Micro-foaming wood plastic composite material plate for building template and preparation method thereof

A technology for wood-plastic composite materials and building templates, which is applied in the fields of foamed wood-plastic composite materials and their processing, micro-foamed wood-plastic composite materials and processing technology, and can solve problems such as easy merging of holes, difficulty in plates, and low surface hardness. , to achieve the effect of reducing and foaming, good lubricating effect and improving internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

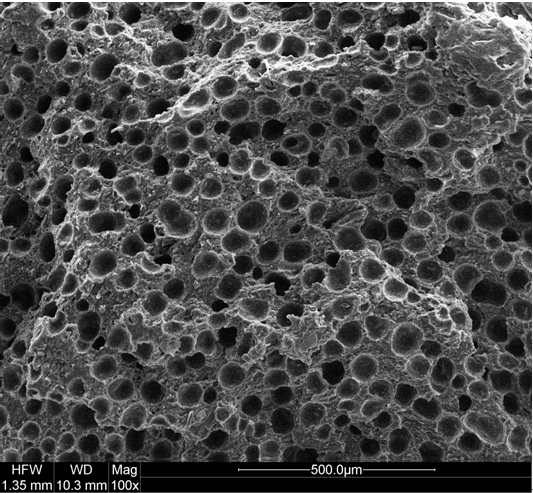

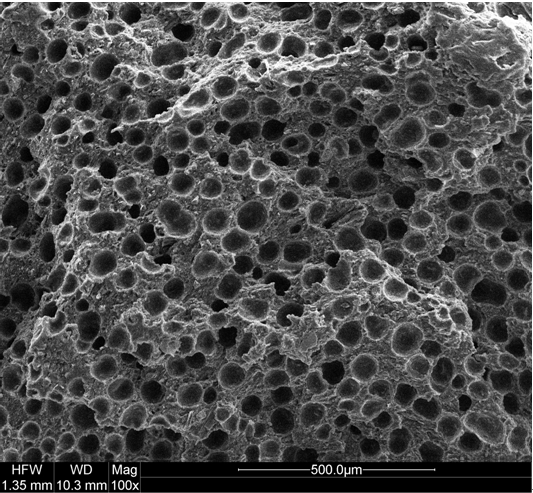

Image

Examples

Embodiment 1

[0069] (1) 40.0 parts by mass of polyvinyl chloride (PVC S-700);

[0070] (2) 20.0 parts by mass of wood flour with a particle size of 100-200 mesh;

[0071] (3) 11.5 parts by mass of light active calcium carbonate (1000-1500 mesh);

[0072] (4) Foaming agent (azodicarbonamide) 1.2 parts by mass;

[0073] (5) Foaming stabilizer (dibutyltin) 0.6 parts by mass;

[0074] (6) 1.5 parts by mass of polyethylene wax;

[0075] (7) Titanate coupling agent (NDZ311) 1.0 parts by mass;

[0076] (8) 10.0 parts by mass of chlorinated polyethylene;

[0077] (9) 6.0 parts by mass of adsorbent;

[0078] The adsorbent is nano calcium oxide with a particle size of 100~500nm, and the purity is >98%wt;

[0079] (10) 1.0 parts by mass of foaming aid;

[0080] Zinc oxide with a particle size of 30~60nm;

[0081] (11) Silicone processing aid (LYSI-100) 0.7 parts by mass;

[0082] (12) E-glass fiber (diameter 12um, length 5mm) 6.5 parts by mass;

[0083] 2. Process

[0084] First mix the wo...

Embodiment 2

[0102] (1) 50.0 parts by mass of polyvinyl chloride (PVC S-700);

[0103] (2) 15.0 parts by mass of wood flour with a particle size of 100-200 mesh;

[0104] (3) 10.0 parts by mass of light active calcium carbonate (1000-1500 mesh);

[0105] (4) Foaming agent (azodicarbonamide) 0.4 parts by mass;

[0106] (5) Foam stabilizer (dibutyltin) 3.5 parts by mass;

[0107] (6) 0.5 parts by mass of polyethylene wax;

[0108] (7) Titanate coupling agent (NDZ311) 1.1 parts by mass;

[0109] (8) 4.0 parts by mass of chlorinated polyethylene;

[0110] (9) Adsorbent (nano-calcium oxide with particle size of 100-500nm, purity>98%wt;) 8.0 parts by mass;

[0111] (10) Foaming aid (zinc oxide with a particle size of 30-60nm) 2.0 parts by mass;

[0112] (11) Silicone processing aid (LYSI-100) 1.5 parts by mass;

[0113] (12) E-glass fiber (diameter 10um, length 6mm) 4.0 parts by mass

[0114] 2. Process

[0115] First mix the wood flour and nano-calcium oxide powder at a high speed of 1...

Embodiment 3

[0133] (1) 41.0 parts by mass of polyvinyl chloride (PVC S-700);

[0134] (2) 25.0 parts by mass of wood flour with a particle size of 100-200 mesh;

[0135] (3) 11.5 parts by mass of light active calcium carbonate (1000-1500 mesh);

[0136] (4) Foaming agent (azodicarbonamide) 0.2 parts by mass;

[0137](5) Foam stabilizer (dibutyltin) 0.8 parts by mass;

[0138] (6) 2.5 parts by mass of polyethylene wax;

[0139] (7) Titanate coupling agent (NDZ311) 2.0 parts by mass;

[0140] (8) 5.0 parts by mass of chlorinated polyethylene;

[0141] (9) Nano-adsorbent (nano-calcium oxide with particle size of 100-500nm, purity>98%wt;) 5.0 parts by mass;

[0142] (10) 3.5 parts by mass of nano-foaming aid (zinc oxide with a particle size of 30-60nm);

[0143] (11) Silicone processing aid (GM100) 0.5 parts by mass;

[0144] (12) E-glass fiber (diameter 14um, length 3mm) 3.0 parts by mass.

[0145] 2. Process

[0146] First mix the wood flour and nano-calcium oxide powder at a high ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com