Composition for flame-retardant polyvinyl chloride (PVC) plastic foam board, product prepared from same, and preparation method thereof

A foamed plastic board and composition technology, applied in the field of thermal insulation materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

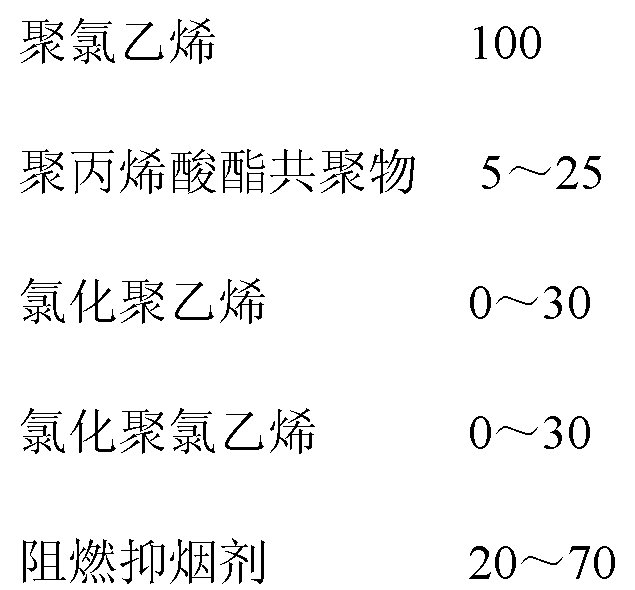

[0035] The composition formula for flame-retardant PVC foam plastic board is as follows:

[0036]

[0037]

[0038] After the composition is made into a foamed plastic insulation board according to the above method, the product has good flame retardancy and produces less black smoke when burned.

Embodiment 2

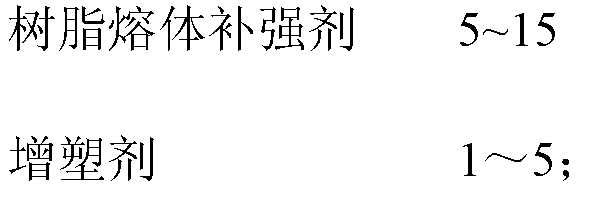

[0040] The composition formula for flame-retardant PVC foam plastic board is as follows:

[0041]

[0042] After the composition is made into a foamed plastic insulation board according to the above method, the product is tested to have good flame retardancy, extinguishes immediately after leaving the fire, has no black smoke, and only has a small amount of green and yellow smoke. The thermal weight loss is the least (6% / 30s) under the blowtorch.

Embodiment 3

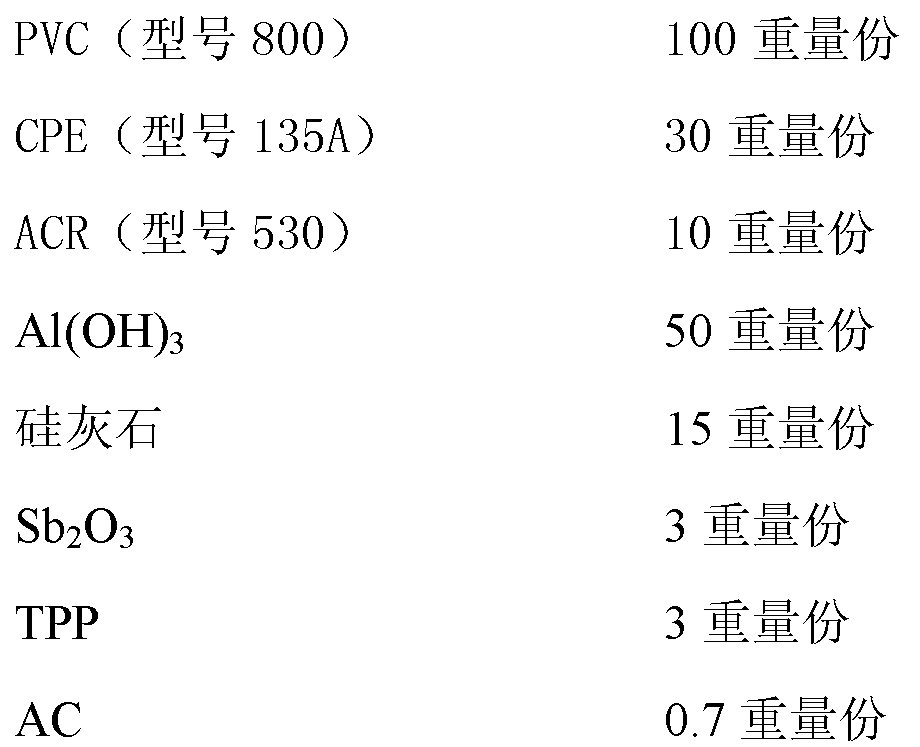

[0044] The composition formula for flame-retardant PVC foam plastic board is as follows:

[0045]

[0046]

[0047] After the composition is made into a foamed plastic insulation board according to the above method, the product is tested to have good flame retardancy, extinguishes immediately after leaving the fire, and has no black smoke. Thermal weight loss under blowtorch is less (7% / 30s).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com