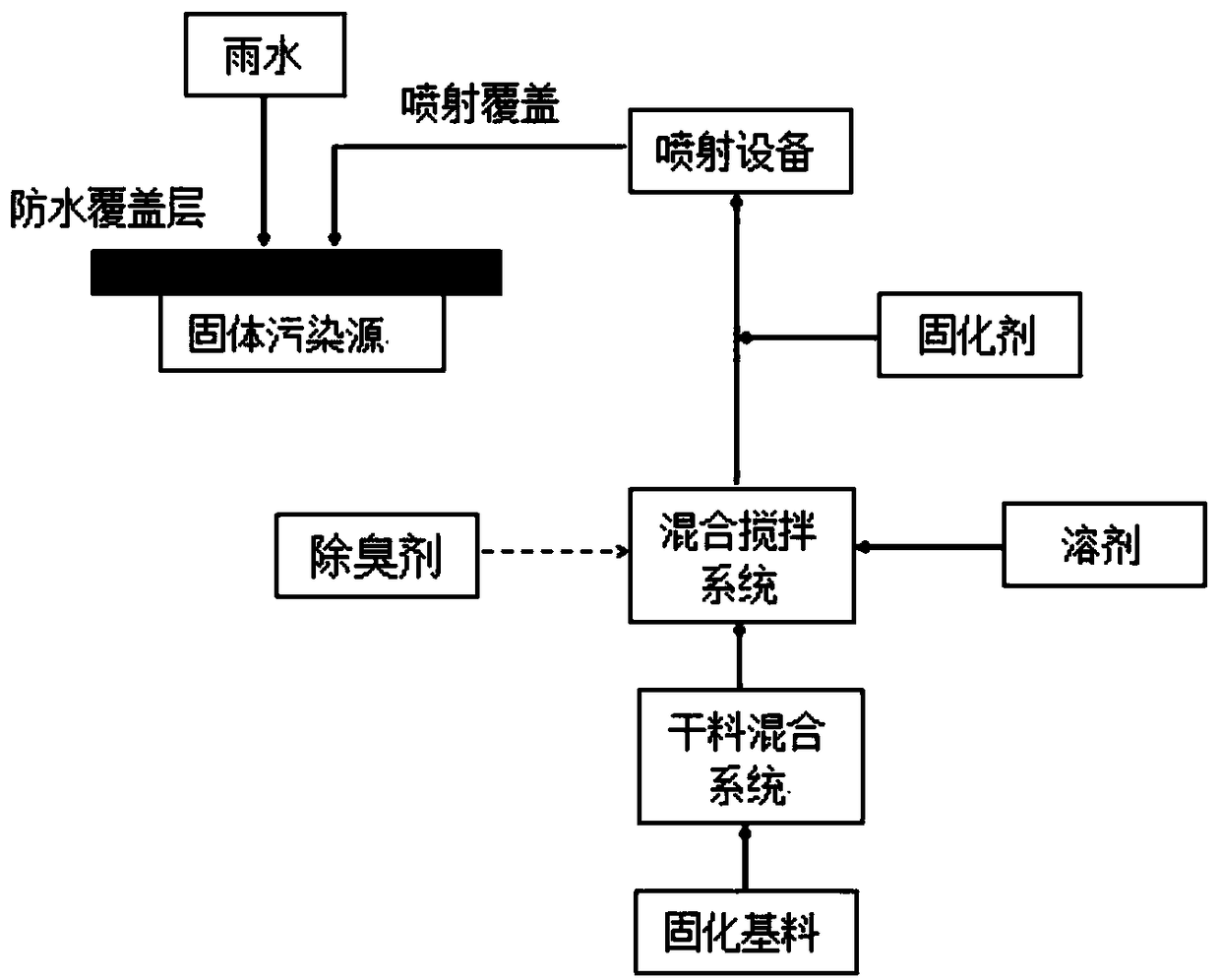

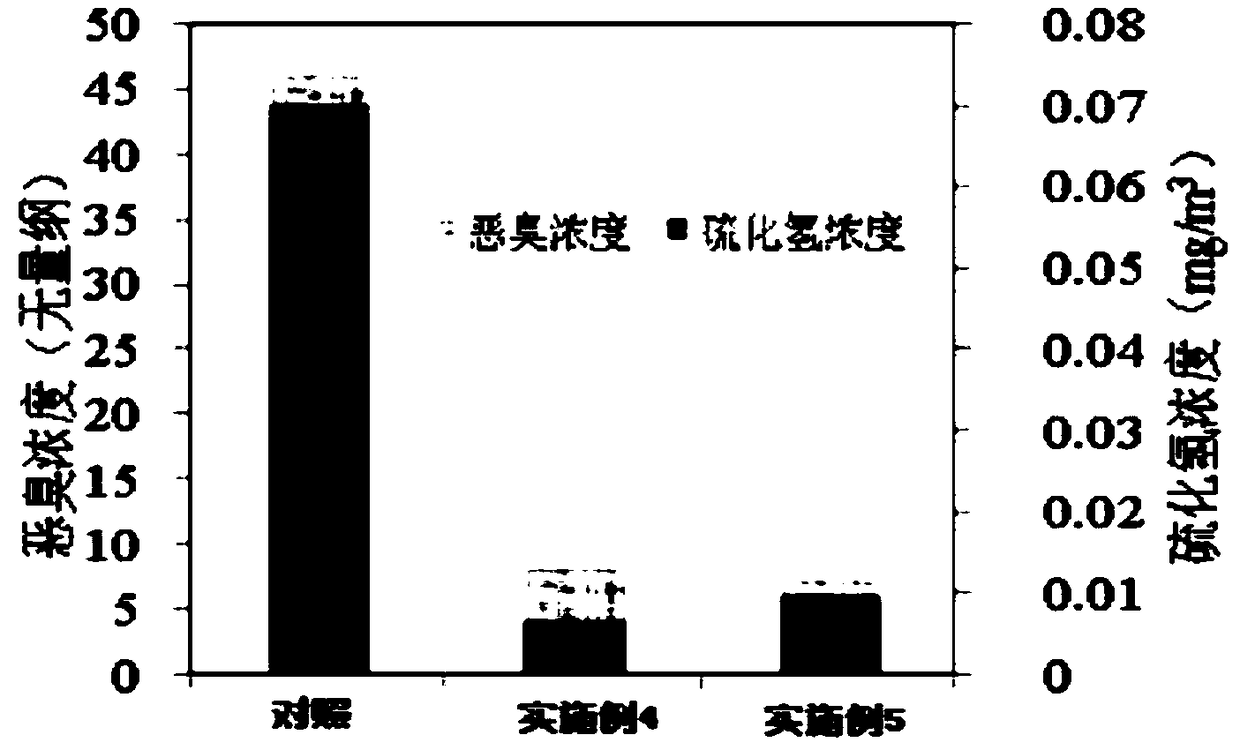

Concentrated solution resourceful treatment and refuse waterproof covering in-situ application process of refuse landfill

ActiveCN109332344APrevent floatingReduce formationLandfill technologiesSolid waste disposalFireproofingEnvironmental engineering

The invention discloses a concentrated solution resourceful treatment and refuse waterproof covering in-situ application process of a refuse landfill. The concentrated solution resourceful treatment and refuse waterproof covering in-situ application process comprises the following steps: (1) a solidified base material is put into a dry material mixing system to be mixed, and a solidified base material mixture is formed; (2) a concentrated solution generated after leachate is treated through a biochemical and film filtering process and the solidified base material mixture are put into a mixingstirring system jointly to be evenly stirred, and an even mixture is formed; and (3) a refuse leachate concentrated solution and a solidifying agent are added into the even mixture, a high-viscosity pasty composite material is formed, and the even mixture is evenly sprayed on the surface of an operating area of the refuse landfill through spraying equipment to directly cover the refuse landfill insitu. The surface of the operating area of the sanitary landfill is covered in situ directly, after drying, a hard film with rainproofing, fireproofing, odor isolating and deodorizing functions is formed, thus most rainwater is obstructed from permeating, and generation of the refuse leachate is reduced.

Owner:LIAONING HAITIANGE ENVIRONMENTAL PROTECTION TECH

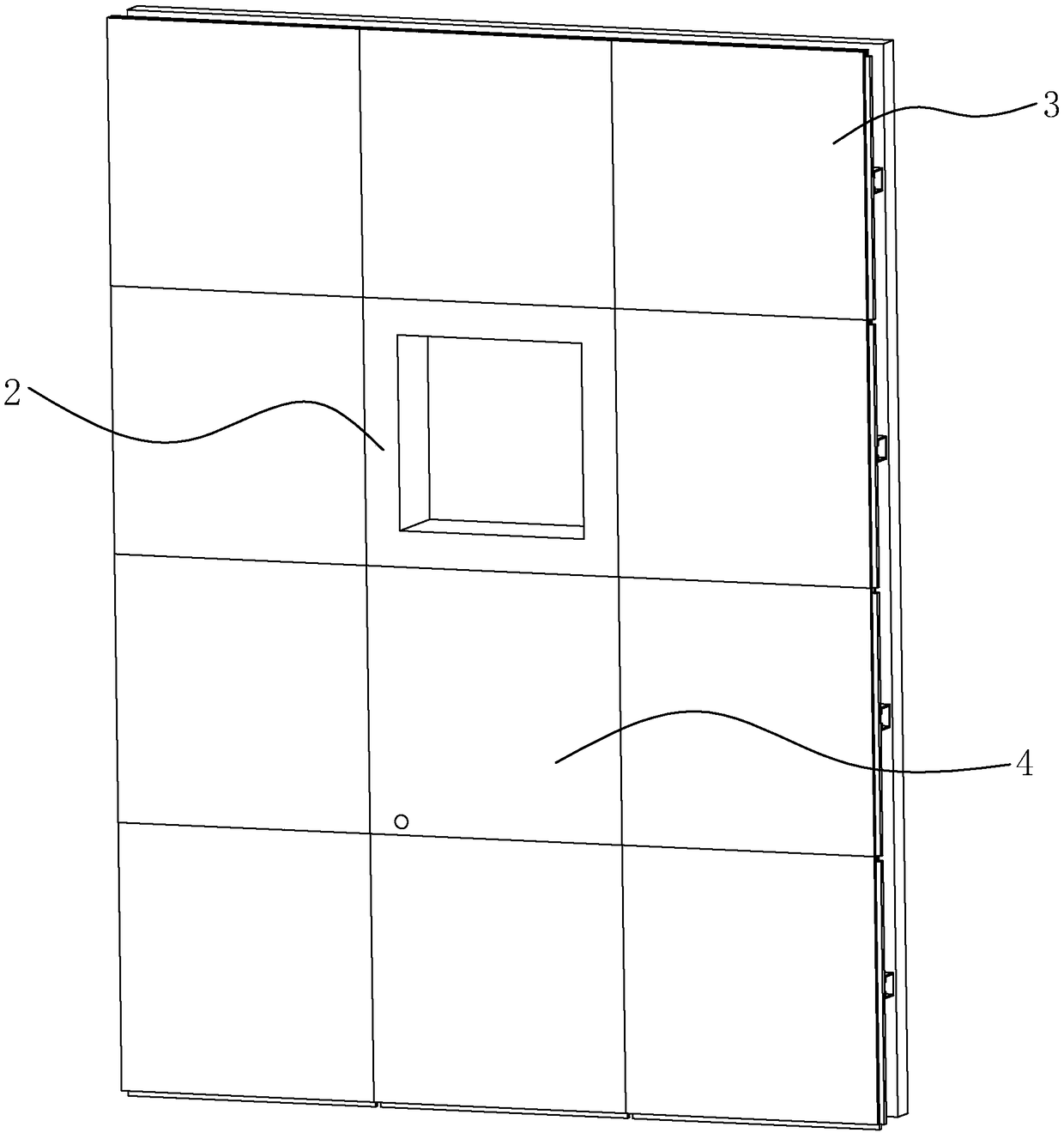

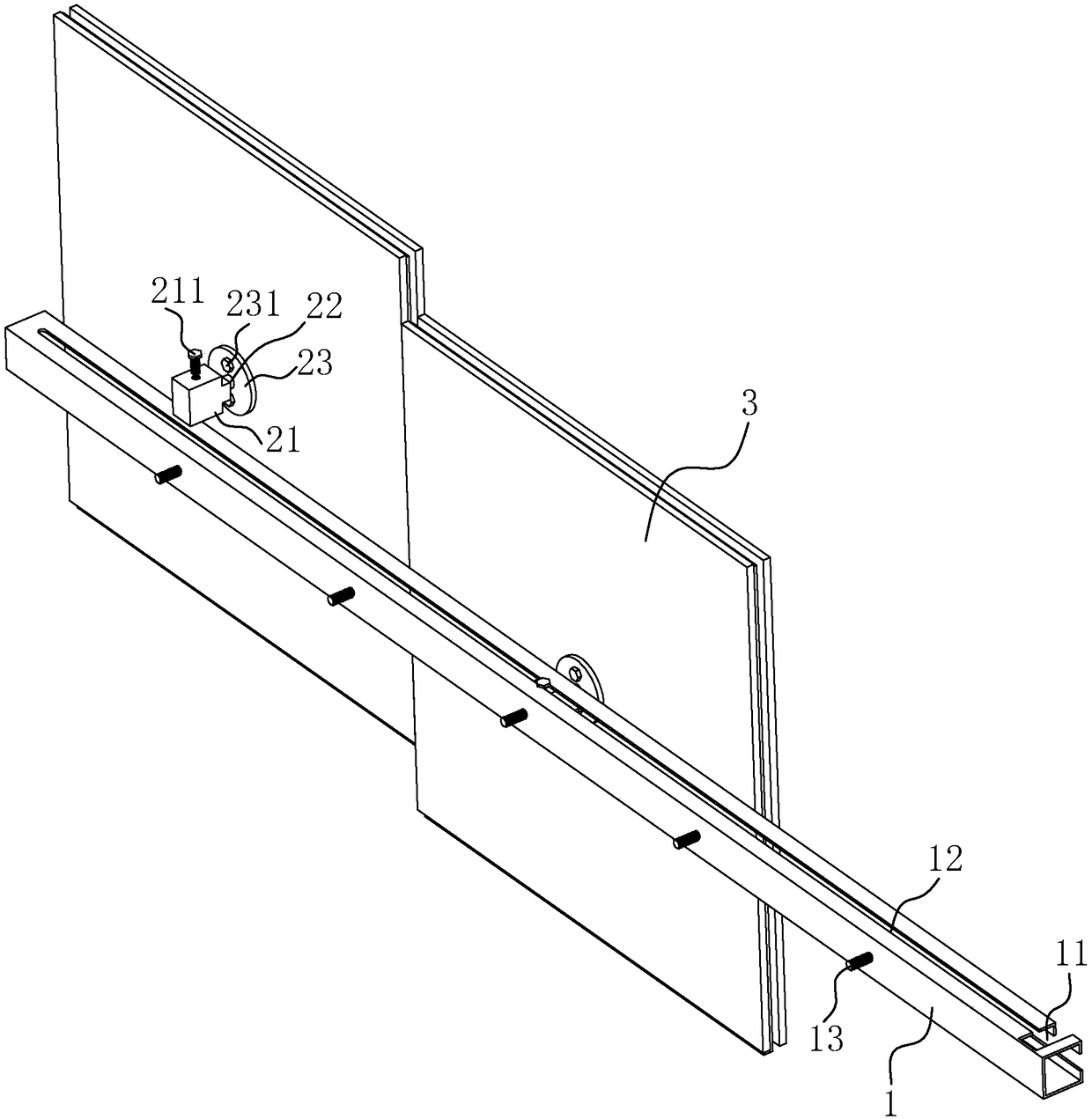

Integrated fabricated heat preservation external wall

ActiveCN108252427AReduce exchangeImprove insulation effectHeat proofingBuilding insulationsWindow openingEnergy conservation

The invention relates to the field of external heat preservation of building external walls, aims to solve the problems that heat preservation external walls of structures such as windows and balconies need multi-block splicing resulting in multiple splicing seams and poor heat preservation performance, and particularly relates to an integrated fabricated heat preservation external wall. The integrated fabricated heat preservation external wall comprises a plurality of horizontally-arranged groove steel, the groove steel is connected with first wall plates corresponding to the window opening position and second wall plates corresponding to the wall surface position, the first wall plates are formed integrally, and the second wall plates are spliced mutually. The first wall plates and the second wall plates are sealed through sealing glue. Protruding edges are arranged on one set of adjacent side edges of the second wall plates in the length direction correspondingly in an extending mode. Grooves matched with the protruding edges are formed in the other set of adjacent side edges of the second wall plates. The protruding edges and the grooves are located in the middles of the side edges of the second wall plates. The first wall plates are manufacture and formed integrally according to a concrete window or balcony structure, the number of the splicing seams is decreased effectively, and heat preservation performance of the heat preservation external wall is improved, so that indoor and outdoor heat exchanging is reduced, and the effect of energy saving is achieved.

Owner:江苏南通三建建筑装饰集团有限公司

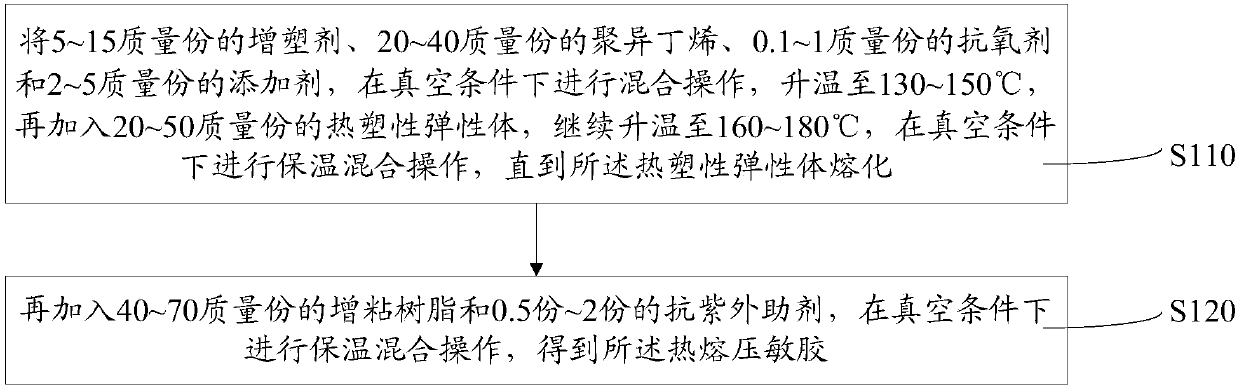

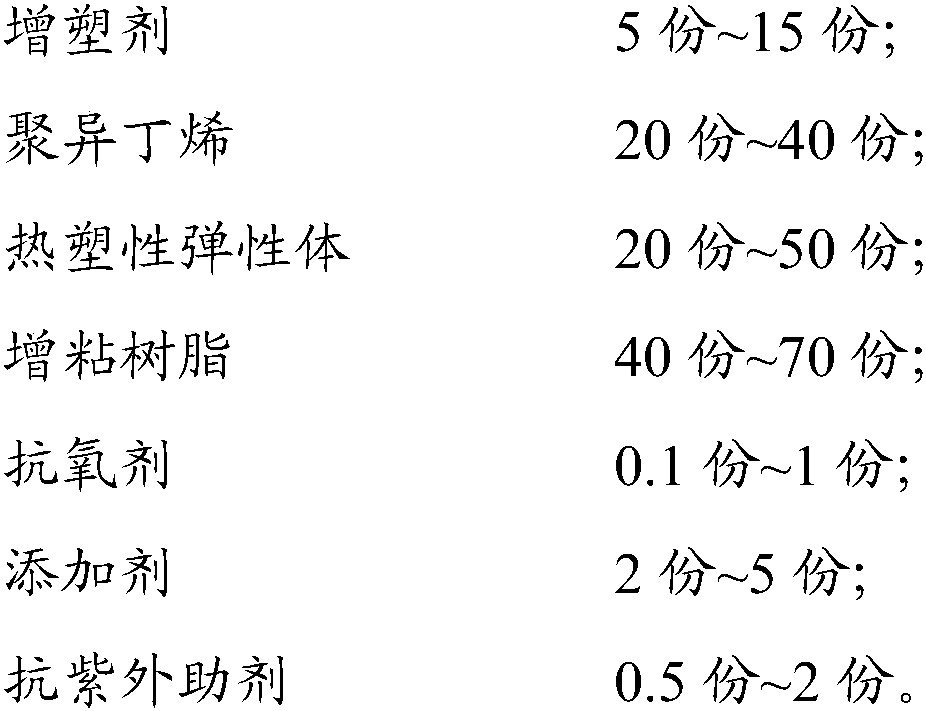

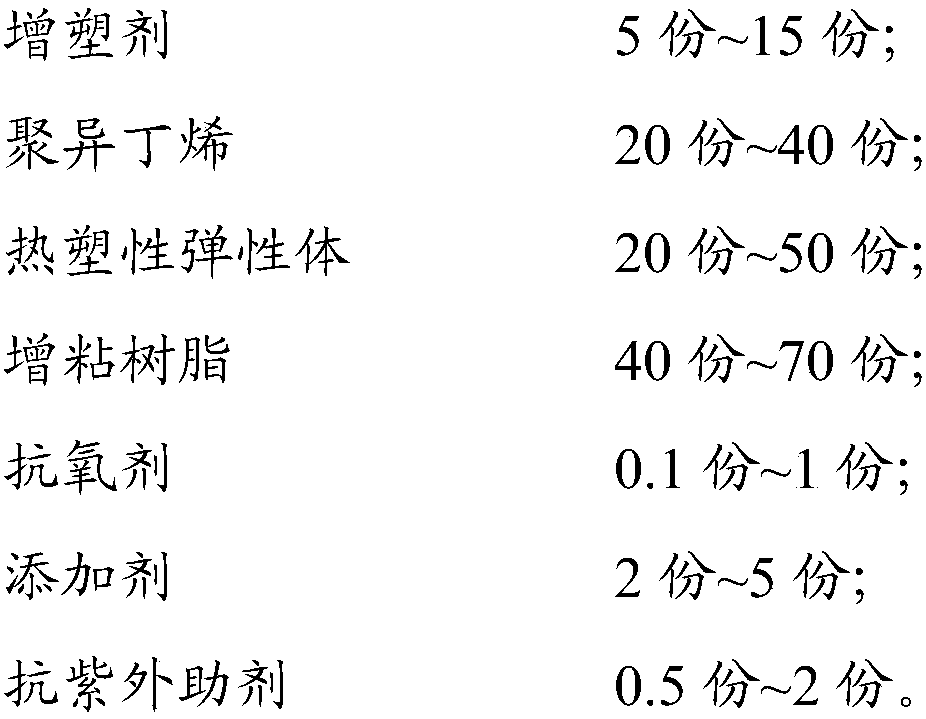

Hot-melt pressure-sensitive adhesive and preparation method thereof

InactiveCN107722925ACohesion does not decreaseImprove cohesionMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAntioxidantUltraviolet lights

The invention relates to a hot-melt pressure-sensitive adhesive and a preparation method thereof. The hot-melt pressure-sensitive adhesive comprises, by mass, 5-15 parts of a plasticizer, 20-40 partsof polyisobutylene, 20-50 parts of a thermoplastic elastomer, 40-70 parts of tackifying resin, 0.1-1 part of an antioxidant, 2-5 parts of an additive and 0.5-2 parts of an anti-UV assistant. The additive can increase the Van der Waals force among hot-melt adhesive molecules to effectively prevent pop-open of overlap edges, caused by the sliding of an adhesive layer; and the polarity of the polyisobutylene is similar to that a waterproof coiled material, so the wettability to the waterproof coiled material of the hot-melt pressure-sensitive adhesive is enhanced, thereby the skin-like contact between the hot-melt adhesive and the waterproof coiled material is generated, the intermolecular effect between the hot-melt adhesive and the waterproof coiled material is increased, the infiltration of water molecules is blocked, water escaping from the overlap edges of the coiled material is prevented, and the peeling strength of the overlap edges is increased. The anti-UV assistant can absorb ultraviolet lights in sunshine, and releases the ultraviolet lights in a heat form in order to achieve a good anti-UV aging effect.

Owner:HUIZHOU NENGHUI CHEM CO LTD

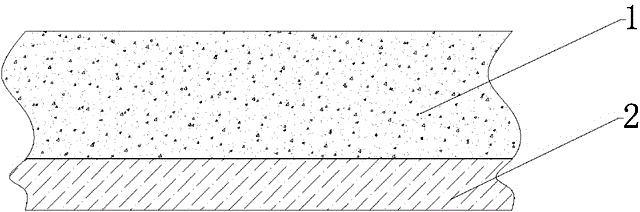

Inorganic fiber heat-insulation layer protection surface layer and spraying method thereof

The invention discloses an inorganic fiber-made heat-insulation layer protection surface layer. The protection surface layer is formed by mixing an inorganic cementing material, a dispersible emulsion powder, other fillers and auxiliary agents and the like. Water is added on the spot according to the weight ratio of powder to water being 1.0:0.7-0.8, and the materials are fully stirred and mixed to obtain slurry with a certain viscosity; the slurry is directly sprayed onto the surface of an inorganic fiber spray heat-insulation layer by a special spray machine; and a film is formed after hardening for a certain period of time so as to become the protection surface layer with waterproof, anti-crack and decorative effects.

Owner:北京海纳联创节能科技股份有限公司

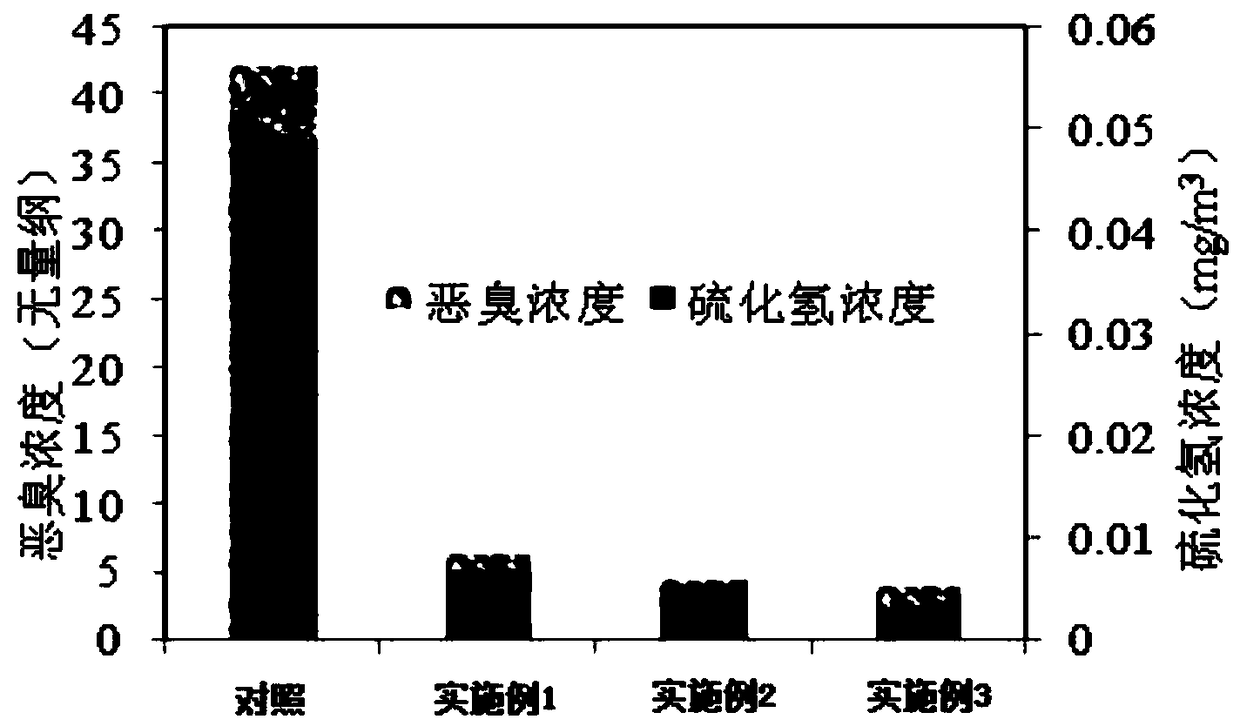

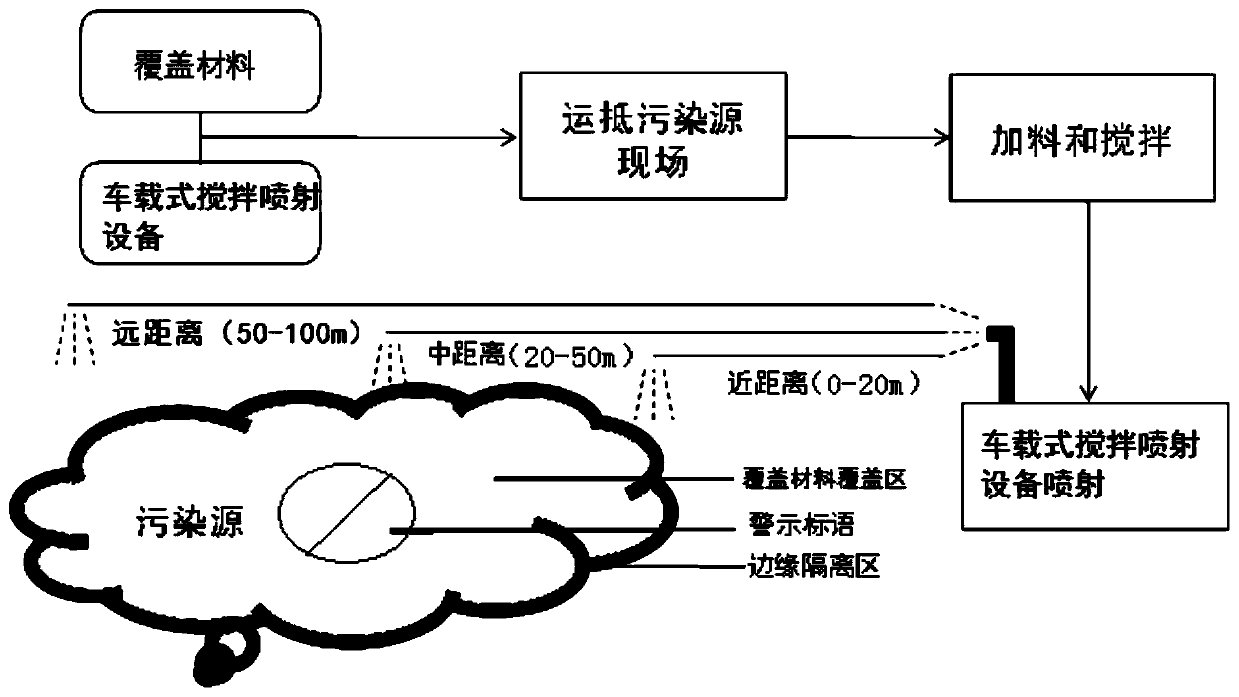

Spray covering process of solid pollution sources

ActiveCN109332343AGood odor and deodorization functionRainproofLandfill technologiesSolid waste disposalSludgeSewage

The invention relates to a spray covering process of solid pollution sources. The solid pollution sources include refuse landfills, sludge stockpiling sites, industrial waste stacking sites, mineral tailings ponds or solid pollution sources formed by contaminated sites. The spray covering process includes the steps that a curing base material, a curing agent and a solvent are mixed to form a highviscosity paste composite material, and the surfaces of the solid pollution sources are covered by uniform spraying of spraying equipment. According to the spray covering process, diversion of rain and sewage from solid pollution source piles or sites is realized, sewage generation caused by rainwater mixing is reduced remarkably, and safety of soil and groundwater in stacking sites is ensured; meanwhile according to stink source piles, the odor isolation (deodorization) effect is good, and friendly environment is achieved; and furthermore, the functions of fire prevention, dust prevention andseepage prevention are achieved, application is wide, and practicability is high.

Owner:LIAONING HAITIANGE ENVIRONMENTAL PROTECTION TECH

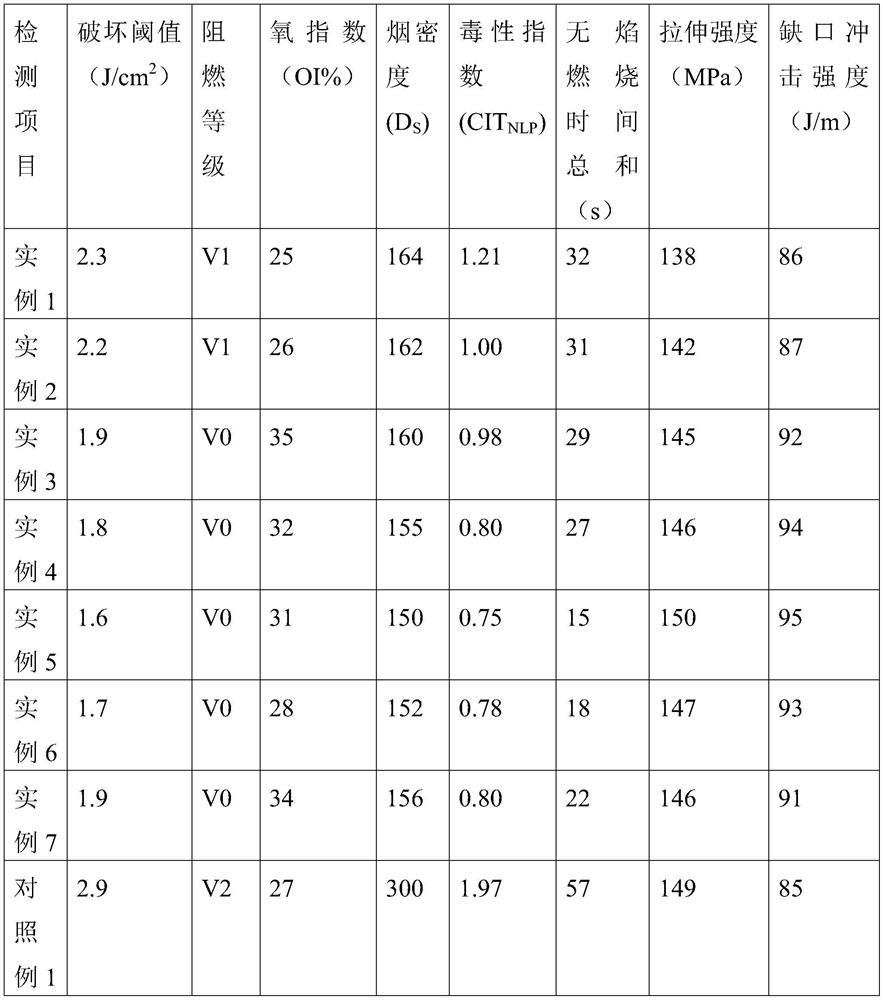

Halogen-free flame-retardant identification sleeve capable of being subjected to laser etching and preparation method thereof

The invention relates to a halogen-free flame-retardant identification sleeve capable of being subjected to laser etching and a preparation method thereof, and belongs to the technical field of sleeve preparation. By adding a laser etching aid into a base material, the laser absorptivity of a material system is improved, the damage threshold of laser to the material system is reduced, and the technical problems that an existing mark is not clear, poor in permanent resistance, not environmentally friendly and the like are solved; and by using the phosphorus-nitrogen halogen-free flame retardant, the problems of high combustion smoke density, high toxicity and the like of a halogen-containing flame retardant are solved, and the phosphorus-nitrogen halogen-free flame retardant has a wide application prospect.

Owner:昶力管业(常州)有限公司

Solvent type polyurethane resin and preparation method thereof, and fluoride-free clothes with lotus leaf effect

ActiveCN110818880AExcellent resistance to hydrolysisLower surface energyTextiles and paperFluorine freeIsocyanate

The invention relates to solvent type polyurethane resin and a preparation method thereof, and fluoride-free clothes with a lotus leaf effect. The polyurethane resin is prepared from the following rawmaterials according to a formula: polycarbonate polyol, polyether polyol, polyethylene glycol, micromolecular polyol, isocyanate, a solvent, a catalyst, reactive organic silicon oil, fumed silica, aterminating agent and an auxiliary agent. According to the invention: the polycarbonate polyol, the polyether polyol and the polyethylene glycol are combined according to a specific ratio to constitute a macromolecular polyol mixture, while the micromolecular polyol in a specific proportion is matched, and specifically the reactive organic silicon oil and the fumed silica in a certain proportion are matched, so the coating formed by the polyurethane resin prepared by using the preparation method provided by the invention has the advantages of good hydrolysis resistance, aging resistance, moisture penetrability and low surface energy, wherein the surface energy of the coating is 15 to 20N / m, while the surface energy of water is 60 N / m.

Owner:JIANGSU HUADA NEW MATERIAL CO LTD

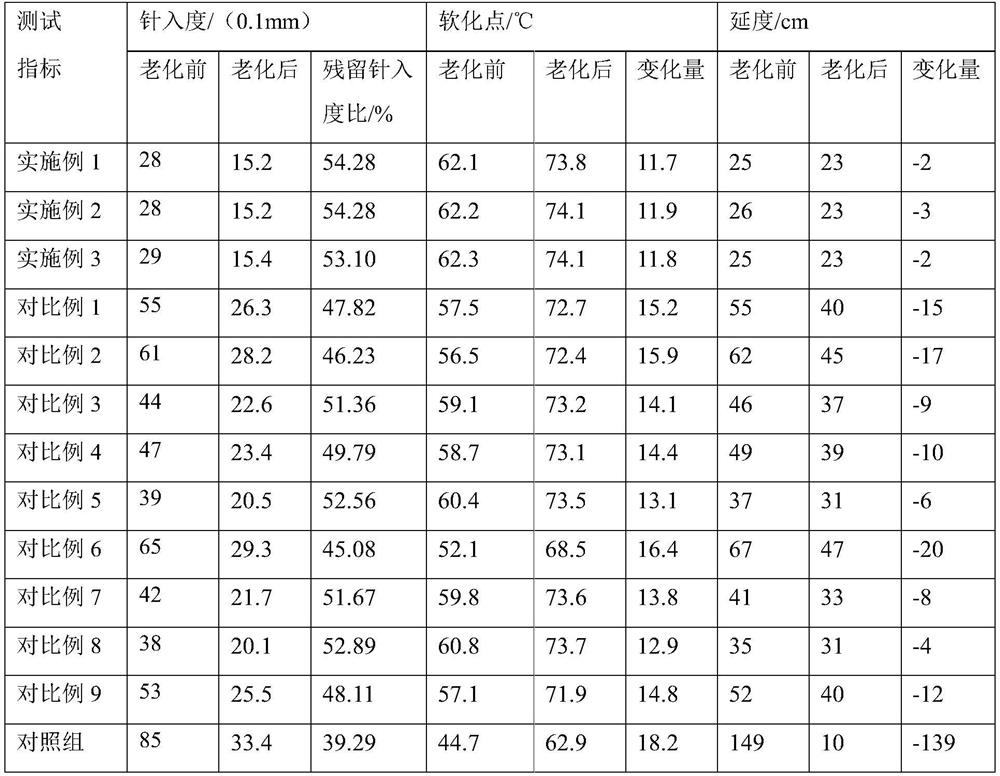

Road net-shaped crack sticker and preparation method thereof

PendingCN113249054AShort repair cycleImprove tensile propertiesNon-macromolecular adhesive additivesBituminous material adhesivesStructural engineeringRoad surface

The invention provides a road net-shaped crack sticker, which comprises a net-shaped crack sticker body, wherein the net-shaped crack sticker body comprises an adhesive layer, a rock layer adhered to the outer side face of the adhesive layer and an anti-sticking isolation layer adhered to the outer side face of the adhesive layer, a tire base cloth layer is arranged in the middle of the adhesive layer, the arranged tire base cloth layer can improve the tensile property of the road net-shaped crack sticker and preventwater from permeating into cracks so as to prevent the adhesive layer from falling off, and the net-shaped crack sticker body serving as a surface layer of a repairing structure can be well bonded with an original road surface and well adapt to crack changes.

Owner:河南公路卫士交通科技有限公司

Asphalt modifier and preparation process thereof

ActiveCN111607241AImprove stabilityGood compatibilityUltrasonic/sonic fibre treatmentBuilding insulationsPolymer scienceVegetable oil

The invention discloses an asphalt modifier. The asphalt modifier comprises, by weight, 20-30 parts of graphene, 10-15 parts of carbon nanotubes, 4-8 parts of dopamine, 15-25 parts of vegetable oil polyol, 30-40 parts of polytetrafluoroethylene fibers and 1-3 parts of a stabilizer. The asphalt modifier has good compatibility with asphalt, the adhesion with asphalt is improved, and the segregationphenomenon is avoided; the vegetable oil polyol is used as a solvent, so that the dispersity of other components can be improved, and the utilization rate of effective substances is increased; and dopamine and graphene which have an obvious effect of improving the oxidation and aging resistance of the asphalt are added, so that the aim of improving the durability of the asphalt is fulfilled.

Owner:CHINA ROAD & BRIDGE

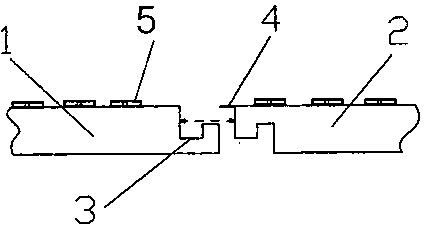

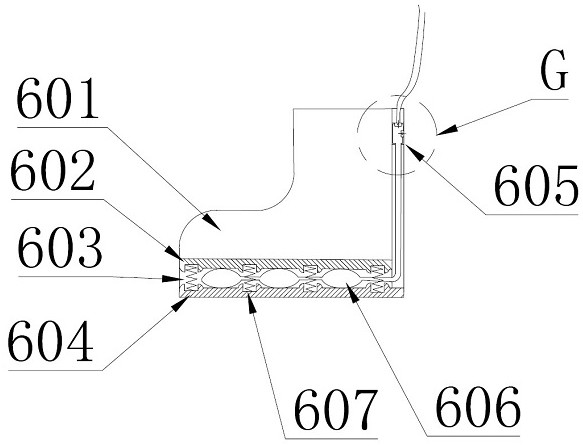

Electric cover plate

InactiveCN103375034AImprove biteBarrier infiltrationTransformer housesWater dischargePower equipment

An electric cover plate is formed by splicing two cover plates. The mid-plane of the cover plate is high, and the splicing edges are sunken; the two cover plates are spliced and assembled together by adopting a clamping buckle and are mutually matched and buckled; the lower cover plate pressed at the lower side is sunken; the upper cover plate above is buckled downwards; a shield plate is arranged at a splicing gap; a convex anti-skid pattern is formed on the outer surface of the electric cover plate. The electric cover plate has good occlusion at the splicing place, can prevent water efficiently, can dredge the water discharge while preventing the water as a water separation groove is also arranged, can well protect internal power equipment, can prevent water permeated from the gap efficiently as the shield plate is provided, and can achieve the anti-skid effect efficiently as the convex anti-skid pattern is formed on the outer surface of the cover plate.

Owner:夏航

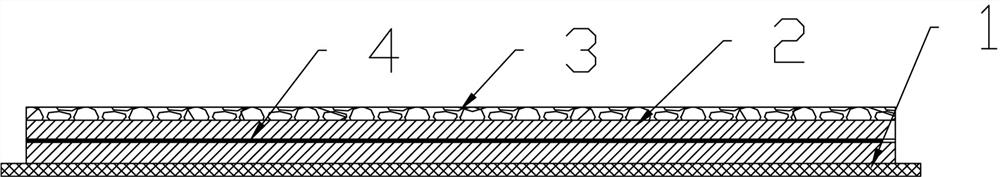

Composite structure of top plate waterproof pavement layer of underground road under shallow burial soil

InactiveCN104264562AWith strengthAvoid destructionIn situ pavingsProtective foundationEpoxyLoad resistance

The invention relates to a composite structure of a top plate waterproof pavement layer of an underground road under shallow burial soil. The composite structure is characterized by comprising a cement concrete protection layer, a synchronous rubble sealing layer, an epoxy resin waterproof layer and a cement concrete top plate in sequence from top to bottom. The composite structure of the top plate waterproof pavement layer has excellent waterproof performance and impact load resistance, largely improves the integrality and the effectiveness of an underground road waterproof system, improves the structural durability, and can satisfy the waterproof requirement of the underground road top plate.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

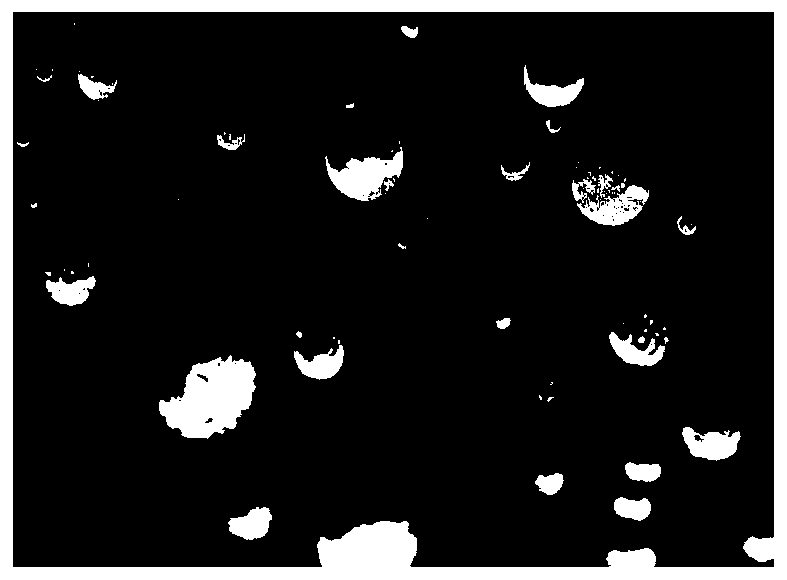

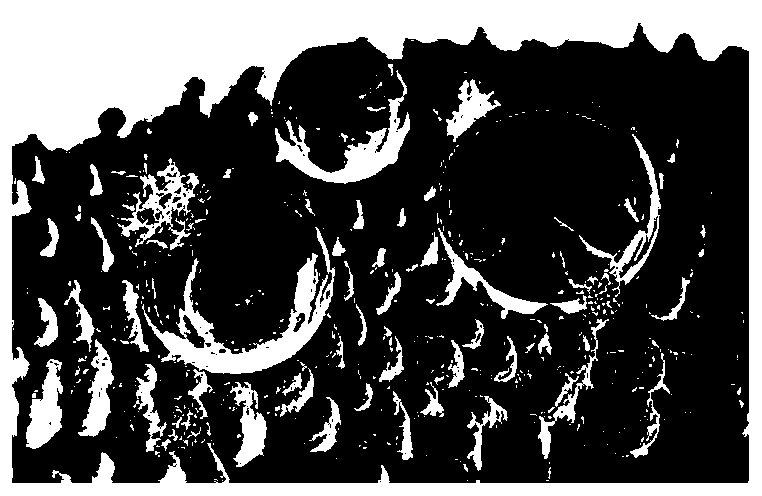

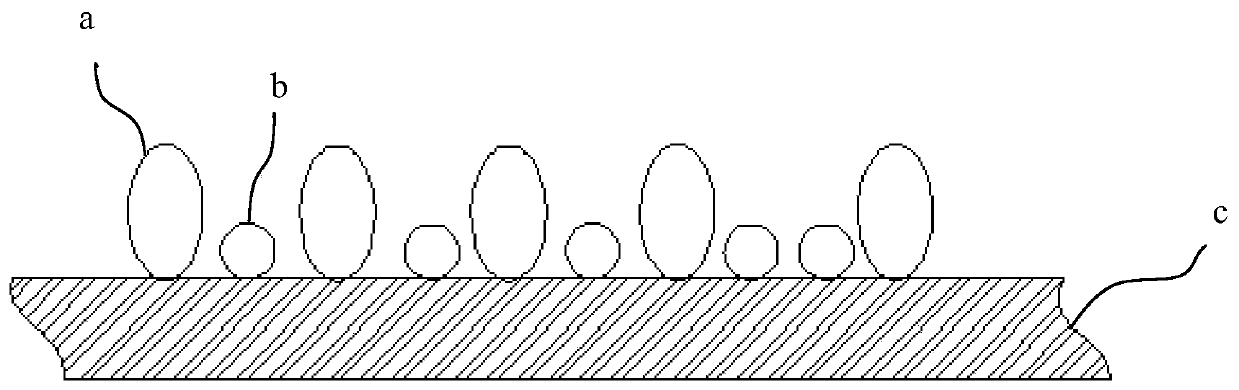

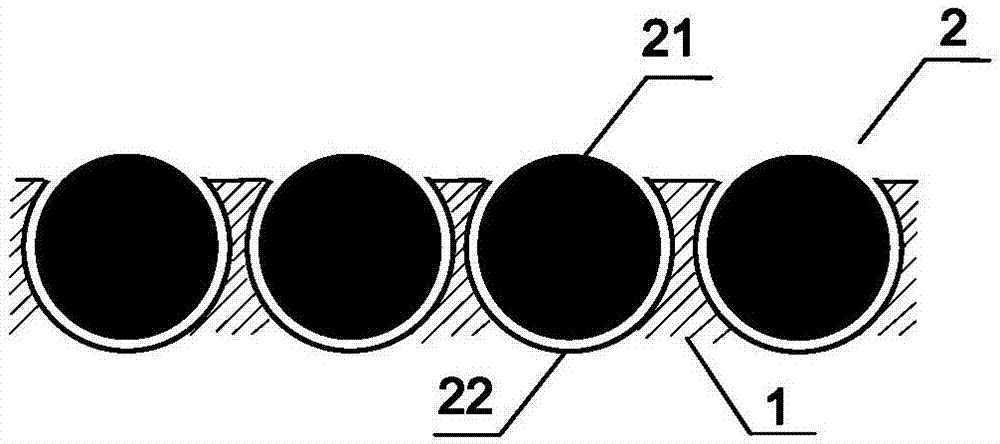

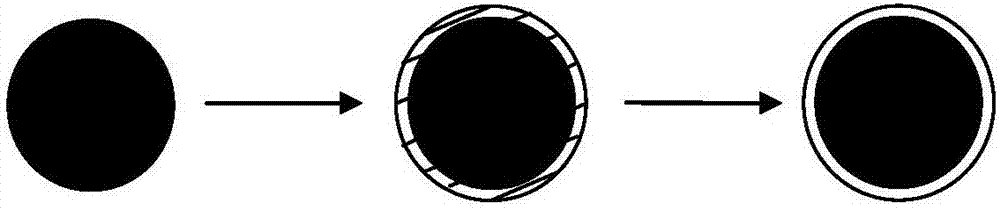

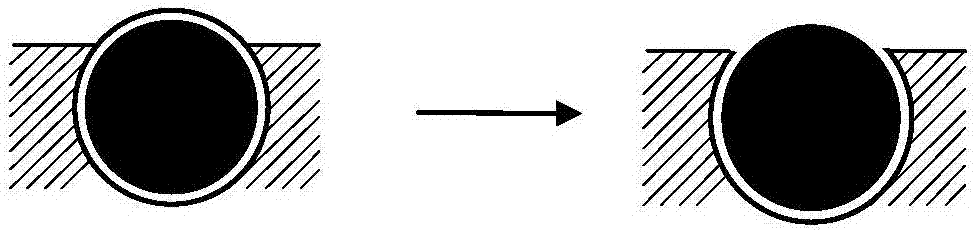

High-wear-resistant super-amphiphobic catalyst coating and preparation method and application thereof

ActiveCN107570217AReduce carbon deposition rateAvoid destructionCatalyst carriersOrganic-compounds/hydrides/coordination-complexes catalystsCoated surfaceInorganic particle

The invention relates to the technical field of catalysts and particularly provides a high-wear-resistant super-amphiphobic catalyst coating. A super-amphiphobic coating is prepared on the surface ofa catalyst carrier, so that the coke deposition rate of the surface of the catalyst can be effectively reduced, and the service life of the catalyst is prolonged. Due to an embedded composite microsphere on the surface of the super-amphiphobic coating, the problems difficult to solve in the prior art that an inorganic particle on a surface of the super-amphiphobic coating is taken away from the coating under the action of the frictional force and then the micro coarse structure is destroyed are solved. A gap is further arranged between a core and a shell of the composite microsphere, so that astable air cavity is formed on the solid-liquid interface, the infiltrating of a liquid drop is effectively stopped, and the oleophobic and hydrophobic performances are further improved. The materials adopted by the provided high-wear-resistant super-amphiphobic catalyst coating are easy to prepare or are products capable of being directly purchased, the preparation process is simple and is easyto operate, and the high-wear-resistant super-amphiphobic catalyst coating has an excellent industrial application prospect.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

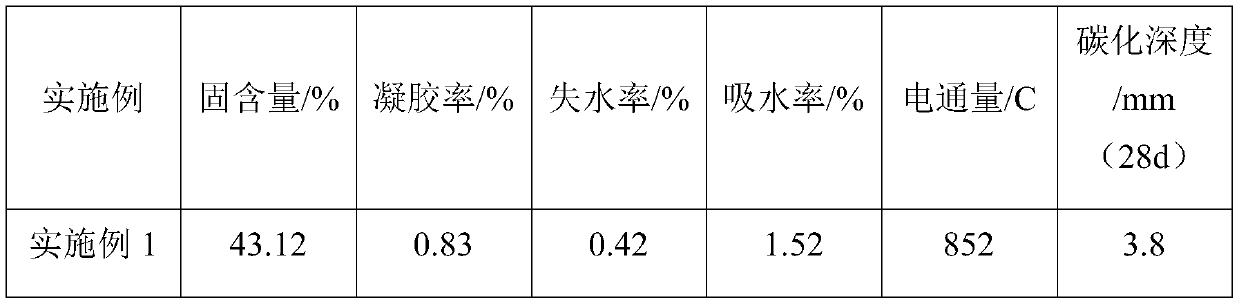

Concrete protective agent and preparation method thereof

Relating to the technical field of concrete protection, the invention in particular discloses a concrete protective agent and a preparation method thereof. The concrete protective agent includes the following raw materials by mass: 18-23 parts of a polyurethane emulsion; 30-43 parts of an acrylate monomer; 0.1-1 part of a carboxyl-containing monomer; 2-10 parts of a carbonyl-containing monomer; 0.2-0.8 part of an initiator; 2-9 parts of a cross-linking agent; and 32-38 parts of deionized water. The protective agent provided by the invention can be applied to brush coating on a concrete surfaceto form a protective coating, thus obstructing water outside the concrete from infiltrating the concrete, not impeding the interior water from discharging outwards, improving the chlorine ion penetration resistance and carbonization resistance of concrete, and improving the concrete durability.

Owner:贝正河北工程技术有限公司

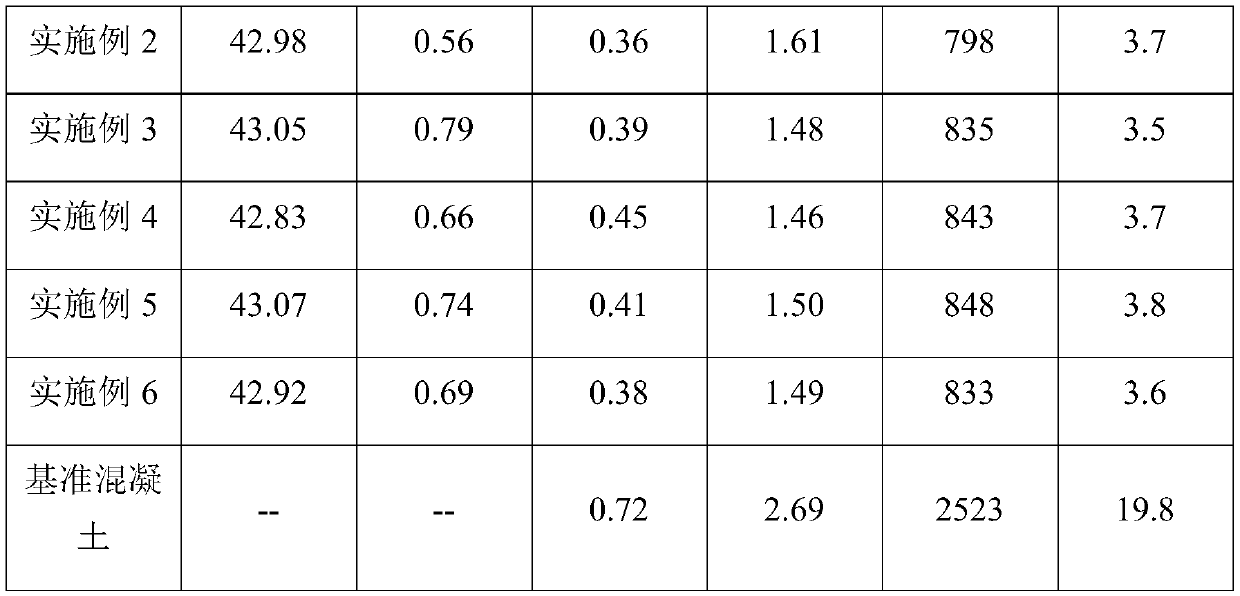

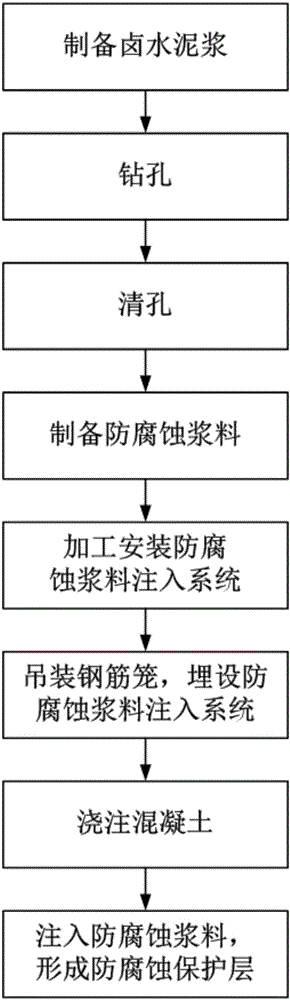

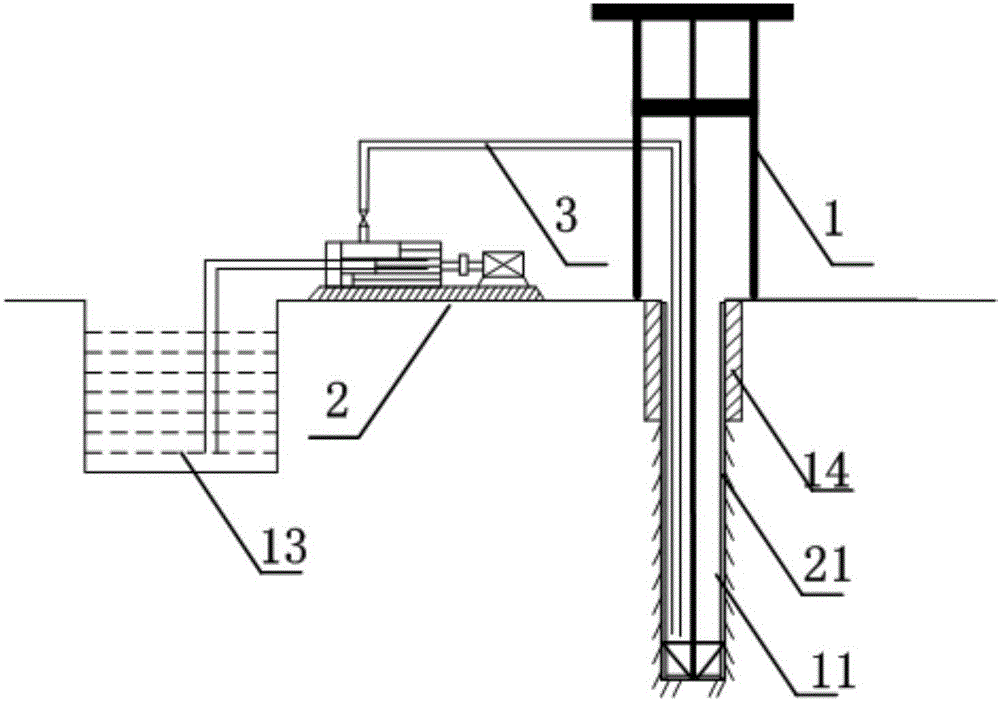

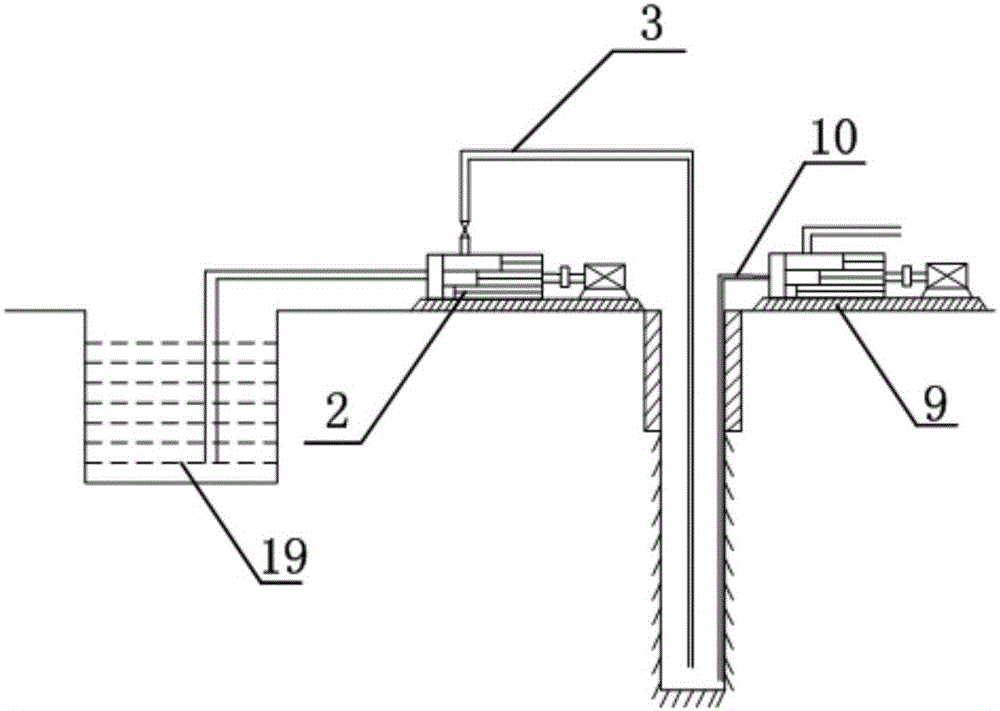

Construction process and method for erosion-resistant protective layer of concrete foundation in salty soil zone

The invention provides a construction process and method for an erosion-resistant protective layer of a concrete foundation in a salty soil zone. The construction process comprises the following steps of: carrying out mud wall-protecting treatment before pouring a concrete foundation of an underground structure to form a layer of mud cakes; then, after completing concrete foundation pouring for certain time, pressing erosion-resistant slurry into the periphery of the concrete foundation, wherein the erosion-resistant slurry sufficiently reacts with underground brine and mud, and is solidified to form a stable, compact and uniform protective layer, and the thickness of the protective layer is a bit greater than that of the mud cakes, so that erosion, on the concrete foundation, of the underground brine can be effectively blocked. According to the process and the method provided by the invention, measures are clear, operability is strong, project cost is low, and the concrete erosion-resistant protective layer can be quickly and accurately formed, so that effective protection is formed on the concrete foundation of the underground structure in the salty soil zone.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP +1

Emergency covering material, and construction method and application thereof

InactiveCN110655353AImprove compactnessHigh strengthOther chemical processesFire extinguisherEnvironmental resource managementHazardous substance

The invention discloses an emergency covering material, and a construction method and an application thereof. The problems that an emergency site with complex site conditions is extremely difficult toconstruct, and cannot be quickly covered are solved. The emergency covering material comprises a curing agent, an adsorbent, a gelatinizing agent, a deodorizing disinfectant, a dye and a solvent. Theinvention further provides a construction method and an application of the covering material. The covering material can be used for carrying out emergency rapid covering on an emergency pollution event site, so that rapid rain and sewage diversion, toxic and harmful substance isolation and safety warning effects on the emergency event site are realized, and secondary and chain environmental hazards of the emergency event are greatly reduced. A covering layer has good rain-proof and seepage-proof effects and good peculiar smell and pollutant isolation effects, and is environmentally friendly.In addition, the covering material can also play a role in fire prevention and dust prevention when applied to fields of fire disasters, earthquakes and the like, and also has the advantages of wide application, high economic feasibility and high practicability.

Owner:宋军

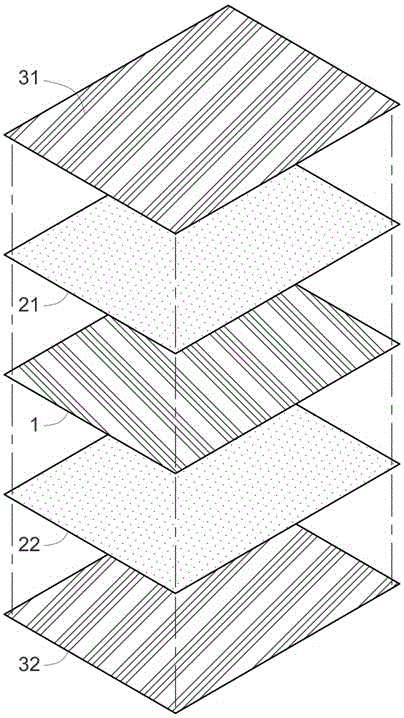

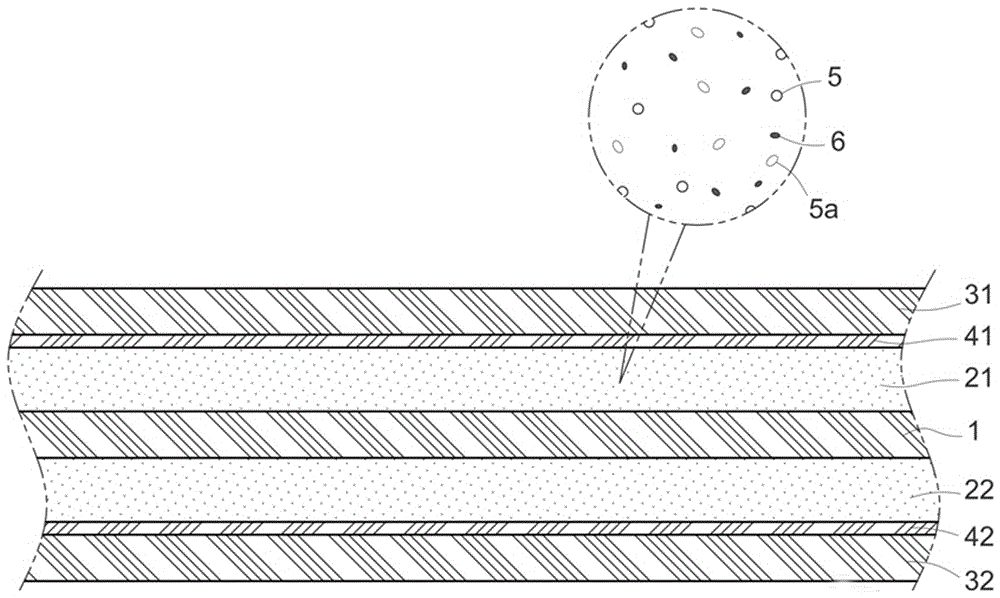

Moisture-resistant randomly-fixed adhering film

InactiveCN106634664AEasy to useAvoid wrinklesNon-macromolecular adhesive additivesWax adhesivesWrinkle skinWax

The invention discloses a moisture-resistant randomly-fixed adhering film. The moisture-resistant randomly-fixed adhering film comprises a sheet type base material layer, wherein a first adhesive layer and a second adhesive layer are arranged on the double sides of the base material layer correspondingly; a first debonding layer and a second deboning layer cover the surfaces of the first adhesive layer and the second adhesive layer correspondingly; and the first adhesive layer and the second adhesive layer comprise the following raw materials in percentage by weight: 45 to 55 percent of SEBS, 25 to 35 percent of naphthenic oil and 15 to 25 percent of white wax oil. The adhering film provided by the invention can resist moisture, accept water washing and repeatedly adhere to a foreign object, is convenient to use, accords with the environmental requirement, can prevent artistic works such as painting and calligraphy from generating bade phenomena such as wrinkle and warping, also can effectively prevent the painting and calligraphy from growing mildew and being damaged by worms, and releases fragrance and generates color change to improve beauty and interestingness of articles.

Owner:XIAMEN UNIV TAN KAH KEE COLLEGE

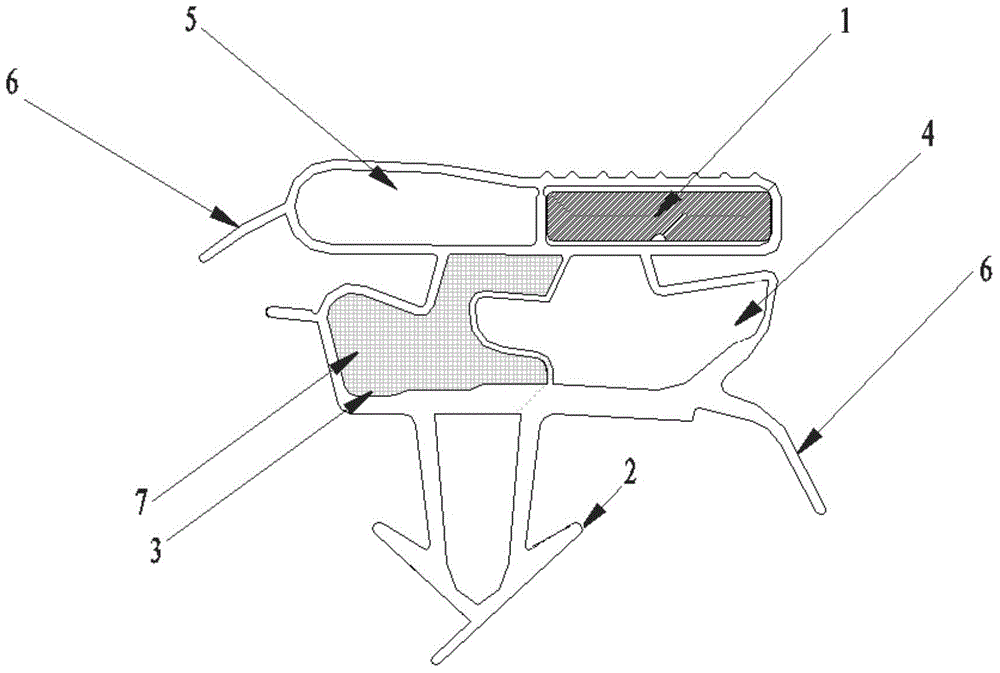

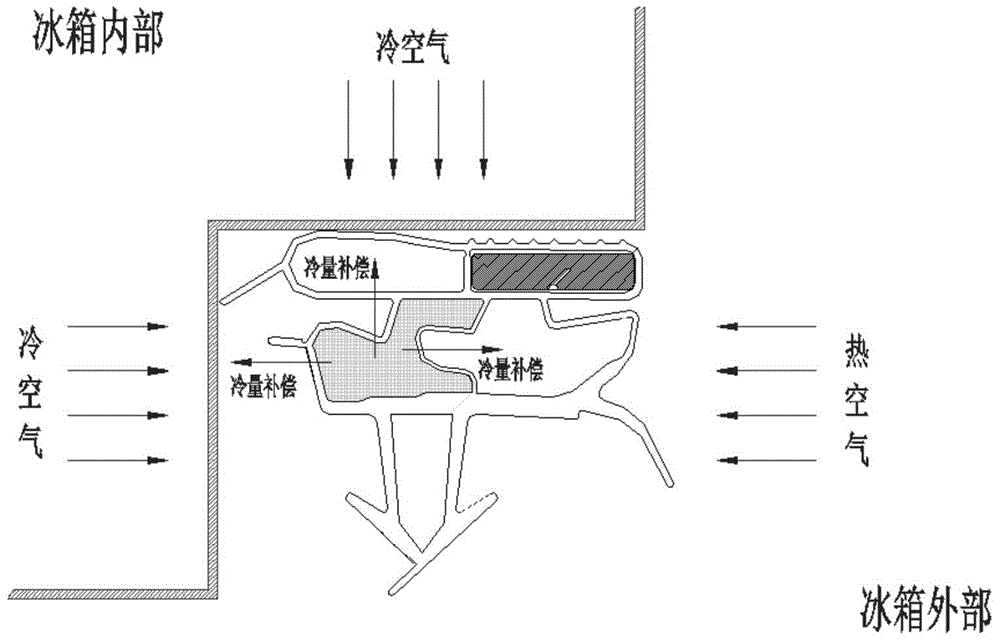

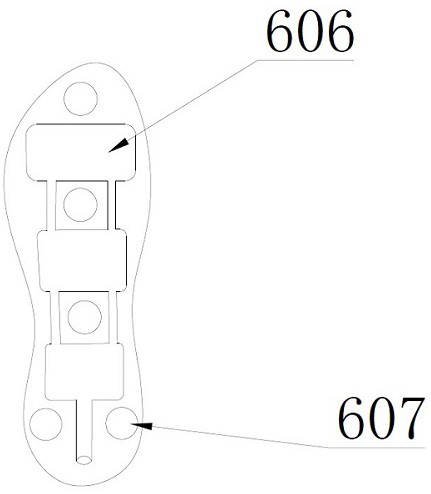

Sealing strip of cold storage door and refrigerator

InactiveCN104896843AImprove sealingBarrier infiltrationLighting and heating apparatusDomestic refrigeratorsEnergy transferState variation

The invention relates to the technical field of refrigerating equipment, and in particular relates to a sealing strip of a cold storage door and a refrigerator. The sealing strip of the cold storage door comprises an air bag, a magnetic strip cavity, mounting pins, and a cold storage cavity which is arranged close to the air bag; a cold storage medium is arranged in the cold storage cavity. The invention further provides the refrigerator employing the sealing strip of the cold storage door. According to the sealing strip of the cold storage door, a heat storage cavity is formed in the sealing strip; the heat loss in the refrigerator can be compensated according to the state variation of heat storage material in the heat storage cavity and the energy transfer among the heat storage material, the inside of the refrigerator and the air bag; in addition, outside air can be effectively prevented from entering the refrigerator; therefore, the sealing effect of the refrigerator can be improved, and the energy loss of the refrigerator can be decreased.

Owner:HEFEI KINGHOME ELECTRICAL CO LTD

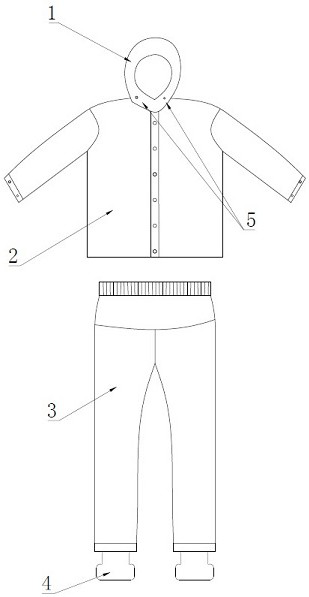

Filling type soft breathable raincoat

PendingCN112438449AAvoid enteringEasy to storeSolesMonocomponent synthetic polymer artificial filamentEngineeringAtmospheric sciences

According to a filling type soft breathable raincoat provided by the invention, by utilizing the dislocation of an upper special-shaped air bag and a lower special-shaped air bag, after the air bags are inflated, a breathable channel is formed through the matching of the upper special-shaped shape and the lower special-shaped shape, so that the breathability of the raincoat is improved while a user is protected; and meanwhile, the breathable air bags at the raincoat cap can be adjusted differently according to different states of the rain shoes under different behavior states so as to meet different requirements under different states. Besides, the raincoat material made of the environment-friendly soft breathable material is environmentally friendly, excellent in mechanical performance, soft and breathable, the defect that a traditional raincoat fabric is hard is overcome, the raincoat is comfortable to wear and breathable, permeation of macromolecular rainwater is effectively blocked, and the raincoat is comfortable to wear. Meanwhile, small molecular gas and water vapor between the raincoat and a human body can be dispersed out through the breathable material, and no stuffy feeling exists.

Owner:安福县易阳雨具有限公司

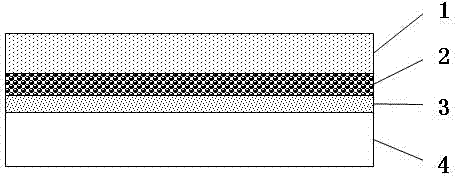

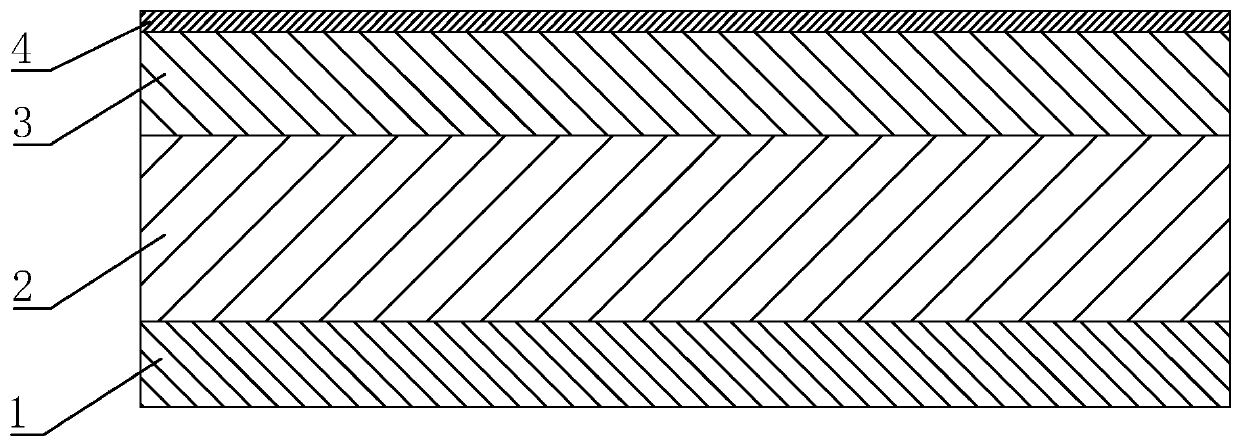

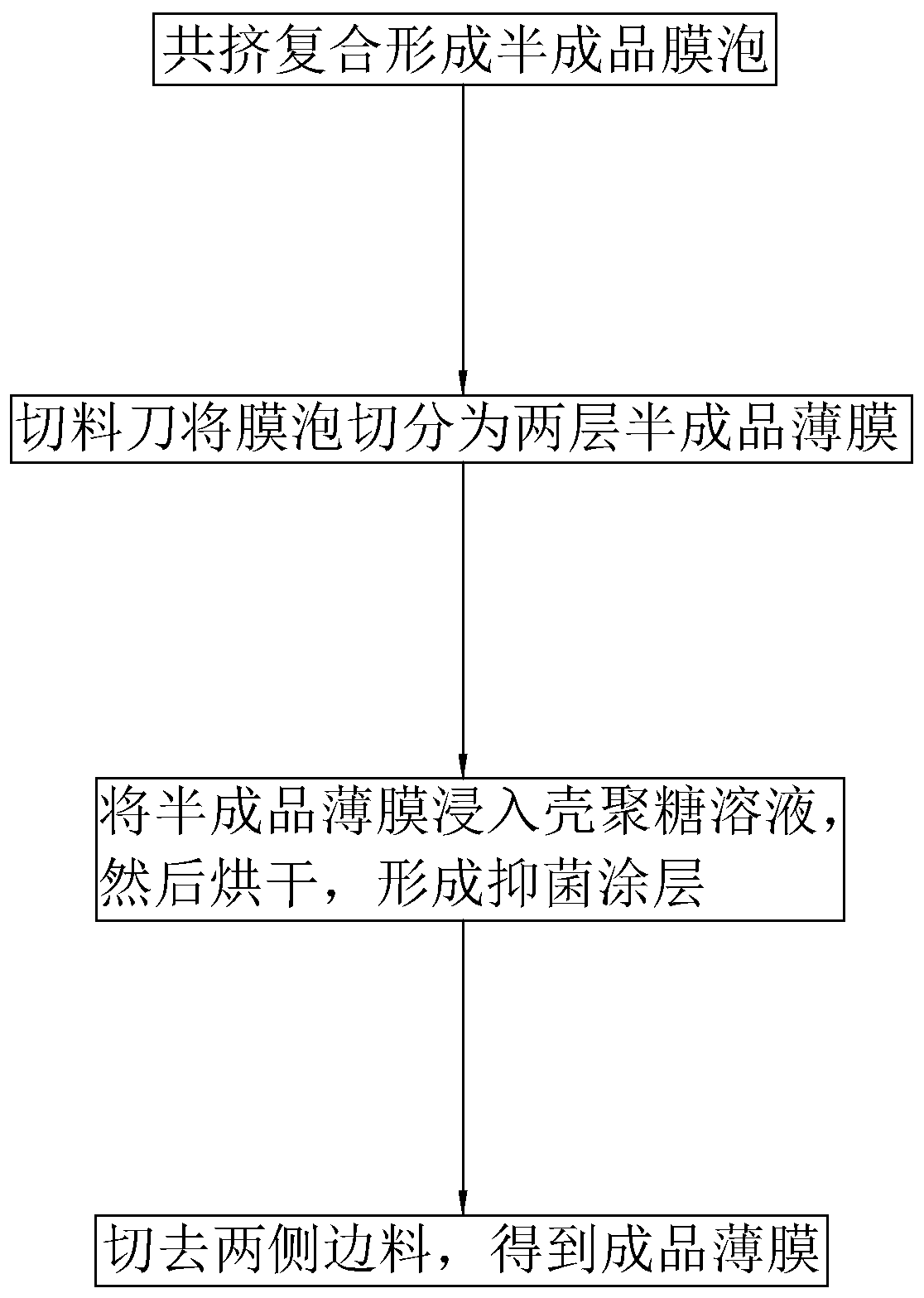

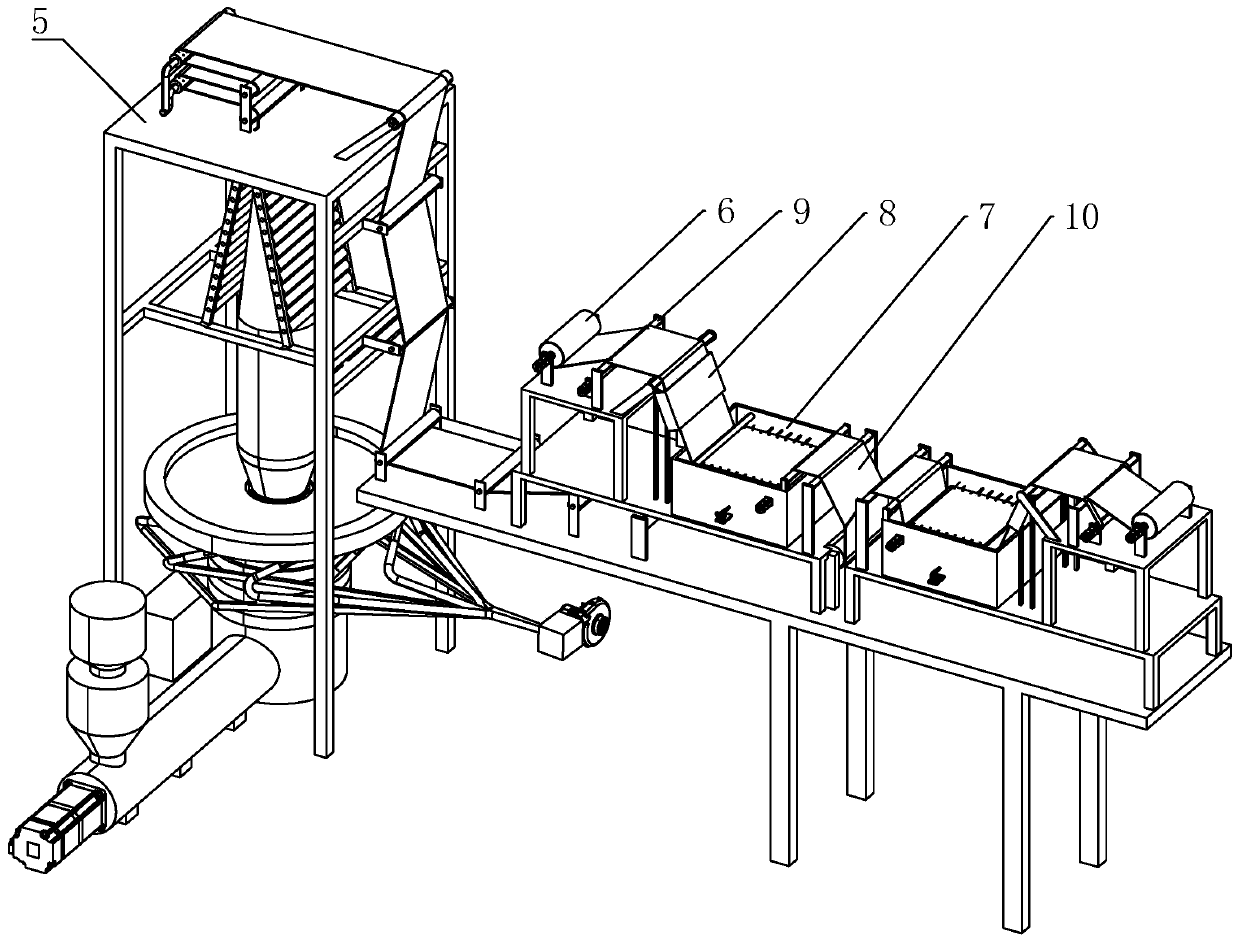

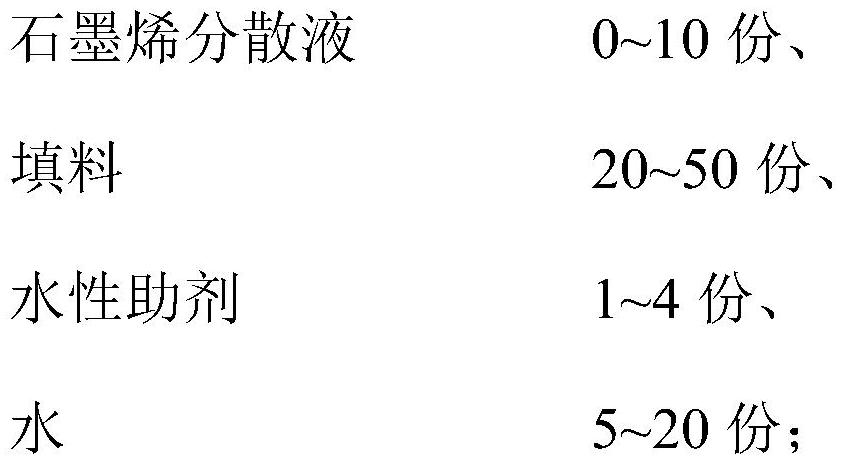

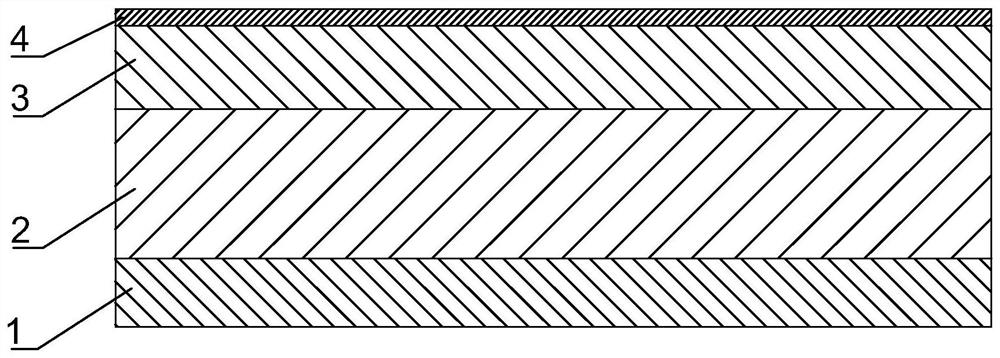

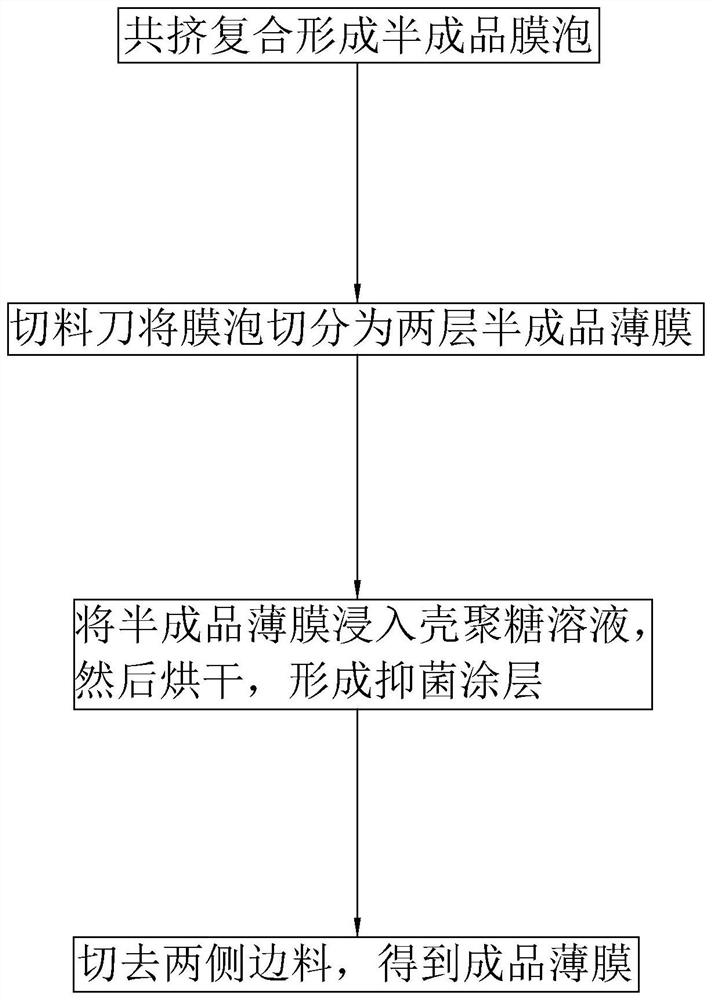

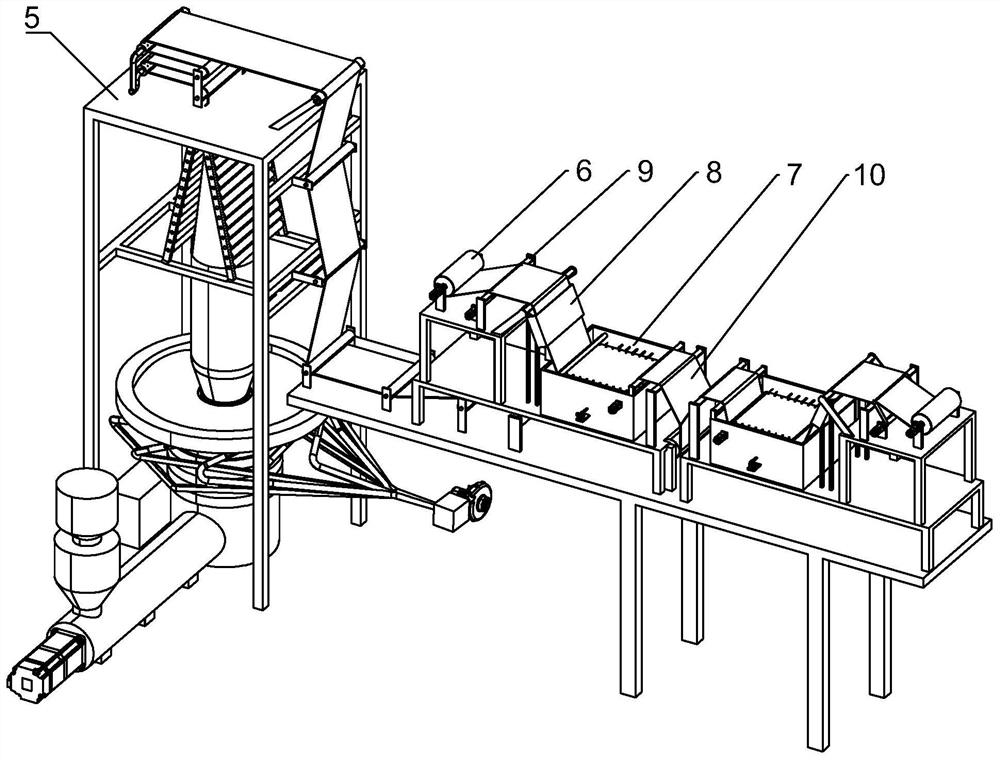

Biopolymer food packaging bag film, preparation process thereof and production equipment

ActiveCN110202858ABarrier infiltrationLess syntheticSynthetic resin layered productsCoatingsFood packagingAntibacterial coating

The invention belongs to the technical field of food packaging bag films and discloses a biopolymer food packaging bag film. The biopolymer food packaging bag film is technically characterized by comprising a chitin lining, a starch / LDPE blending layer, a PLA waterproof layer and an antibacterial coating. The invention also discloses a process for producing the biopolymer food packaging bag film.The process is technically characterized by comprising the steps of performing co-extrusion lamination for film forming, cutting film bubbles into two layers of films with a material cutter, forming abacteriostatic coating, cutting off leftover materials on the two sides to obtain a finished film, and winding the finished film. The invention also discloses production equipment required by the preparation process of the biopolymer food packaging bag film. The equipment is technically characterized by comprising a three-layer co-extrusion film blowing machine, a winding machine, a soaking tank,a drying oven and a material cutting roller, wherein the soaking tank, the drying oven and the material cutting roller are sequentially arranged. The effects are achieved that the degradable film issynthesized by adopting various biopolymer materials, raw materials are taken from plants, animals and microorganisms, few artificial compounds are adopted, and therefore the construction of a resource-saving and environment-friendly society is facilitated.

Owner:上海唐科新材料科技有限公司

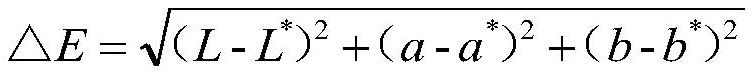

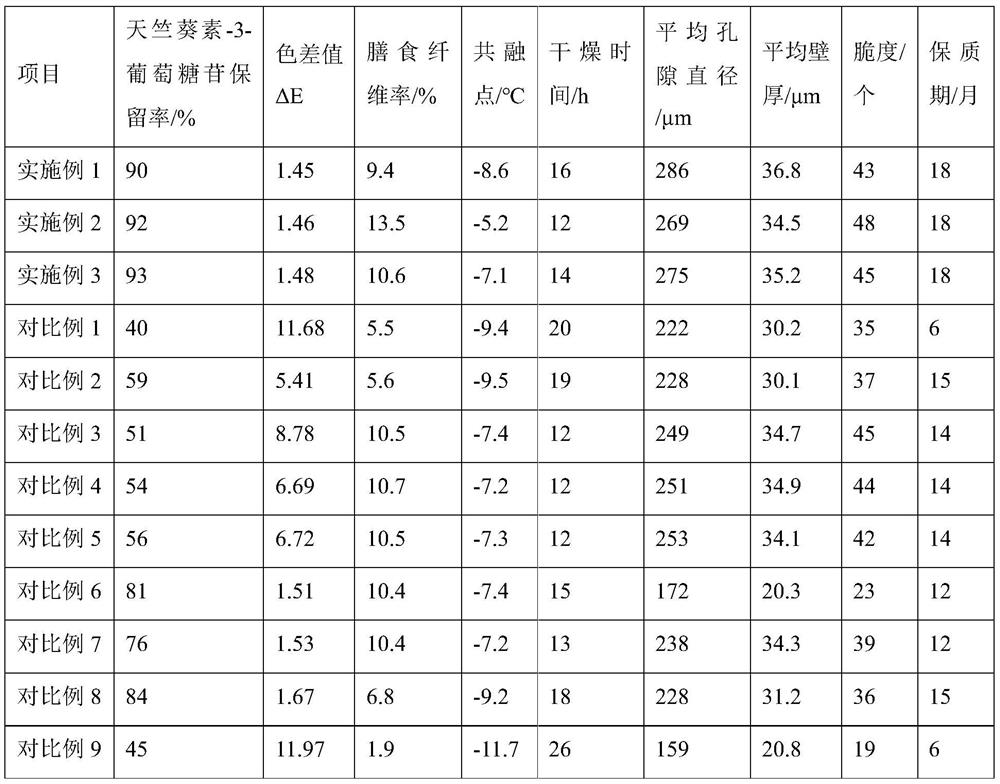

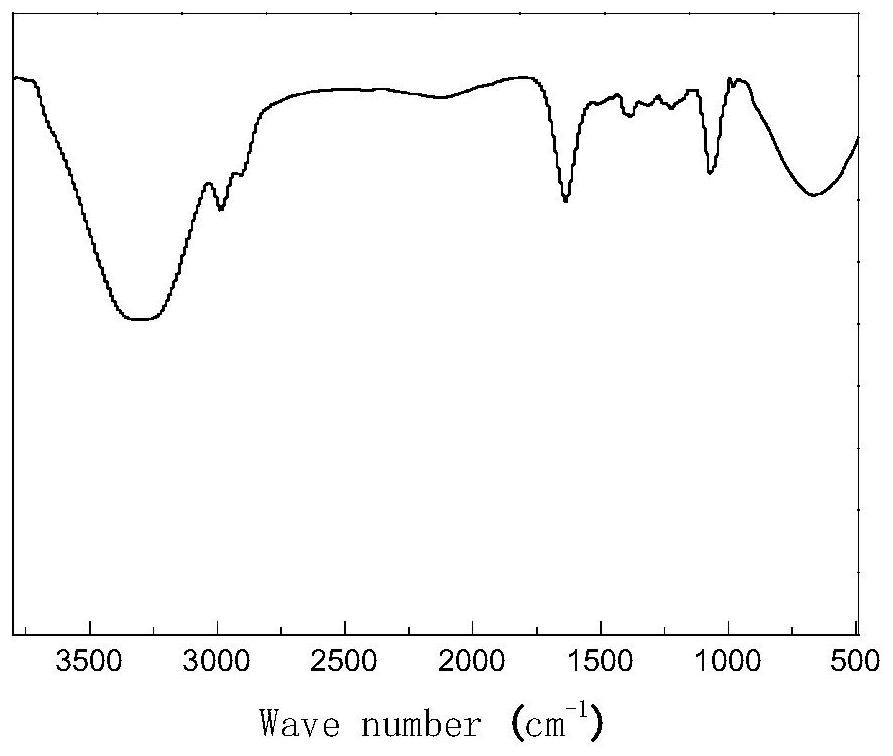

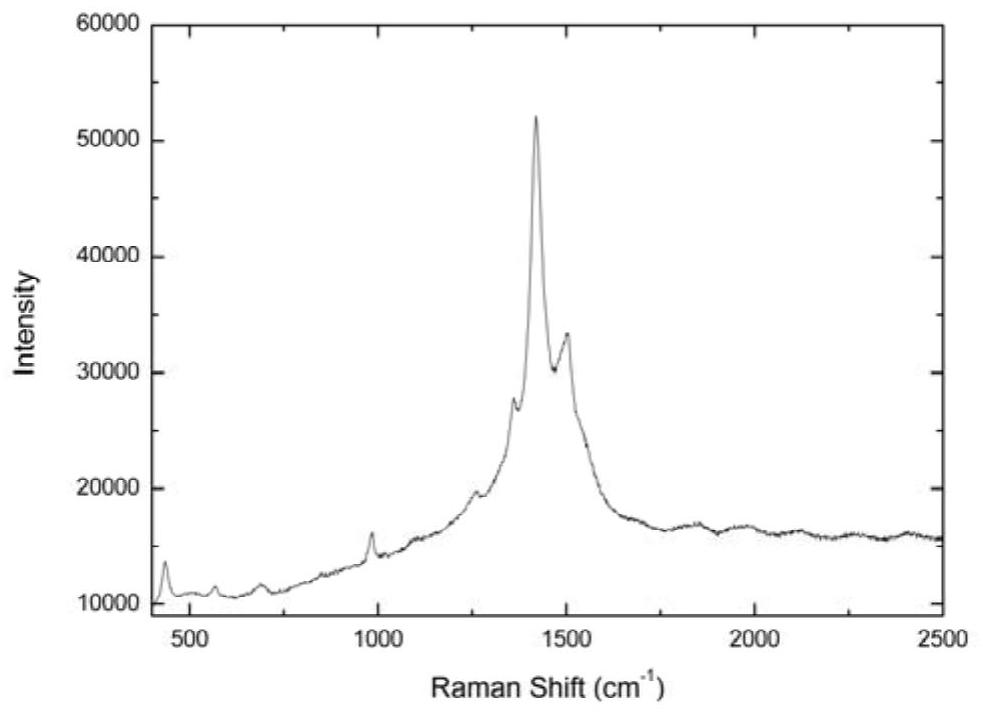

Method for improving color and texture quality of vacuum freeze-dried recombinant strawberry chips

ActiveCN112544919AImprove stabilityHigh chemical stabilityFood freezingFood homogenisationComposite materialFragaria

The invention discloses a method for improving color and texture quality of vacuum freeze-dried recombinant strawberry chips, which comprises the following steps: step 1. crushing strawberries to obtain a strawberry pulp, uniformly mixing the strawberry pulp with pectin and protocatechuic acid, and regulating the pH value to 3.0-3.8 to obtain a material A; wherein the mass ratio of the strawberrypulp to the pectin is 1: (0.02-0.08), and the mass concentration of protocatechuic acid in the material A is 0.1-1.0 g / kg; step 2, pouring the material A into a mold tray, and carrying out freeze-thawtreatment in a refrigeration house at -18 DEG C to obtain a blocky material B; step 3, coating the surface of the material B with a layer of chitosan to obtain a material C; and step 4, drying the material C in a vacuum freeze-drying box, and then performing nitrogen-filled packaging to obtain the strawberry chips. According to the invention, brand-new recombinant strawberry chips are created, and the problems of unstable storage period of pelargonidin-3-glucoside and low hardness and brittleness of the product are effectively solved.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Poly 3,4-ethylenedioxythiophene/polyethyleneimine modified waterborne epoxy emulsion, preparation method thereof and anticorrosive coating

ActiveCN113754891AImprove solubilityImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyPolymer science

The invention relates to the technical field of high-molecular polymer new materials, in particular to a poly 3,4-ethylenedioxythiophene / polyethyleneimine modified waterborne epoxy emulsion, a preparation method thereof and an anticorrosive coating. The preparation method comprises the following steps: mixing a 3,4-ethylenedioxythiophene monomer and a solvent, then adding an initiator, and carrying out a stirring reaction to prepare a poly (3,4-ethylenedioxythiophene) dispersion liquid; mixing polyethyleneimine and water-borne epoxy resin, and stirring to prepare a polyethyleneimine modified water-borne epoxy resin emulsion; and mixing the poly (3, 4-ethylenedioxythiophene) dispersion liquid, the polyethyleneimine modified waterborne epoxy resin emulsion and an auxiliary agent, and carrying out shearing emulsification. According to the PEDOT / PEI modified waterborne epoxy emulsion prepared by the preparation method, the dispersion stability of PEDOT in the waterborne epoxy emulsion is improved. The anticorrosive coating prepared from the PEDOT / PEI modified waterborne epoxy emulsion has the advantages of excellent corrosion resistance and favorable dispersion stability.

Owner:泽铱(佛山)工业技术有限公司 +1

Biopolymer food packaging bag film and its preparation process and production equipment

ActiveCN110202858BLess syntheticEasy constructionSynthetic resin layered productsCoatingsBiotechnologyComposite film

The invention belongs to the technical field of food packaging bag films, and discloses a biopolymer food packaging film. The key points of the technical solution include a chitin lining, a starch / LDPE blend layer, a PLA waterproof layer and an antibacterial coating; A process for producing the above-mentioned biopolymer food packaging film is disclosed. The main points of the technical scheme include co-extrusion composite film formation, cutting the film bubble into two layers of film with a cutting knife, and forming an antibacterial coating. Cut off the side materials on both sides, obtain the finished film and wind it up; disclose a kind of production equipment required for the above-mentioned biopolymer food packaging bag film preparation process, and the key points of the technical scheme include a three-layer co-extrusion film blowing machine and a winder , which also includes infiltration tanks, ovens and cutting rollers arranged in sequence, with a variety of biopolymer materials to synthesize degradable films, raw materials from plants, animals and microorganisms, less artificial synthetics, which is conducive to resource conservation and environmental protection The effect of building a friendly society.

Owner:上海唐科新材料科技有限公司

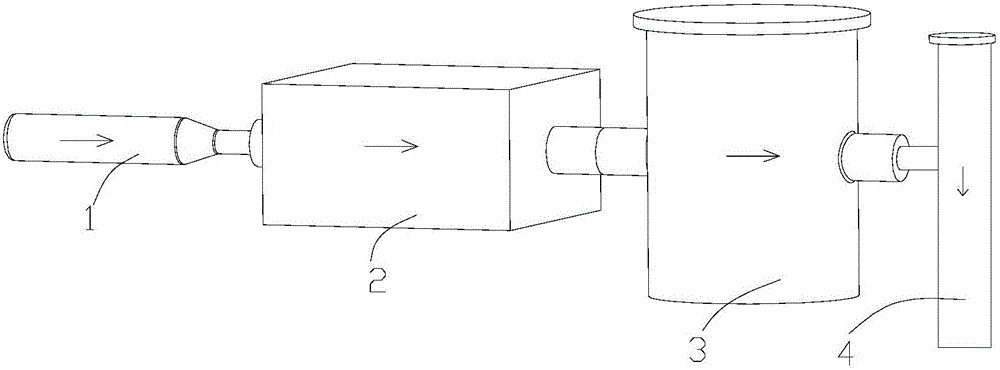

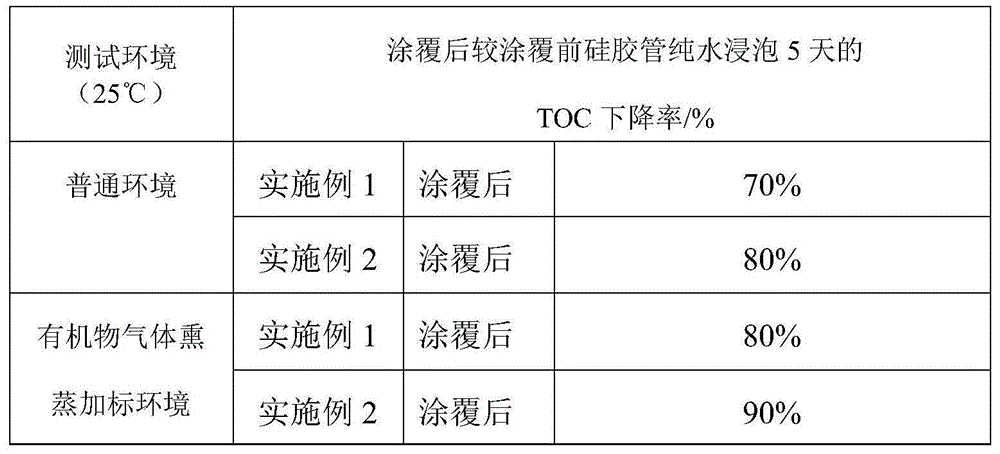

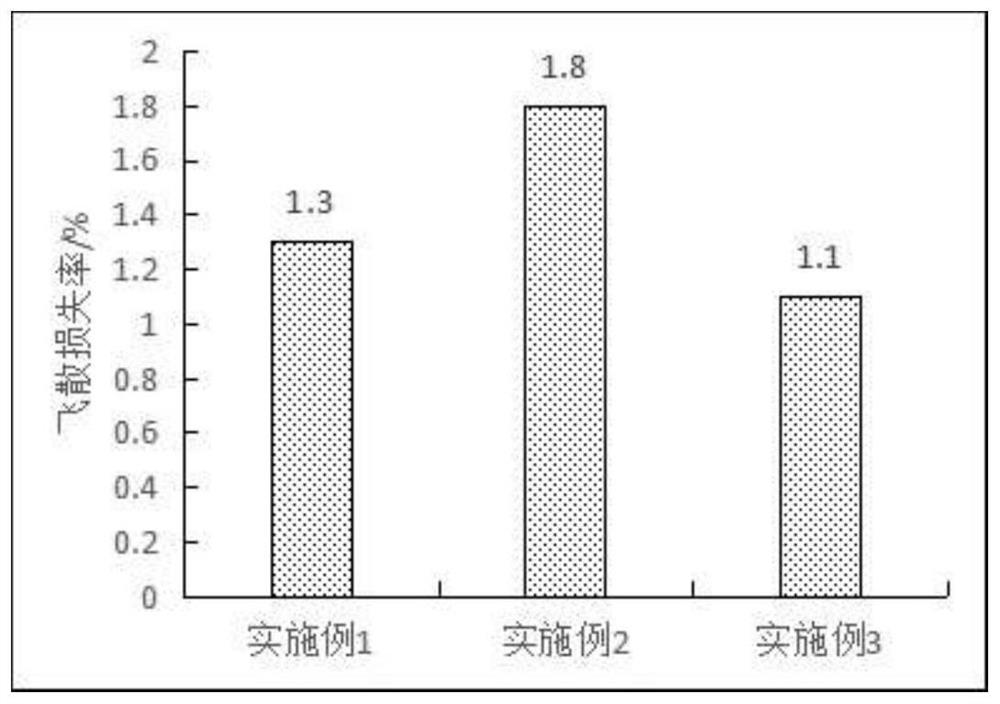

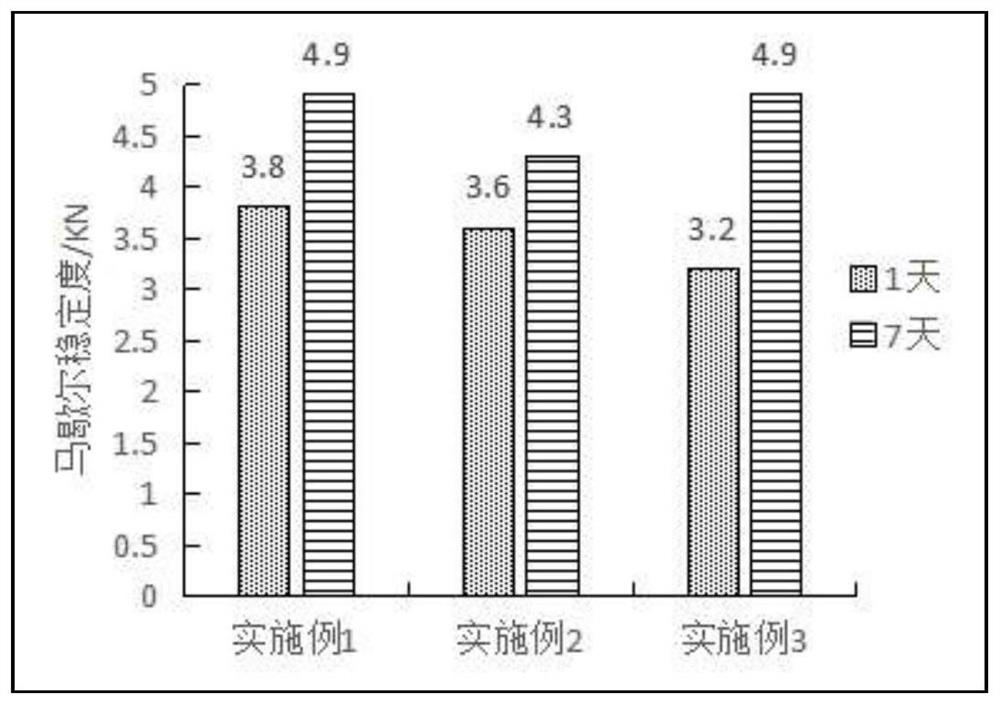

Silicone tube coating method and application

The invention provides a silicone tube coating method and application. The silicone tube coating method comprises the following steps of (1) silicone tube pretreatment; (2) reliability detection of silicone tube pretreatment; (3) mounting of silicone tubes on a frame; and (4) depositing and coating. According to an embodiment of the silicone tube coating method and the application, through a gas-phase depositing mode, the effect that the surfaces of the silicone tubes are coated with compact thin films is achieved, and micro holes in the surfaces of the silicone tubes are closed, so that the surfaces of the silicone tubes are smooth and free of the holes. External smells are prevented from infiltrating into a water body after entering the micro holes of the silicone tubes, and meanwhile, the phenomenon that incompletely-vulcanized chemical substances of silicone tube materials separate out and enter the water body is inhibited, so that the peculiar smell of the water body is effectively lowered. The silicone tube coating method is applied to surface coating of the silicone tubes, has the advantages that batch production is easily achieved, raw materials are saved, and pollution is low and can be applied to production of the silicone tubes of water dispensers.

Owner:SHENZHEN ANGEL DRINKING WATER IND GRP

Curing cold patch material suitable for low-temperature humid environment and preparation method thereof

The invention relates to a curing cold patch material suitable for a low-temperature humid environment and a preparation method of the curing cold patch material. The cold patch material comprises the following components in parts by weight: 64-78 parts of an RAP material, 16-31 parts of a novel aggregate, 0.9-1.1 parts of a regenerant and 3-5 parts of cold patch asphalt. Wherein the cold patch asphalt comprises the following components in parts by weight: 45-56 parts of modified asphalt, 28 parts of liquid soap and 20-26 parts of low-temperature curing epoxy glue (latent epoxy resin). The preparation method comprises the following steps: slowly adding the regenerant into the preheated RAP material at a constant speed, uniformly mixing the components, adding the cold patch asphalt and the preheated new aggregate, uniformly mixing the components, and discharging the mixture when the temperature is less than or equal to 80 DEG C. Compared with the prior art, the cold patch material disclosed by the invention has the advantage of being rapidly combined with a damaged pavement in a low-temperature humid environment, and has a wide prospect when being applied to the fields of road maintenance and emergency maintenance.

Owner:SOUTHEAST UNIV

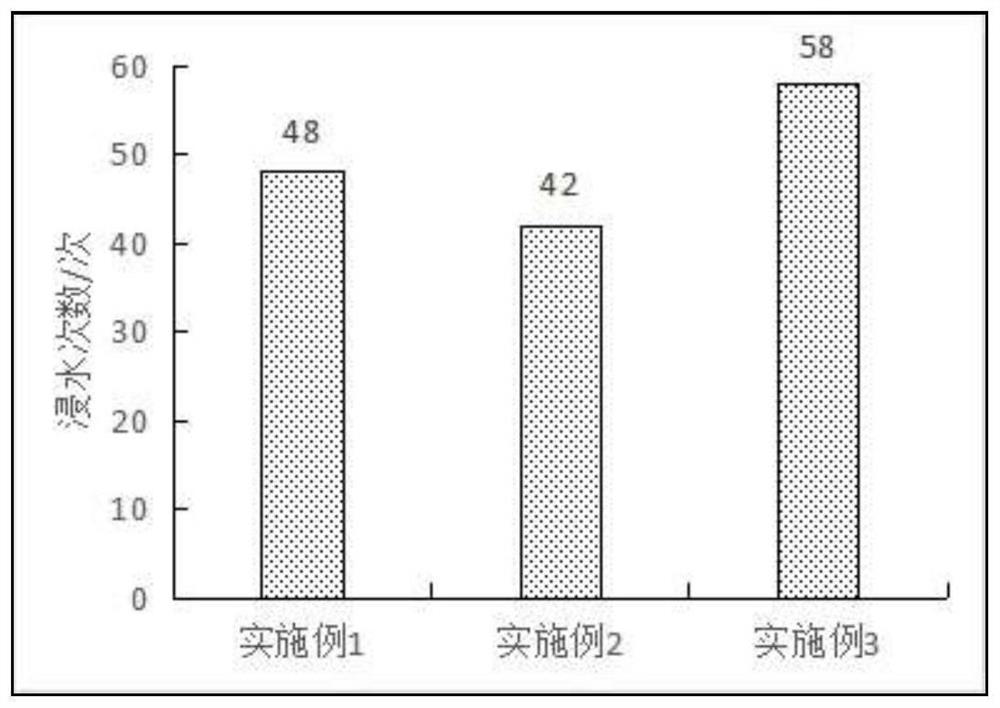

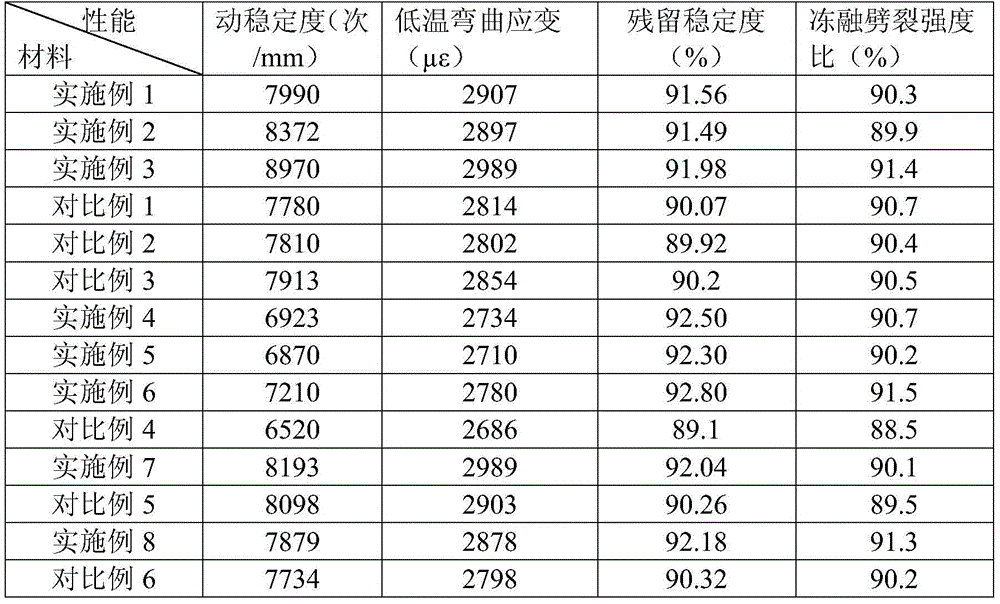

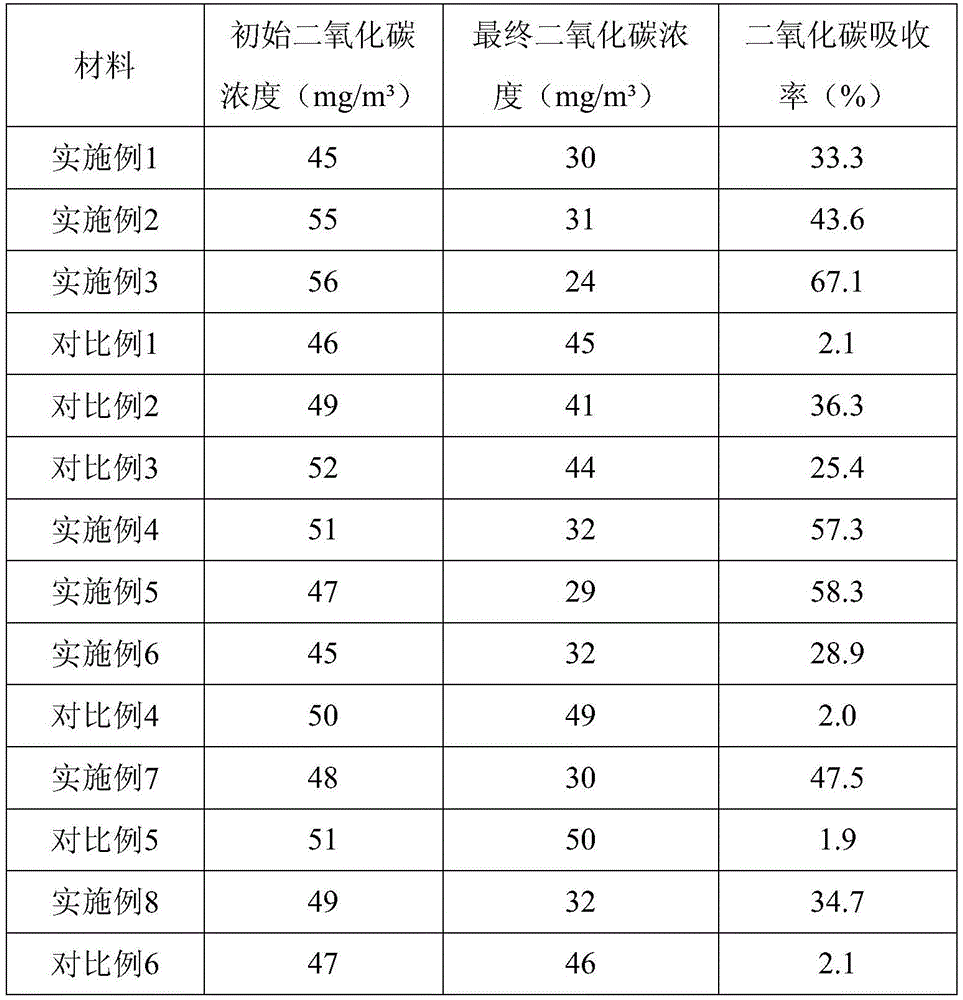

Modified asphalt concrete capable of adsorbing carbon dioxide

The invention provides modified asphalt concrete capable of adsorbing carbon dioxide. The modified asphalt concrete is prepared from the following raw materials in parts by weight: 100 parts of mineral aggregate, 4.0-9.0 parts of asphalt, 0.4-2.4 parts of hedenbergite powder, 0.2-2.0 parts of chlorite powder, 0.01-0.05 part of nephelite powder, 0.15-1.0 part of dioctyl terephthalate, 0.04-0.2 part of tert-butyl-acetyl citrate, 0.075-0.5 part of a surfactant and 0.01-0.06 part of a dispersant. As tert-butyl-acetyl citrate has excellent cold resistance and water stability, and a layer of dense metal oxide is formed on the surface of nephelite powder, the modified asphalt concrete has favorable corrosion resistance. Meanwhile, the modified asphalt concrete has good dispersity, can play the roles of dispersion and activation together with the surfactant (FMEE), and can effectively improve the bonding strength of modified powder and asphalt. As the compound modified powder is added into the asphalt concrete, the low-temperature crack resistance, the water damage resistance and the corrosion resistance of the asphalt concrete are effectively improved.

Owner:CHANGAN UNIV

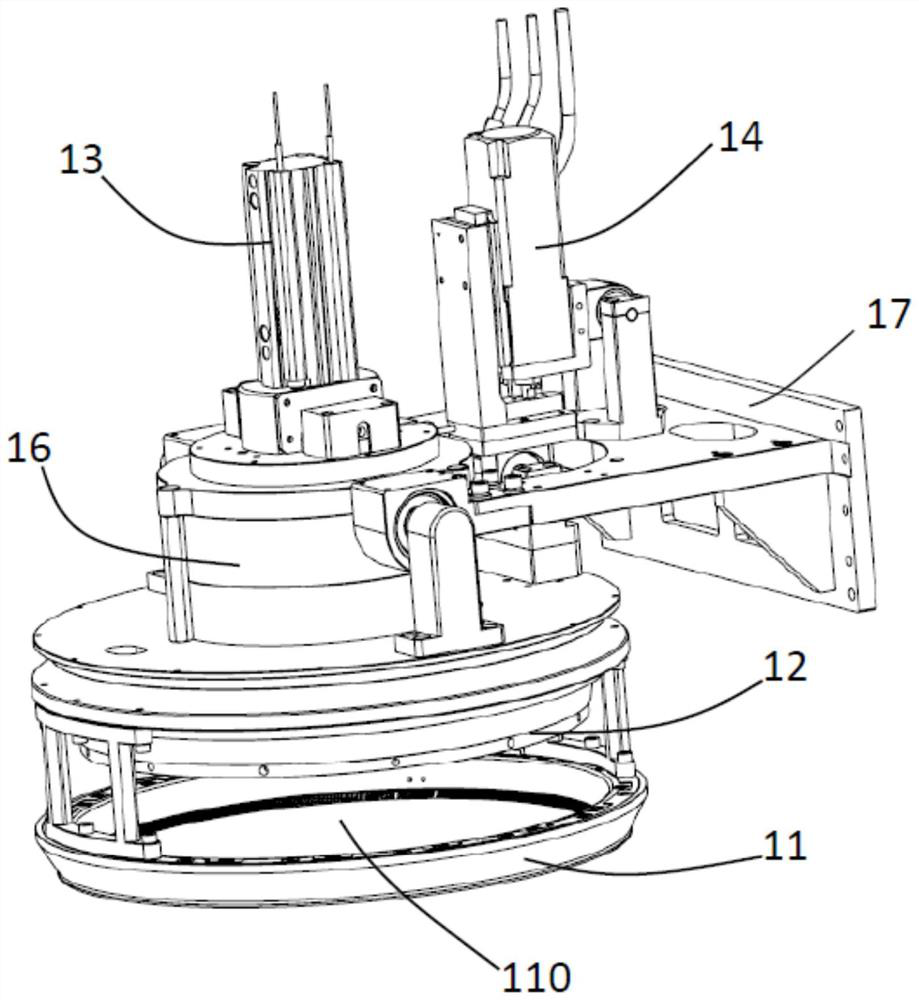

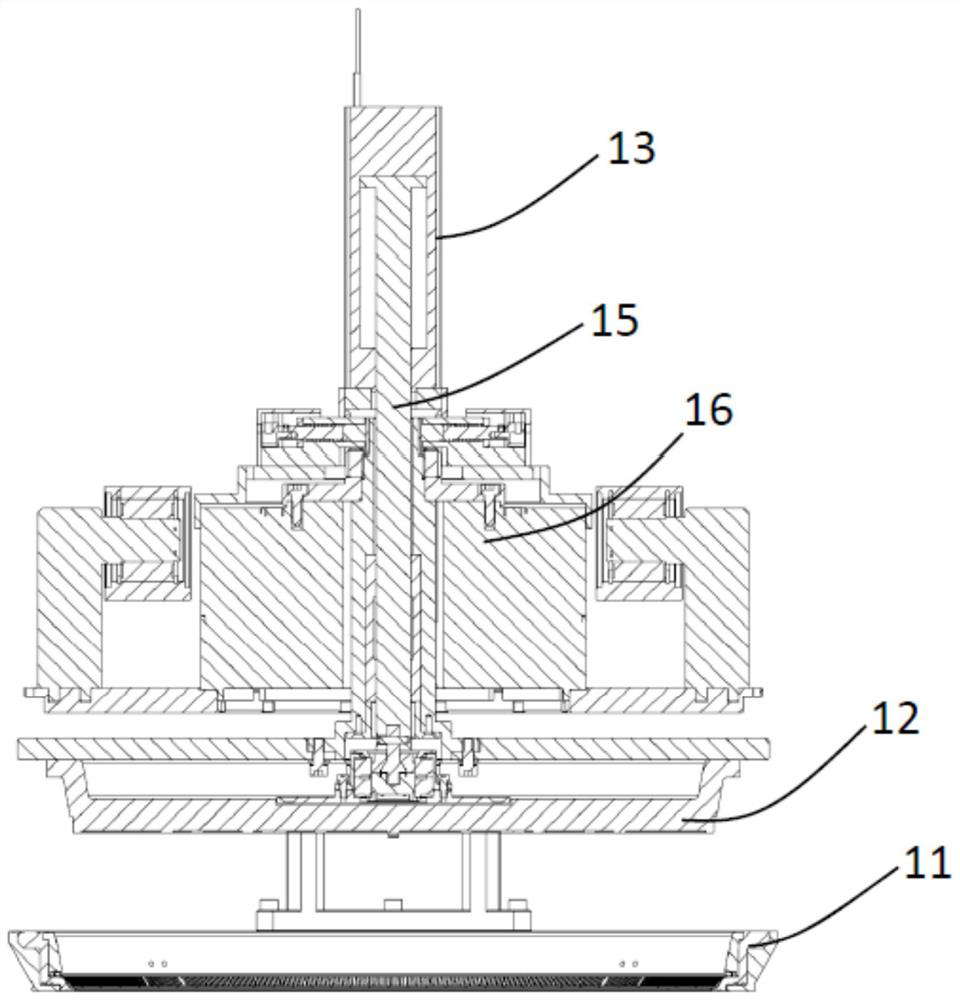

Cup chuck of substrate holding device and substrate holding device

PendingCN114645311AReduce exposed areaReduced risk of breakageElectrolysis componentsSemiconductor devicesEngineeringMechanical engineering

The invention discloses a cup-shaped chuck of a substrate holding device. The cup-shaped chuck comprises an inner pressing ring, a middle framework, a sealing piece, an outer pressing ring and a contact ring, and the inner pressing ring is locked on the inner circumferential surface of the middle framework. The sealing piece is provided with an outer end, a bottom and an inner end, the outer end of the sealing piece wraps at least part of the outer circumferential face of the middle framework, the bottom of the sealing piece wraps the bottom of the middle framework and is exposed out of the cup-shaped chuck, and the inner end of the sealing piece wraps at least part of the inner circumferential face of the middle framework and is exposed out of the cup-shaped chuck. And the inner end part of the sealing piece is tightly pressed between the inner pressing ring and the middle framework through the inner pressing ring. The outer pressing ring is made of insulating materials and is locked on the peripheral face of the middle framework, and the outer end of the sealing piece is pressed between the outer pressing ring and the middle framework through the outer pressing ring. The contact ring is located on the sealing piece and connected between the inner pressing ring and the middle framework in a pressed mode, and a sealing ring is arranged between the inner pressing ring and the contact ring.

Owner:ACM RES SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com