Destaticizer for textile materials and preparation method thereof

A technology for textile materials and static electricity removal, applied in textiles, papermaking, fiber treatment, etc., can solve problems such as poor biodegradability and environmental impact, and achieve strong stability, good antistatic performance, and good antistatic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

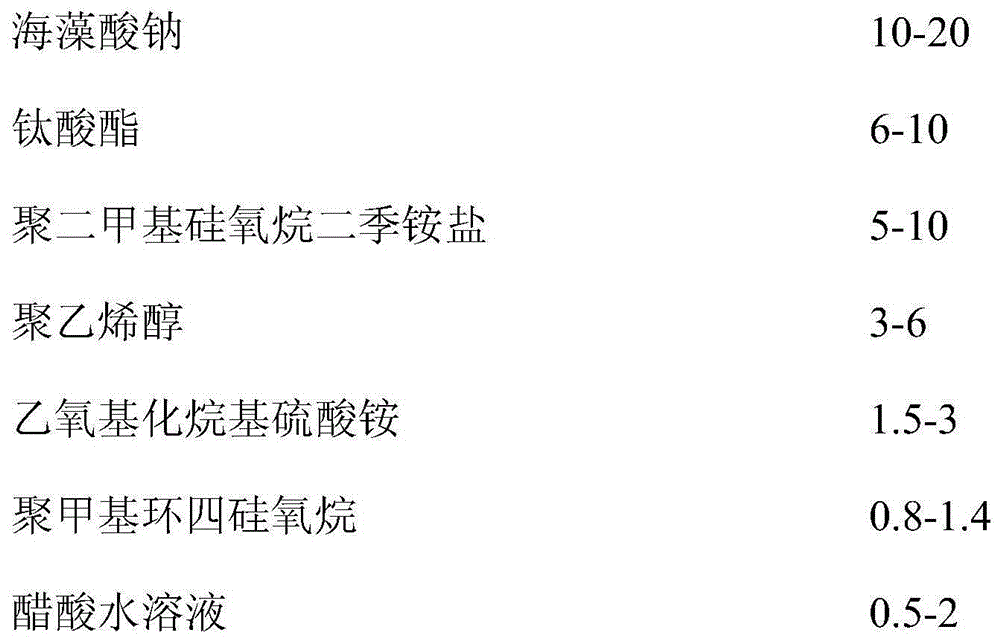

[0037] A kind of antistatic agent for textile materials, said antistatic agent is mainly prepared from the following raw materials in parts by weight:

[0038]

[0039] The preparation method of described antistatic agent, this method comprises the following steps:

[0040] (1) Add sodium alginate, n-butyl titanate, polydimethylsiloxane diquaternary ammonium salt, polyvinyl alcohol, and ethoxylated alkylammonium sulfate to deionized water according to the above-mentioned formula amount, and heat at 55°C down, stir well;

[0041] (2) Slowly add acetic acid aqueous solution, under the heating condition of 50° C., add ethanol and polymethylcyclotetrasiloxane, and stir evenly to obtain a destaticizer for textile materials.

Embodiment 2

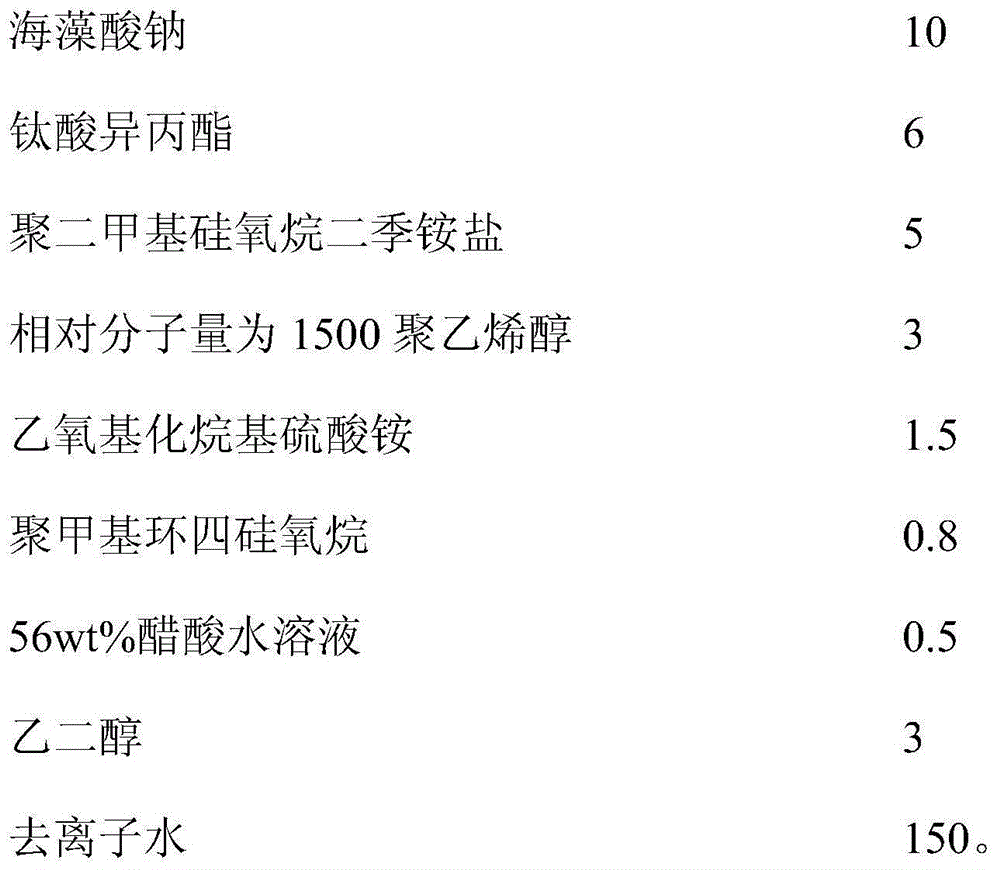

[0043] A kind of antistatic agent for textile materials, said antistatic agent is mainly prepared from the following raw materials in parts by weight:

[0044]

[0045] The preparation method of the antistatic agent is the same as in Example 1, the stirring temperature in step (1) is 70°C, and the heating temperature in step (2) is 65°C.

Embodiment 3

[0047] A kind of antistatic agent for textile materials, said antistatic agent is mainly prepared from the following raw materials in parts by weight:

[0048]

[0049]

[0050] The preparation method of the antistatic agent is the same as in Example 1, the stirring temperature in step (1) is 65°C, and the heating temperature in step (2) is 60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com