Solvent type polyurethane resin and preparation method thereof, and fluoride-free clothes with lotus leaf effect

A polyurethane resin and solvent-based technology, which is applied in the field of polyurethane resin, can solve the problems that fluoride cannot be used, and achieve good hydrolysis resistance, water resistance, and low surface energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

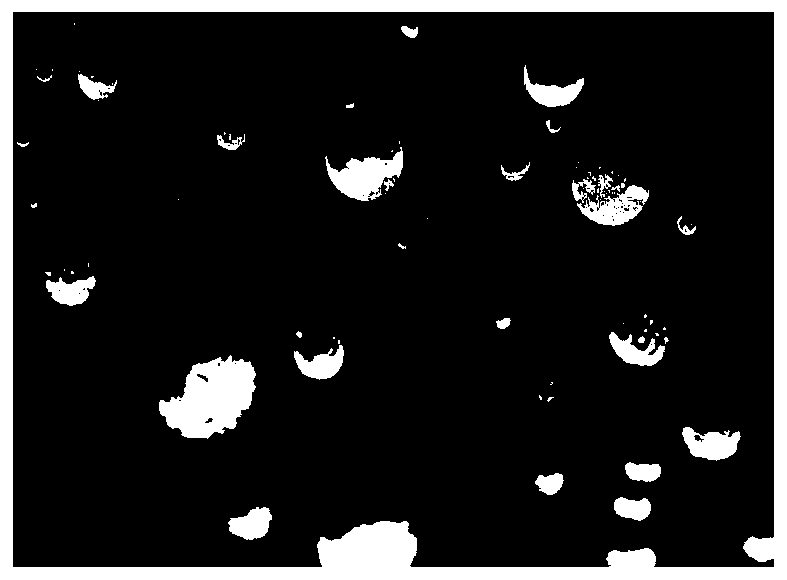

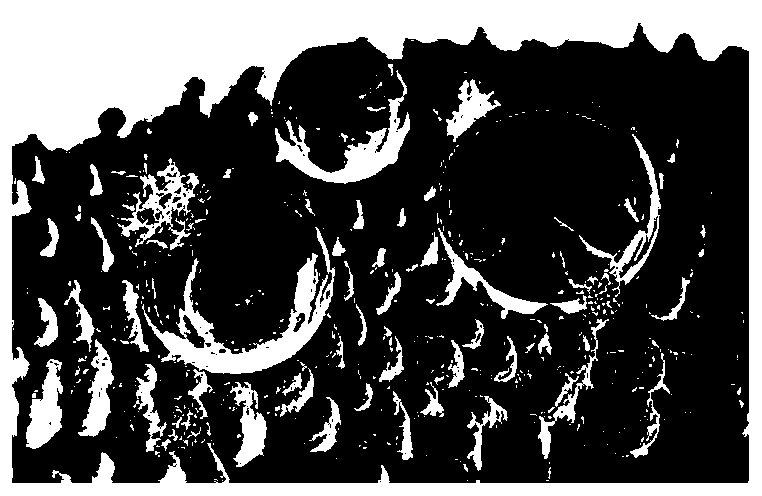

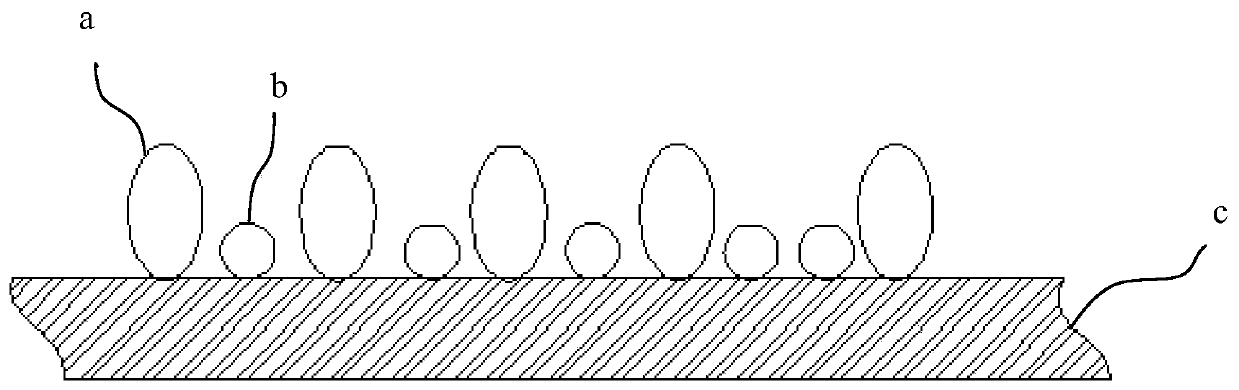

Image

Examples

Embodiment 1

[0039] For the solvent-based polyurethane resin provided in this embodiment, the composition of the raw material formula used is shown in Table 1, wherein,

[0040] The number average molecular weight of polycarbonate polyol is 2000, purchased from Japan Ube Company.

[0041] The number-average molecular weight of polytetrahydrofuran ether glycol is 2000, purchased from BASF, Germany.

[0042] The isocyanate is 4,4-diphenylmethane diisocyanate.

[0043] The additive is antioxidant, specifically CHINOX 1010 with double bond chemistry.

[0044] The catalyst is bismuth carboxylate.

[0045] The number average molecular weight of polyethylene glycol is 2000.

[0046] The reactive silicone is X-22-176DX from Japan's Shin-Etsu.

[0047] The fumed silica is DM-10 from Tokusei Co., Ltd., Japan.

[0048] The solvent-based polyurethane resin is prepared by the following method:

[0049] In the reactor, add 25% N,N-dimethylformamide of formula quantity, the polytetrahydrofuran ethe...

Embodiment 2

[0051] For the solvent-based polyurethane resin provided in this example, the composition of raw materials used is shown in Table 1, and the others are the same as in Example 1.

[0052] In this example, the reactive silicone is made up of X-22-176DX and X-22-176F from Shin-Etsu Japan in a mass ratio of 1:1; the fumed silica is DM-20S and DM- 10 according to the mass ratio of 1:1 composition.

Embodiment 3

[0054] For the solvent-based polyurethane resin provided in this example, the composition of raw materials used is shown in Table 1, and the others are the same as in Example 1.

[0055] In this example, the reactive silicone is X-22-176F from Shin-Etsu Japan; the fumed silica is DM-20S from Tokusei Corporation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com