Fly wheel type composite damper for transmission shafting

A transmission shaft and damper technology, applied in the field of dampers, can solve the problems of increasing research cost and occupying space, and achieve the effects of saving cost, saving space and improving vibration damping ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

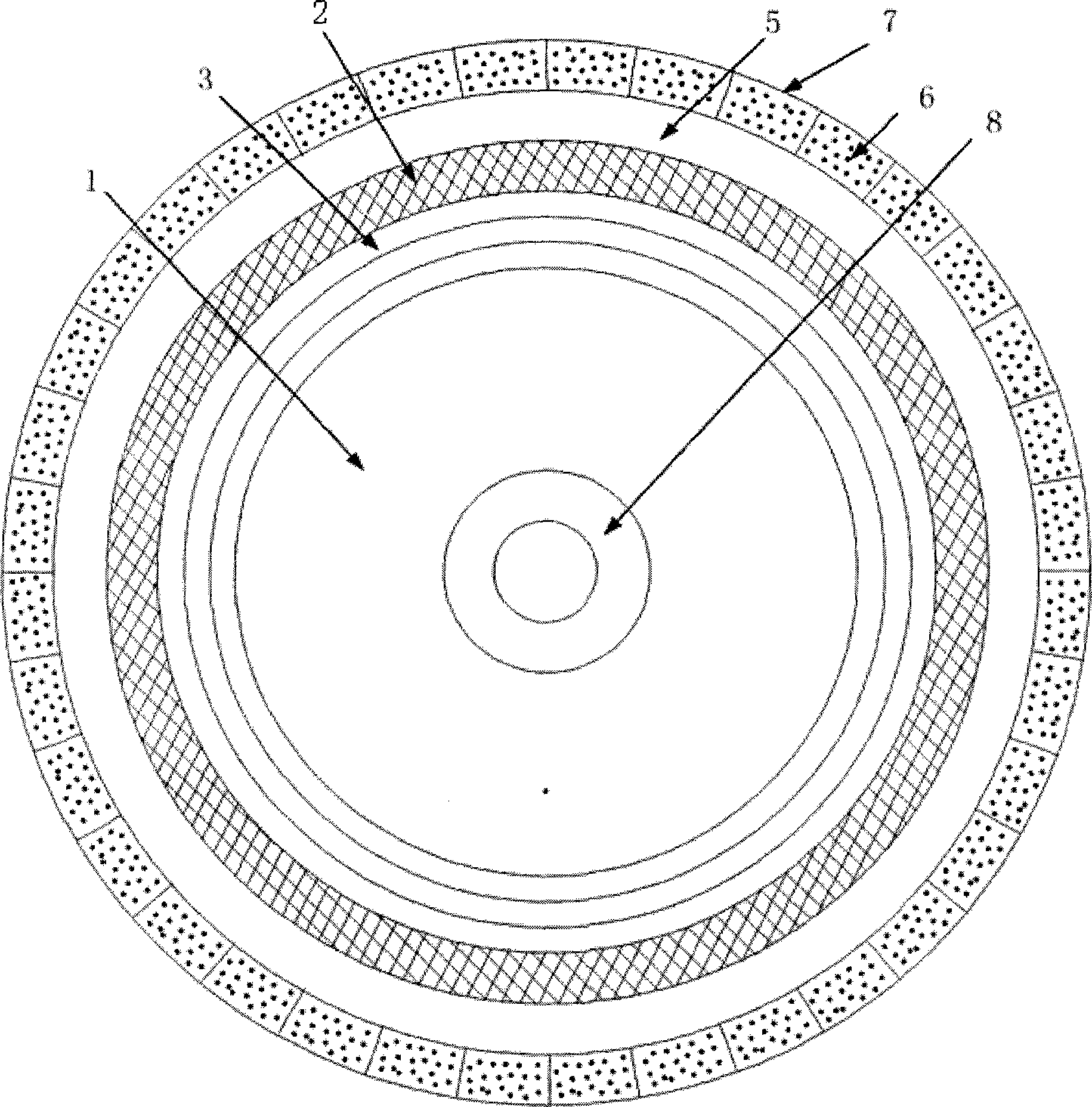

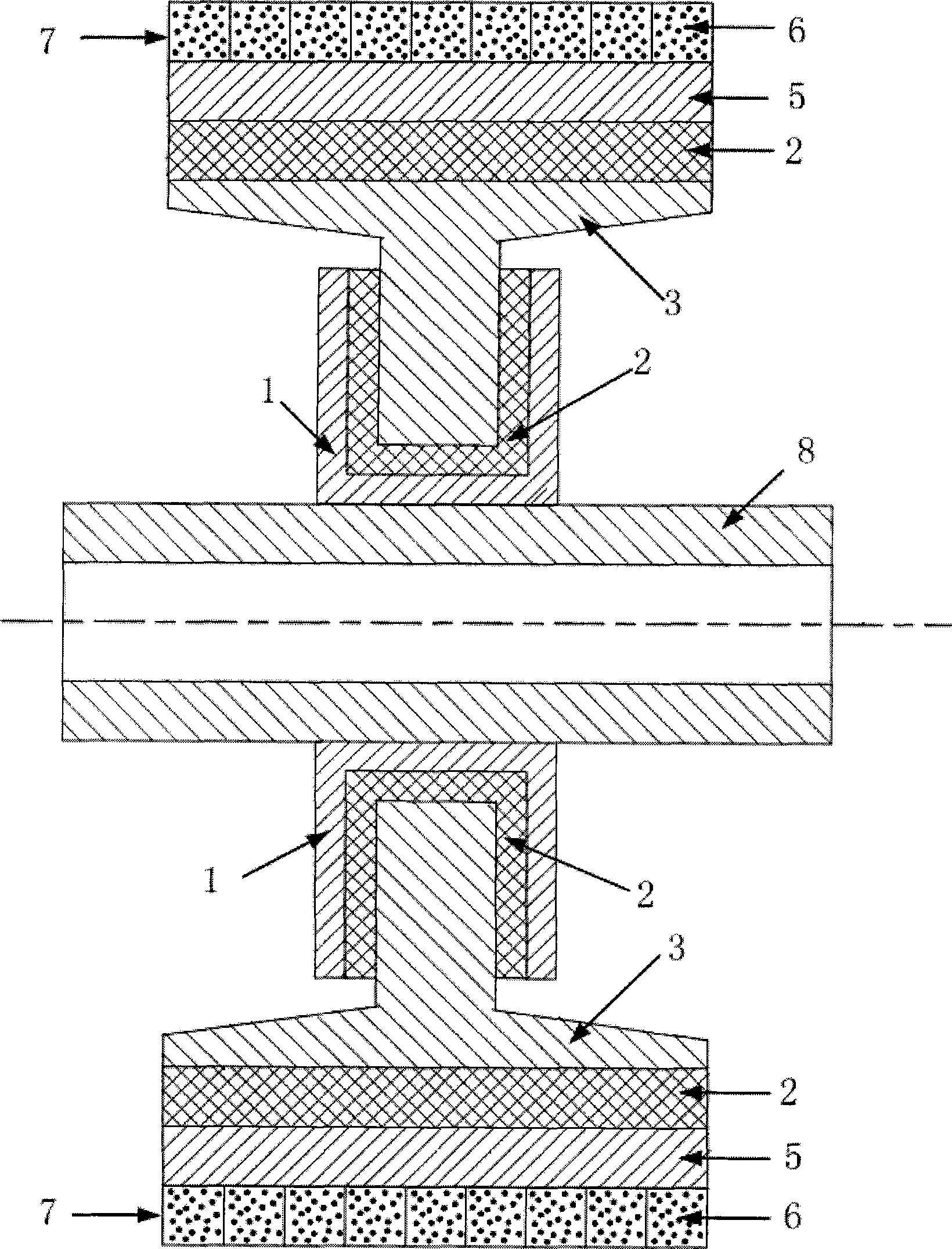

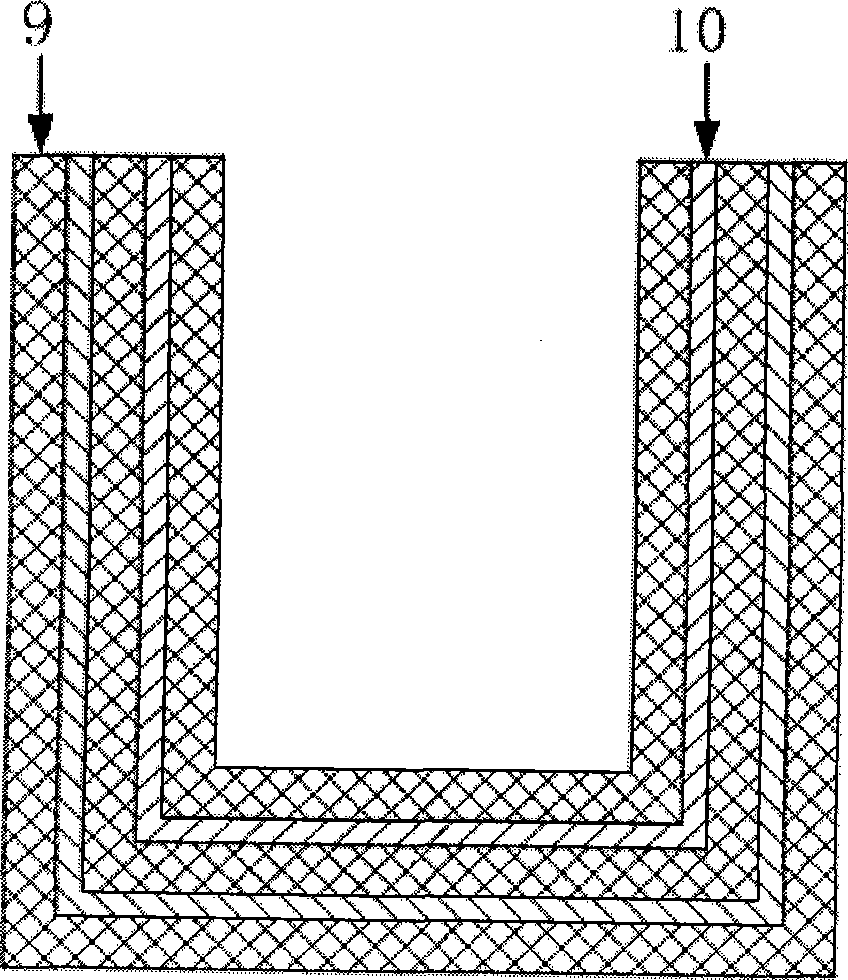

[0012] Such as figure 1 , 2 As shown, the drive shaft system flywheel compound damper of the present invention includes a cross-section mounted on the shaft type of constraining flange 1, also includes a cross-section Type 2 hub, the constraining flange is set on the shaft, the hub is installed in the groove of the constraining flange through its inner ring, and the inner ring of the hub and the inner wall of the constraining flange groove are provided with a viscoelastic damping layer, and the outer ring of the hub It is connected with the inner ring of the flywheel 5 through another viscoelastic damping layer, and the outer ring of the flywheel is also equipped with a damping layer 7 of a honeycomb structure filled with damping particles 6 inside. The damping particles 6 are filled in the cavity of the honeycomb structure with a certain filling rate.

[0013] When the torsional vibration occurs in the shafting, the viscoelastic damping layer between the flywheel 5 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com