High chlorinated potyethlene anti-corrosive paint and preparation method thereof

A technology of high chlorinated polyethylene and anti-corrosion coatings, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor heat resistance and poor heat resistance of high chlorinated polyethylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

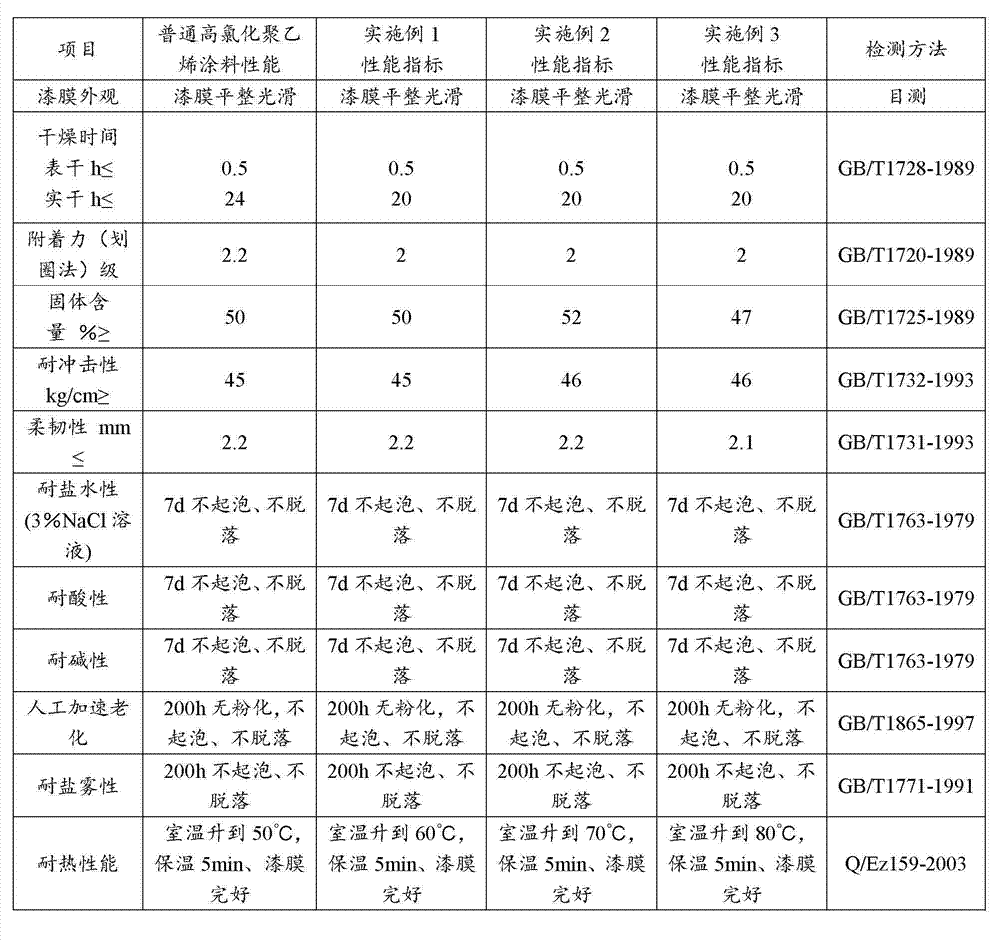

Examples

Embodiment 1

[0025] A kind of high chlorinated polyethylene anticorrosion coating, by weight, the raw material is composed of: 10 parts of high chlorinated polyvinyl chloride, 35 parts of epoxy resin E51, 15 parts of polytrifluoroethyl methacrylate, 19 parts of titanium dioxide , 0.5 parts of zinc phosphate, 0.15 parts of polyethylene wax, 0.05 parts of chlorinated paraffin, 0.3 parts of defoamer BYK065, 20 parts of toluene.

[0026] The molecular weight of the high chlorinated polyvinyl chloride is 1.0w-3.5w, and the mass percentage of chlorine is 60%-65%.

[0027] Its specific steps include:

[0028] (1) Weigh each raw material according to the proportion and set aside;

[0029] (2) Add toluene and polyethylene wax to polytrifluoroethyl methacrylate for pre-grinding; wherein, the mass ratio of polytrifluoroethyl methacrylate to toluene is 1:1;

[0030] (3) Add remaining toluene to epoxy resin E51 for pre-grinding;

[0031] (4) After mixing the above two pre-ground materials, add high-...

Embodiment 2

[0033] A kind of high chlorinated polyethylene anticorrosion coating, by weight, the raw material is composed of: 40 parts of high chlorinated polyvinyl chloride, 5 parts of epoxy resin E51, 5 parts of polyhexafluorobutyl acrylate, 10 parts of zinc powder, three 0.6 parts of aluminum polyphosphate, 0.05 parts of polyethylene wax, 0.15 parts of chlorinated paraffin, 0.2 parts of defoamer BYK065, 39 parts of toluene.

[0034] The molecular weight of the high chlorinated polyvinyl chloride is 1.0w-3.5w, and the mass percentage of chlorine is 60%-65%.

[0035] Its specific steps include:

[0036] (1) Weigh each raw material according to the proportion and set aside;

[0037] (2) Add toluene and polyethylene wax to polyhexafluorobutyl acrylate for pre-grinding; wherein, the mass ratio of polyhexafluorobutyl acrylate to toluene is 1:1;

[0038] (3) Add remaining toluene to epoxy resin E51 for pre-grinding;

[0039] (4) After mixing the above two pre-ground materials, add high-chl...

Embodiment 3

[0041] A kind of high chlorinated polyethylene anticorrosion coating, by weight, the raw material is composed of: 15 parts of high chlorinated polyvinyl chloride, 5 parts of epoxy resin E55, 5 parts of polydodecafluoroheptyl methacrylate, 15 parts of titanium dioxide 0.3 parts of zinc phosphate, 0.1 parts of polyethylene wax, 0.5 parts of chlorinated paraffin, 0.1 parts of defoamer BYK065, 59 parts of xylene.

[0042] The molecular weight of the high chlorinated polyvinyl chloride is 1.0w-3.5w, and the mass percentage of chlorine is 60%-65%.

[0043] Its specific steps include:

[0044] (1) Weigh each raw material according to the proportion and set aside;

[0045] (2) Add xylene and polyethylene wax to polydodecafluoroheptyl methacrylate for pre-grinding; wherein, the mass ratio of polydodecafluoroheptyl methacrylate to xylene is 1:1;

[0046] (3) Add remaining xylene to epoxy resin E55 for pre-grinding;

[0047] (4) After mixing the above two pre-ground materials, add high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com