Processing technology for producing electrical polyester non-woven fabric

A non-woven fabric and processing technology, applied in non-woven fabrics, textiles and paper making, etc., can solve the problems of difficult carding, high fiber static electricity, product insulation effect, etc., to avoid high fiber static electricity, uniform thickness, dense, high Effect of insulation class

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

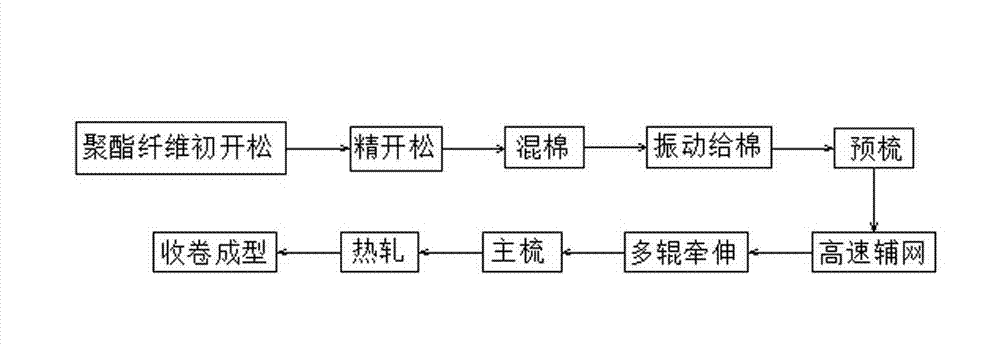

Method used

Image

Examples

Embodiment 1

[0008] Example 1: Production of insulating material with a thickness of 0.05mm

[0009] The specific steps are: (1) Select polyester fiber with a thickness of 1.67D×38mm in length, and use an opener for initial opening; (2) Further use an opener for fine opening; (3) , Use a cotton blender to blend cotton; (4), vibrate the cotton, every 80g as a cotton feed; (5) use a carding machine for pre-carding to remove impurities from its longitudinal fibers; (6), high-speed auxiliary net , The number of auxiliary web layers is 6; (7), multi-roll drafting, to straighten the fiber to prevent crimping; (8), use a carding machine to further main comb to remove short lint; (9), hot rolling, The temperature of the hot rolling mill is 237 degrees Celsius, and the pressure is 70 kilograms; (10). Rewinding and forming are cooled by circulating water, and the temperature of the nonwoven fabric after being off the machine is 40 degrees Celsius.

Embodiment 2

[0010] Example 2: Production of insulating material with a thickness of 0.06mm

[0011] The specific steps are: (1) Select polyester fiber with a thickness of 2.22D×51mm in length, and use an opener for initial opening; (2) Further use an opener for fine opening; (3) , Use a cotton blender to blend cotton; (4), vibrate the cotton, every 80g as a cotton feed; (5) use a carding machine for pre-carding to remove impurities from its longitudinal fibers; (6), high-speed auxiliary net , The number of auxiliary web layers is 9; (7), multi-roll drafting, straighten the fiber to prevent crimping; (8), use a carding machine to further main comb to remove short lint; (9), hot rolling, The temperature of the hot rolling mill is 239 degrees Celsius, and the pressure is 90 kilograms; (10). Rewinding and forming are cooled by circulating water, and the temperature of the nonwoven fabric after being off the machine is 45 degrees Celsius.

Embodiment 3

[0012] Example 3: Production of insulating material with a thickness of 0.07mm

[0013] The specific steps are: (1) Select polyester fiber with a thickness of 2.78D×51mm in length, and use an opener for initial opening; (2) Further use an opener for fine opening; (3) , Use a cotton blender to blend cotton; (4), vibrate the cotton, every 80g as a cotton feed; (5) use a carding machine for pre-carding to remove impurities from its longitudinal fibers; (6), high-speed auxiliary net , The number of auxiliary web layers is 12; (7), multi-roll drafting, to straighten the fiber to prevent curling; (8), use a carding machine to further main comb to remove short lint; (9), hot rolling, The temperature of the hot rolling mill is 241 degrees Celsius, and the pressure is 120 kilograms; (10). Rewinding and forming are cooled by circulating water, and the temperature of the nonwoven fabric after being off the machine is 50 degrees Celsius.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com