Method for manufacturing capacitor of metal-insulator-metal structure

A manufacturing method and technology for insulators, which are applied in semiconductor/solid-state device manufacturing, semiconductor device, metal material coating process, etc., can solve the problems of reduced performance parameters, high coefficient leakage current, affecting voltage and capacitance curves, etc., to improve performance parameters. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

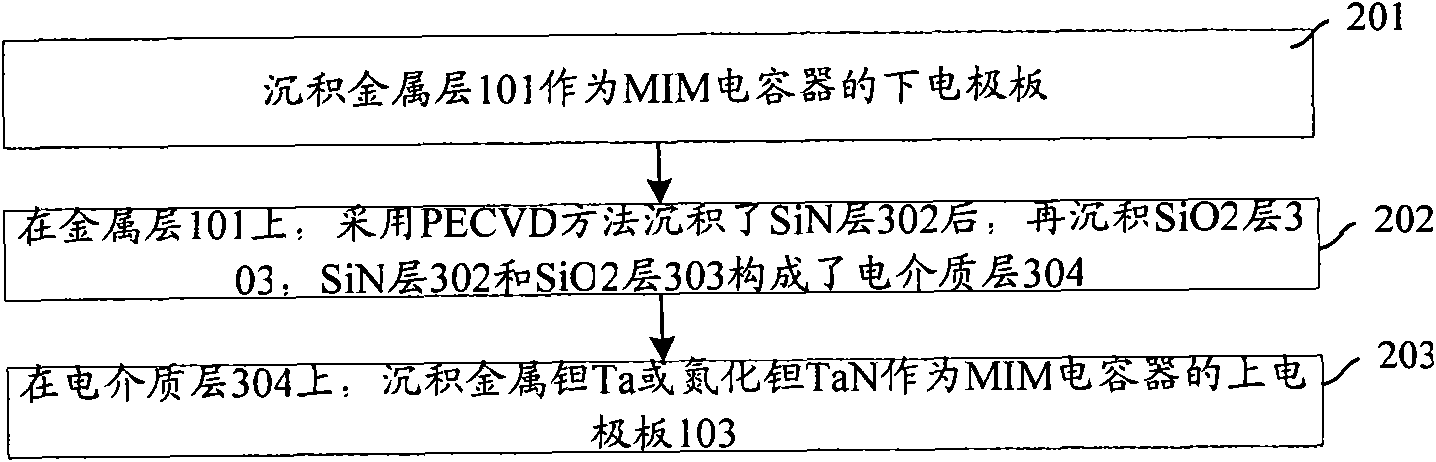

[0027] In order to overcome the performance reduction of the MIM capacitor due to the instability of the bonding bond between Si-N used to manufacture the SiN of the dielectric layer, the present invention deposits a layer of SiO2 at the SiN layer when the dielectric layer is manufactured, the SiO2 The bonding bond between the Si-O layer is more stable than the bonding bond between Si-N, and the SiO2 layer is on the SiN layer, which can cover the SiN layer with low bonding bond stability, which improves the dielectric strength of the manufactured dielectric. Bond stability between atoms in the layer, thereby improving the performance parameters of MIM capacitors with this dielectric layer.

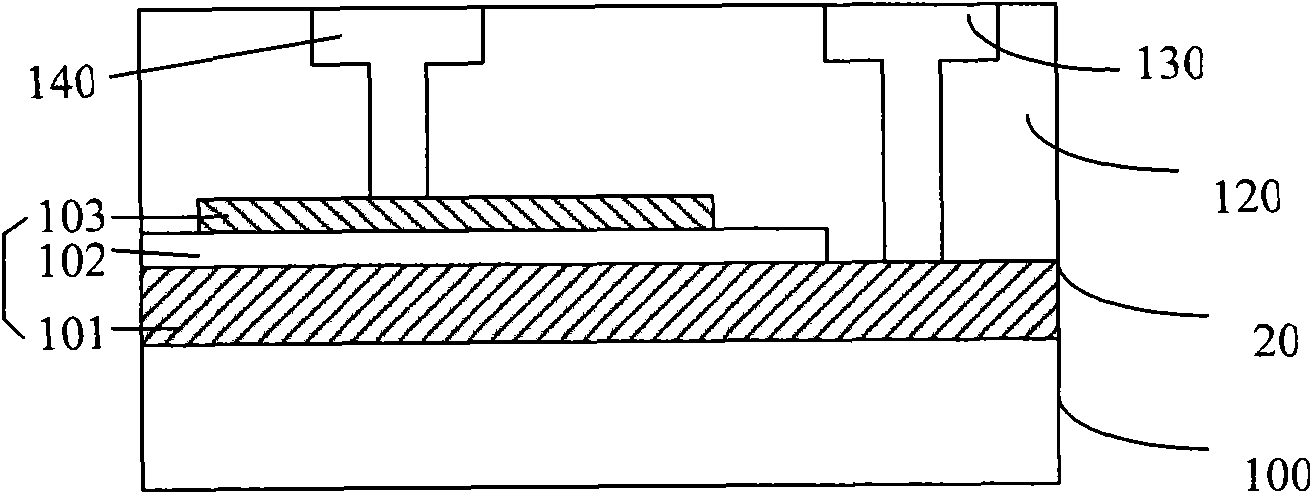

[0028] combine Figure 3a~3c The sectional structure diagram ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com