Air cylindrical plasma generator gap structure

A technology of plasma generator and gap structure, applied in the direction of plasma, electrical components, etc., can solve the problems of unusability and limited application scope, and achieve the effect of long life and optimized cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

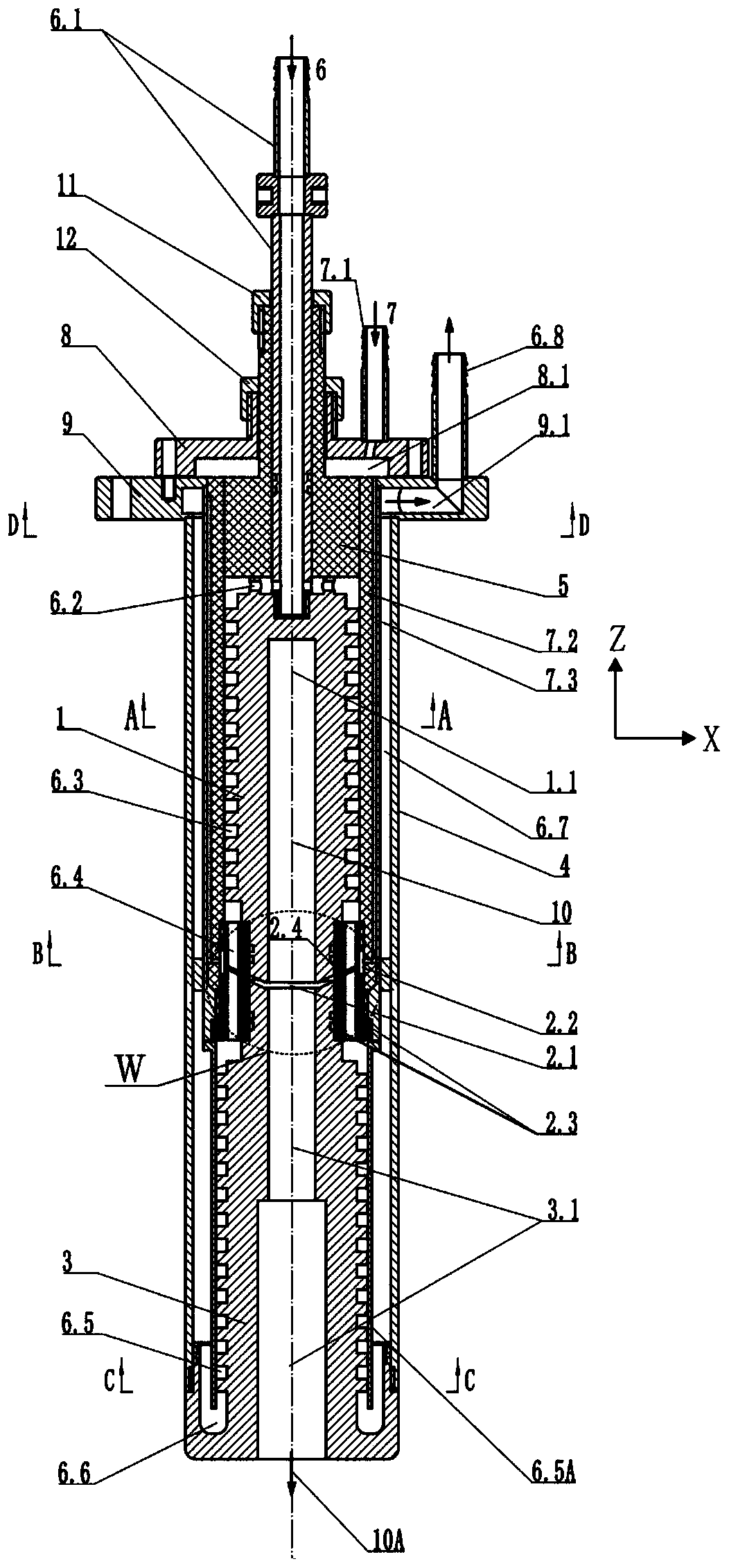

[0029] The gap structure of the air cylindrical plasma generator in this embodiment is as follows:

[0030] 1) Cylindrical electrode and axial arrangement:

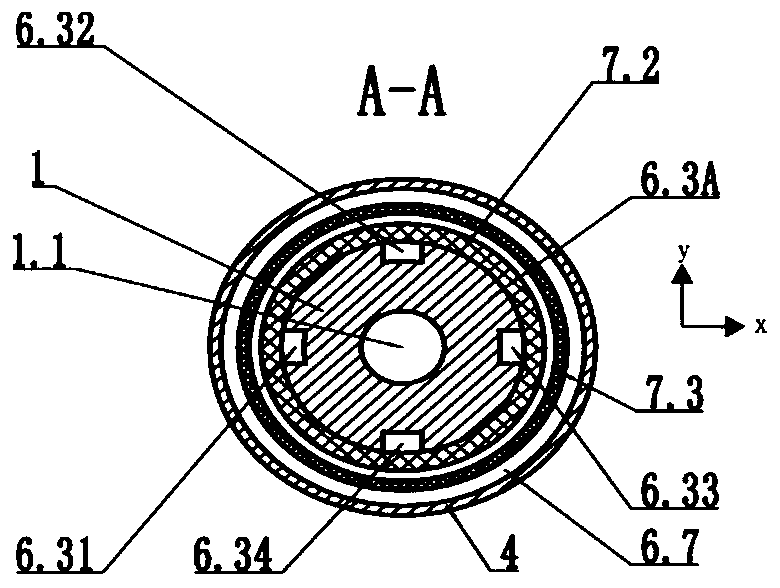

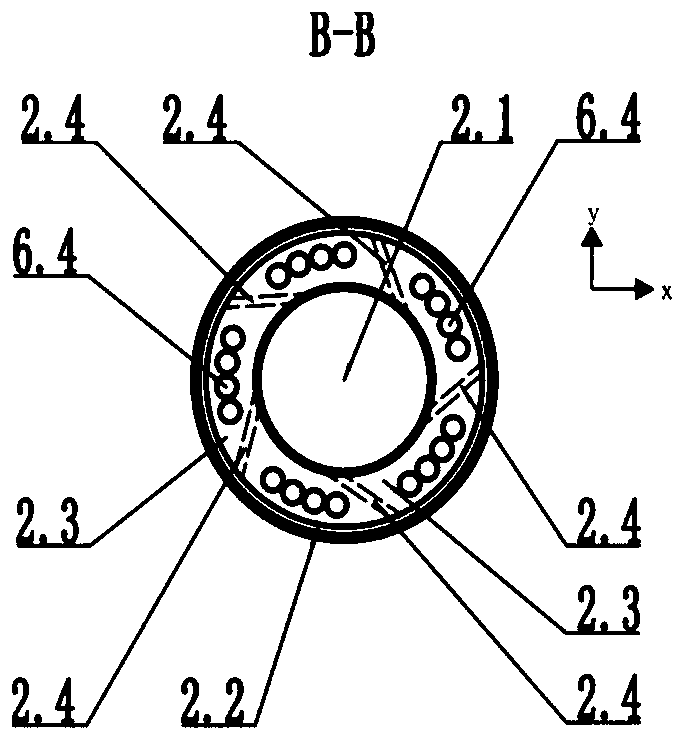

[0031] See figure 1 , the cathode 1 is located at the center of the axial middle section, and is a cylindrical body in which there is a cathode hollow pipe 1.1 for moving the arc 10 . The anode 3 is located at the center of the lower end and is also a cylindrical body, inside which is a hollow anode pipe 3.1 for moving the arc. The diameter of the central hole of the anode hollow pipe 3.1 toward the outlet is in a two-stage enlarged stepped shape. The gap 2 is located at the axial connection between the cathode and the anode. See figure 1 In the water cooling system 6, the vertical water inlet pipe 6.1 and the vertical water outlet pipe 6.8 are arranged at the upper end; in the air inlet system 7, the vertical air inlet pipe 7.1 is arranged at the upper end, and the insulating seat 5 is arranged at the center of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com