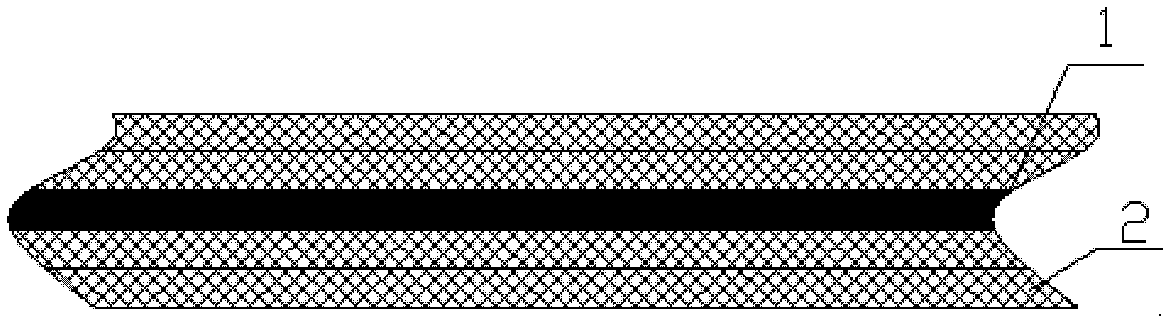

Embedded type high-temperature co-curing high-damping composite material and preparation process thereof

A composite material and embedded technology, applied in the field of materials, can solve the problems of large viscoelastic damping film sheet, embedded co-cured composite material damping structure with low interlayer bonding force, destroying the surface molecular activity of viscoelastic film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

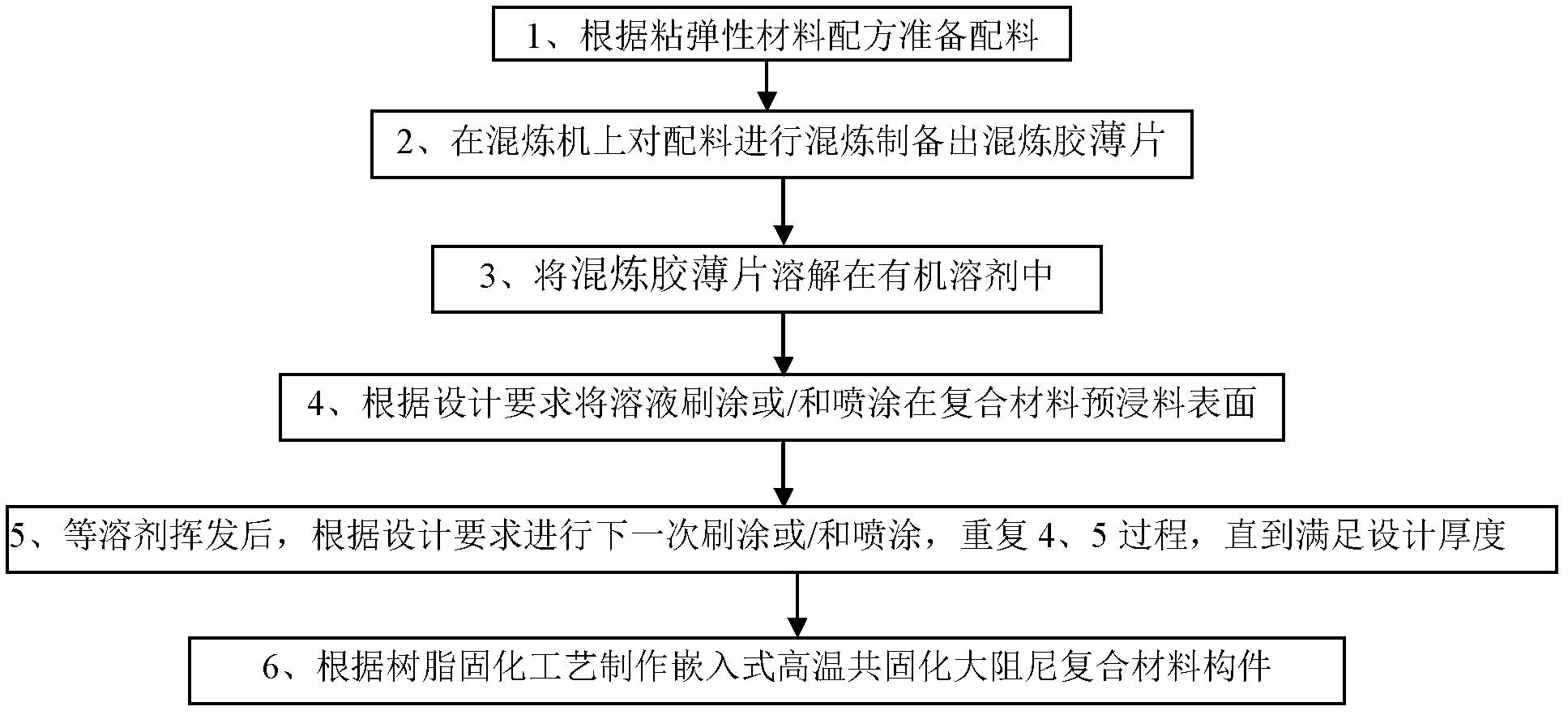

Method used

Image

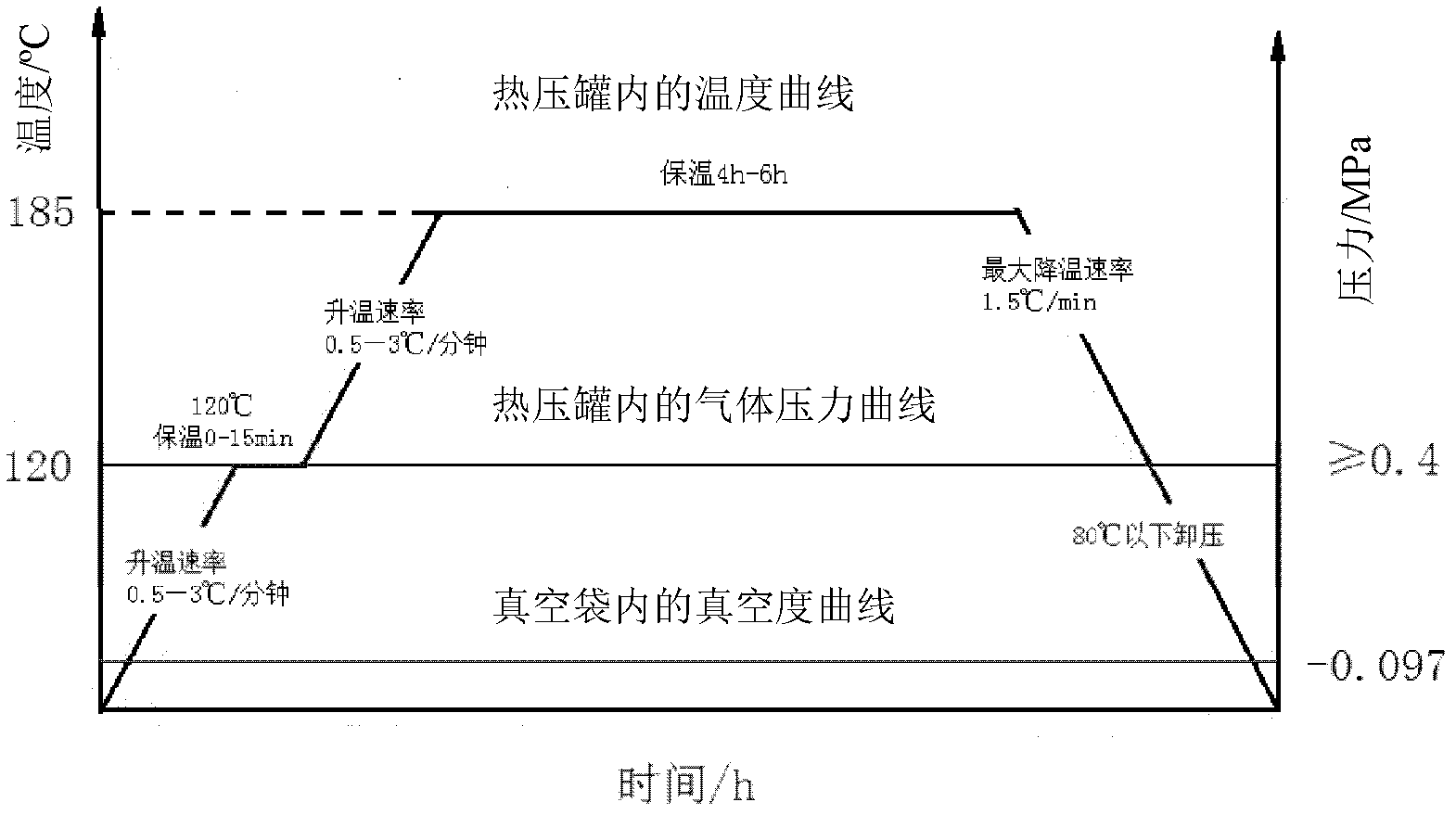

Examples

Embodiment 1

[0049] 1. Preparation of materials:

[0050] An embedded high-temperature co-cured large damping composite material is proposed, and its mass-to-number ratio is: 93 parts of butyl rubber; 7 parts of chlorinated butyl rubber; 3 parts of chlorinated polyethylene; 4 parts of zinc oxide; stearic acid 0.9 parts; 51 parts of carbon black; 6 parts of octyl phenolic resin. And prepare materials according to this ratio.

[0051] 2. Preparation of mixed rubber: first add butyl rubber and chlorinated butyl rubber to the internal mixer and mix for two minutes, then add chlorinated polyethylene and mix for two minutes, after mixing evenly, add zinc oxide and stearin Mix with acid for three minutes, then add carbon black and mix for four minutes, finally add octyl phenolic resin, and mix for two minutes to ensure that the mixed rubber is uniform, take it out from the internal mixer, and finally put the mixed raw rubber into On the double-drum open mill, the roller distance is adjusted to ...

Embodiment 2

[0057] 1. Preparation of materials:

[0058] An embedded high-temperature co-cured large damping composite material is proposed, and its mass-to-number ratio is: 92.5 parts of butyl rubber; 6.5 parts of chlorinated butyl rubber; 2.9 parts of chlorinated polyethylene; 3.9 parts of zinc oxide; stearic acid 0.8 parts; 50 parts of carbon black; 5.9 parts of octyl phenolic resin. And prepare materials according to this ratio.

[0059] 2. Preparation of mixed rubber: first add butyl rubber and chlorinated butyl rubber to the internal mixer and mix for two minutes, then add chlorinated polyethylene and mix for two minutes, after mixing evenly, add zinc oxide and stearin Mix with acid for three minutes, then add carbon black and mix for four minutes, finally add octyl phenolic resin, and mix for two minutes to ensure that the mixed rubber is uniform, take it out from the internal mixer, and finally put the mixed raw rubber into On the double-drum open mill, adjust the roller distanc...

Embodiment 3

[0065] 1. Preparation of materials:

[0066] An embedded high-temperature co-cured large damping composite material is proposed, and its mass-to-number ratio is: 93.5 parts of butyl rubber; 7.5 parts of chlorinated butyl rubber; 3.1 parts of chlorinated polyethylene; 4.1 parts of zinc oxide; stearic acid 1 part; 52 parts of carbon black; 6.1 parts of octyl phenolic resin. And prepare materials according to this ratio.

[0067] 2. Preparation of mixed rubber: first add butyl rubber and chlorinated butyl rubber to the internal mixer and mix for two minutes, then add chlorinated polyethylene and mix for two minutes, after mixing evenly, add zinc oxide and stearin Mix with acid for three minutes, then add carbon black and mix for four minutes, finally add octyl phenolic resin, and mix for two minutes to ensure that the mixed rubber is uniform, take it out from the internal mixer, and finally put the mixed raw rubber into On the double-drum open mill, the roller distance is adjuste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com