Hole machining machine tool

A hole processing and machine tool technology, applied in the field of mechanical processing, can solve problems such as inconvenience in work, and achieve the effect of ensuring normal chip suction, avoiding environmental dust pollution and better dust removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further detailed explanation through specific implementation mode below:

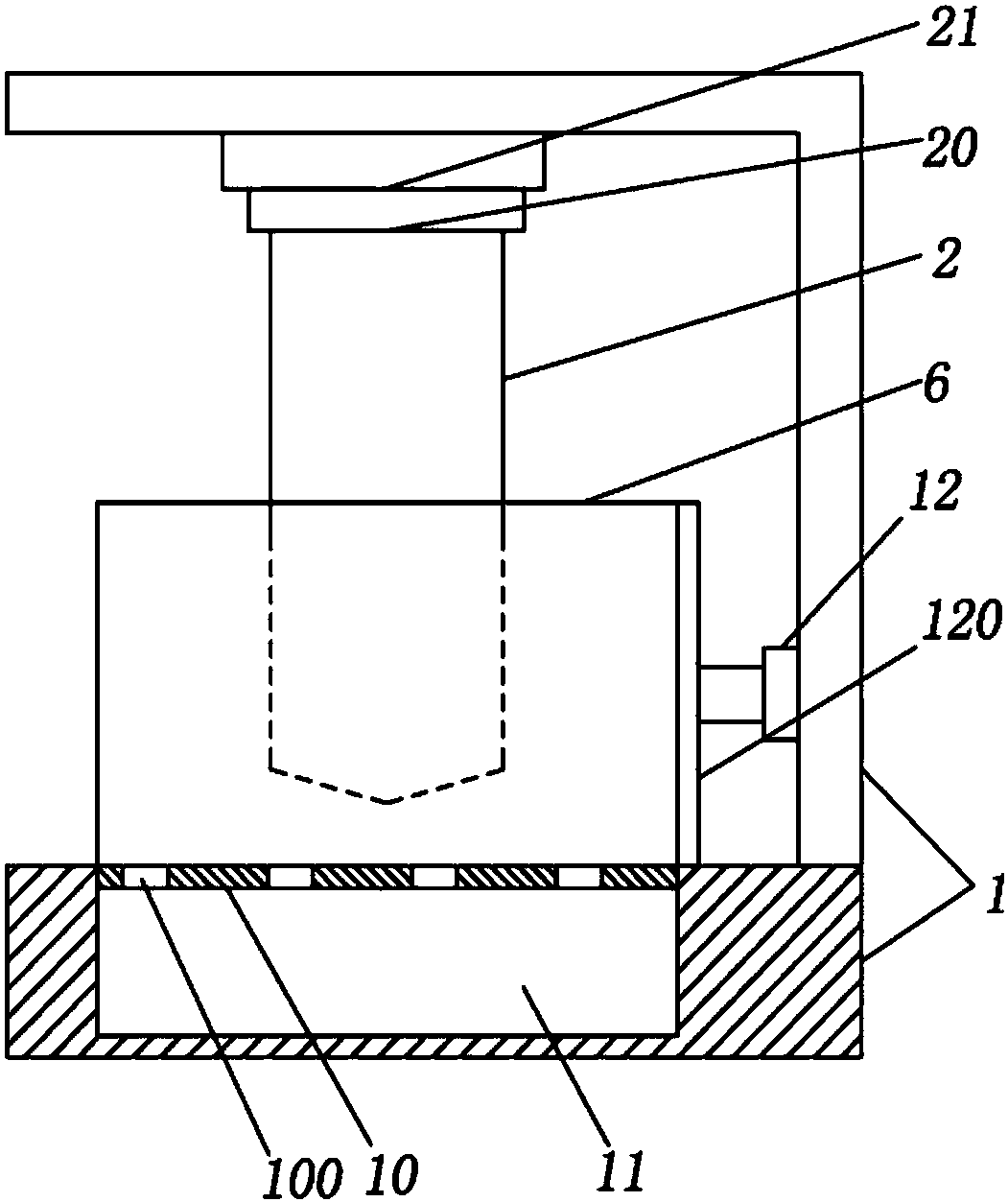

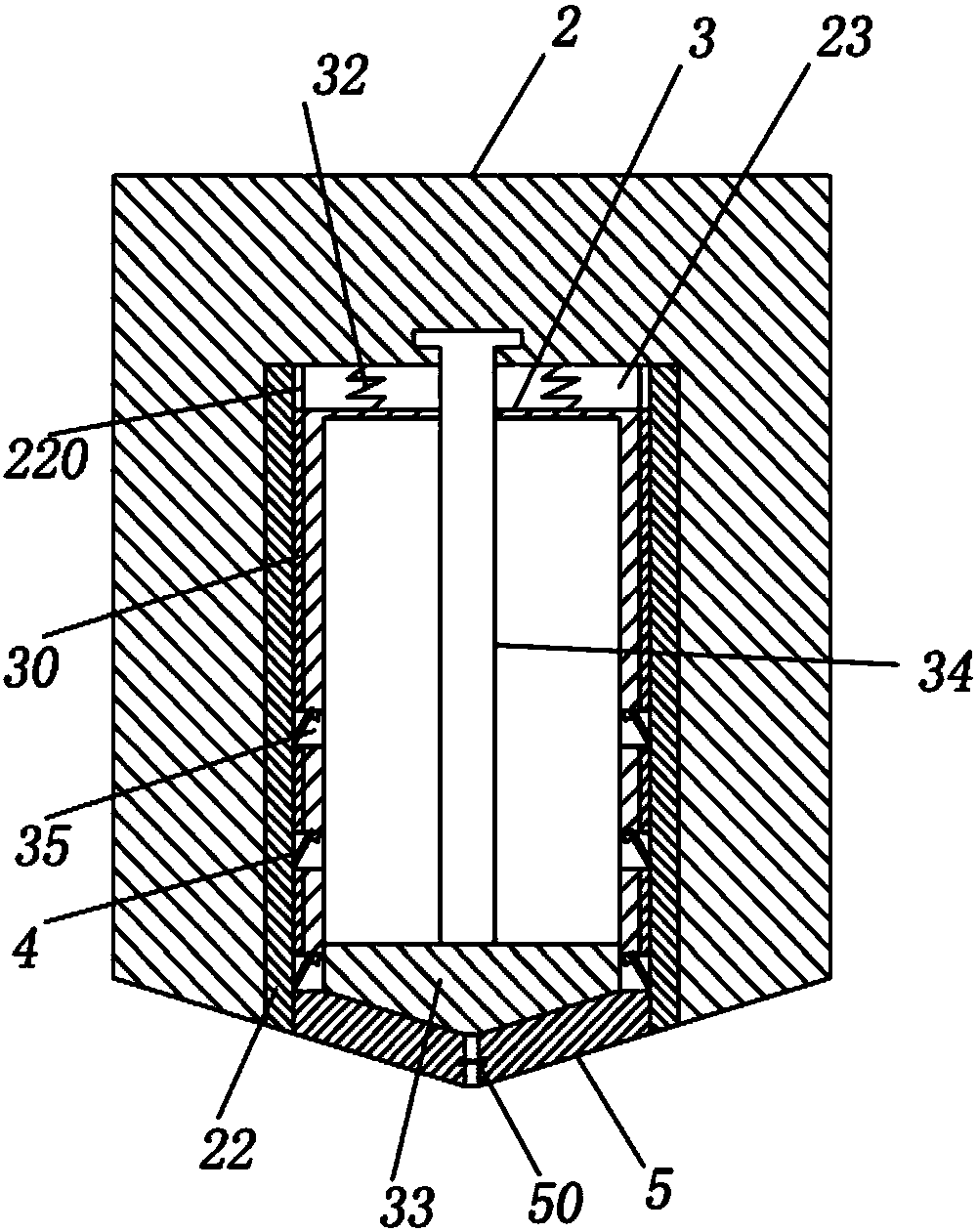

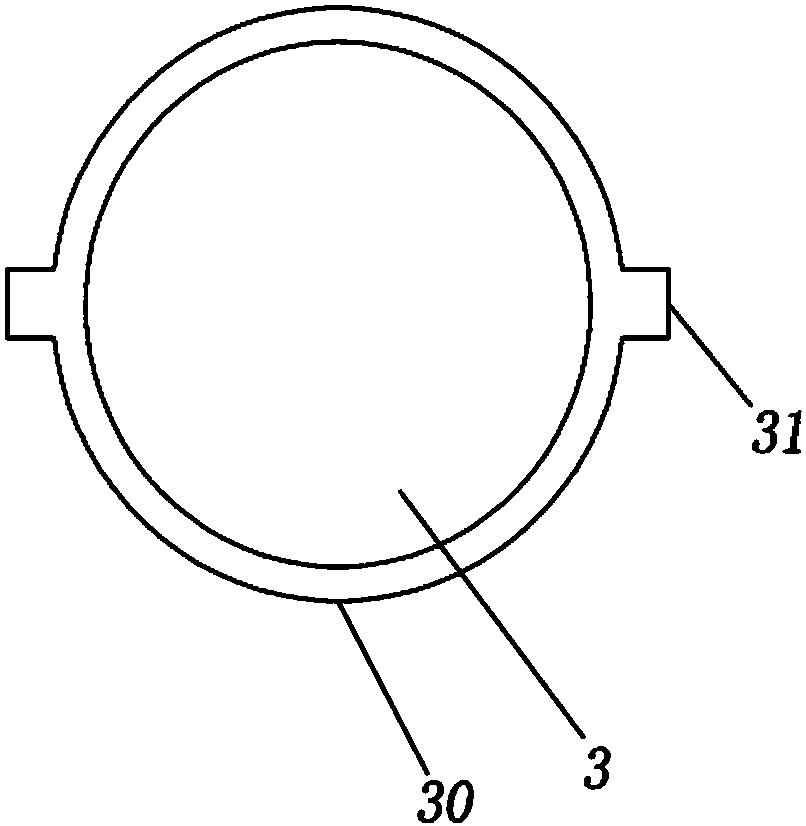

[0020] The reference signs in the drawings of the description include: frame 1, electromagnet 10, chip drain hole 100, chip storage tank 11, pneumatic cylinder 12, push plate 120, drill bit 2, motor 20, hydraulic cylinder 21, cotton cloth layer 22 , keyway 220, sliding cavity 23, chip suction pipe 3, plastic layer 30, feather key 31, extension spring 32, piston 33, piston rod 34, chip suction through hole 35, opening and closing door 4, compression spring 40, drill bit 5, Advance chip through hole 50, plank 6.

[0021] The embodiment is basically as figure 1 Shown: a hole processing machine tool, including a frame 1, a drill 2 and a rotating part that drives the drill 2 to rotate, and also includes a lifting part that drives the drill 2 to rise and fall. The rotating part can directly select the motor 20 in the prior art, and the lifting part can directly select the hydraulic cylinder 21.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com