Embossing machine for both sides

An embossing machine and double-sided technology, which is applied in embossed ornaments, decorative arts, etc., can solve the problems of destroying the external aesthetics of furniture floors, inconsistent textures of upper and lower films, and conveyor belt errors, so as to improve quality and aesthetics and prevent drifting , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

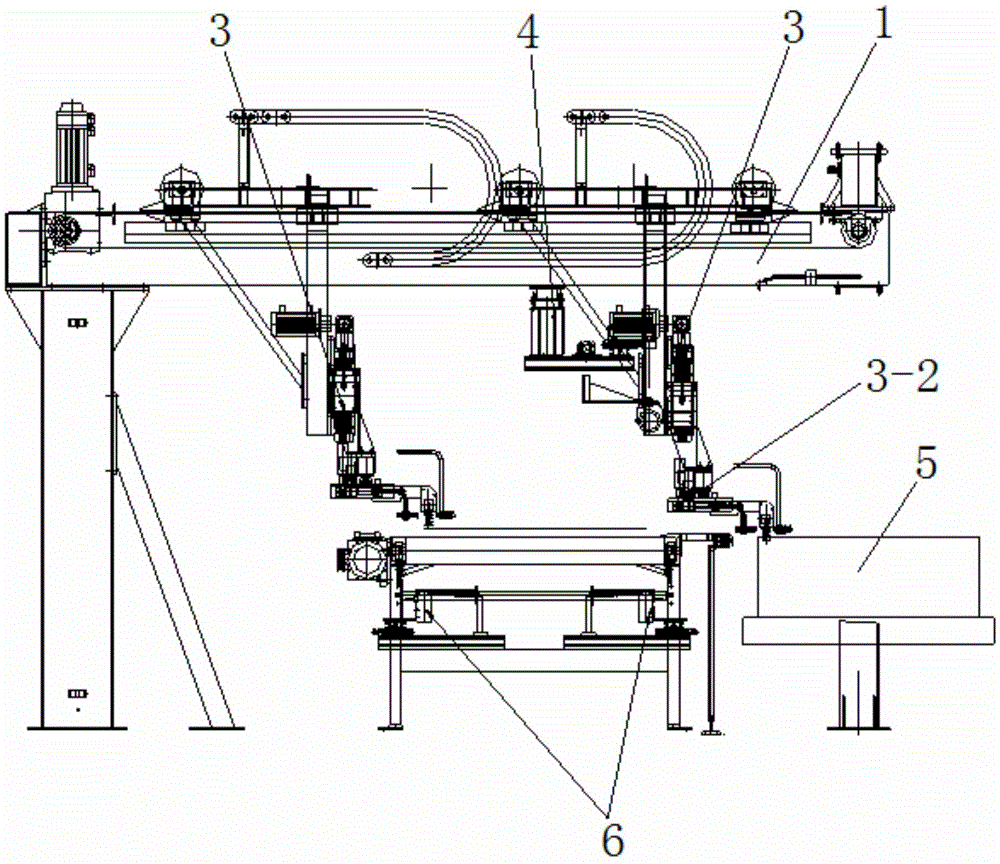

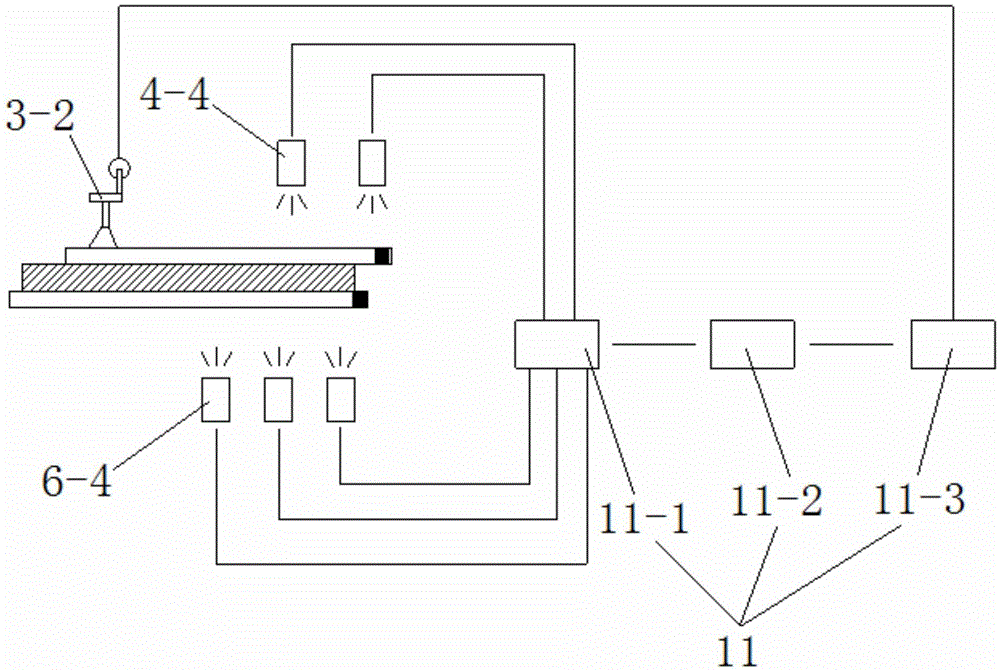

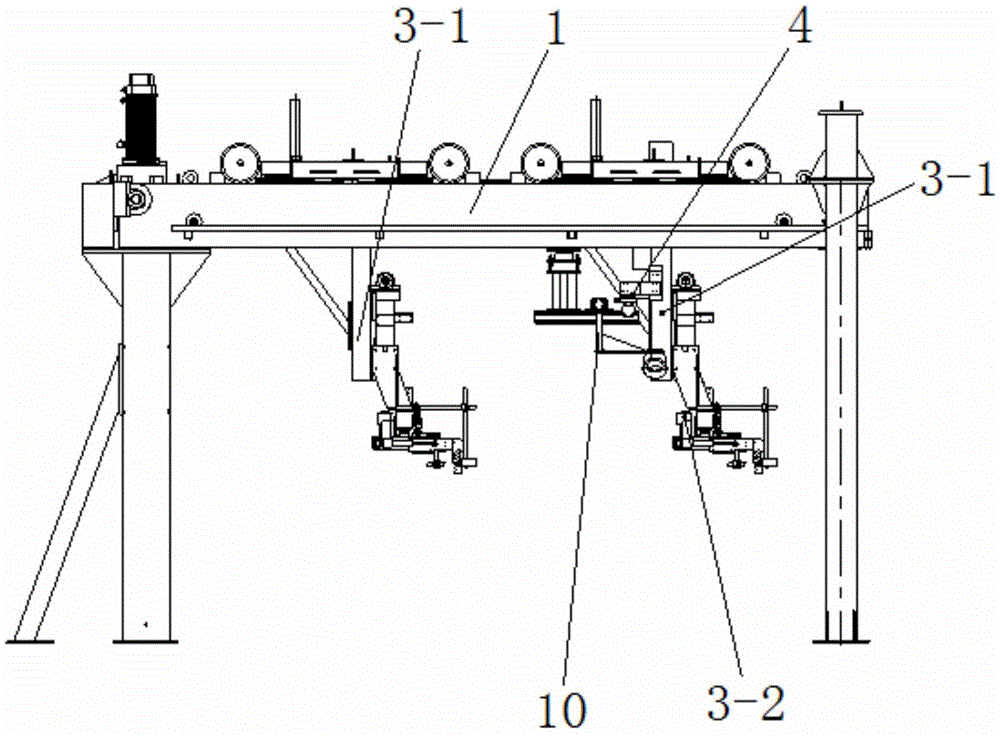

[0028] See Figure 1 to Figure 6 , the double-sided embossing machine of the present embodiment comprises an upper frame 1, a lower frame 2 arranged below the upper frame 1, an upper film transport adjustment mechanism 3 and an upper positioning mechanism 4 installed on the upper frame 1, installed The lower positioning mechanism 6 and the transmission mechanism 7 on the lower frame 2, the work surface 8 installed on the transmission mechanism 7, the electrostatic generator 9 fixed on the work surface 8, installed in the upper positioning mechanism 4 and the lower positioning mechanism 6 The supplementary light mechanism 10, and the control mechanism 11 electrically connected with the upper film transport adjustment mechanism 3, the upper positioning mechanism 4 and the lower positioning mechanism 6.

[0029] Place the substrate with the lower film laid on the workbench 8 . Both the upper film and the lower film are provided with at least one pair of positioning points in the...

Embodiment 2

[0038] This embodiment is basically the same as Embodiment 1, except that it also includes a camera for automatically adjusting the positions of the upper positioning mechanism 4 and the lower positioning mechanism 6, or for automatically adjusting the upper positioning mechanism 4 and the lower positioning mechanism 6. Position automatic position adjustment mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com