Method for extruding ultra-high molecular weight polyethylene product with flame retardant and antistatic properties

A technology of ultra-high molecular weight and molecular weight, applied in the field of ultra-high molecular weight polyethylene products, can solve problems such as fire or explosion, and achieve the effect of preventing migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

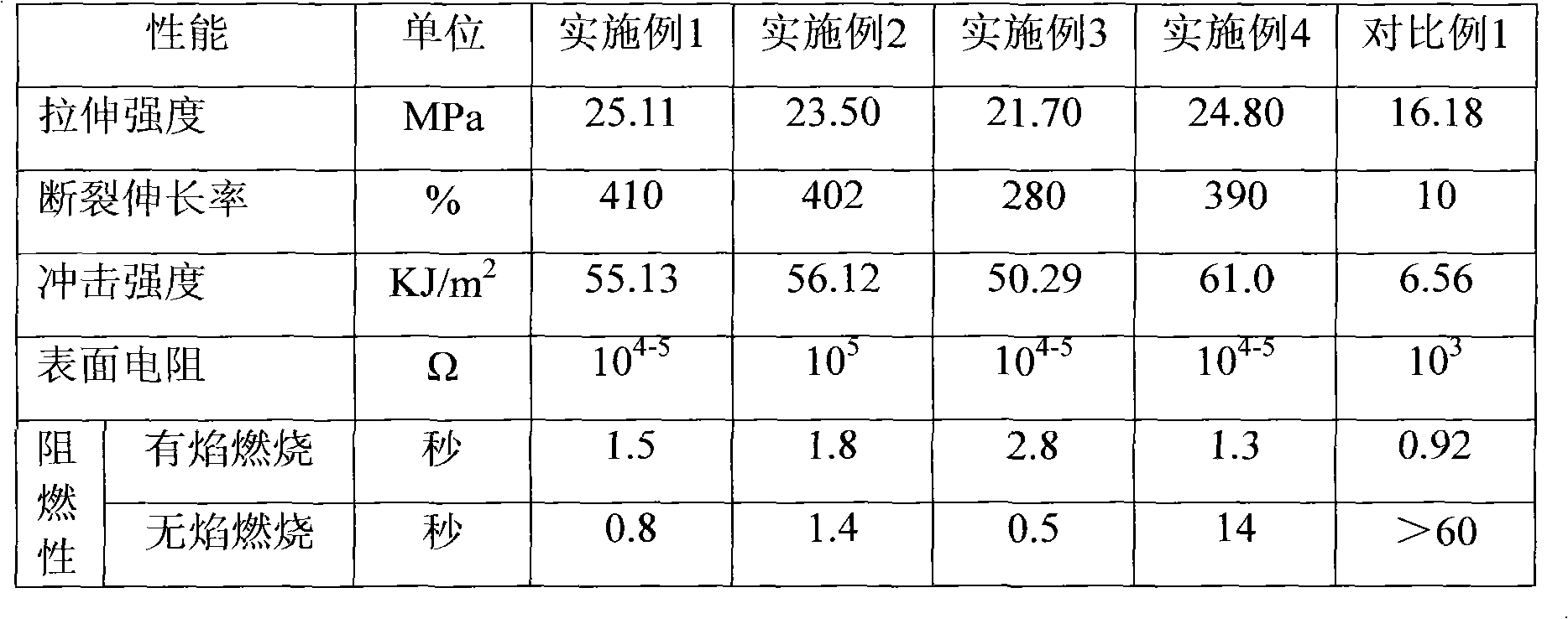

Embodiment 1

[0027] Continuous extrusion of flame-retardant and antistatic UHMWPE pipe with a diameter of 62mm. Take 100 parts of UHMWPE (M3) resin with a molecular weight of 3.8 million; 25 parts of high-density polyethylene resin with a molecular weight of 700,000; and the conductive carbon black / compound flame retardant mixed powder kneaded in an internal mixer at 60°C-80°C for 10 minutes in advance body (including 35 parts of conductive carbon black composite powder; 32 parts of compound flame retardant); 2 parts of polyethylene wax, 2 parts of calcium stearate, 0.2 parts of fluorine additives, and 0.4 parts of B215 antioxidant are added to the single screw In the extruder, the UHMWPE double-resistant pipe with a smooth appearance like a mirror is extruded.

Embodiment 2

[0029] Continuous extrusion of flame retardant and antistatic UHMWPE pipes with a diameter of 227mm. Take 100 parts of UHMWPE (M3) resin with a molecular weight of 3.8 million; 20 parts of a high-density polyethylene resin with a molecular weight of 500,000; and the conductive carbon black / compound flame retardant mixed powder kneaded in an internal mixer at 60°C-80°C for 10 minutes in advance Body (including 30 parts of conductive carbon black composite powder; 30 parts of compound flame retardant); 2 parts of polyethylene wax, 2 parts of calcium stearate, 0.2 parts of fluorine additives, 0.4 parts of B215 antioxidant are added to the single screw In the extruder, the UHMWPE double-resistant pipe with a smooth appearance like a mirror is extruded.

Embodiment 3

[0031] Continuous extrusion of UHMWPE sheets with a width of 1000mm X 7mm. Take 100 parts of UHMWPE (M3) resin with a molecular weight of 3.8 million; 25 parts of a high-density polyethylene resin with a molecular weight of 500,000; and the conductive carbon black / compound flame retardant mixed powder kneaded in an internal mixer at 60°C-80°C for 10 minutes in advance body (including 35 parts of conductive carbon black composite powder; 32 parts of compound flame retardant); 2 parts of polyethylene wax, 2 parts of calcium stearate, 0.2 parts of fluorine additives, and 0.4 parts of B215 antioxidant are added to the single screw In the extruder, the UHMWPE double-resistant sheet with a smooth appearance like a mirror is extruded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com