Treating method for halogenated organic solid pollutants

A technology of organic solids and treatment methods, applied in the direction of solid waste removal, etc., can solve the problems of weakening the effect of halogenated organic pollutants, difficult to achieve deep dehalogenation, and difficult to remove halogenated groups, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

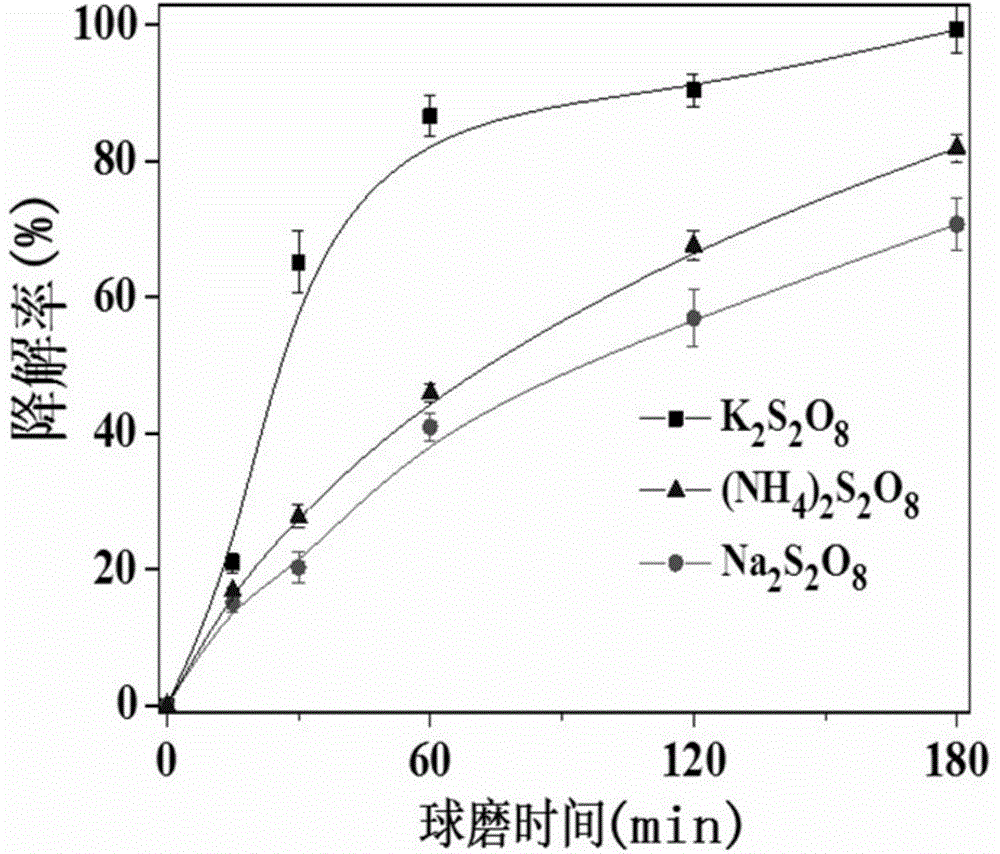

Embodiment 1

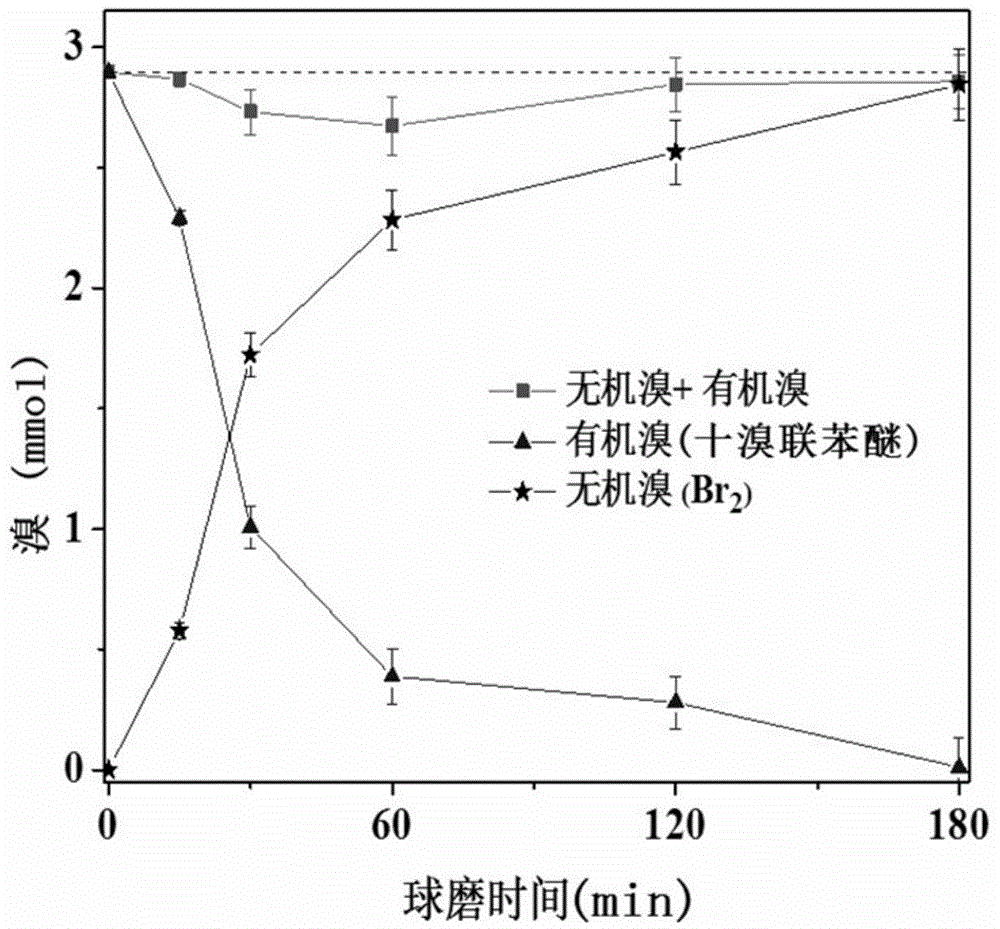

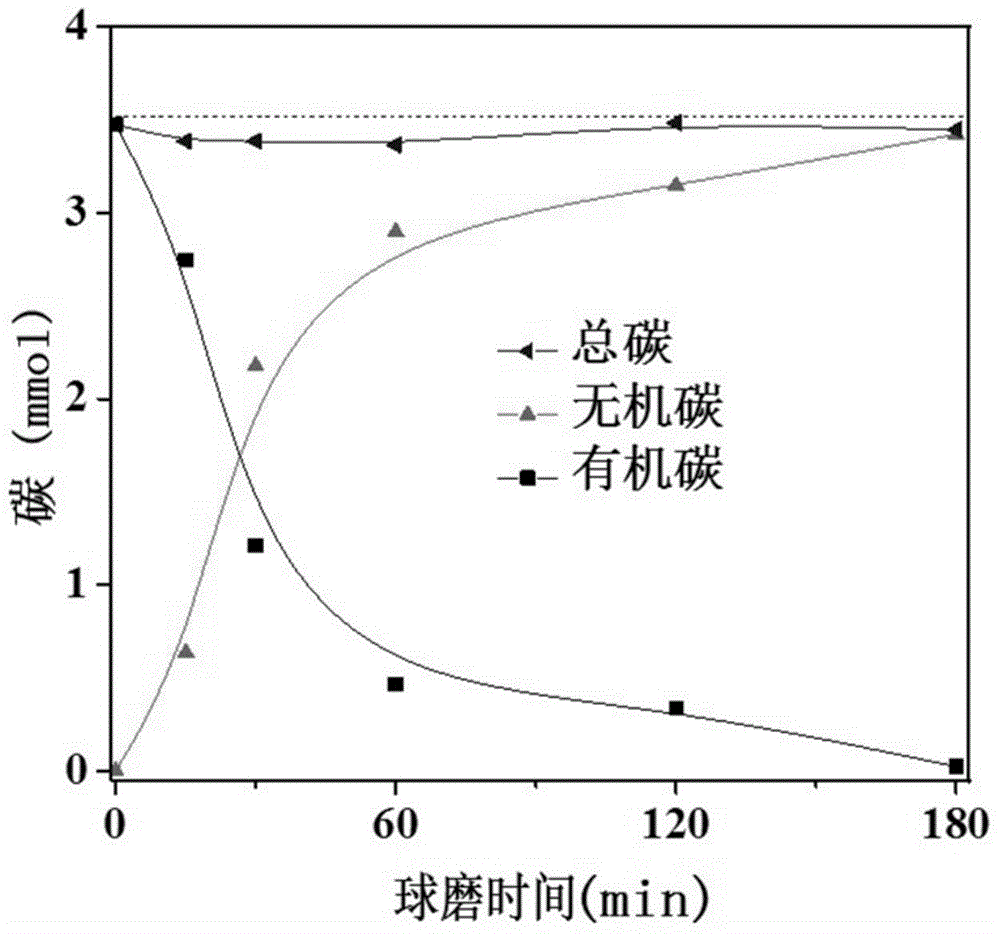

[0026] Step 1: Mix potassium persulfate and decabromodiphenyl ether solid powder in a mortar according to the material molar ratio of 50:1, and transfer them to a 250mL stainless steel ball mill jar. Then add 4 large grinding balls and 16 small grinding balls in the ball mill jar. Each large grinding ball weighs 32g and has a diameter of 20mm; the weight of the large grinding ball is 4g and has a diameter of 10mm. The weight of the ball mill jar is 3.5kg, the inner depth of the jar body is 65cm, and the inner diameter is 75cm. Both the ball mill pot and the ball mill are made of stainless steel, and the space between the ball mill pot and the ball mill cover is sealed with an elastic gasket.

[0027] Step 2: Set the rotating speed of the ball mill to 400rpm, perform the grinding process under the condition of normal temperature and pressure, and change the rotation direction of the ball mill every 15 minutes during the grinding. The ball milling reaction was carried out to 1...

Embodiment 2

[0029] Repeat Example 1 by the same steps as described, but the persulfate used in step one is ammonium persulfate.

Embodiment 3

[0031] Repeat Example 1 by the same steps as described, but the persulfate used in step one is sodium persulfate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com