Patents

Literature

31results about How to "Static electricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blended material with high acetate fiber content and preparation method of blended material

ActiveCN105297443AGood touchImprove breathabilityBiochemical fibre treatmentFilament/thread formingFiberCrack resistance

The invention provides a blended material with high acetate fiber content and a preparation method of the blended material. According to the invention, on one hand, the strength of acetate fiber per se is improved, and the crack resistance is improved; on the other hand, the clothing material obtained after blending is subjected to surface strengthening treatment, the stretch resistance, tear resistance and abrasion resistance are further improved, and the wet strength of the material is obviously improved. Through the treatment, the weakness that the mechanical strength of the acetate fiber is poor is eliminated, so that the content of the acetate fiber component in the blended material can be increased, and the excellent wearing properties of excellent touch, good air permeability, no static electricity and easiness in coloring of the acetate fiber can be reserved in the blended material to the maximum extent.

Owner:ZHEJIANG CHAOFAN GARMENT CO LTD

Flame retarding anti-static plastic braiding bags

A flame-retarded and antistatic Polywoven Bag is used to solve the problem that whose average surface resistance is sharply lower than that of the national standards and is prepared by: (1) Making flame-retarded masterbatch A by mixture and plastication of the antimony oxide and the polypropylene; (2) Making flame-retarded masterbatch B by mixture and plastication of the Decabromobiphenyl ether and the polypropylene; (3) Making antistatic masterbatch by mixture and plastication of the static agent and the polypropylene; (4) Making the mixture of the flame-retarded masterbatch A, B,antistatic masterbatch and the polypropylene through the high rate agitator; (5) Making the filamentus disk through drawing it to pellicle and filamentus using the plastic machine; and (6) Surface treating using the static agent. It can be used in coal mine and chemical lines.

Owner:吴珍山

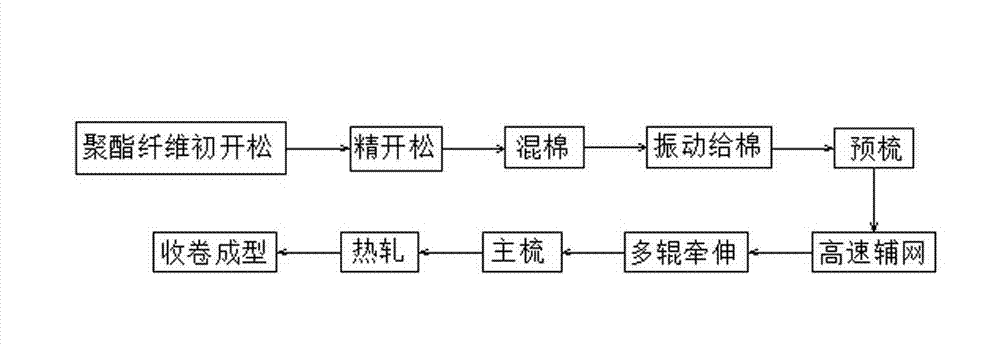

Processing technology for producing electrical polyester non-woven fabric

The invention relates to the technical field of non-woven fabric processing, in particular to a processing technology for producing an electrical polyester non-woven fabric. The processing technology specifically comprises the following steps of: primary opening and fine opening of polyester fibers, cotton blending, vibratory cotton feeding, pre-combing, high-speed net laying, multi-roll drawing, primary combing, hot rolling and winding formation. A combing machine is used for pre-combing to remove impurities in longitudinal fibers of polyester fibers; the fibers are straightened through a multi-roll drawing process to prevent the fibers from being curled; and the combing machine is further used for primary combing to remove short staples. By adopting the processing technology, the situations that the static electricity of the fibers is much, the fibers are uneasy to comb, the cloudiness of the product is much and the like in the prior art can be avoided, the produced polyester non-woven fabric is enabled to have the characteristics of small thickness, good evenness and compactness, high tensile strength, high insulation class and the like, and the polyester non-woven fabric can be widely used as an insulating material for making insulated electrical equipment such as motors, power generators and transformers.

Owner:HAIAN YINCHUAN FABRIC

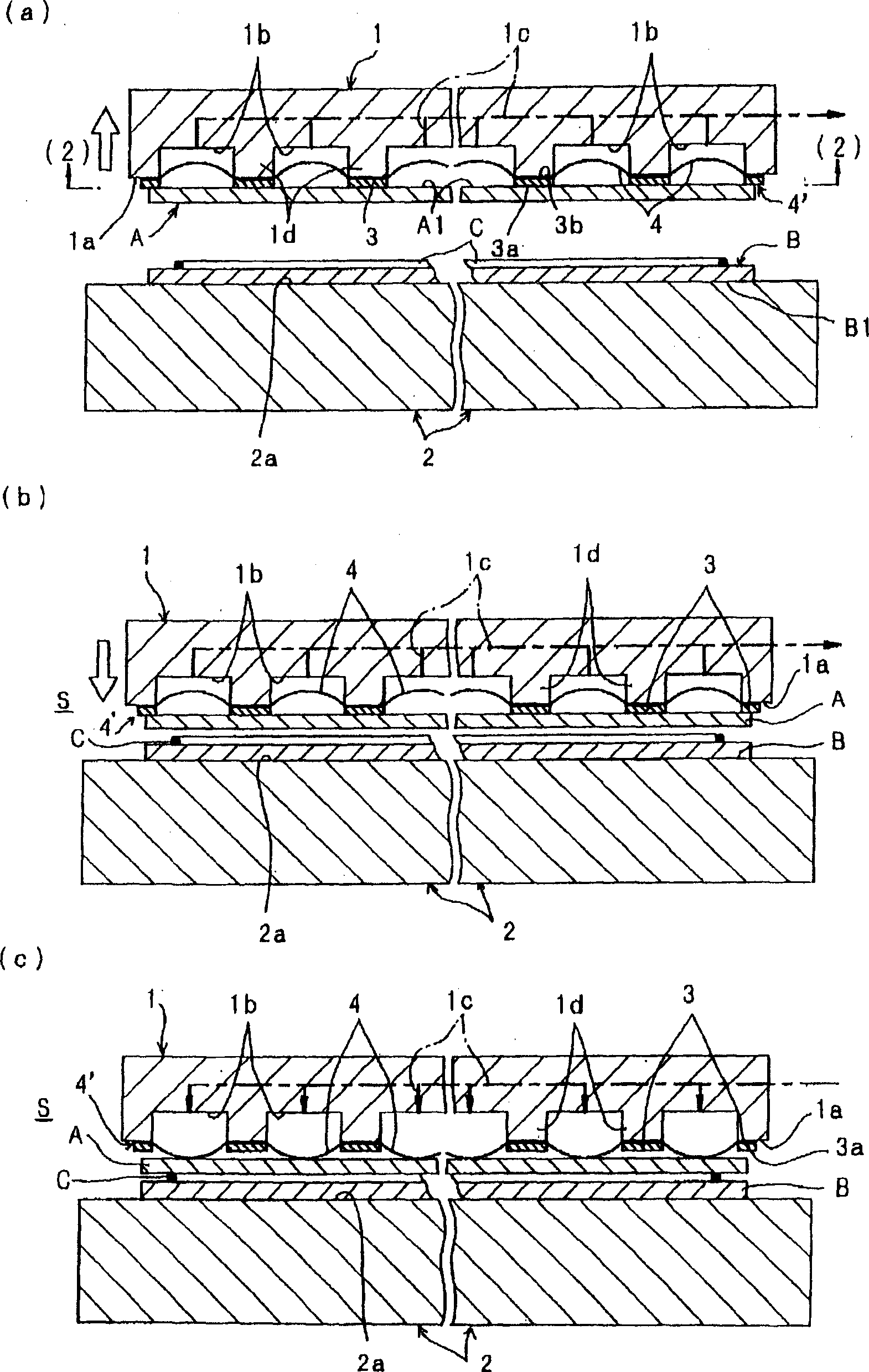

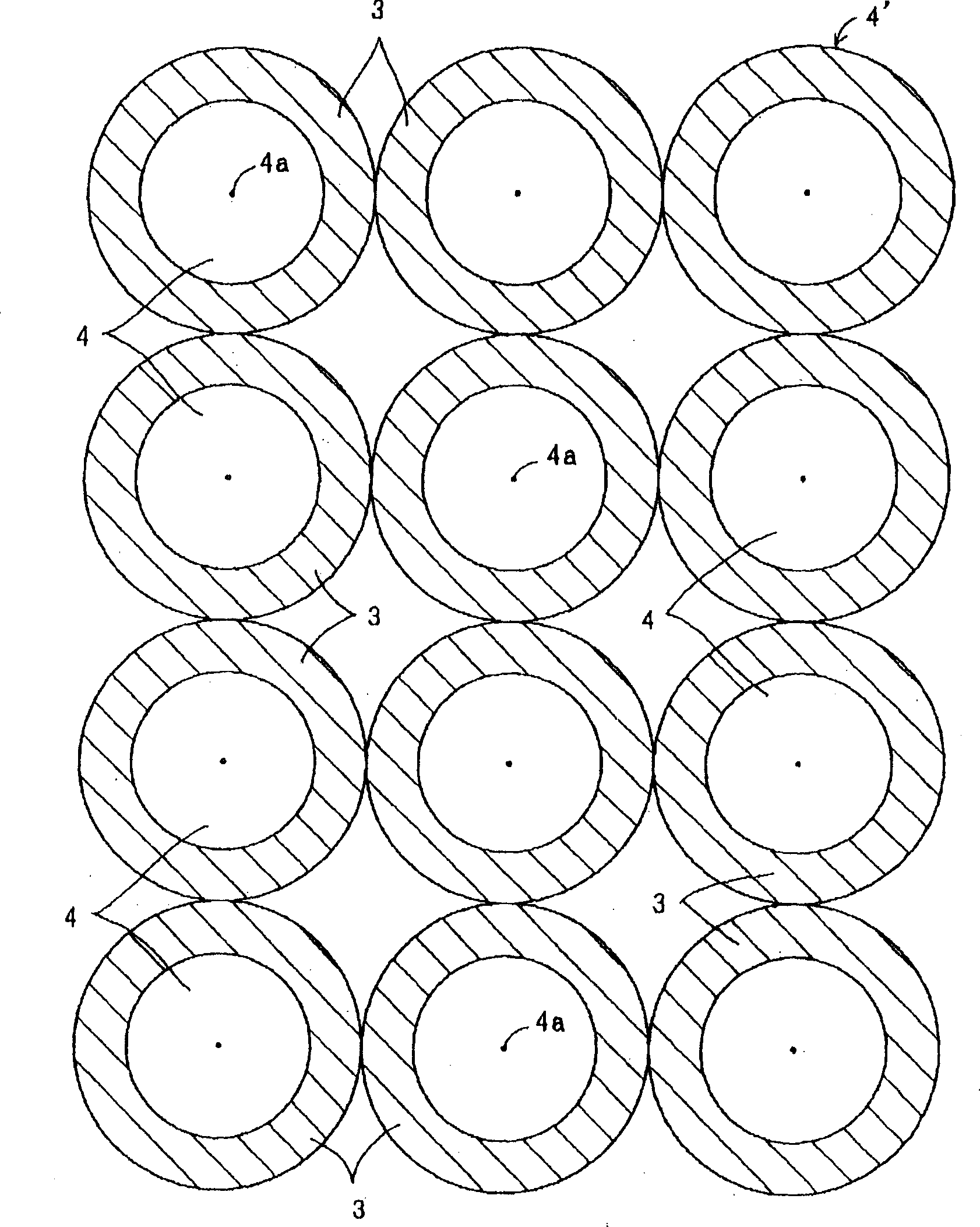

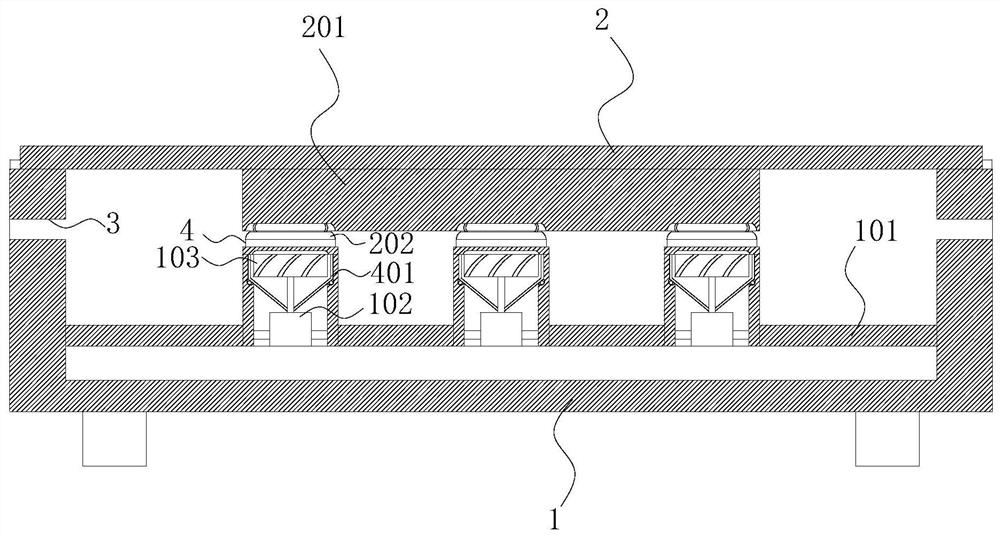

Adhesive chuck device

ActiveCN1777832AActual loading and unloadingReduce failure rateConveyorsSemiconductor/solid-state device manufacturingEngineering

An adhesive chuck device capable of reliably loading and unloading substrates with a simple structure, on the substrate side of a holding plate (1), an adhesive member (3) and a deformable film (4) are provided, and the adhesive member (3) and The reverse side (A1) of the substrate (A) is relatively bonded and maintained, and the deformable film (4) can be deformed in and out in a direction intersecting with the side of the substrate (1a), and the substrate (A ) is bonded in contact with the bonding surface (3a) of the bonding member (3), and at the same time by forcibly pulling the two apart, the substrate (A) can be easily removed from the bonding surface of the bonding member (3) (3a) Stripping.

Owner:SHIN ETSU ENG

Alignment film, method of manufacturing the alignment film, retardation film, method of manufacturing the retardation film, and display

InactiveUS20130335942A1Reduce generationStatic electricityLiquid crystal compositionsLayered productsDisplay deviceEngineering

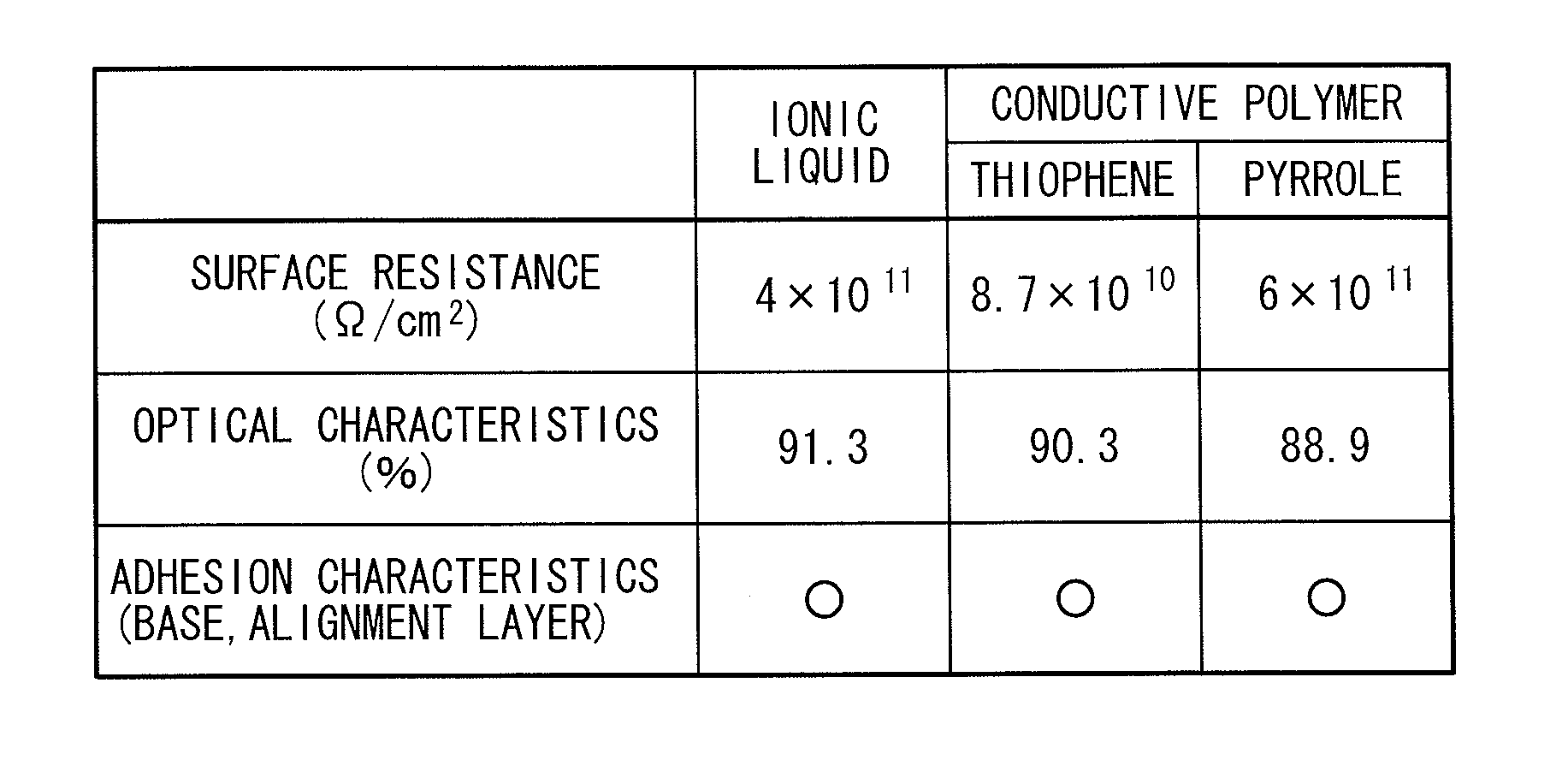

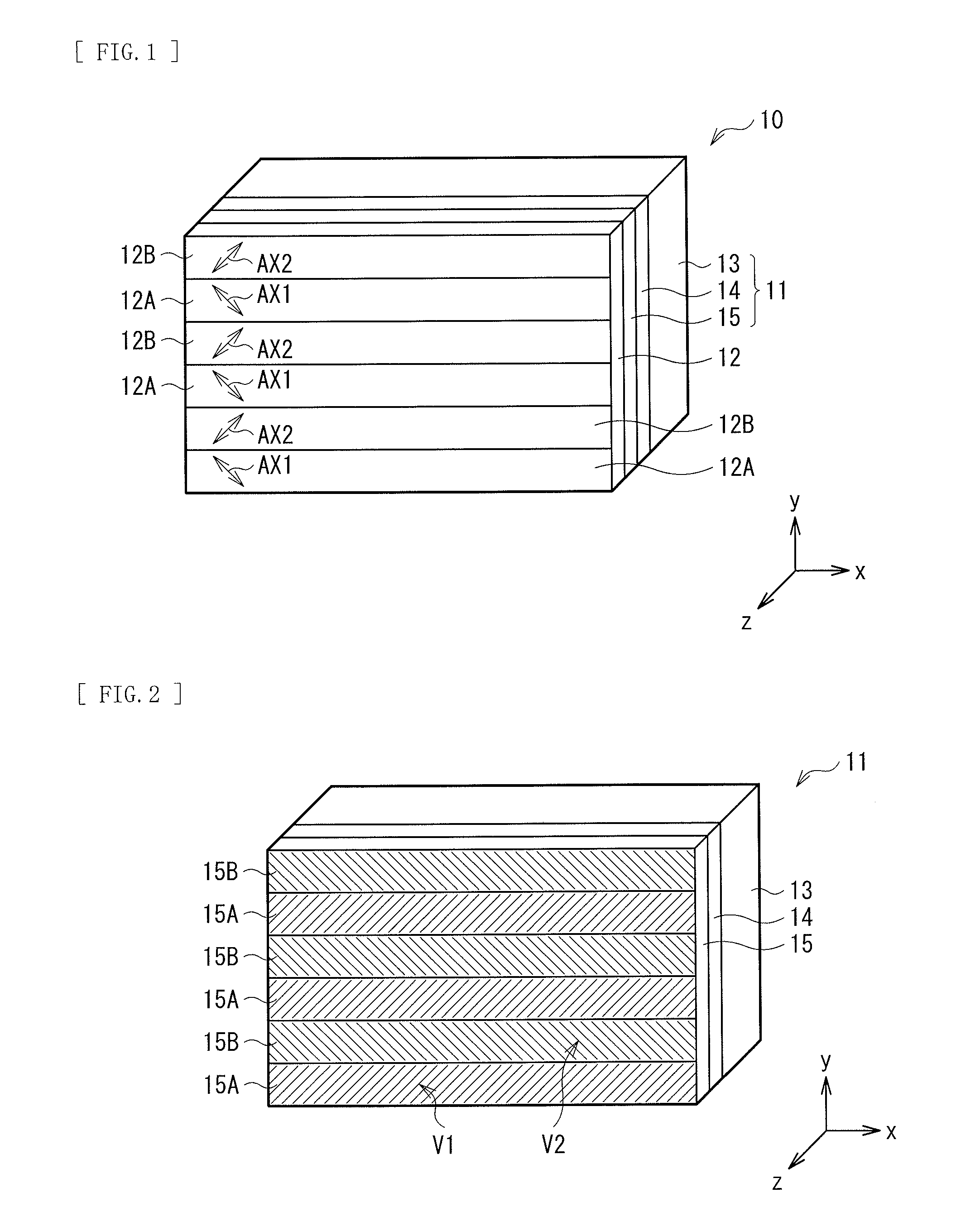

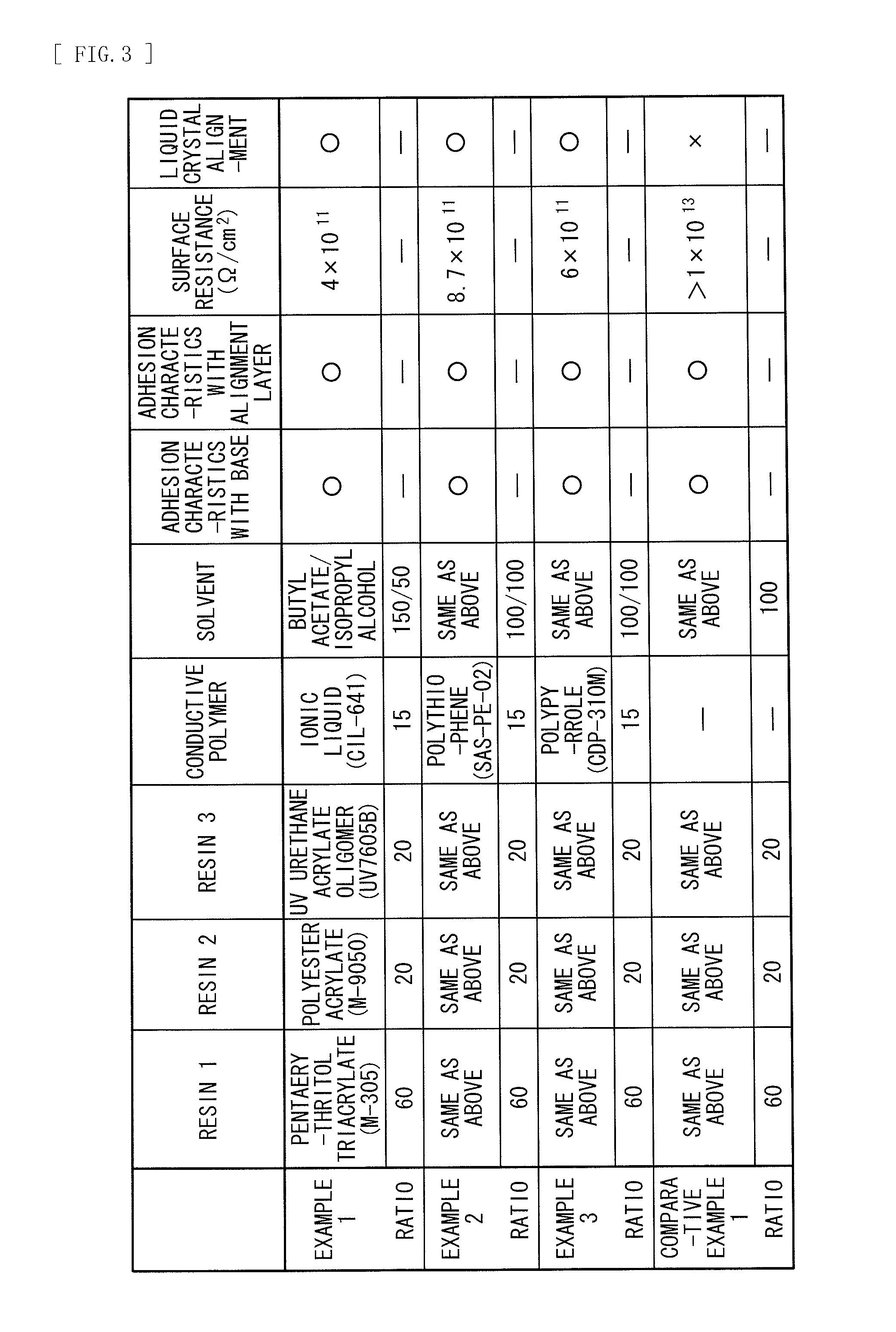

An alignment film capable of reducing occurrence of alignment disorder in a simple manner, a method of manufacturing the alignment film, a retardation film, a method of manufacturing the retardation film, and a display are provided. An alignment film is configured of an anchor layer and an alignment layer stacked in this order on a base. The alignment layer includes a groove region having a plurality of fine grooves on a surface thereof, and a groove region having a plurality of fine grooves on a surface thereof. The anchor layer provided between the base and the alignment layer is provided with an antistatic function in addition to a function of bringing the alignment layer into close contact with the base.

Owner:SATURN LICENSING LLC

Aerosol electrostatic averager

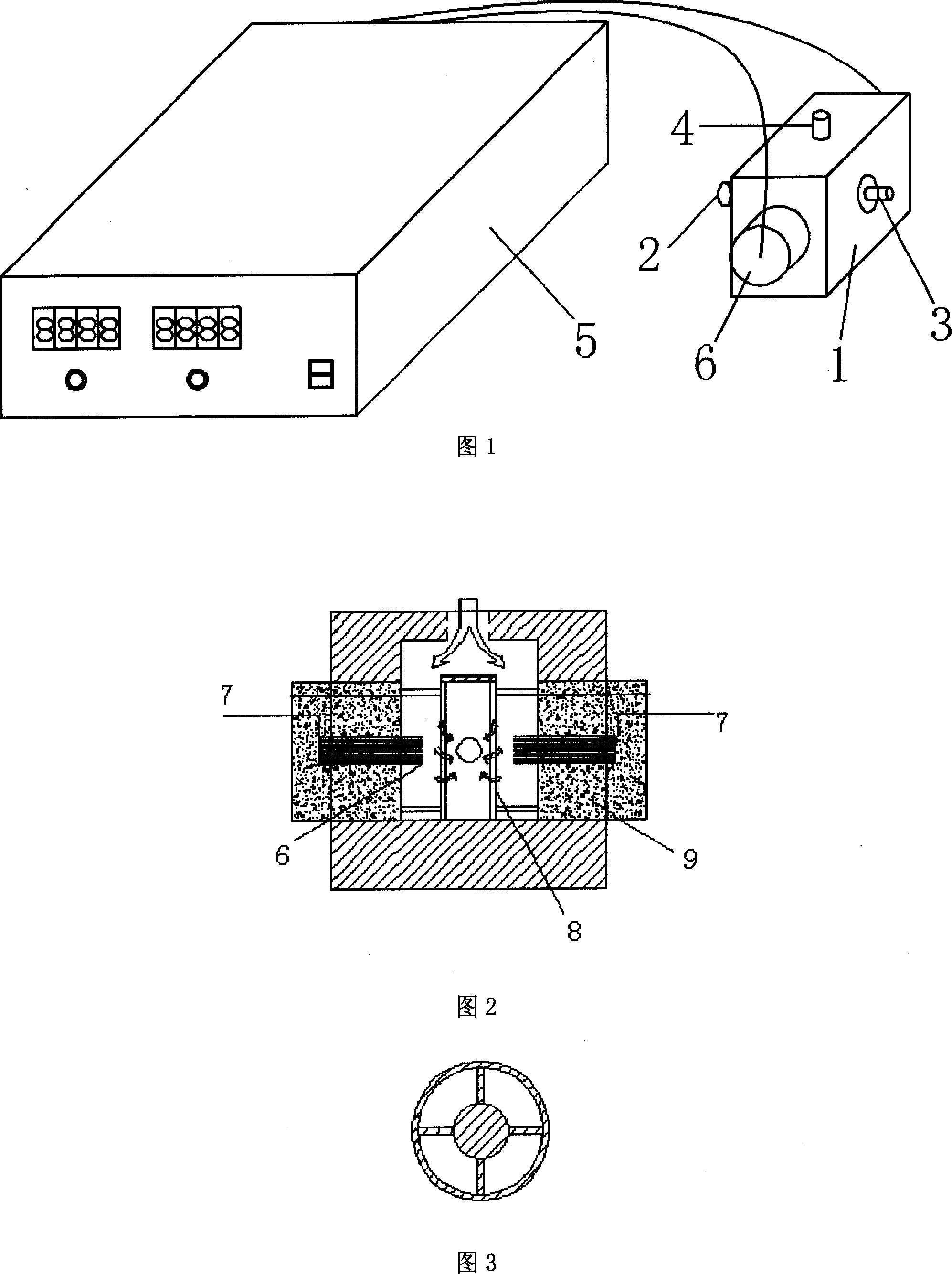

The present invention belongs to aerosol filter and relative equipment detecting technology field, relates to a aerosol electrostatic eliminator, comprising an electrostatic eliminating box, high voltage electrical source output device, and two high voltage electrodes, the electrostatic eliminating box is arranged with an air inlet, an air outlet and a mixed air open, the air inlet position opposites to the air outlet, the two high voltage electrodes separately are fixed at two sides of the box, the box inner is fixed with earth-plate, the output of the high voltage electric source output device connect to the two high voltage electrodes. The present invention can balance charge of the aerosol under the condition without change the ratio of particle size shift, leading charge distribution to content Boltzmann distribution.

Owner:TIANJIN UNIV

Water-based environment-friendly ink printing method for corrugated carton

InactiveCN110641175AImprove qualityGood colorBox making operationsPattern printingCartonProcess engineering

The invention discloses a water-based environment-friendly ink printing method for a corrugated carton, and relates to the field of corrugated carton production. The method comprises the following steps of S1, cleaning; S2, detecting; S3, preparing liquid; S4, neutralizing; S5, quick-drying; S6, ink jetting; S7, drying; and S8, trimming. The method has the following advantages and effects that thepH value of the surface of the corrugated board is 7 by detecting and neutralizing the pH value of the corrugated board, so that the ink can be better colored after ink jet printing, meanwhile, the decoloration phenomenon occurs after printing of the ink is avoided, and the product quality of the corrugated board is improved.

Owner:杭州明聪包装有限公司

Wrap-up device for textile

The invention discloses a wrap-up device for textile. The wrap-up device comprises a first bracket, wherein the vertical inner side wall of one side of the first bracket is fixedly connected with an ultraviolet lamp tube; the lower surface of the ultraviolet lamp tube is fixedly connected with a first distance sensor; the outer wall of one side, away from the first bracket, of the ultraviolet lamptube is fixedly connected with a second bracket; the vertical inner side wall of the first bracket and the vertical inner side wall of the second bracket are movably connected with the same first rotary rod and the same second rotary rod; the second rotary rod is arranged above the first rotary rod; the outer surface of the first rotary rod is fixedly connected with a rolling barrel; and the outer surface of the rolling barrel is movably connected with a first adhesive pad. The wrap-up device is simple in structure, is convenient to operate, and is additionally equipped with an electrostatic-elimination and distance-sensing device, so that hands of a worker do not easily generate an aching feeling, follow-up use of cloth is not affected, working efficiency is improved, compacting effect is more ideal, and wrapped textile fabric is more flat.

Owner:响水县奕杰制衣有限公司

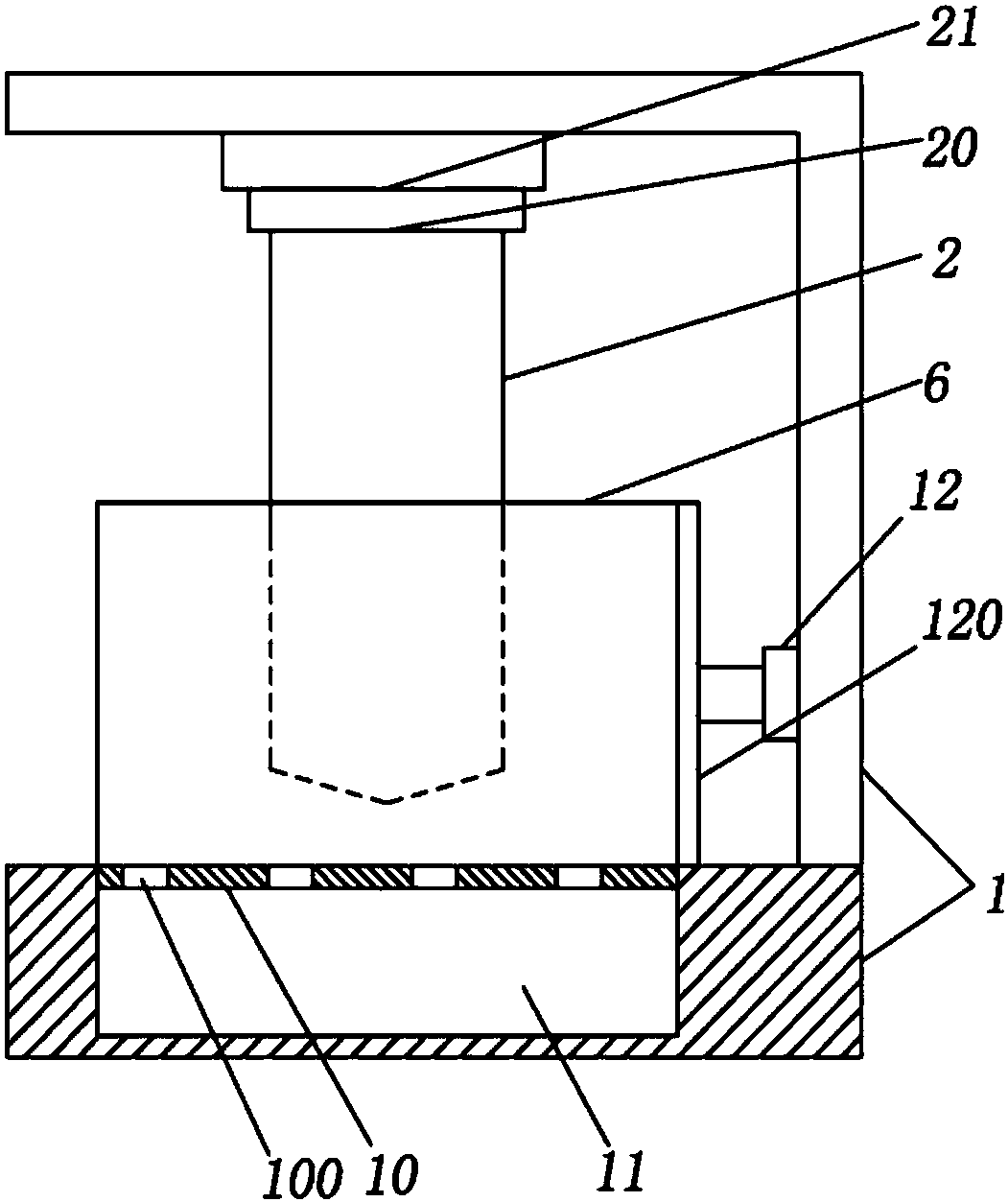

Hole machining machine tool

InactiveCN108284491AReduce air pressureSolve pollutionStationary drilling machinesBark-zones/chip/dust/waste removalEngineeringMachine tool

The invention belongs to the technical field of machining, and particularly relates to a hole machining machine tool. The hole machining machine tool comprises a rack, a drilling tool and a rotating part for driving the drilling tool to rotate. The hole machining machine tool further comprises a lifting part for driving the drilling tool to rise and fall; an electromagnet for supporting a workpiece is fixedly connected to the rack, multiple bit leakage holes are formed in the electromagnet, and a bit storage tank located below the electromagnet is arranged in the rack; a sliding cavity with anopening formed in the lower end is formed in the drilling tool, a first friction layer is fixedly connected to the inner side wall of the drilling tool, a bit sucking pipe capable of sliding out of the sliding cavity is slidingly connected to the inner side wall of the drilling tool, and an elastic reset part is connected between the drilling tool and the bit sucking pipe; a piston is slidingly connected into the bit sucking pipe, a piston rod is fixedly connected between the piston and the drilling tool, and the piston rod is slidingly connected with the bit sucking pipe; a bit sucking through hole is formed in the pipe wall of the bit sucking pipe, and a second friction layer is arranged on the outer side of the bit sucking pipe; and the bottom of the bit sucking pipe is fixedly connected with a drill bit capable of being attracted by the electromagnet. By means of the scheme, wood bits in blind holes can be conveniently cleared away.

Owner:宁波高新区神台德机械设备有限公司

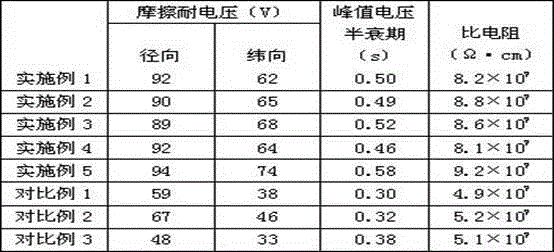

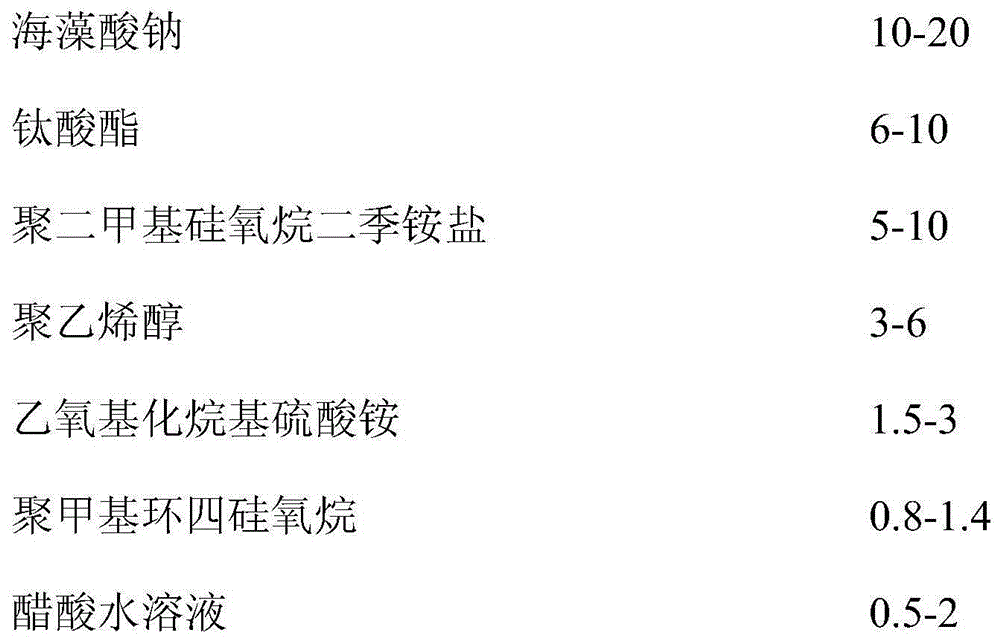

Static-eliminating cleaning agent for textile materials and preparation method thereof

InactiveCN105113243AStrong stabilityMild formulaOrganic detergent compounding agentsNon-ionic surface-active compoundsAmmonium sulfateIon

The invention discloses a static-eliminating cleaning agent for textile materials and a preparation method thereof. The static-eliminating cleaning agent is prepared from, by weight, 10-20 parts of sodium alginate, 6-10 parts of titanate, 5-10 parts of polydimethylsiloxane bis-quaternary ammonium salt, 3-7 parts of polyvinyl alcohol, 1.5-3 parts of ethoxylated alkyl ammonium sulfate, 0.8-1.4 parts of octamethyl cyclotetrasiloxane, 0.5-2 parts of acetic acid aqueous solution, 3-7 parts of solvent, 60-100 parts of deionized water, 3-7 parts of sodium lauroyl sarcosine, 2-6 parts of polymethyl methacrylate, 7-12 parts of fatty alcohol-polyoxyethylene ether and 80-120 parts of alpha-olefin sulfonate solution. All the raw materials of the static-eliminating cleaning agent are environmentally friendly and degradable. The static-eliminating cleaning agent has good antistatic performance and also has good softening, maintaining and cleaning effects on clothes.

Owner:杨洋

Washable long-acting filtering graphene antibacterial mask and preparation method thereof

ActiveCN113243589AImprove antibacterial propertiesImprove dispersion stabilityNon-woven fabricsMonocomponent polyolefin artificial filamentPolymer scienceSpinning

The invention belongs to the technical field of protective masks, and discloses a washable long-acting filtering graphene antibacterial mask and a preparation method thereof. The mask is composed of a spunbond non-woven fabric, a graphene water electret melt-blown non-woven fabric, a melt-blown non-woven fabric and a spunbond non-woven fabric which are stacked in sequence. The preparation method comprises the following steps: carrying out surface modification on graphite oxide by using a fluorosilane coupling agent, carrying out melt blending extrusion and granulation on the graphite oxide, polypropylene resin and compatibilizing resin to obtain graphene antibacterial water electret master batches, mixing the graphene antibacterial water electret master batches with the polypropylene resin, carrying out melt-blowing spinning molding, obtaining a graphene water electret melt-blown non-woven fabric through a water electret, laying and cutting all the layers of non-woven fabric into a mask shape, and pressing to obtain a mask finished product. According to the invention, the mask is durable in antibacterial effect, washable and high in bacteria filtering efficiency; and the air permeability and washing air permeability retainability are good, and the fabric can be washed repeatedly.

Owner:惠州市栢诗新材料有限公司

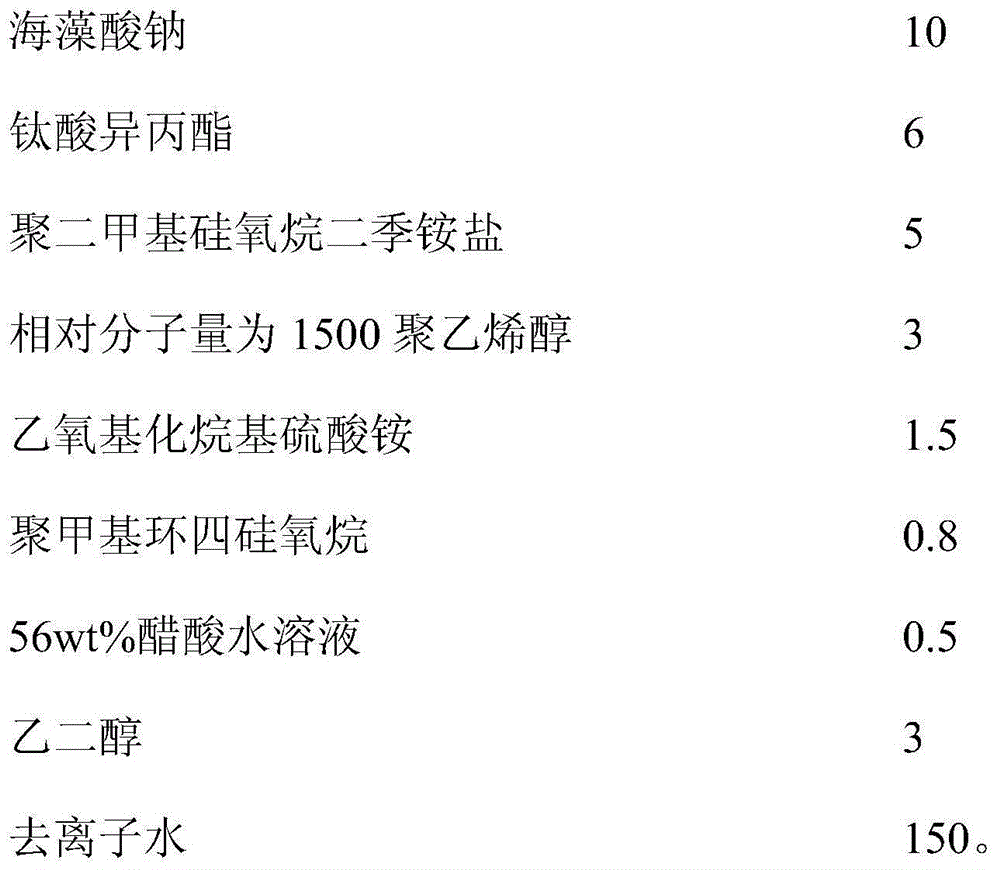

Destaticizer for textile materials and preparation method thereof

The invention discloses a destaticizer for textile materials and a preparation method thereof. The destaticizer is mainly prepared from the following materials in parts by weight: 10 to 20 parts of sodium alginate, 6 to 10 parts of titanate, 5 to 10 parts of polydimethylsiloxane bis-quaternary ammonium salt, 3 to 6 parts of polyvinyl alcohol, 1.5 to 3 parts of ammonium ethoxylated alkyl sulfate, 0.8 to 1.4 parts of polymethylcyclotetrasiloxane, 0.5 to 2 parts of aqueous acetic acid, 3 to 6 parts of solvent and 100 to 150 parts of deionized water. All the materials in the destaticizer disclosed by the invention are environment-friendly materials or degradable, environment-friendly materials; besides good antistatic property, the destaticizer disclosed by the invention also has a good smoothing and maintaining effect on clothes.

Owner:WUXI CHANGAN SHUGUANG GLOVE FACTORY

Polishing device for sensing conditions by utilizing mirror reflection

InactiveCN112338763AExpand the spraying rangeIncrease the smear rangeGrinding machine componentsPolishing machinesMirror reflectionEngineering

The invention relates to the technical field of automobile decoration, and provides a polishing device for sensing conditions by utilizing mirror reflection. The polishing device capable of sensing the conditions by utilizing mirror reflection comprises a shell, light emitters are fixedly connected to the inner wall of the shell, photoresistors are fixedly connected to the outer walls of the lightemitters, and a filter screen spray head is fixedly connected to the inner wall of the shell. According to the polishing device for sensing the conditions by utilizing mirror reflection, the light emitters cannot reflect light to the photoresistors, the resistance of the photoresistors changes the power-on state of an electromagnet, the electromagnet is immediately changed from being dragged to being pushed and pressed, a push rod moves on the inner wall of an infusion tube in a large range, the push rod extrudes and pushes out polishing agents in the interiors of a polishing agent box and the infusion pipe, the plurality of light emitters and the plurality of photoresistors are arranged, the photoresistors control the infusion tube at the corresponding position to eject the polishing agents, a rotating shaft drives a brush to rotate, the brush is completely opened by utilizing a centrifugal mode, the painting range is increases, and the automobile polishing conditions are reflected by utilizing mirror reflection of the automobile shell.

Owner:温州奥爵文贸易有限责任公司

Strip dye amendment

The present invention is strip dyeing amendment is prepared with cationic dimethyl hydroxy silicon oil emulsion as basic material and through adding softening agent and antistatic agent. The softening agent is stearic polyoxyethlene ether and the antistatic agent is stearic amine polyoxyethlene ether. The present invention has relatively high antistatic performance and softening performance.

Owner:徐维青

Static eliminating precoated sand and preparation method thereof

ActiveCN108526385AEliminate hazardsReduce stratificationFoundry mouldsMould handling/dressing devicesAntistatic agentMold filling

The invention relates to static eliminating precoated sand. A stratification phenomenon of the precoated sand is reduced and the size distribution is more uniform. The flowability of the precoated sand is improved, so that a mold-filling capacity of the precoated sand is increased in a core preparation process, the generating probability of detects such as loose sand cores and defective blocks isreduced, and therefore, the rate of finished products of castings is increased, the production cost is lowered, and damage of static electricity in the using process of the precoated sand on human body is also eliminated. According to a preparation method of the static eliminating precoated sand provided by the invention, the preparation process is adjusted properly according to compositions of raw materials. The preparation method comprises the following steps: firstly, blending phenolic resin and an antistatic agent; and then adding the mixture into heated raw sand, wherein the coating effect of the phenolic resin is excellent, static electricity generated in the blending process of the phenolic resin and the original sand is eliminated, and the size distribution and flowing property ofthe produced precoated sand are good. A conducting device is additionally arranged to export static electricity in a precoated sand product, so that the antistatic agent does not act yet, and the produced static electricity is eliminated immediately.

Owner:YANCHENG RENCHUANG SAND IND TECH CO LTD

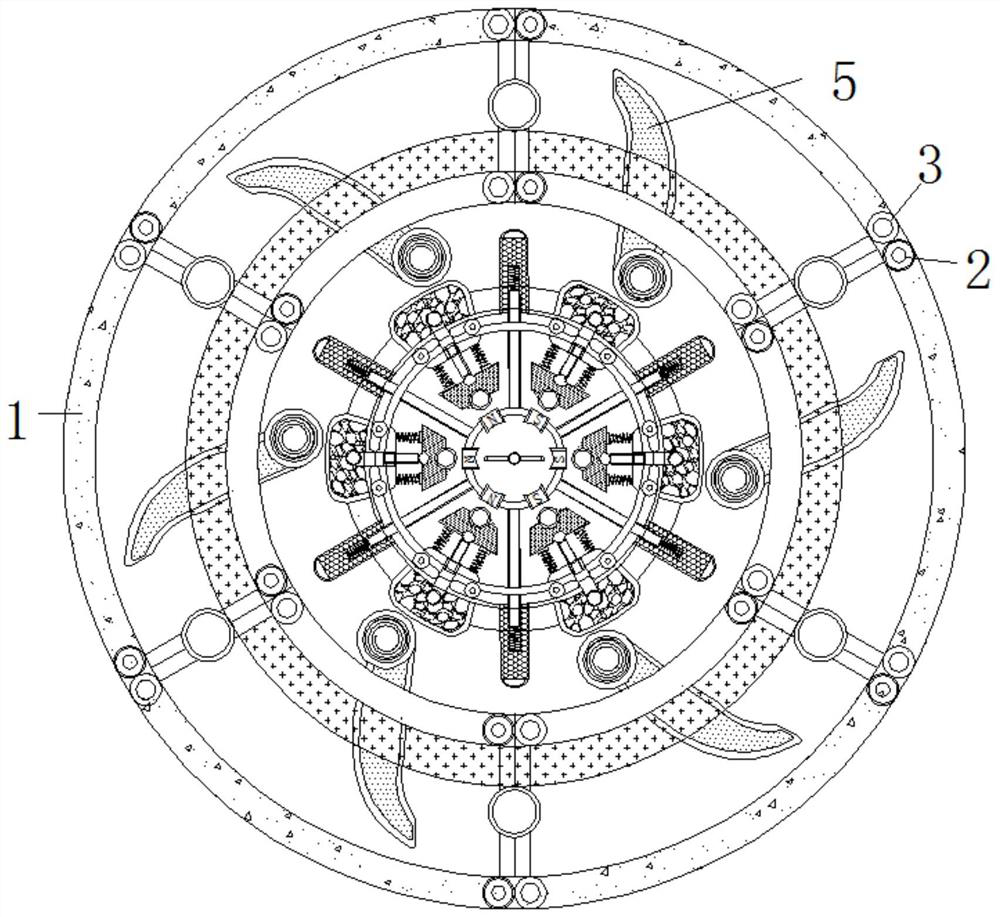

Embroidery fabric surface burr removing and leveling device

InactiveCN112981830AImprove adsorption capacityIncrease contact areaLace shearingCleaning using gasesElectric machineEngineering

The invention discloses an embroidery fabric surface burr removing and leveling device, and relates to the technical field of embroidery fabric surface burr removing and leveling. The embroidery fabric surface burr removing and leveling device includes a box body, wherein a cover plate is rotationally installed at the top of the box body, ventilation openings are formed in the left side and the right side of the box body, a burr removing mechanism is arranged on the inner side of the box body, the box body includes a fixed plate, a motor and a fan, the fixed plate is fixedly installed on the inner side of the lower end of the box body, the motor is fixedly installed at the upper end of the fixed plate through a fixing column, and the fan is movably installed at the output end of the motor through a connecting shaft. According to the embroidery fabric surface burr removing and leveling device, the burr removing mechanism is arranged, through rotation of a rotating disc relative to a fixed disc, static electricity is generated between a first burr removing net and a second burr removing net through friction, generated burrs are adsorbed by the static electricity and vertically stand downwards, and finally the burrs are cut off through a cutting knife stretching out periodically.

Owner:陈永

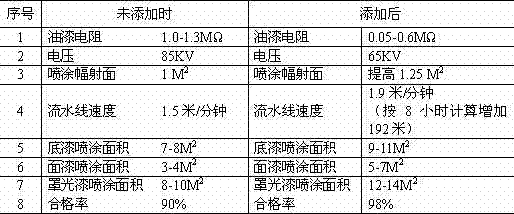

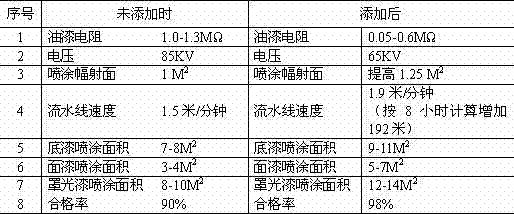

Additive capable of improving electrostatic effect for spraying fluorocarbon paint

ActiveCN102268210BLower resistanceImprove conductivityElectrically-conductive paintsDiethylene glycol monobutyl etherButyl acetate

The invention belongs to the technical field of fluorocarbon paints, and particularly relates to an additive capable of improving the electrostatic effect for spraying fluorocarbon paint. The additive consists of the following components in percentage by weight: 15-25 percent of methyl ethyl ketone, 10-20 percent of diethylene glycol monobutyl ether, 2-4 percent of methyl isobuthyl ketone, 3-6 percent of butyl acetate and 45-70 percent of alkane main solution. The additive can be used for overcoming the defects of low atomizing efficiency of a spray gun, low adsorption force, low painting efficiency and non-uniform distribution of metal fine particles and the like caused by weak electrostatic effect and poor electric conductivity in the spraying process of the fluorocarbon paint at present.

Owner:上海新大余氟碳喷涂材料有限公司

Additive for fluorocarbon paint spraying that can increase electrostatic effect

ActiveCN102268210ALower resistanceImprove conductivityElectrically-conductive paintsDiethylene glycol monobutyl etherButyl acetate

The invention belongs to the technical field of fluorocarbon paints, and particularly relates to an additive capable of improving the electrostatic effect for spraying fluorocarbon paint. The additive consists of the following components in percentage by weight: 15-25 percent of methyl ethyl ketone, 10-20 percent of diethylene glycol monobutyl ether, 2-4 percent of methyl isobuthyl ketone, 3-6 percent of butyl acetate and 45-70 percent of alkane main solution. The additive can be used for overcoming the defects of low atomizing efficiency of a spray gun, low adsorption force, low painting efficiency and non-uniform distribution of metal fine particles and the like caused by weak electrostatic effect and poor electric conductivity in the spraying process of the fluorocarbon paint at present.

Owner:上海新大余氟碳喷涂材料有限公司

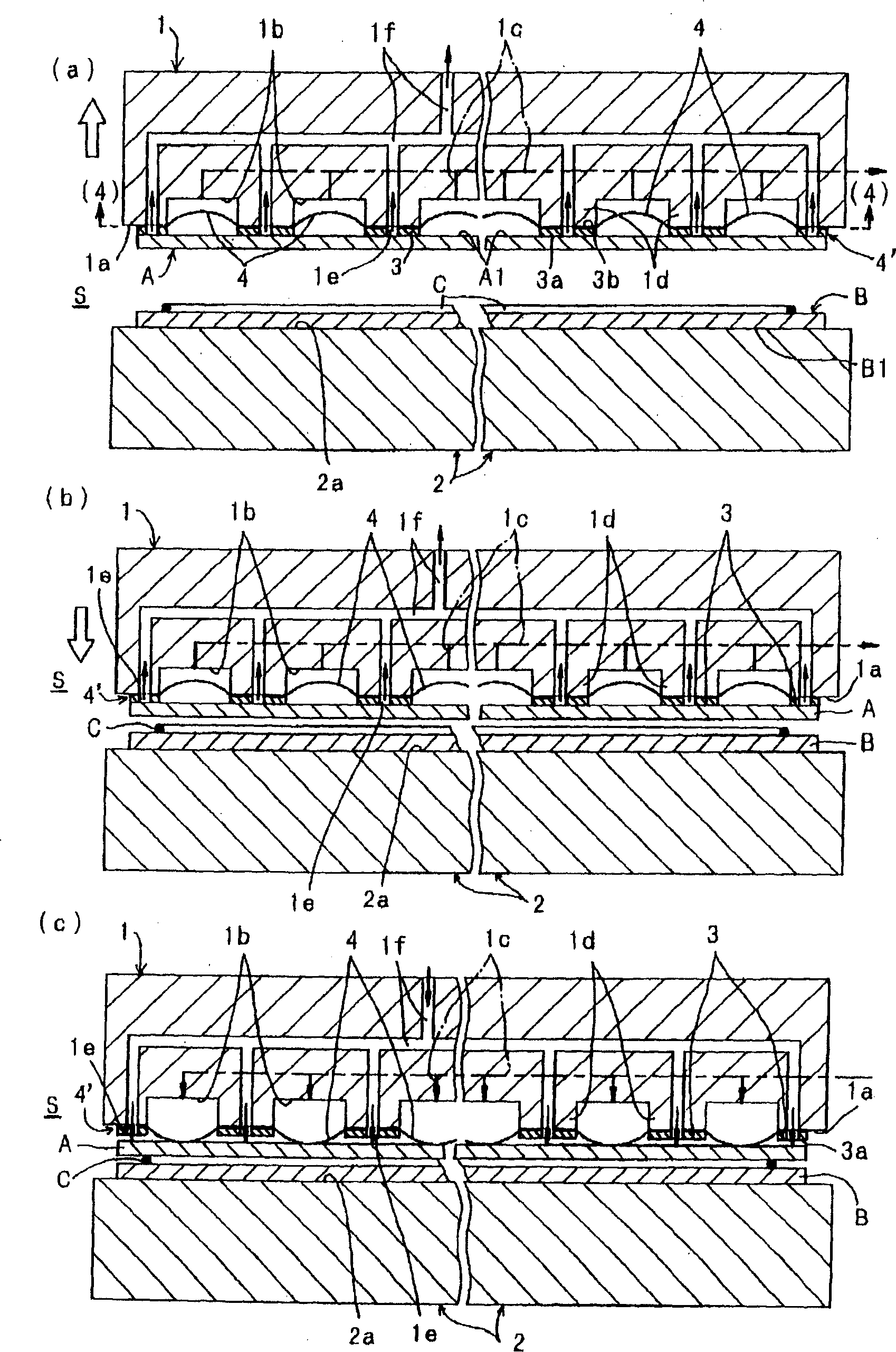

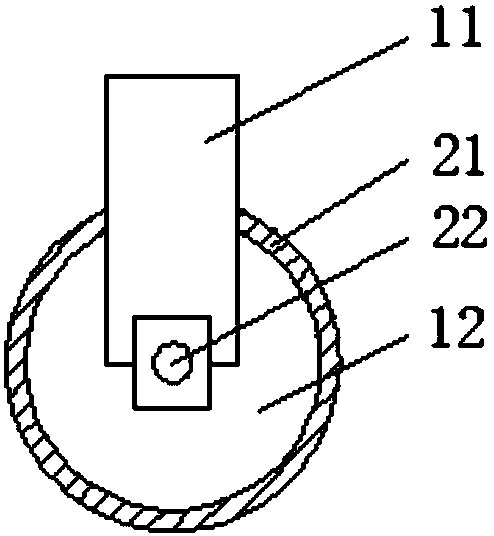

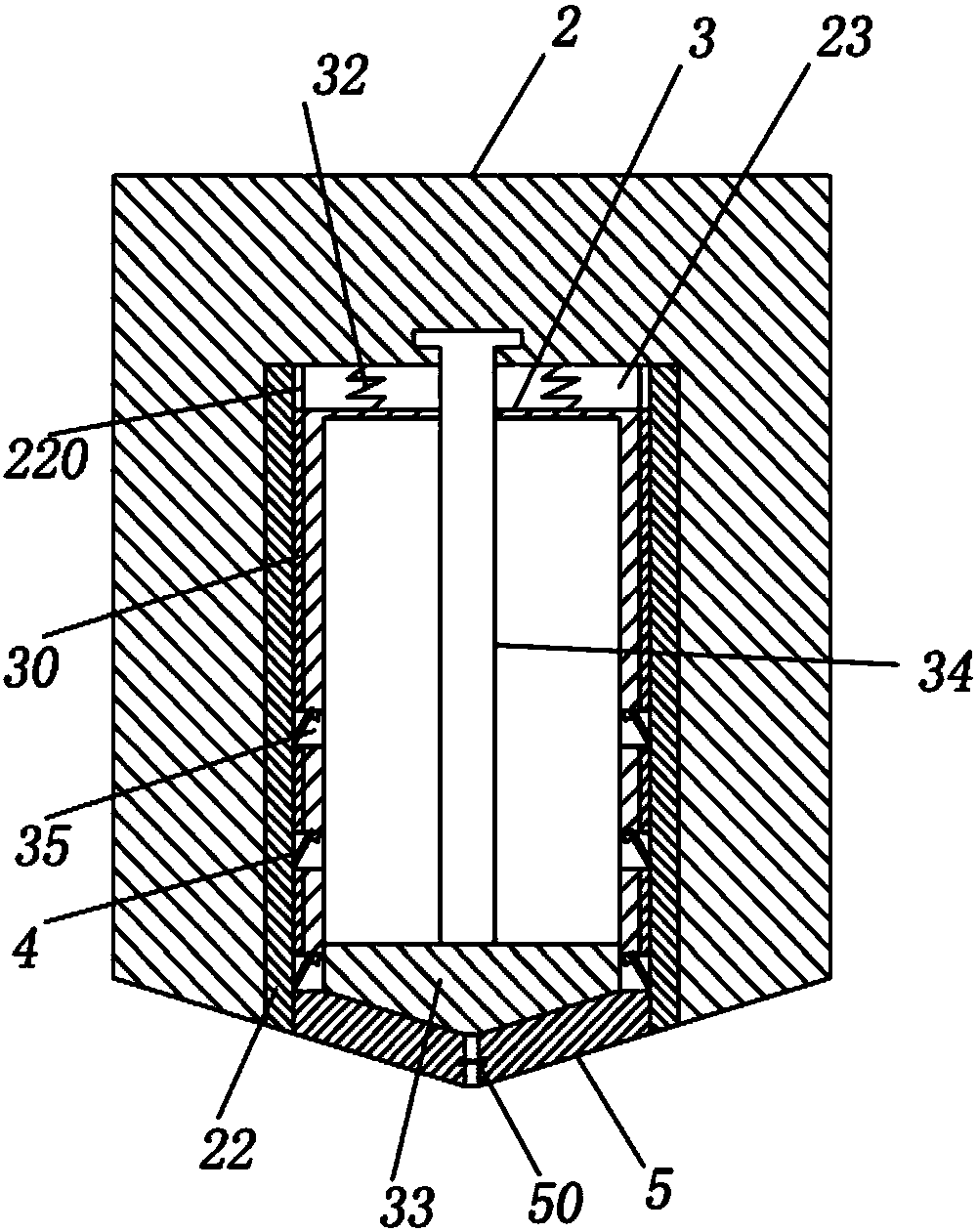

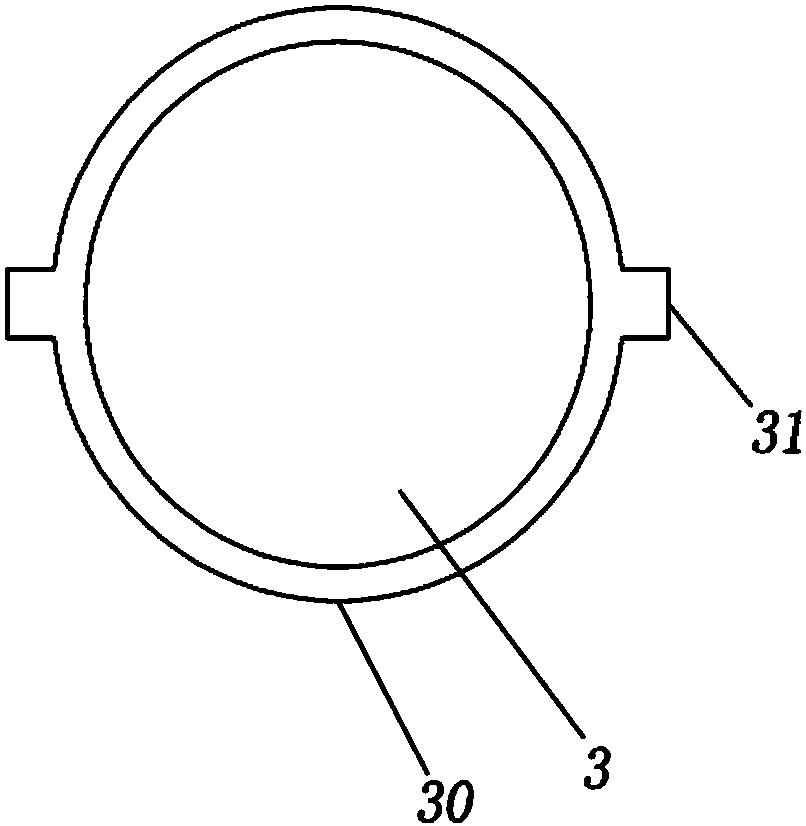

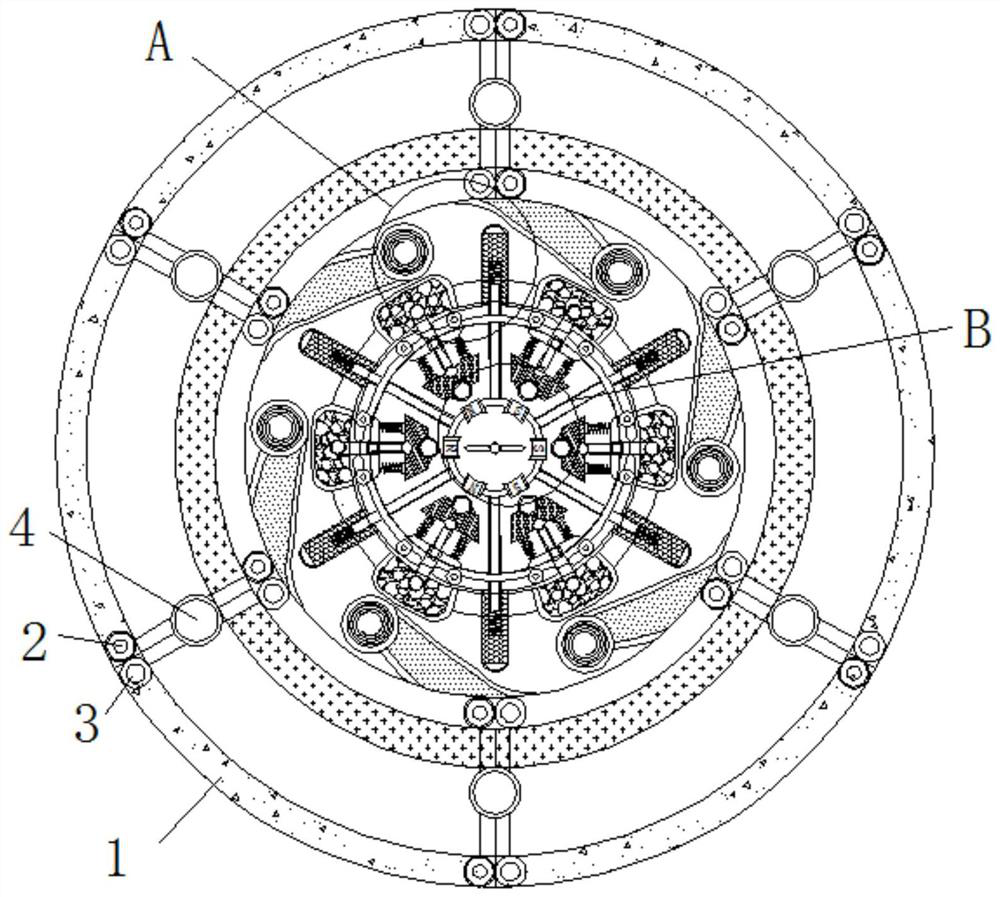

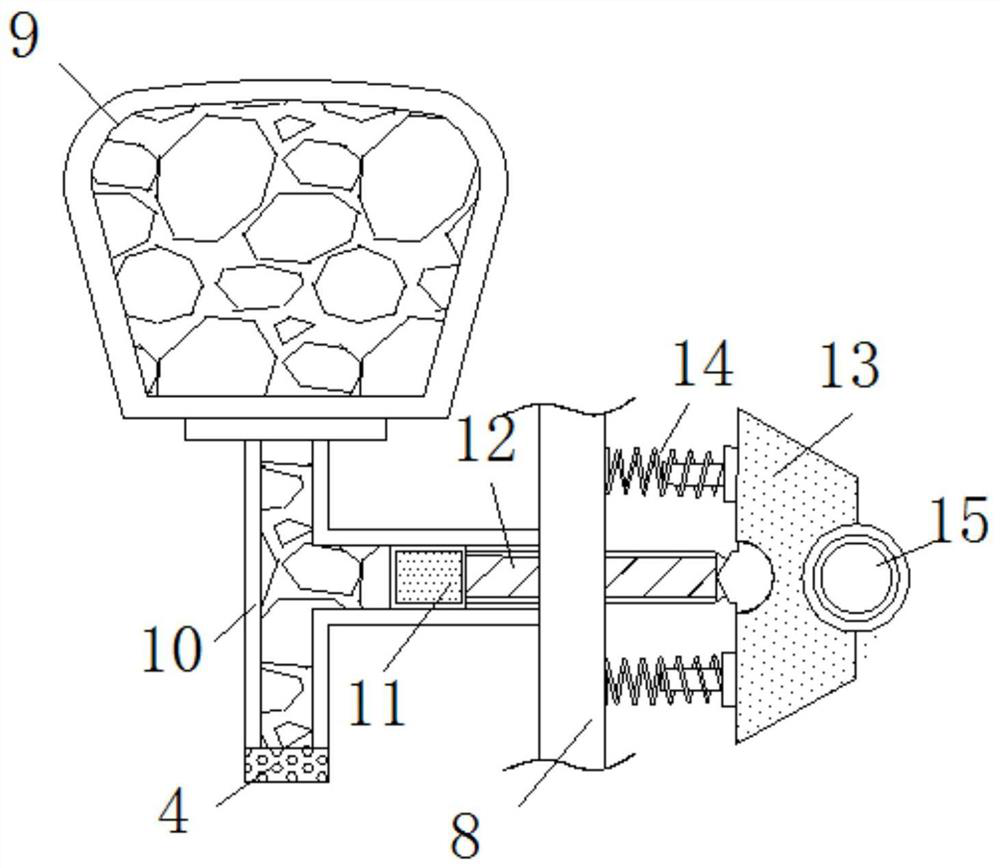

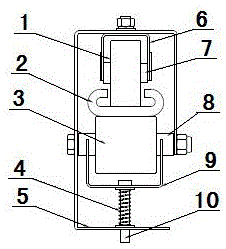

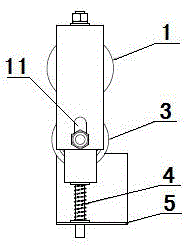

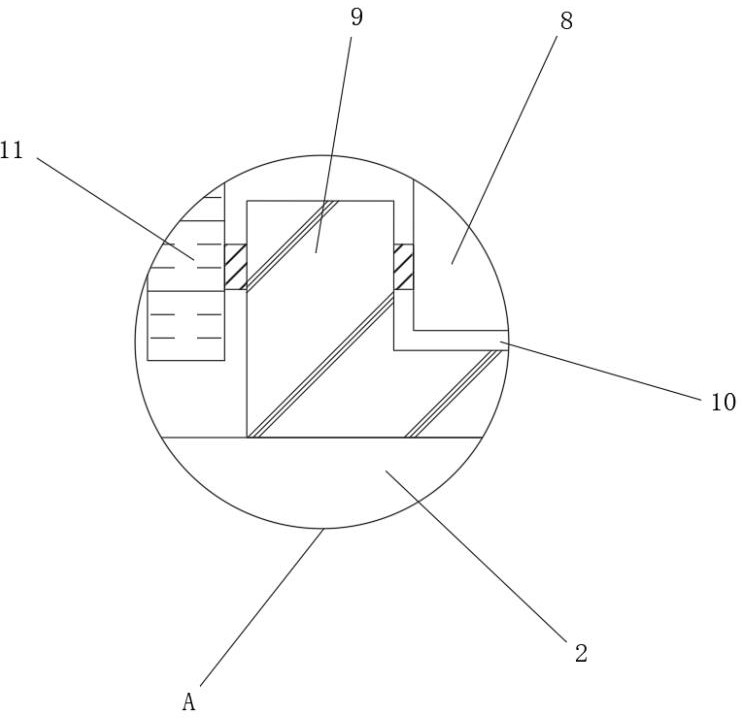

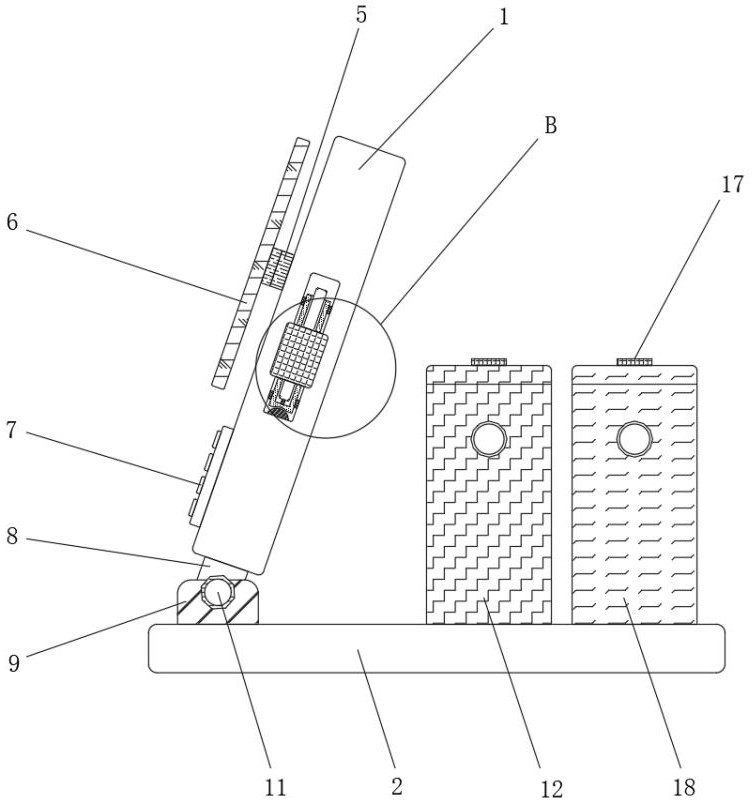

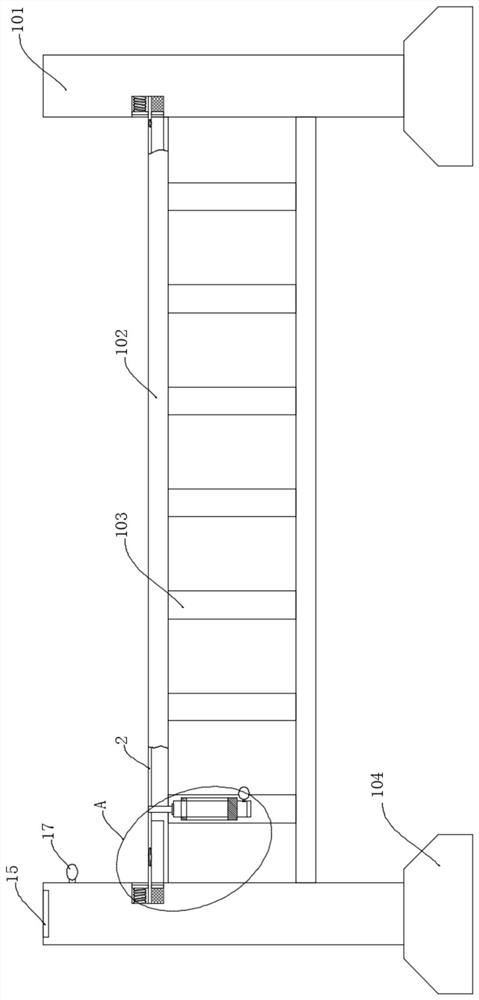

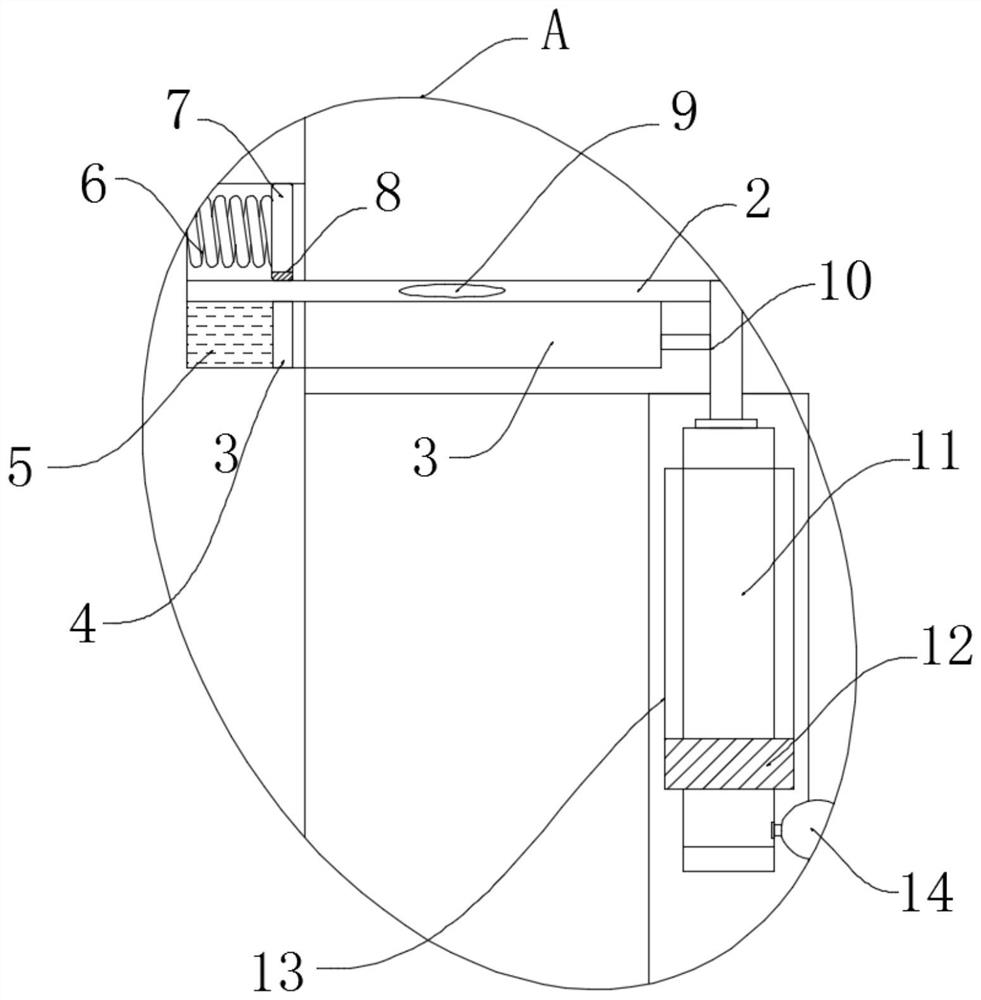

Destaticizing device for hand strap of escalator or moving walk

The invention relates to a destaticizing device for a hand strap of an escalator or a moving walk. The destaticizing device comprises a guide wheel (1), the hand strap (2), a guide wheel supporting frame (6), a guide wheel shaft (7) and an electrostatic wheel shaft (8), and is characterized in that the hand strap (2) is located between the guide wheel (1) and an electrostatic wheel (3); the electrostatic wheel shaft (8) is located in a slideway (11) of an electrostatic wheel supporting frame (5); the electrostatic wheel (3) is pressed on the surface of the hand strap all the time through a tension spring (4) and a tension supporting frame (9); the tension supporting frame (9) is fixedly welded to a rod piece (10); the rod piece (10) is sleeved with the tension spring (4); and the tension supporting frame (9) is fixedly welded to the electrostatic wheel shaft (8). The destaticizing device can effectively eliminate static electricity generated by the hand strap.

Owner:SHANDONG FUJI ZHIYU ELEVATOR

Flame retarding anti-static plastic braiding bags

A flame-retarded and antistatic Polywoven Bag is used to solve the problem that whose average surface resistance is sharply lower than that of the national standards and is prepared by: (1) Making flame-retarded masterbatch A by mixture and plastication of the antimony oxide and the polypropylene; (2) Making flame-retarded masterbatch B by mixture and plastication of the Decabromobiphenyl ether and the polypropylene; (3) Making antistatic masterbatch by mixture and plastication of the static agent and the polypropylene; (4) Making the mixture of the flame-retarded masterbatch A, B,antistatic masterbatch and the polypropylene through the high rate agitator; (5) Making the filamentus disk through drawing it to pellicle and filamentus using the plastic machine; and (6) Surface treating using the static agent. It can be used in coal mine and chemical lines.

Owner:吴珍山

Strip dye amendment

Owner:徐维青

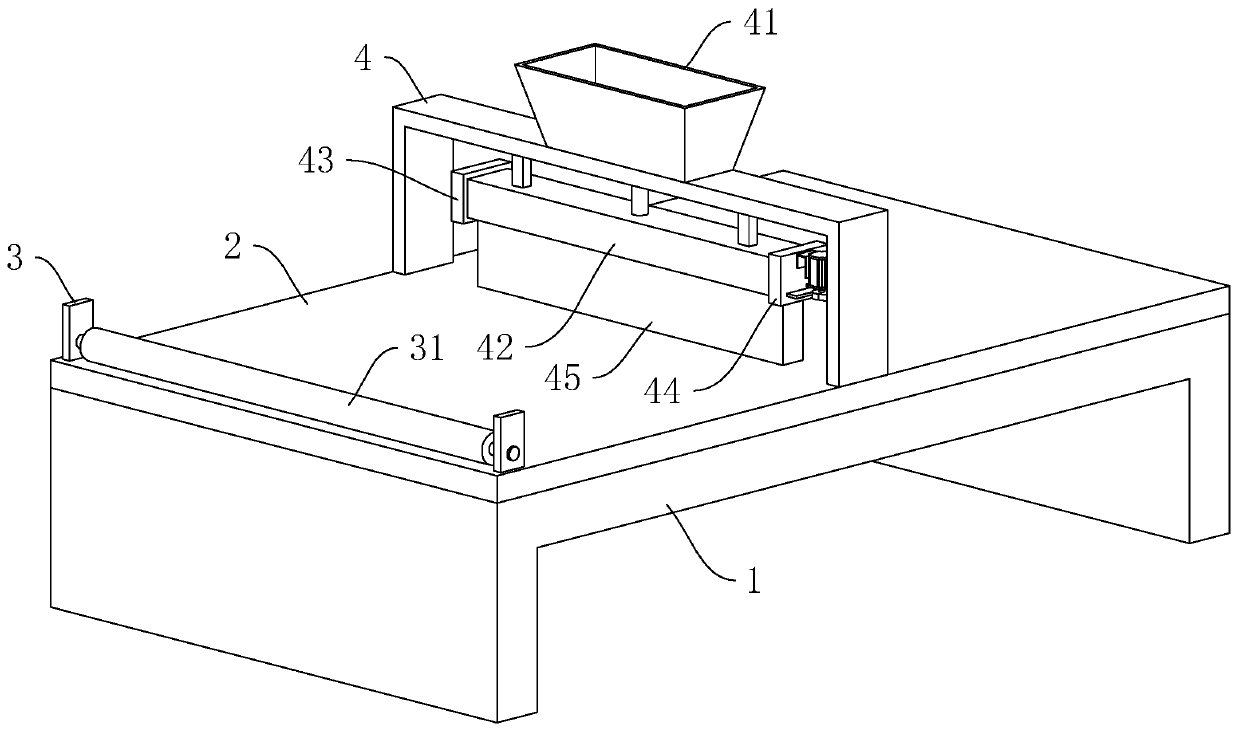

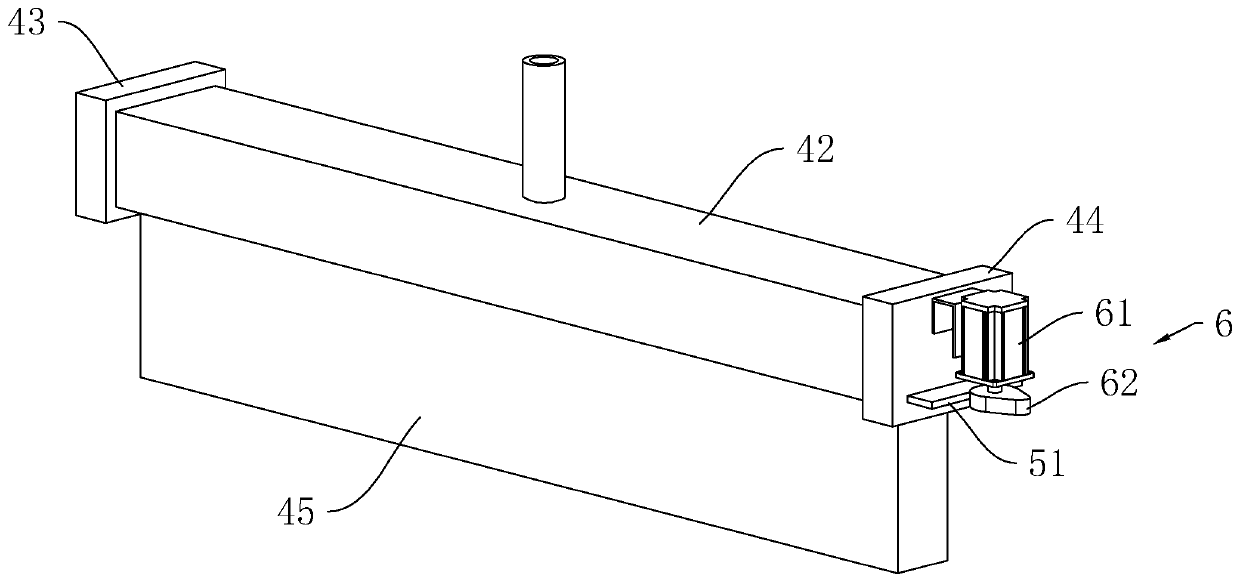

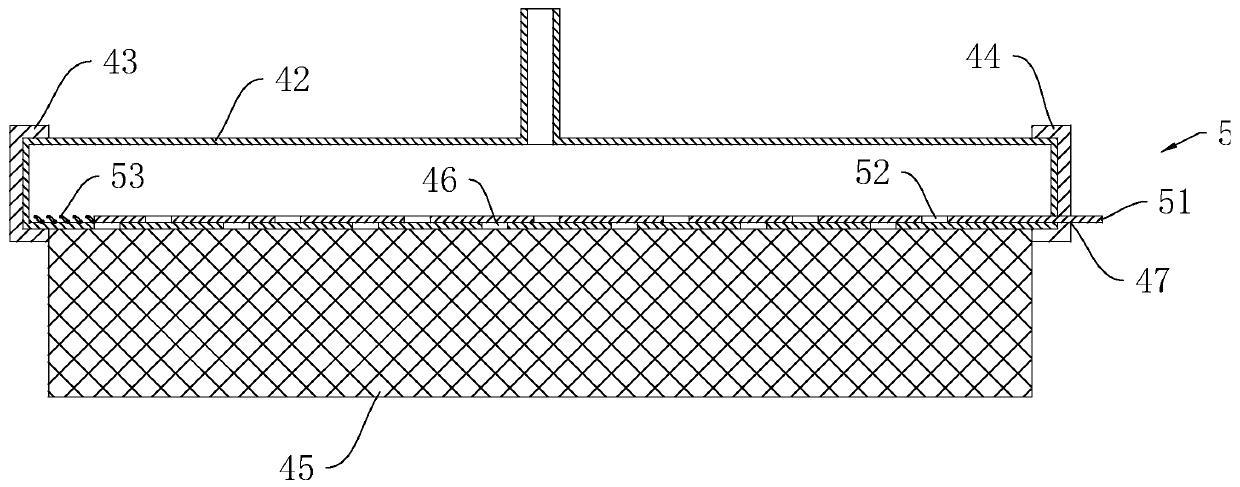

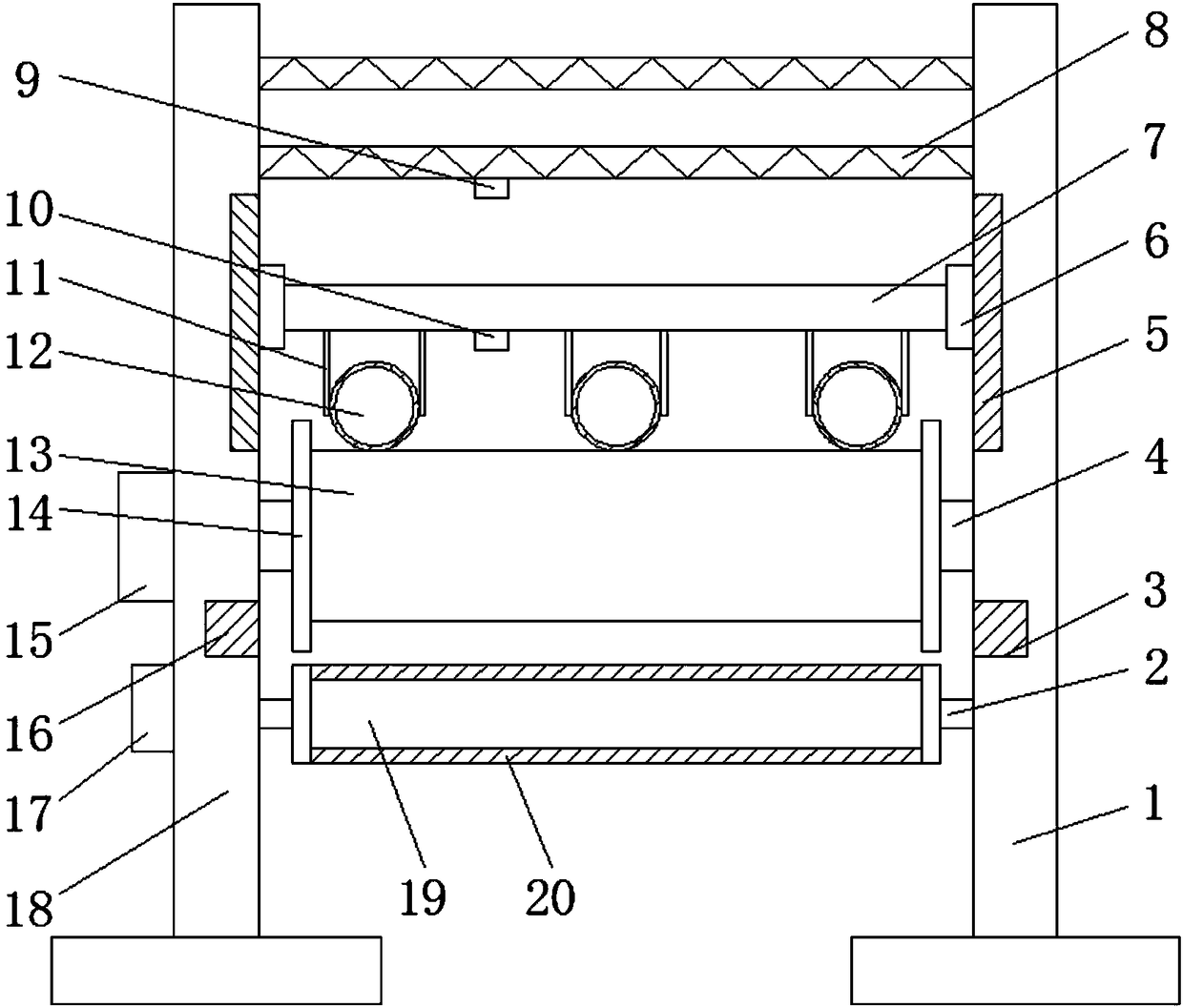

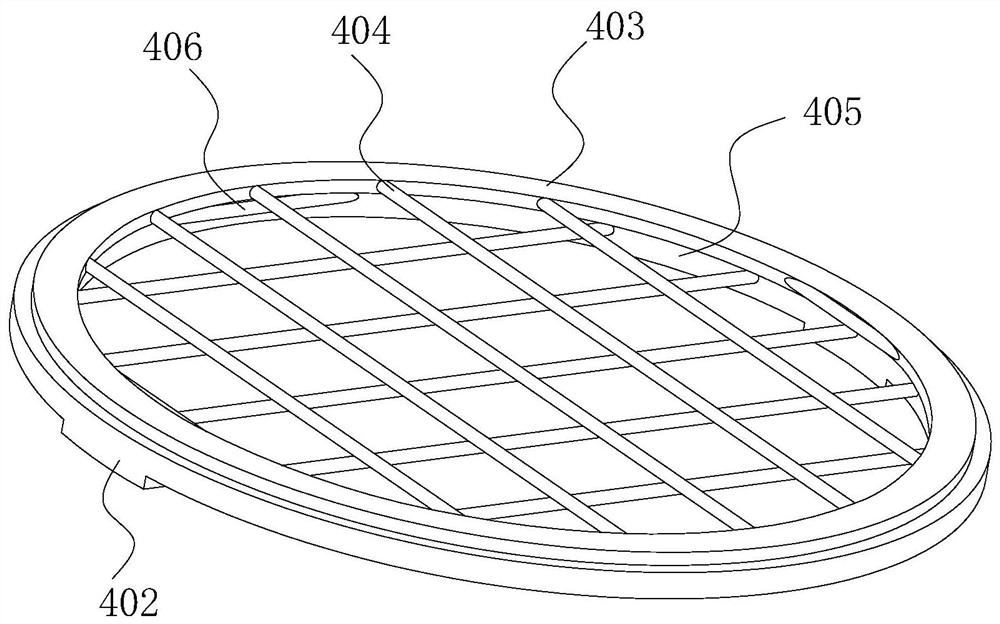

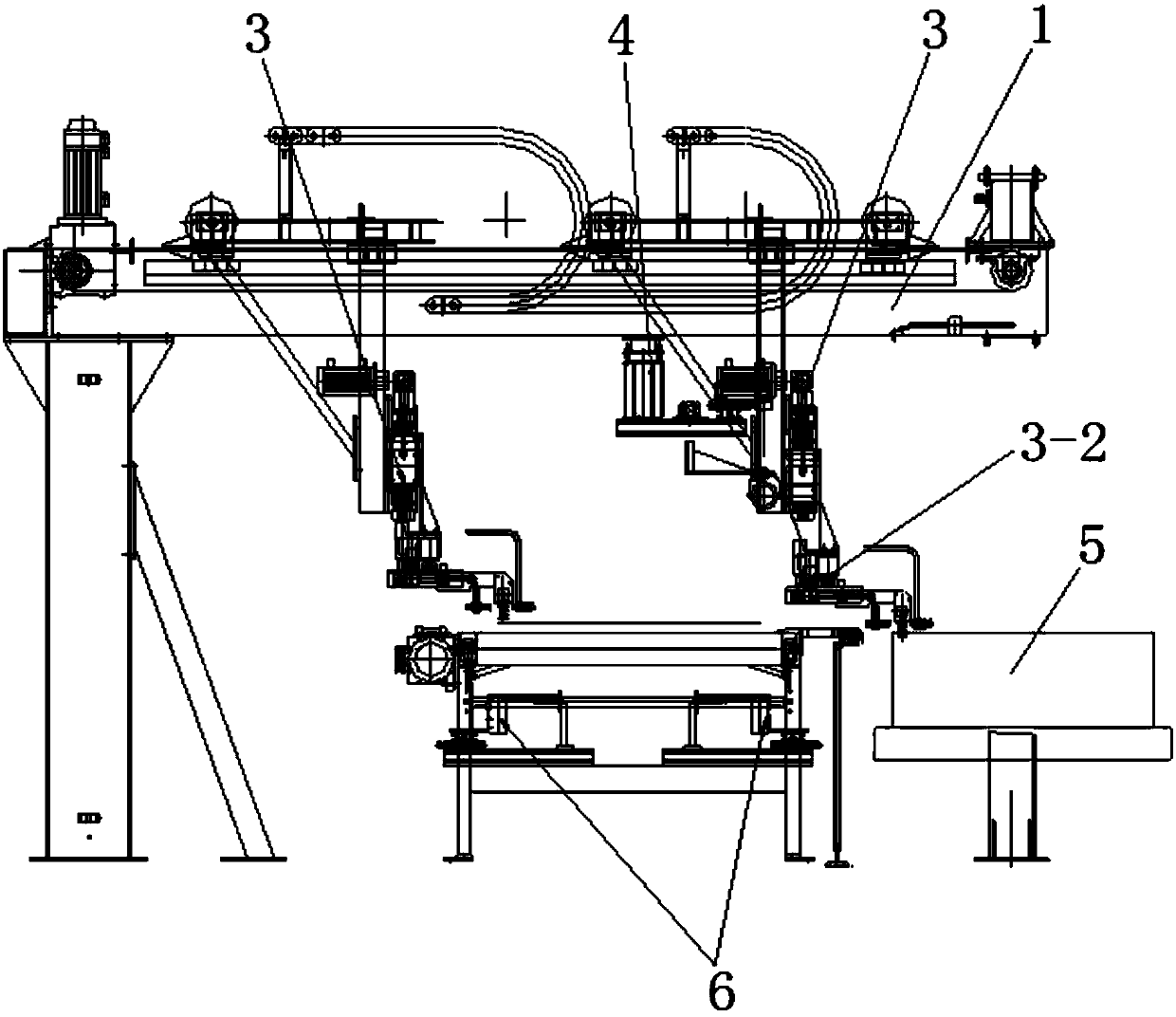

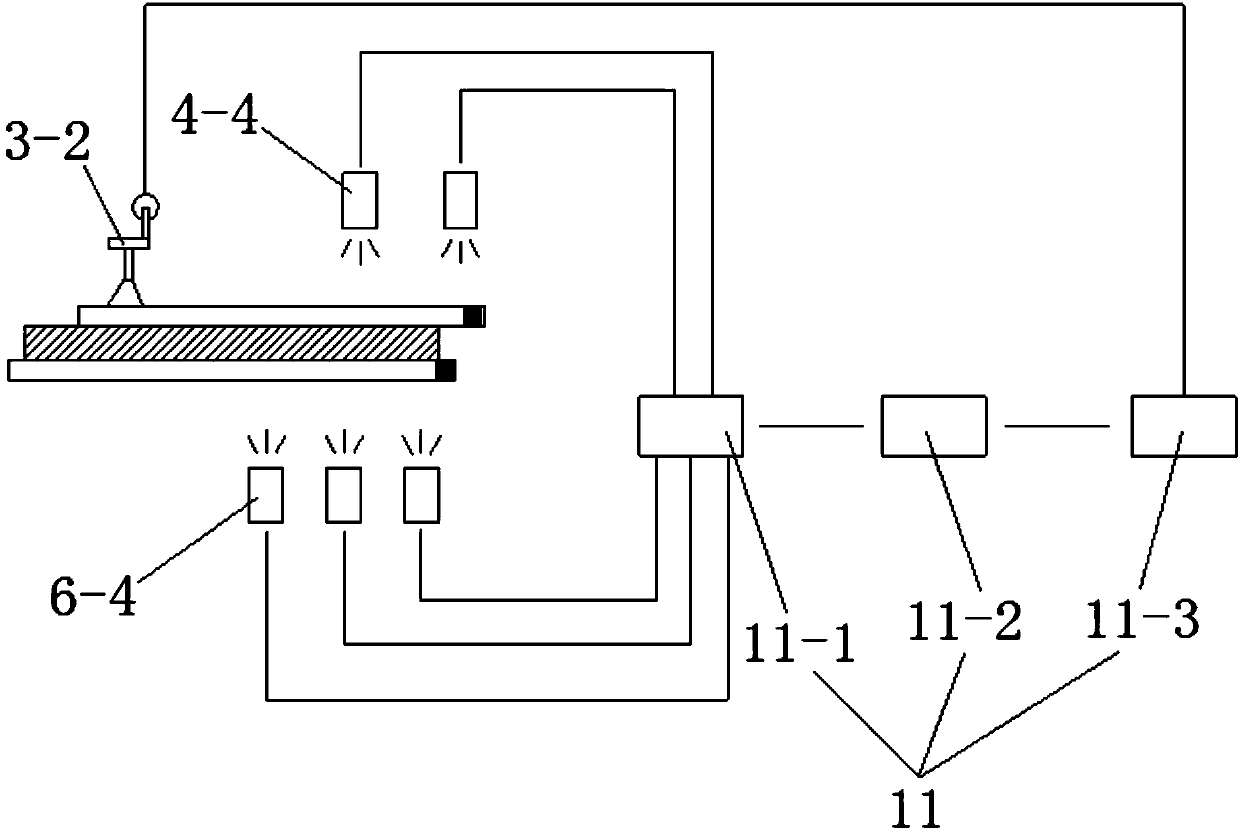

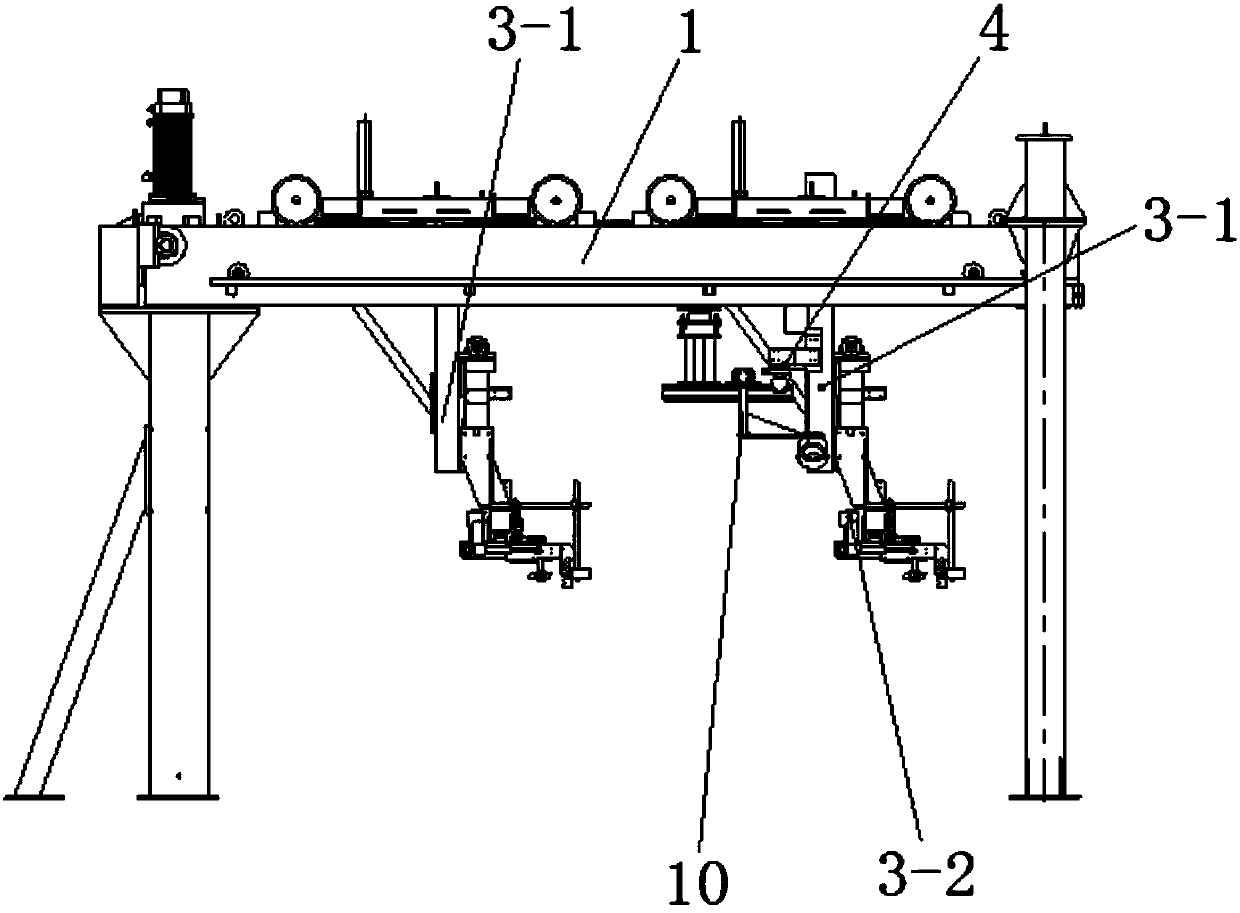

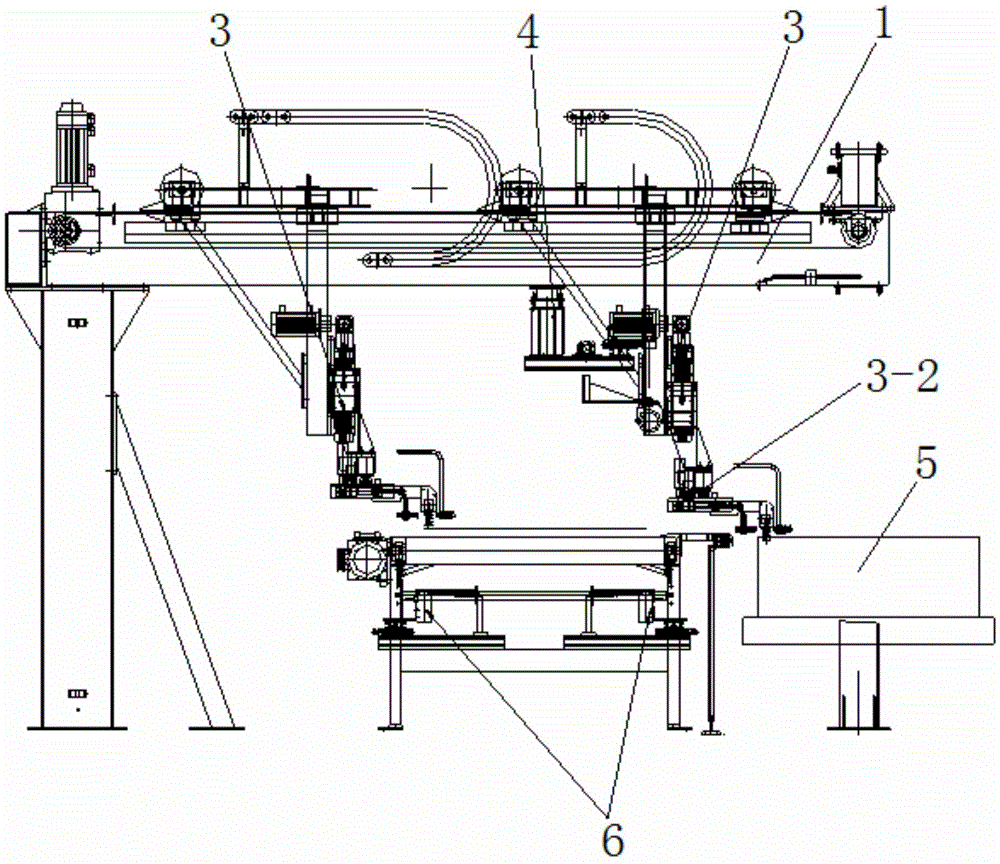

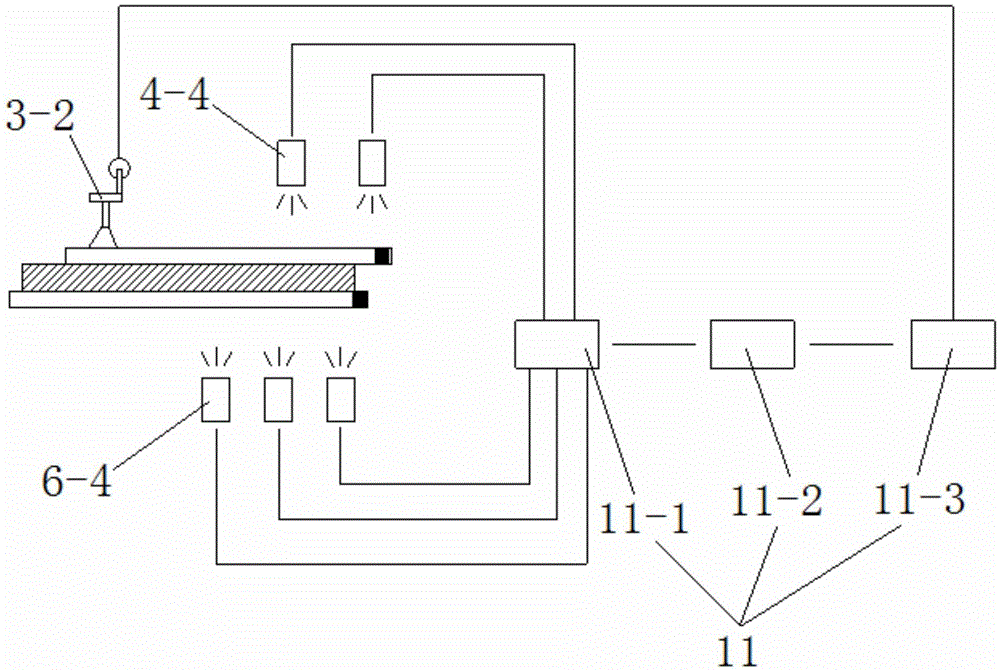

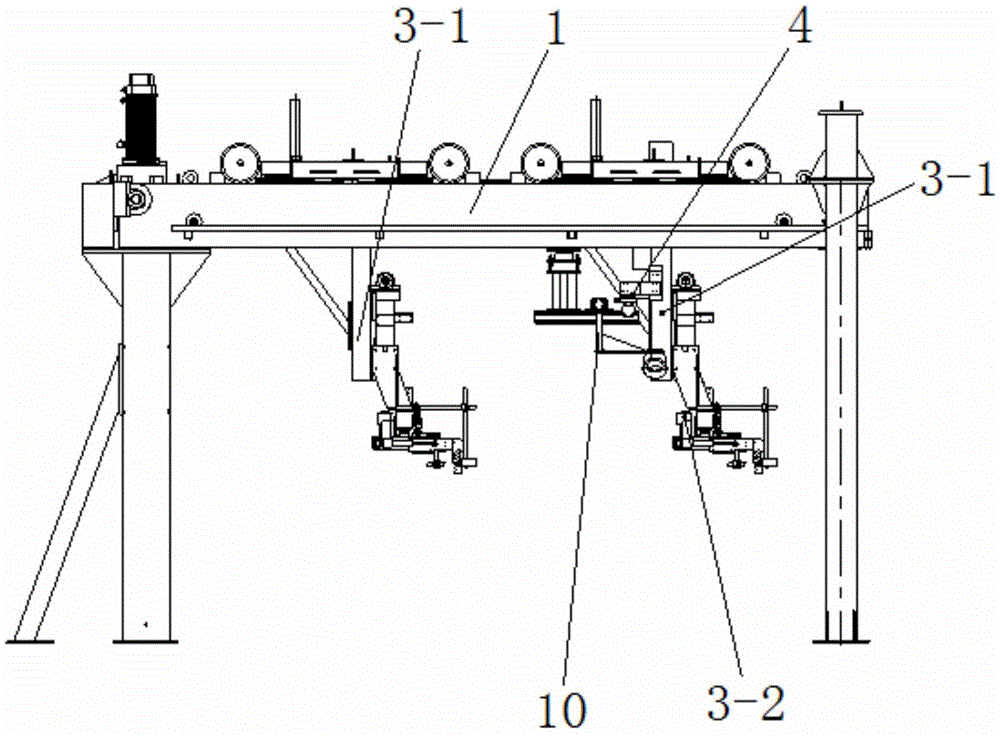

A double-sided embossing machine

ActiveCN105584279BEnsure consistencyQuality improvementEmbossing decorationsEngineeringMechanical engineering

Owner:WEMHOENER CHANGZHOU MACHINERY MFG

Embossing machine for both sides

The invention discloses an embossing machine for both sides. The embossing machine for both sides comprises an upper machine frame, a lower machine frame arranged below the upper machine frame, an upper film conveying regulation mechanism, an upper positioning mechanism, a lower positioning mechanism, a working table face and a control mechanism, wherein the upper film conveying regulation mechanism and the upper positioning mechanism are mounted on the upper machine frame; the lower positioning mechanism and the working table face are mounted on the lower machine frame; the control mechanism is electrically connected with the upper film conveying regulation mechanism, the upper positioning mechanism and the lower positioning mechanism; a base plate paved with a lower film is placed on the working table face; the upper film conveying regulation mechanism is used for conveying an upper film to the position above the working table face. The control mechanism regulates the angle of deflection of the upper film through the upper film conveying regulation mechanism according to the positioning data sent by the upper positioning mechanism and the lower positioning mechanism, so that the vertical positions of the upper film and the lower film are coincident, then the consistency of an upper embossed pattern and a lower embossed pattern is ensured, and convenience is brought to later assembling while the product quality and the degree of beauty are increased.

Owner:WEMHOENER CHANGZHOU MACHINERY MFG

A kind of blended material with high acetate fiber content and preparation method thereof

ActiveCN105297443BGood touchImprove breathabilityBiochemical fibre treatmentFilament/thread formingFiberPolymer science

The invention provides a blended material with high cellulose acetate content and a preparation method thereof. The present invention proceeds from two aspects. On the one hand, the strength of the acetate fiber itself is enhanced to improve its anti-break performance; Abrasion resistance, and significantly improve the wet strength of the material. Through the above treatment, the weak point of poor mechanical strength of acetate fiber can be eliminated, so the content of acetate fiber can be increased in blended materials, so that acetate fiber has good touch, good air permeability, no static electricity and easy coloring. The properties can be preserved in the blended materials to the greatest extent.

Owner:ZHEJIANG CHAOFAN GARMENT CO LTD

Antistatic composite material and preparation method thereof

InactiveCN106065108AImprove antistatic performanceSolve the problem of discharge damageNano structuringEther

The invention belongs to the technical field of composite materials and specifically relates to an antistatic composite material. The antistatic composite material comprises, by weight, 40 parts of a polyethylene-acetic ether copolymer, 10-35 parts of conducting particles, 0.01-0.3 part of a coupling agent, 1-6 parts of an antioxidant and 20-35 parts of polyphenylene sulfide PPS. The conducting particles are core-shell structured particles formed by ferric oxide / silver. By addition of the core-shell nano-structured conducting particles, the prepared composite material has good antistatic property, and electro-discharge damage of electrostatic accumulation due to existing packaging to various sensitive electronic components and instruments and apparatuses, etc. can be solved. By the utilization of the conducting particles uniformly distributed in the film, conductivity is increased, electrostatic accumulation is reduced, and the problem of damage of static electricity to packaged goods is solved. The antistatic composite material has extensive significance in promotion and use.

Owner:苏州市奎克力电子科技有限公司

A self-bacteria and anti-static high-safety porcelain tile and its manufacturing method

The invention discloses a self-antibacterial anti-static high safety porcelain throwing brick and a manufacturing method thereof. The physical structure of the porcelain throwing brick is composed oftwo parts, and a part is a porous large-sized silicon carbide ceramic constructed by silicon carbide fine powders and cerium oxide fine powders, the other part is a sodium-alumina-based sol filler andcross-linking monomer which are internally and uniformly mixed with nano-pilent powder, silica, bamboo charcoal powder and titanium oxide powder; the two parts are prepared by one-time oxidation andphysical pressure sintering under the combined action of the initiator ammonium citrate, and the cross-linking agent N, N-methylene bis acrylamide; the porcelain throwing brick is printed with a decorative pattern on the upper surface; the upper and lower surfaces of the porcelain throwing brick are provided with a three-dimensional compressive stress microstructures on the shallow surface 0.3 mm-0.5 mm away from the surface. The porcelain throwing brick combines the functions of the antistatic ceramic tile and the physical and biochemical characteristics of the porcelain throwing brick, and has the advantages of stereoscopic configuration, self-antibacterial, anti-static electricity, antistatic, the environmental protection, and the safety.

Owner:董孟富

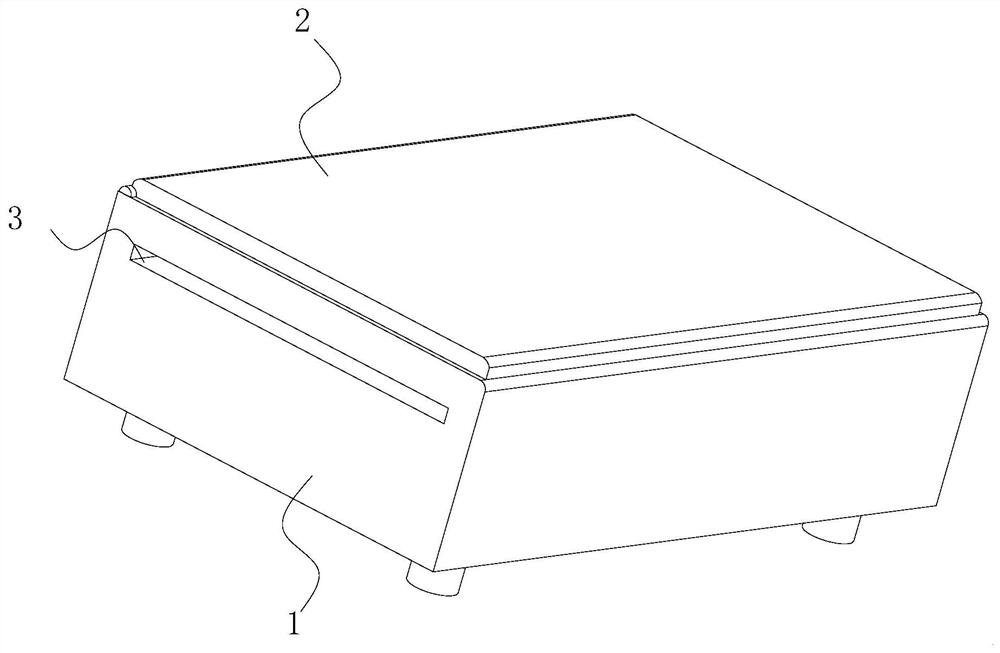

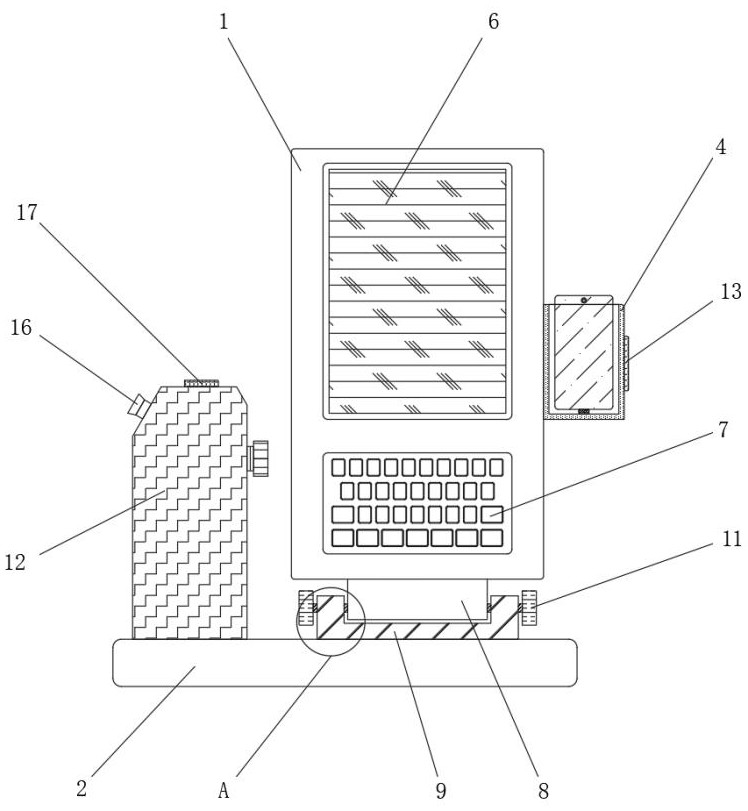

Laboratory-based communication device

InactiveCN113778181AActive connection extensionResponsive and clear displayDigital data processing detailsLavatory sanitoryStructural engineeringMechanical engineering

A laboratory-based communication device disclosed by the present invention comprises a case and a base, the side edge of the case is provided with a movable groove, and the movable groove is internally provided with a loading box; the surface of the case is fixedly connected with a rotator, the side edge of the rotator is fixedly connected with an expansion screen, and the surface of the case is fixedly connected with entity keys. An angle adjusting block is fixedly connected to the bottom of the case, a connecting block is fixedly connected to the top of the base, and a placement groove is formed in the top of the connecting block; the angle adjusting block is arranged in the placement groove, and an angle adjusting bolt is in threaded connection with the side edge of the connecting block. According to the laboratory-based communication device, through the connection and action of the case, the base, the movable groove, the loading box, the rotator, the expansion screen, the entity keys, the angle adjusting block, the connecting block, the placement groove, the angle adjusting bolt and other parts, the effects of effective connection, sensitive response and adjustable visual angle of the communication device are achieved.

Owner:GUIZHOU INST OF TECH

A kind of anti-static coated sand and preparation method thereof

ActiveCN108526385BEliminate hazardsReduce stratificationFoundry mouldsMould handling/dressing devicesAntistatic agentMold filling

The invention relates to static eliminating precoated sand. A stratification phenomenon of the precoated sand is reduced and the size distribution is more uniform. The flowability of the precoated sand is improved, so that a mold-filling capacity of the precoated sand is increased in a core preparation process, the generating probability of detects such as loose sand cores and defective blocks isreduced, and therefore, the rate of finished products of castings is increased, the production cost is lowered, and damage of static electricity in the using process of the precoated sand on human body is also eliminated. According to a preparation method of the static eliminating precoated sand provided by the invention, the preparation process is adjusted properly according to compositions of raw materials. The preparation method comprises the following steps: firstly, blending phenolic resin and an antistatic agent; and then adding the mixture into heated raw sand, wherein the coating effect of the phenolic resin is excellent, static electricity generated in the blending process of the phenolic resin and the original sand is eliminated, and the size distribution and flowing property ofthe produced precoated sand are good. A conducting device is additionally arranged to export static electricity in a precoated sand product, so that the antistatic agent does not act yet, and the produced static electricity is eliminated immediately.

Owner:YANCHENG RENCHUANG SAND IND TECH CO LTD

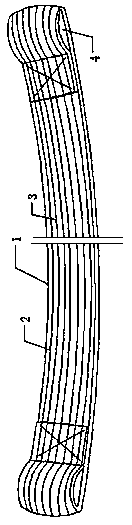

Multifunctional rescuing belt of firefighter

The invention discloses a multifunctional rescuing belt of a firefighter. The multifunctional rescuing belt of the firefighter comprises a belt body which is a tubular flat belt, wherein the belt bodyis manufactured by knitting Kevlar lines; a plurality of uniformly-distributed light reflecting lines and antistatic lines are knitted at two sides of the belt body; and two ends of the belt body aresewed to form connecting buckles. The multifunctional rescuing belt of the firefighter to use in a fire extinguishing and recusing site has a plurality of purposes such as the purposes of manufacturing a self-rescuing or other-rescuing emergency safety belt, dragging and transferring injured people, binding and fixing a device and carrying apparatuses; a plurality of light reflecting lines are added, so that the visibility is high in a dense smoke and hard environment; the belt is manufactured by knitting the Kevlar lines, so that the belt is high in fireproofing and flame retarding performance, high in strength and low in flame radiation heat influence; Kevlar is one of synthetic aramid fibers, the synthetic fibers are easy to cause static electricity and are not suitably used in a flammable and combustible environment; and the antistatic lines are added, so that the static electricity can be timely transferred out.

Owner:刘柏辰

Anti-spanning type safety guardrail

InactiveCN111778900AAcross blockHeating fastSolar heating energyBatteries circuit arrangementsClassical mechanicsTraffic accident

The invention discloses an anti-spanning type safety guardrail. The safety guardrail comprises a plurality of sets of guardrail bodies, and each guardrail body comprises two stand columns and a crossbeam fixedly connected between the two stand columns. The bottom of each stand column is fixedly connected with a base. A plurality of vertical rods are fixedly connected in the two cross beams; a rubber layer is arranged on the surface of each cross beam; a first cavity is formed in each cross beam; a first magnetic block is connected into each first cavity in a sealing and sliding manner; each stand column communicates with the corresponding first cavity and is provided with a second cavity; each second cavity comprises a part with the same size as the first corresponding cavity and anotherpart located above the rubber layer, each second cavity is fixedly connected with a spring, the free end of each spring is fixedly connected with a second magnetic block, a friction layer is arrangedat the bottom of each second magnetic block, and the friction layers and the rubber layers are electrified in a friction mode. The safety guardrail has the advantages that pedestrians are prevented from crossing the guardrail in various modes, a driver is reminded at night, and traffic accidents are avoided.

Owner:陈会会

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com