Biopolymer food packaging bag film and its preparation process and production equipment

A biopolymer and production equipment technology, applied in the direction of layered products, synthetic resin layered products, coatings, etc., can solve the problems of consumption, dependence on artificial synthesis, multiple resources and energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

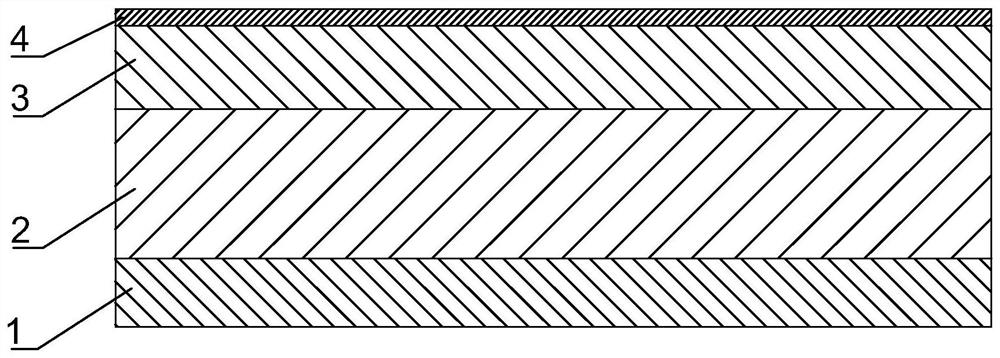

[0037] A kind of biopolymer food packaging bag film, such as figure 1 As shown, it includes chitin lining 1, starch / LDPE blend layer 2, PLA waterproof layer 3 and antibacterial coating 4, the four are arranged in sequence, and the chitin lining 1 is used as the inner surface of the food packaging bag, and the antibacterial Bacteria coating 4 is chitosan film, as the outer surface of food packaging bag.

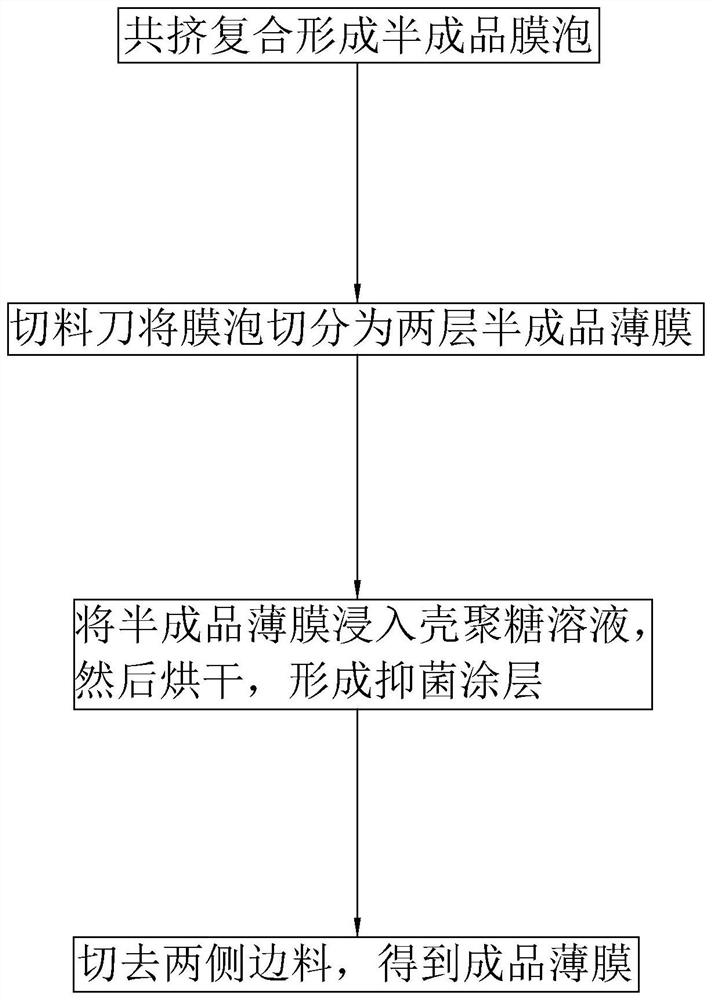

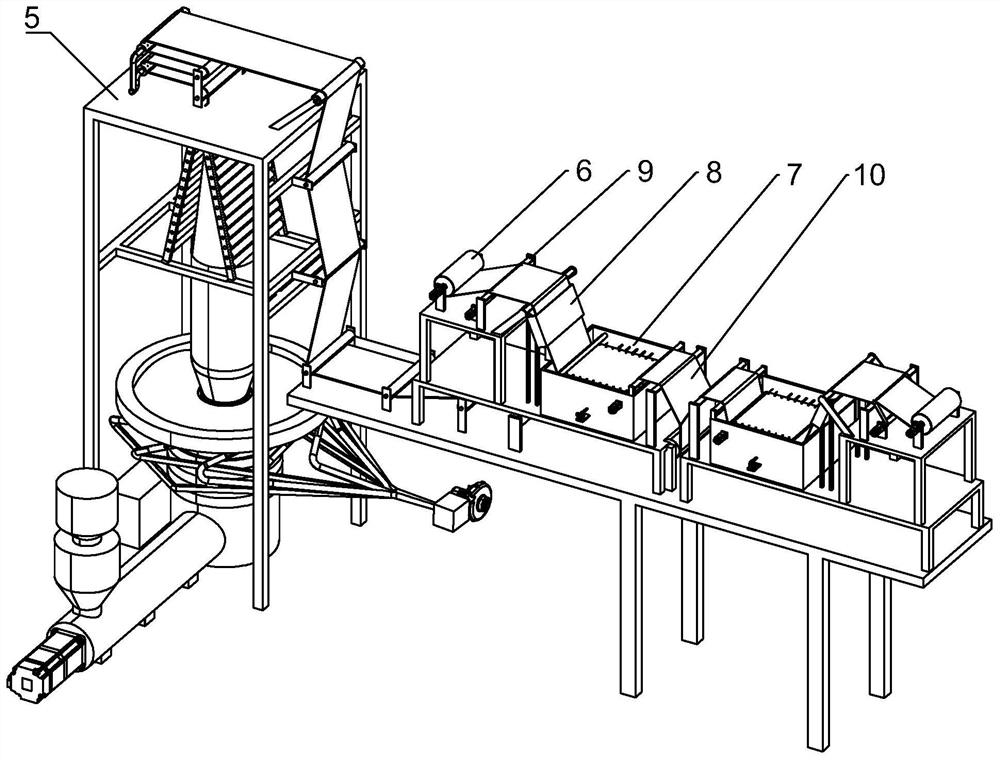

[0038] A kind of technique for producing above-mentioned biopolymer food packaging bag film, such as figure 2 shown, including:

[0039] S1, mix the powdered chitin and resin particles according to the mass ratio of 1:3, and put them into the screw conveyor connected with the inner die head of the film blowing machine. The starch and LDPE granules are mixed according to the mass ratio of 3:7, and loaded into the screw conveyor connected to the middle die head of the film blowing machine. Mix pectin and PLA particles in a mass ratio of 1:5, and load them into a screw convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com