Production method of meta-position aramid nonwoven material for electric insulation

A non-woven material, electrical insulation technology, used in non-woven fabrics, textiles, papermaking, adhesives, etc., can solve the problems of single aramid insulating material, large static electricity of aramid fibers, low tensile strength, etc. Uniform and dense, high insulation grade performance, thickness and uniform and dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Production of insulating material with a thickness of 0.1 mm

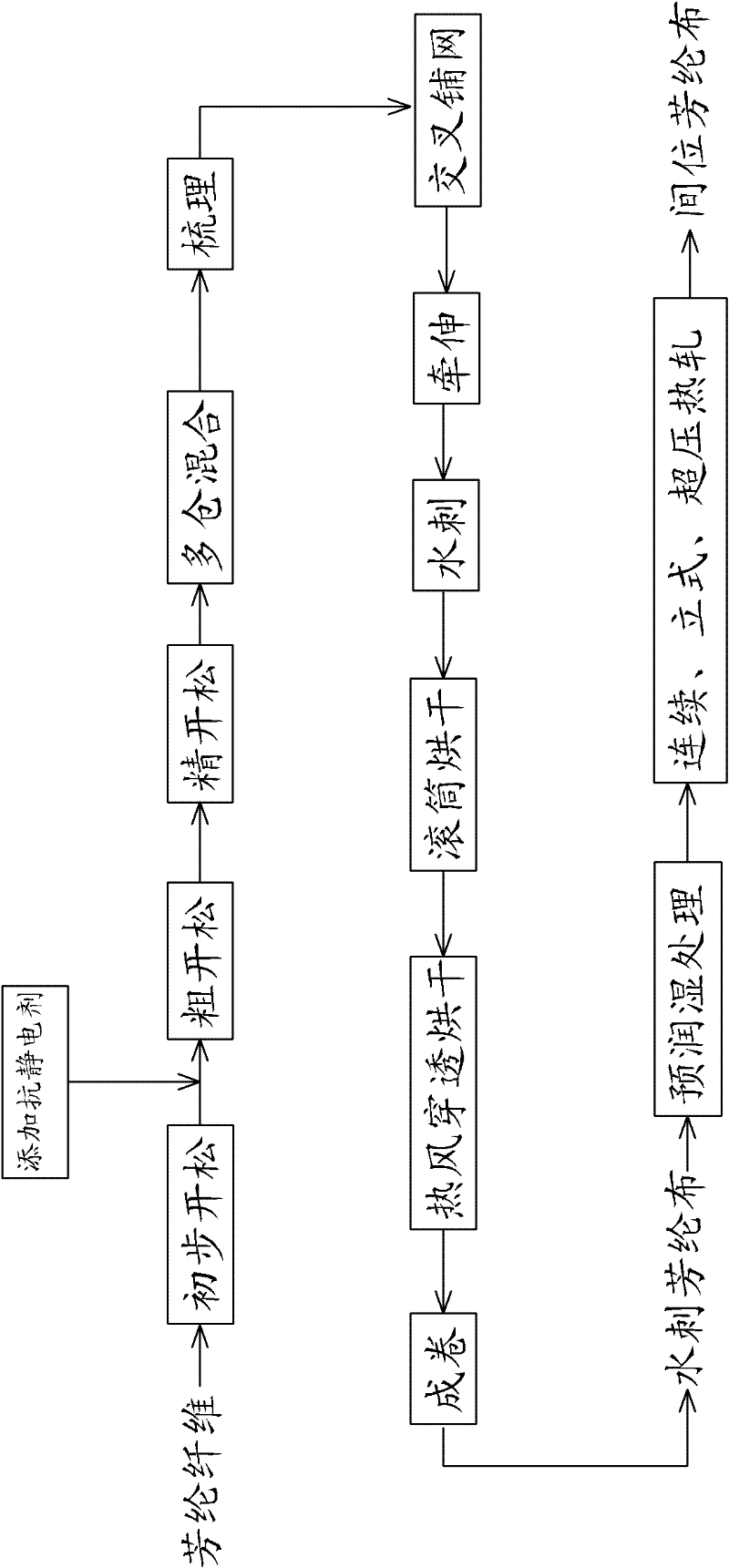

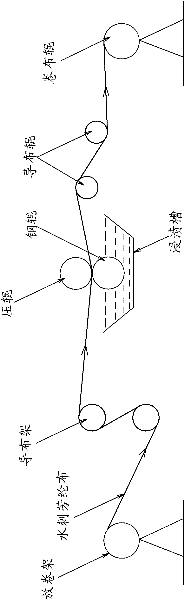

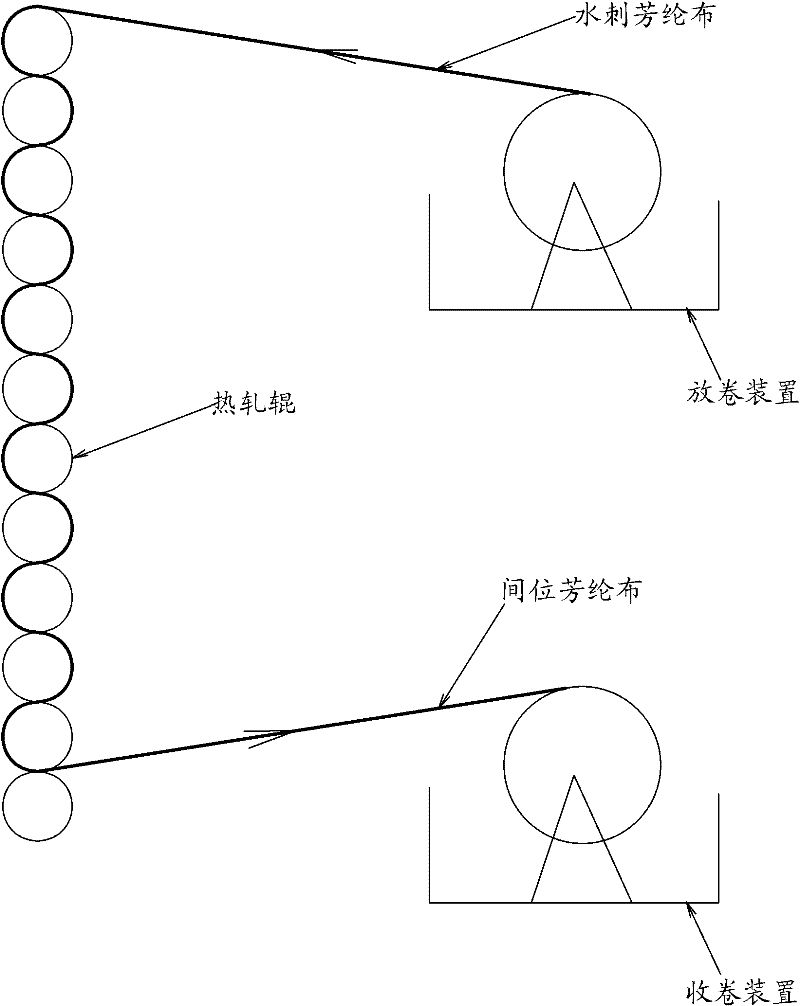

[0027] The first step of the spunlace nonwoven process has the following steps:

[0028] Aramid fibers with a fineness of 2 Denier and a length of 51mm are selected; two bale opening machines are used to feed the aramid fibers in proportion to the initial opening, followed by two openings, multi-bin mixing, carding, cross-lapping, In the processes of drawing, spunlace, drum drying, hot air penetration drying and coiling, the antistatic agent aqueous solution is applied according to 4.5% of the total fiber weight before opening or at the multi-compartment mixing place, and the antistatic agent aqueous solution is determined by mass percentage It is composed of 2.5% antistatic agent and 97.5% water to improve the carding effect of fibers.

[0029] The technical requirements of the main equipment or devices in the above process are as follows:

[0030] The main process of the air pressure cotton bo...

Embodiment 2

[0035] Embodiment 2: Production thickness is the insulation material of 0.05mm

[0036] The first step of the spunlace nonwoven process has the following steps:

[0037] Aramid fibers with a fineness of 2 Denier and a length of 51mm are selected; two bale opening machines are used to feed the aramid fibers in proportion to the initial opening, followed by two openings, multi-bin mixing, carding, cross-lapping, In the processes of drawing, spunlace, drum drying, hot air penetration drying and coiling, the antistatic agent aqueous solution is applied according to 4.5% of the total fiber weight before opening or at the multi-compartment mixing place, and the antistatic agent aqueous solution is determined by mass percentage It is composed of 2.5% antistatic agent and 97.5% water to improve the carding effect of fibers.

[0038] The technical requirements of the main equipment or devices in the above process are as follows:

[0039] The main process of the air pressure cotton box ...

Embodiment 3

[0044] Embodiment 3: produce the product of 0.035mm

[0045] The first step of the spunlace nonwoven process for the production of aramid substrates has the following steps:

[0046] Aramid fibers with a fineness of 1.5 denier and a length of 38mm are selected; two bale opening machines are used to feed the aramid fibers in proportion to the initial opening, followed by two openings, multi-bin cotton blending, carding, web laying, For the hydroentangled nonwoven process of drafting, spunlace, drum drying, hot air penetration drying and coiling, apply antistatic oil and water and antistatic agent according to 4.5% of the total fiber weight before opening or at the multi-compartment mixing place The mixture consists of 2.5% antistatic agent and 97.5% water to improve the carding effect of fibers.

[0047] The technical requirements of the main equipment or devices in the above process are as follows:

[0048] The main process of the air pressure cotton box in front of the card...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com