Curing cold patch material suitable for low-temperature humid environment and preparation method thereof

A wet environment, cold patching technology, applied in the field of emergency maintenance and road maintenance, can solve the problem of lack of research and development of cold patching materials, and achieve the effect of improving road safety, high cohesion, and avoiding secondary repairs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] Wherein the preparation method of cold patch asphalt is:

[0049] (1) The modified asphalt was heated to 180°C, and the soap solution was slowly injected, and the composite modified emulsified asphalt was prepared by high-speed shearing at a speed of 4500r / min for 15min.

[0050] (2) Add low-temperature curing epoxy glue into the composite modified emulsified asphalt in proportion, and mix evenly at room temperature to obtain cold patched asphalt.

Embodiment 4

[0051] Embodiment 4 different cold patch performance tests:

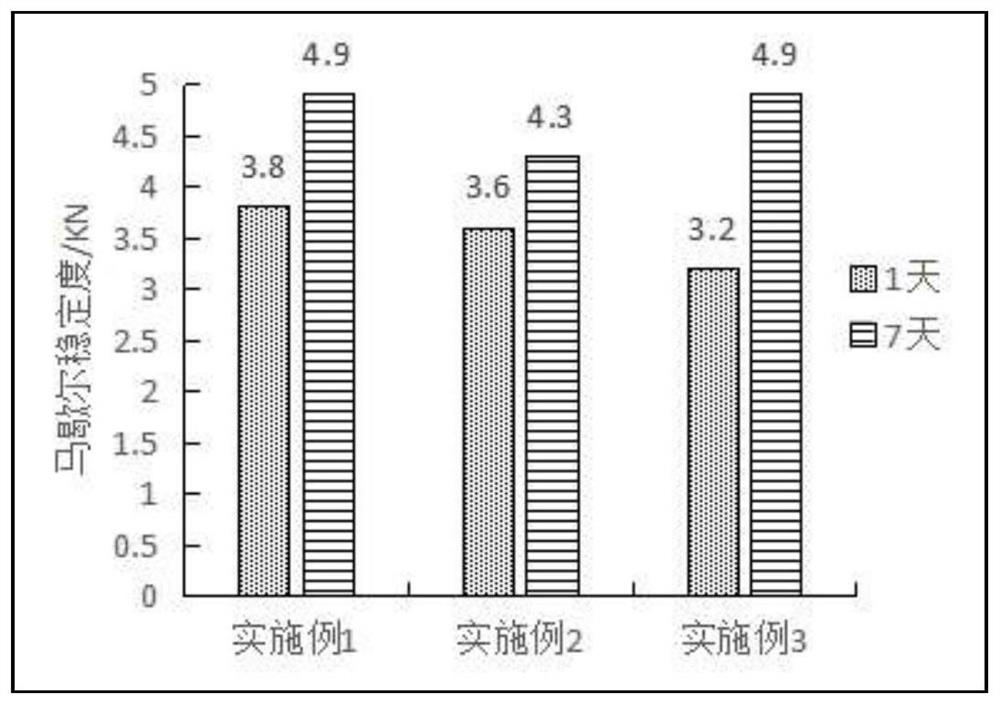

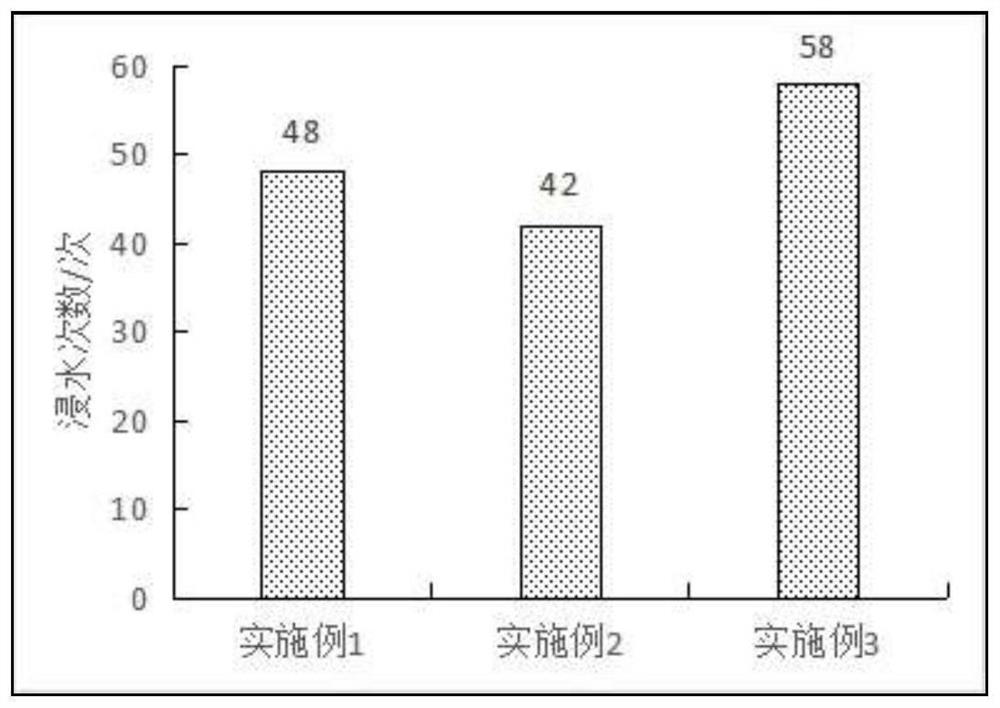

[0052] In order to reflect the cohesion of the cold patch in the presence of humidity, the present invention will design the following test to evaluate the initial stability and durability of a solidified cold patch suitable for low temperature and humid environments.

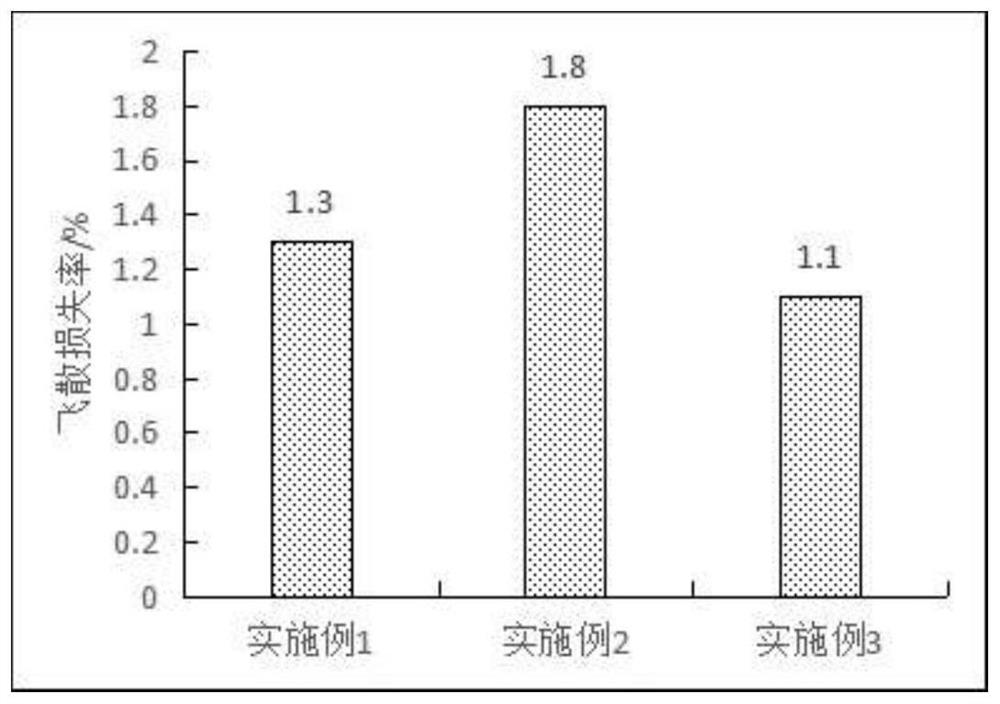

[0053] (1) Fort Kentucky Scatter Test

[0054] The prepared cold patch material was stirred at room temperature and compacted to form (50 times / surface) Marshall specimens. Each cold patch material was formed into 4 specimens. They were cured at 5°C for 24 hours, and then kept at 5°C. Carry out Kentaburg fly-away test in the box. The initial anti-scattering ability of each cold patch material figure 1 , the results show that: within a certain range, the more the asphalt content is, the less the RAP material content is, the better the bonding performance of the cold patch material is, and the better it can adapt to the low temperature and humid envi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com